Preparation method and device of reflecting housing of backlight module

A technology for a backlight module and a manufacturing device, which is applied to reflectors, lighting devices, components of lighting devices, etc., can solve the problems of shortening the bending production time, unsuitable control of the heating temperature of the surface of thermoplastic plastic materials, and variation of reflectors, etc. Achieve shortened bending production time, high regularity and efficient mechanized manufacturing, and improve the effect of unsuitable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

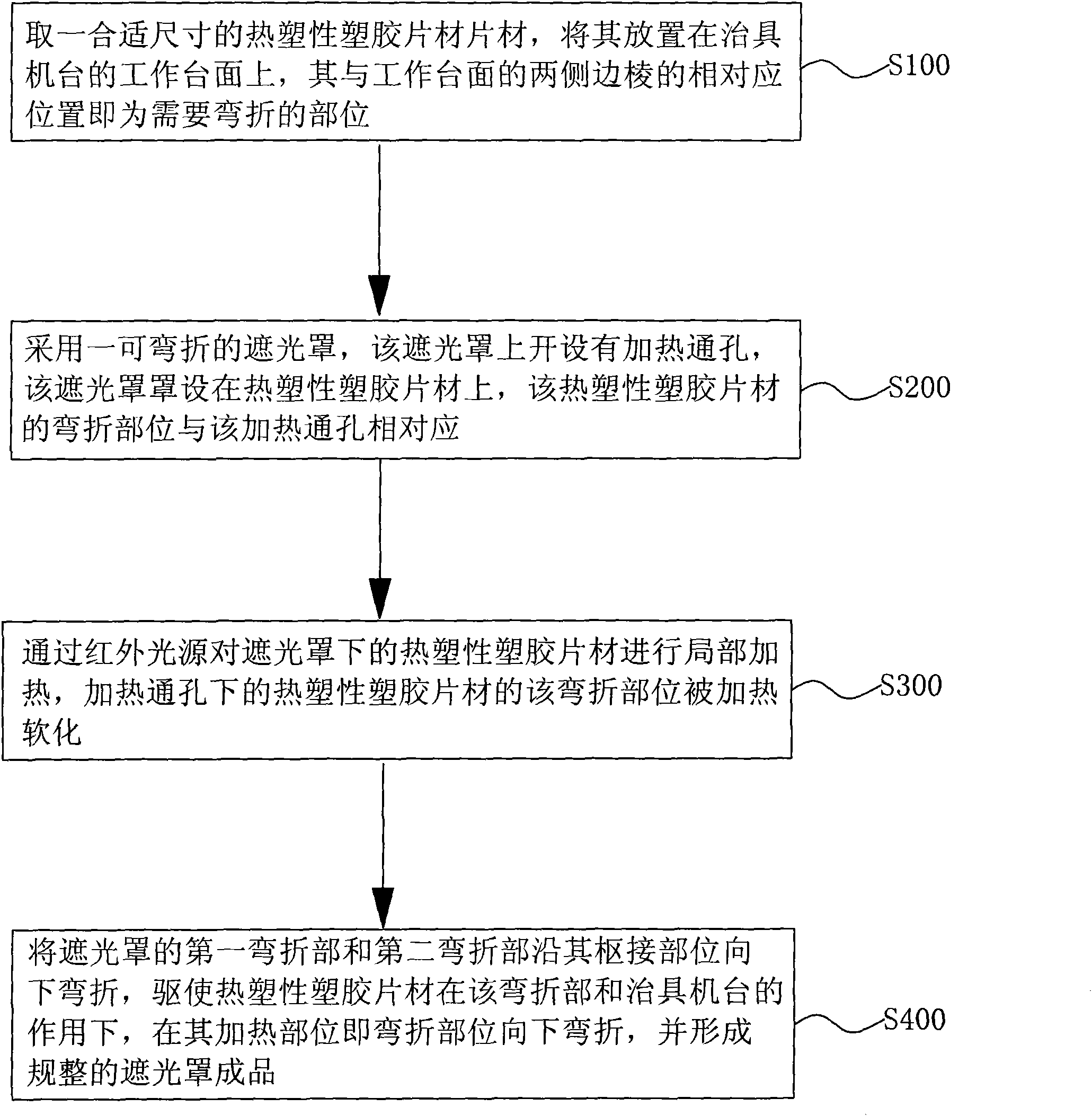

[0029] The preparation method of the reflection cover of the backlight module adopts thermoplastic plastic material as the preparation raw material of the reflection cover, and the preparation steps are as follows: figure 1 shown;

