Patents

Literature

32results about How to "Reduce emission noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

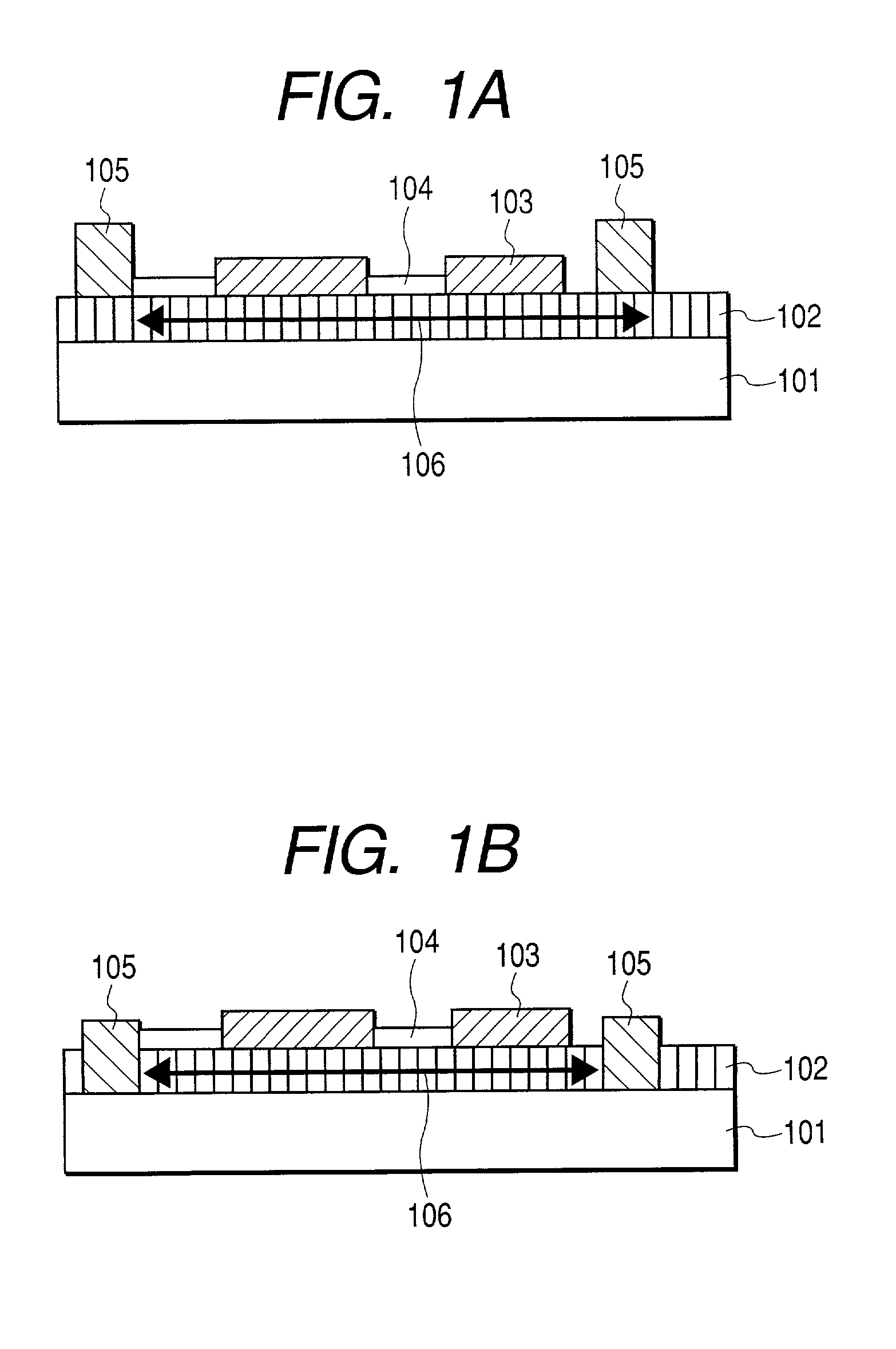

