Automobile frame welding parameter optimization method

A technology of welding parameters and optimization methods, applied in welding equipment, vehicle parts, arc welding equipment, etc., can solve problems such as deterioration of welding effects, achieve the effects of improving welding reliability, reducing welding costs, and reducing adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0048] figure 1 The flow chart of the method for optimizing the welding parameters of the automobile body under the fixed frequency mode provided by the embodiment of the present invention, the method is used for the welding of the aluminum alloy body, specifically includes the following steps:

[0049] S1, construct the mathematical model of double pulse welding current, the mathematical model is

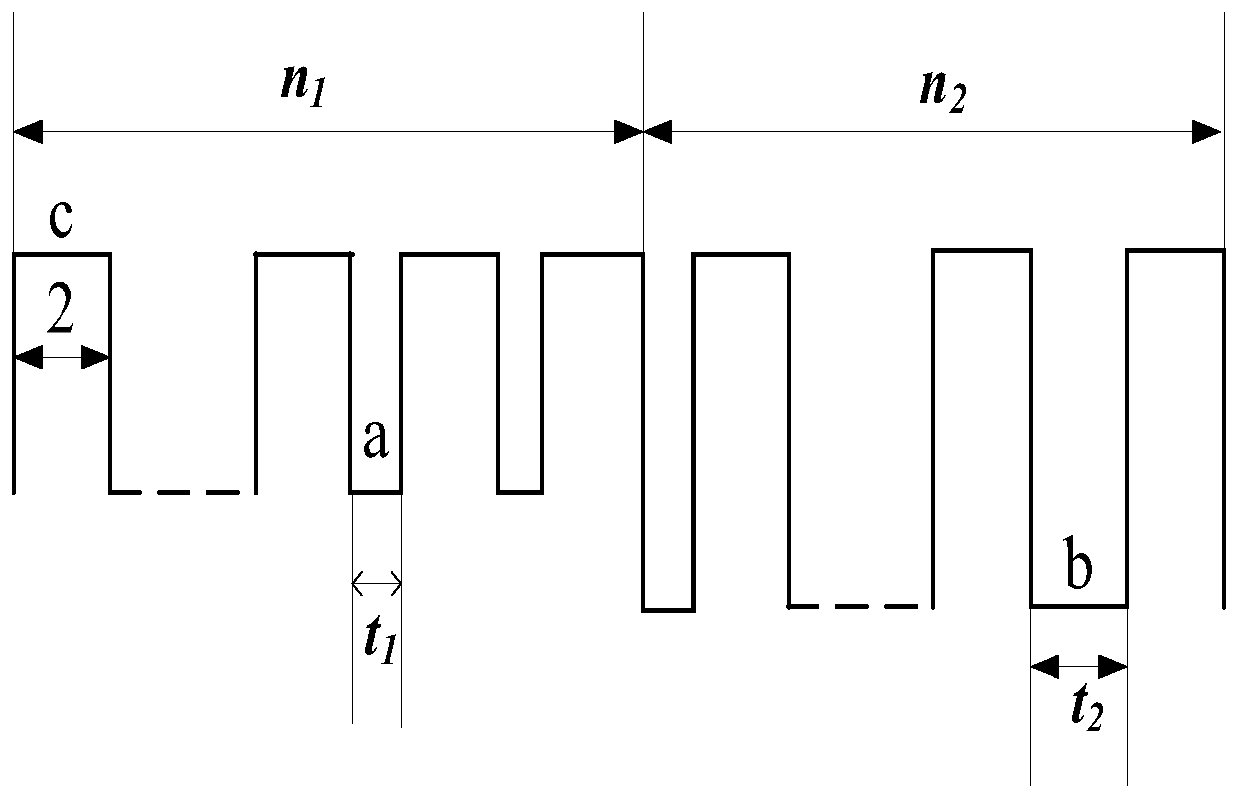

[0050] In the embodiment of the present invention, the construction of the mathematical model is described in conjunction with the double-pulse welding current waveform. The design of the double-pulse model is general, and its mathematical modeling is as follows figure 2 As shown, p represents the unit pulse time, T is the pulse group period, t 1 Indicates the base value time of a strong bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com