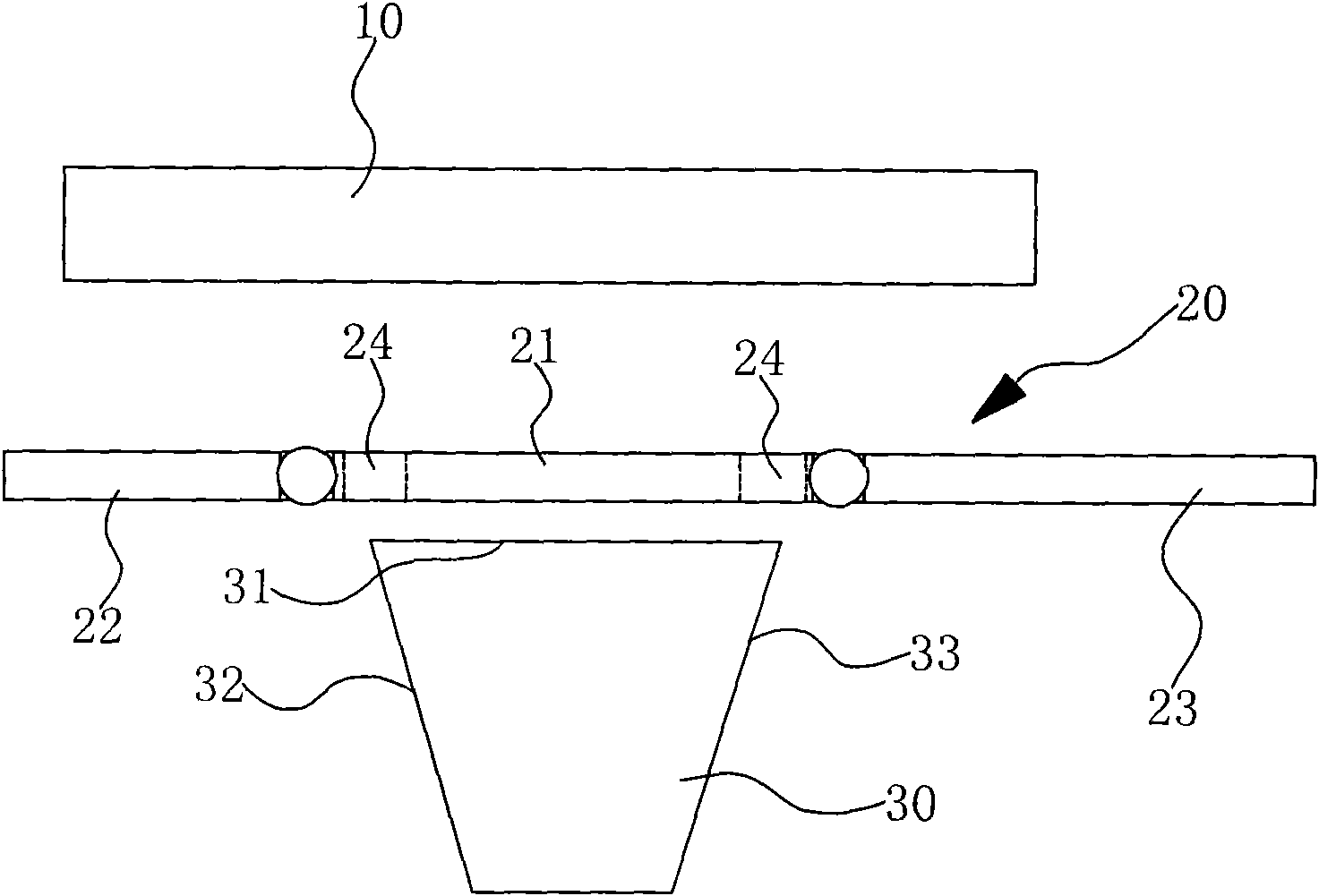

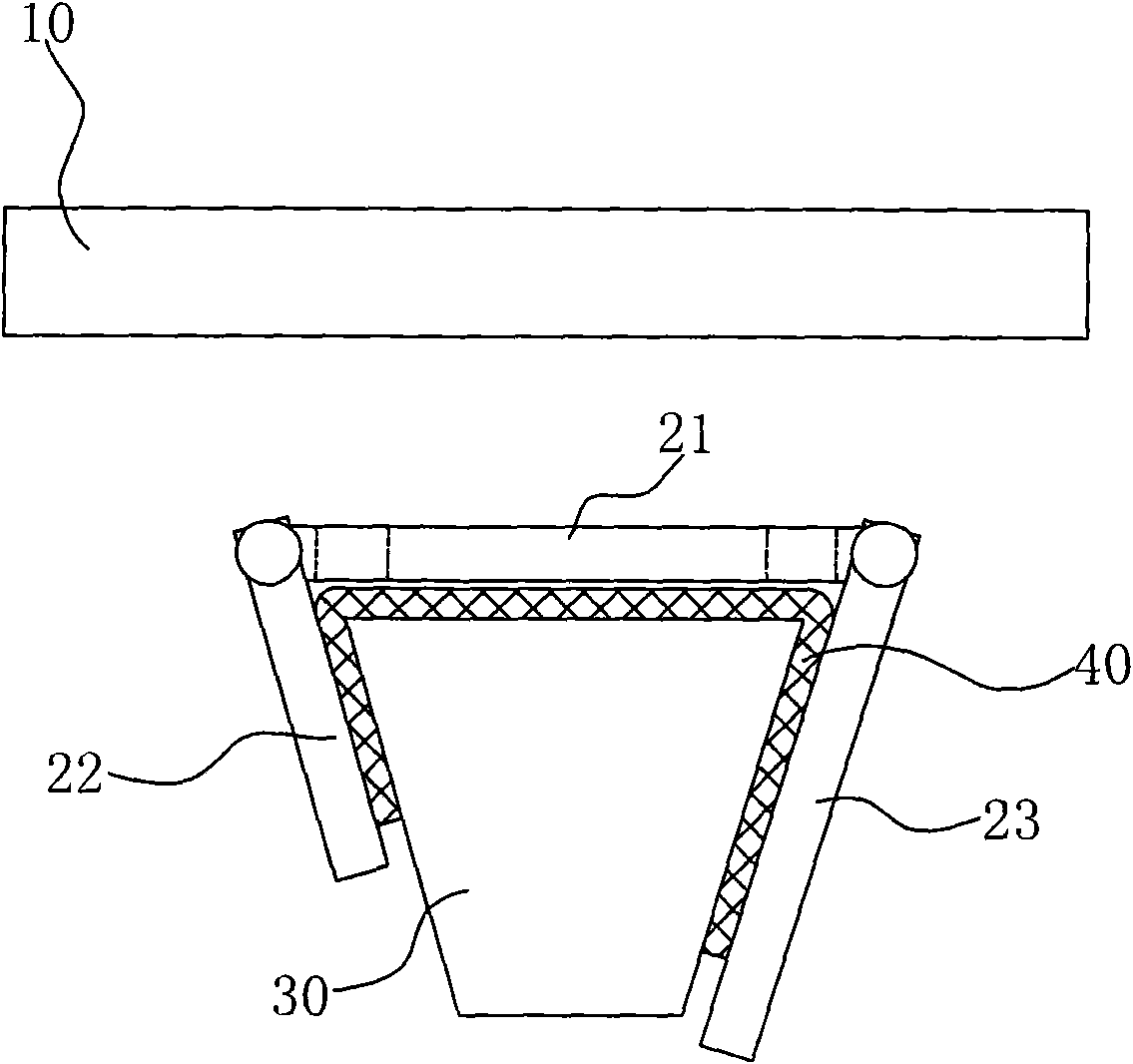

[0030] First, as in step S100, take a thermoplastic sheet of suitable size and place it on the working table of the jig machine, and its corresponding position with the edges on both sides of the working table is the part that needs to be bent . As in step S200, a bendable shading cover is used, and a heating through hole is opened on the shading cover. Corresponding;

[0031] Wherein the bendable sunshade has a first pressing part and a first bending part and a second bending part respectively pivotally connected to both sides of the first pressing part, the first pressing part and the first bending part A heating through hole is provided at the pivot joint between the first part and the second bent part. The heating through hole is a strip-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com