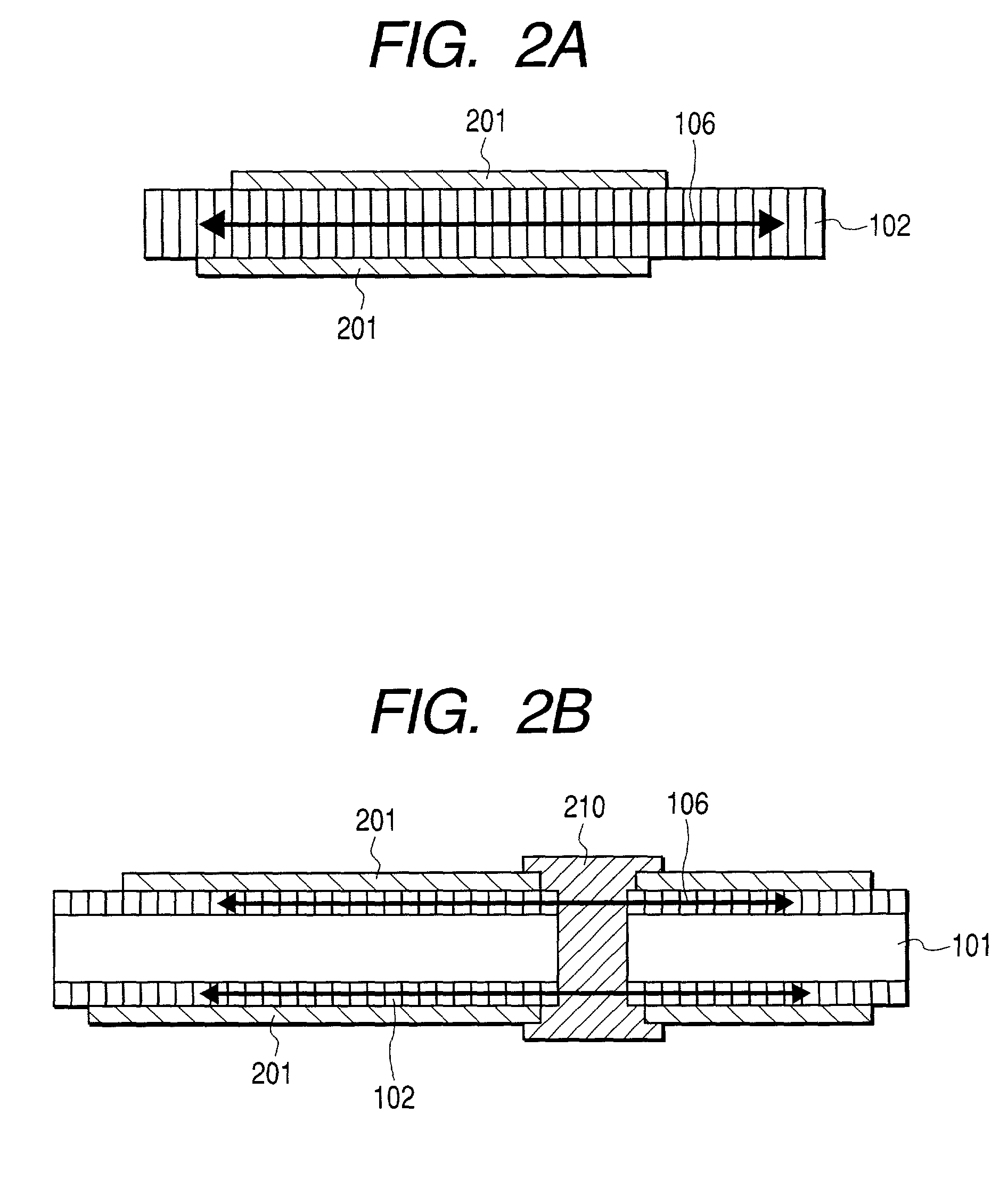

Optoelectronic substrate

InactiveUS6936854B2Increase freedomReduce emission noiseCircuit optical detailsSolid-state devicesPhotonic crystalLength wave

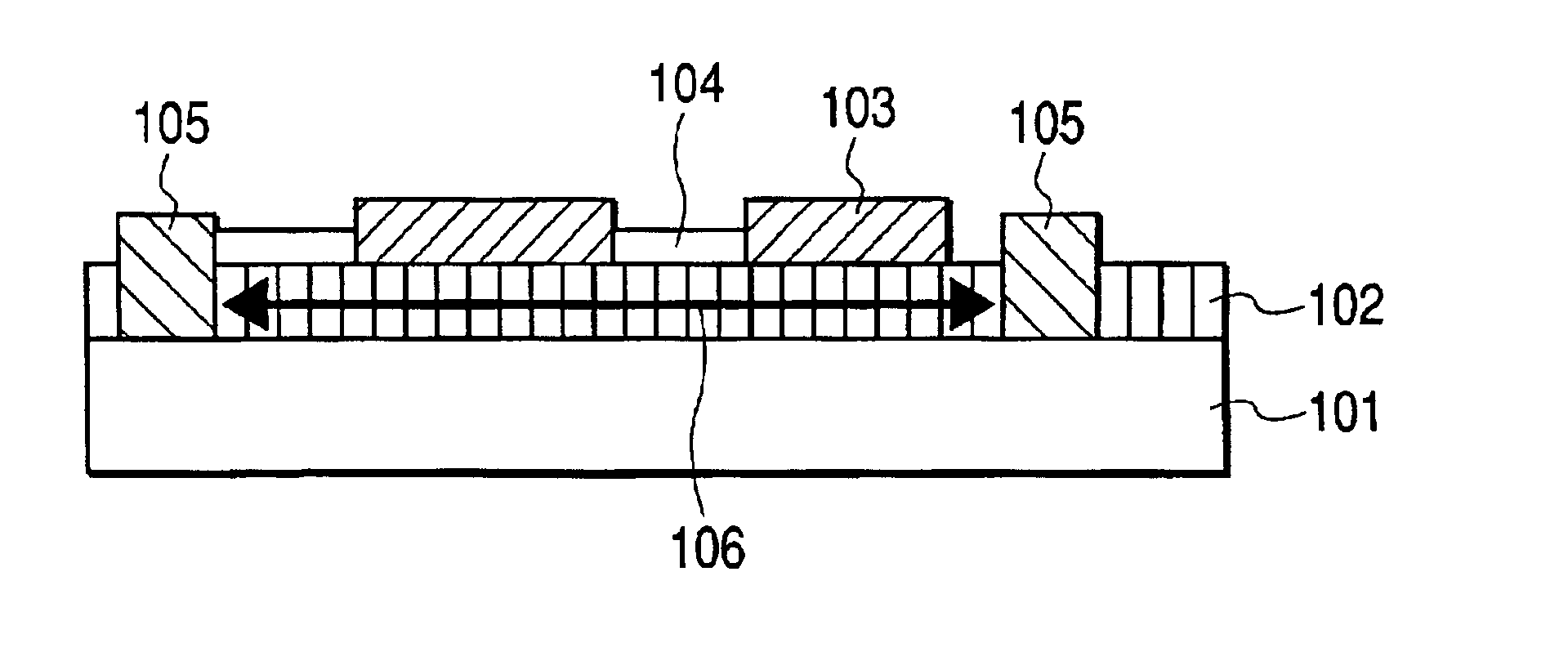

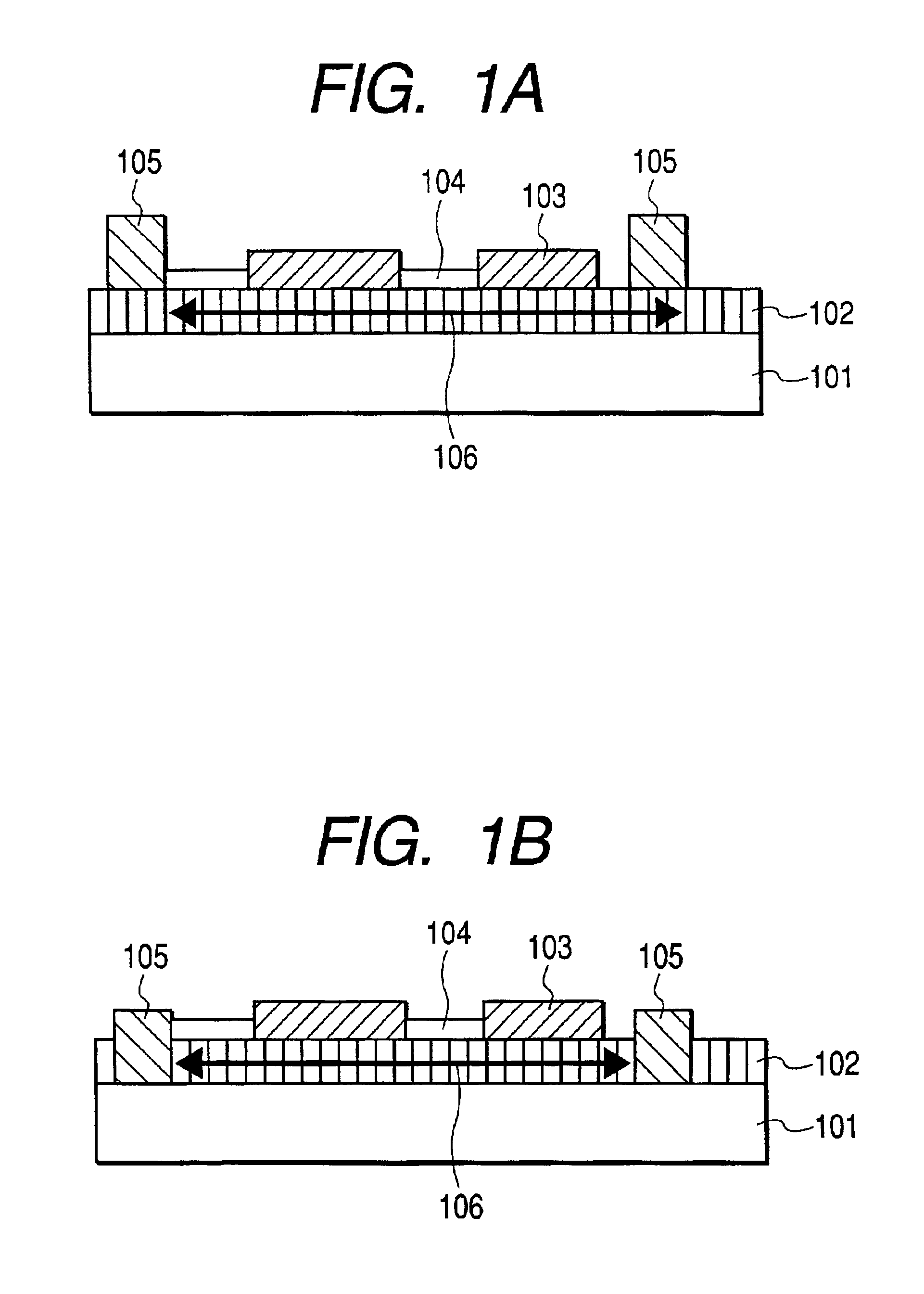

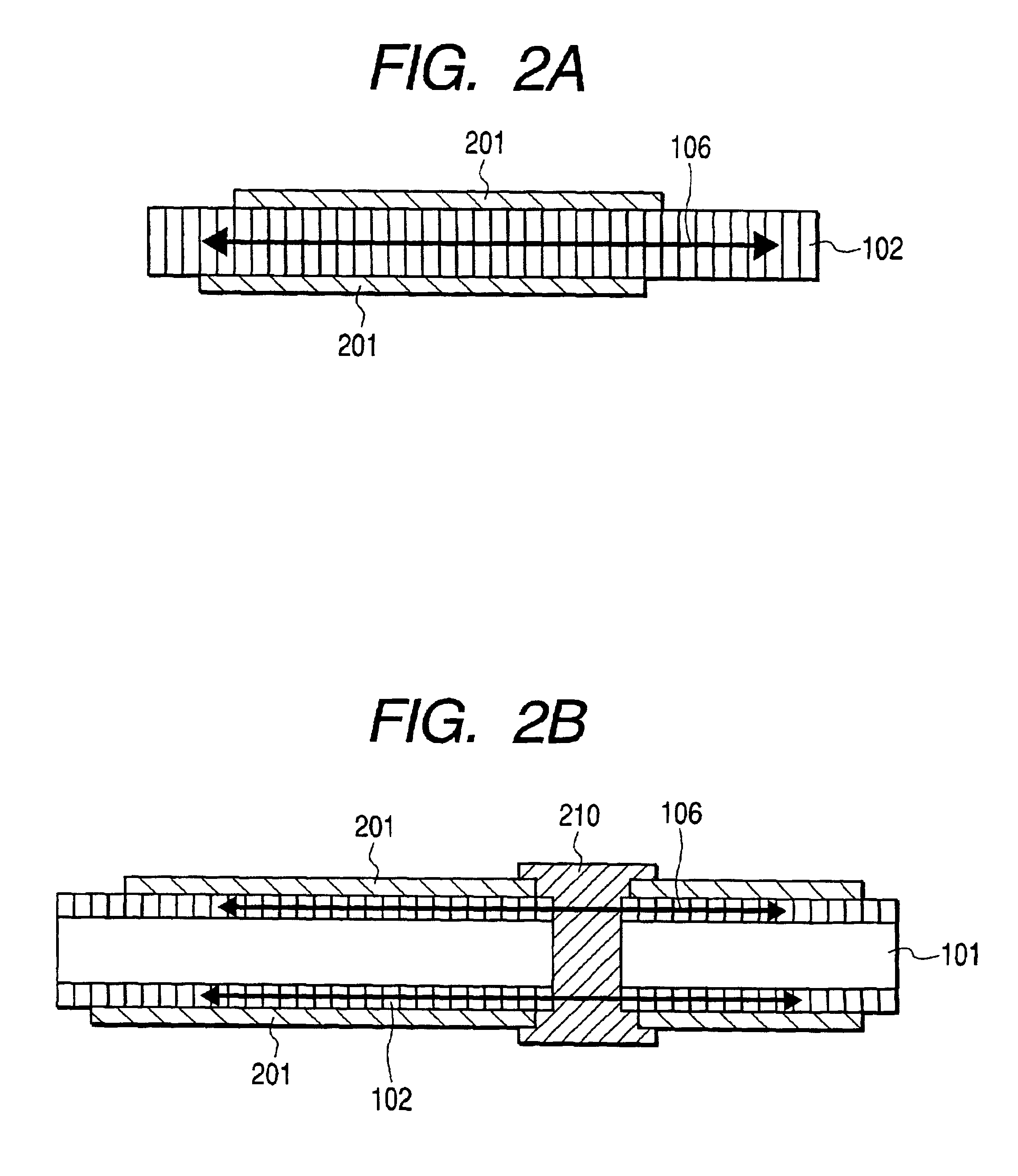

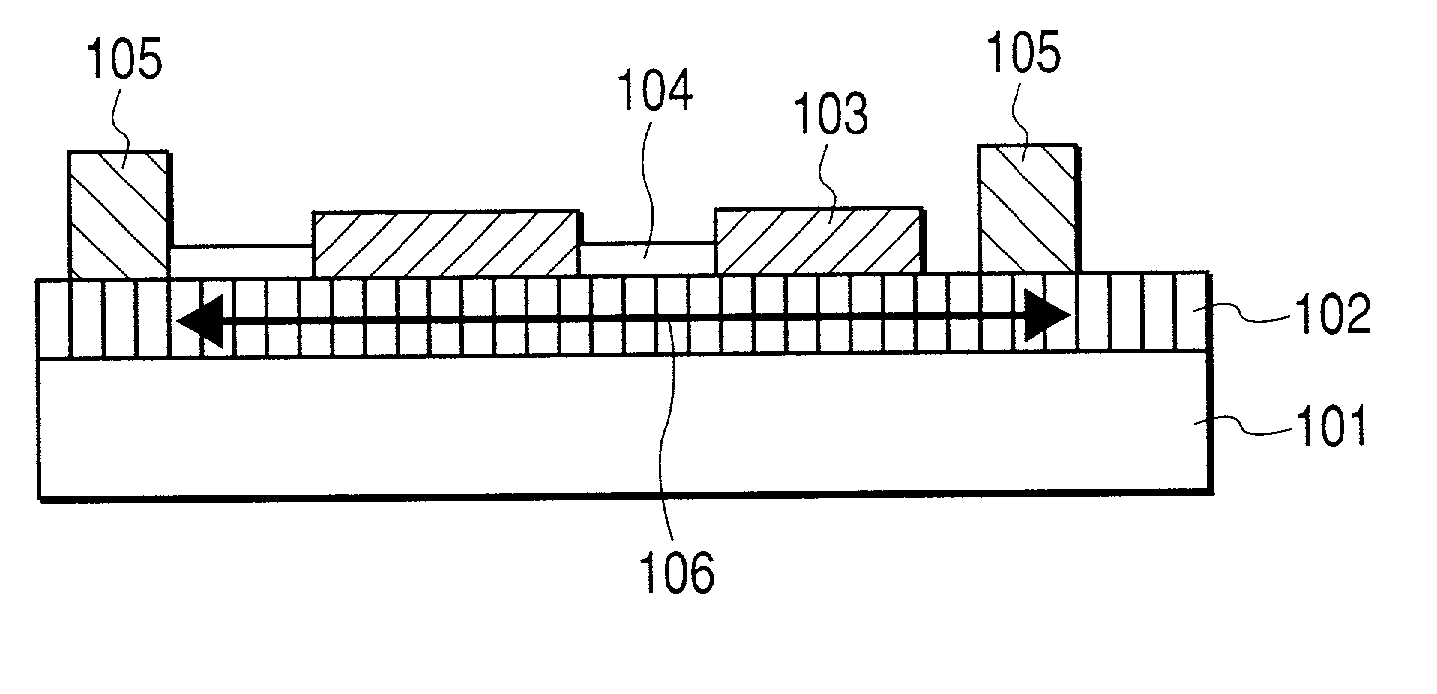

An optoelectronic substrate comprises an electronic device, an optical device, and an optical wiring layer, the optical wiring layer comprising a photonic crystal. An optoelectronic substrate comprises an electronic device, an optical device, and an optical wiring layer, wherein the optical wiring layer is comprised of a periodic structure having a repeating period nearly equal to or smaller than the wavelength of light employed for signal transmission. An optoelectronic substrate comprises an electronic device, an optical device, an electric wiring connected to the electronic device, an optical wiring layer, and a base plate, wherein the optical wiring layer is employed as an insulating layer between the base plate and the electric wiring.

Owner:CANON KK

Optoelectronic substrate

InactiveUS20020167013A1Optical coupling characteristicsIncrease freedomCircuit optical detailsSolid-state devicesPhotonic crystalElectrical wiring

An optoelectronic substrate comprises an electronic device, an optical device, and an optical wiring layer, the optical wiring layer comprising a photonic crystal. An optoelectronic substrate comprises an electronic device, an optical device, and an optical wiring layer, wherein the optical wiring layer is comprised of a periodic structure having a repeating period nearly equal to or smaller than the wavelength of light employed for signal transmission. An optoelectronic substrate comprises an electronic device, an optical device, an electric wiring connected to the electronic device, an optical wiring layer, and a base plate, wherein the optical wiring layer is employed as an insulating layer between the base plate and the electric wiring.

Owner:CANON KK

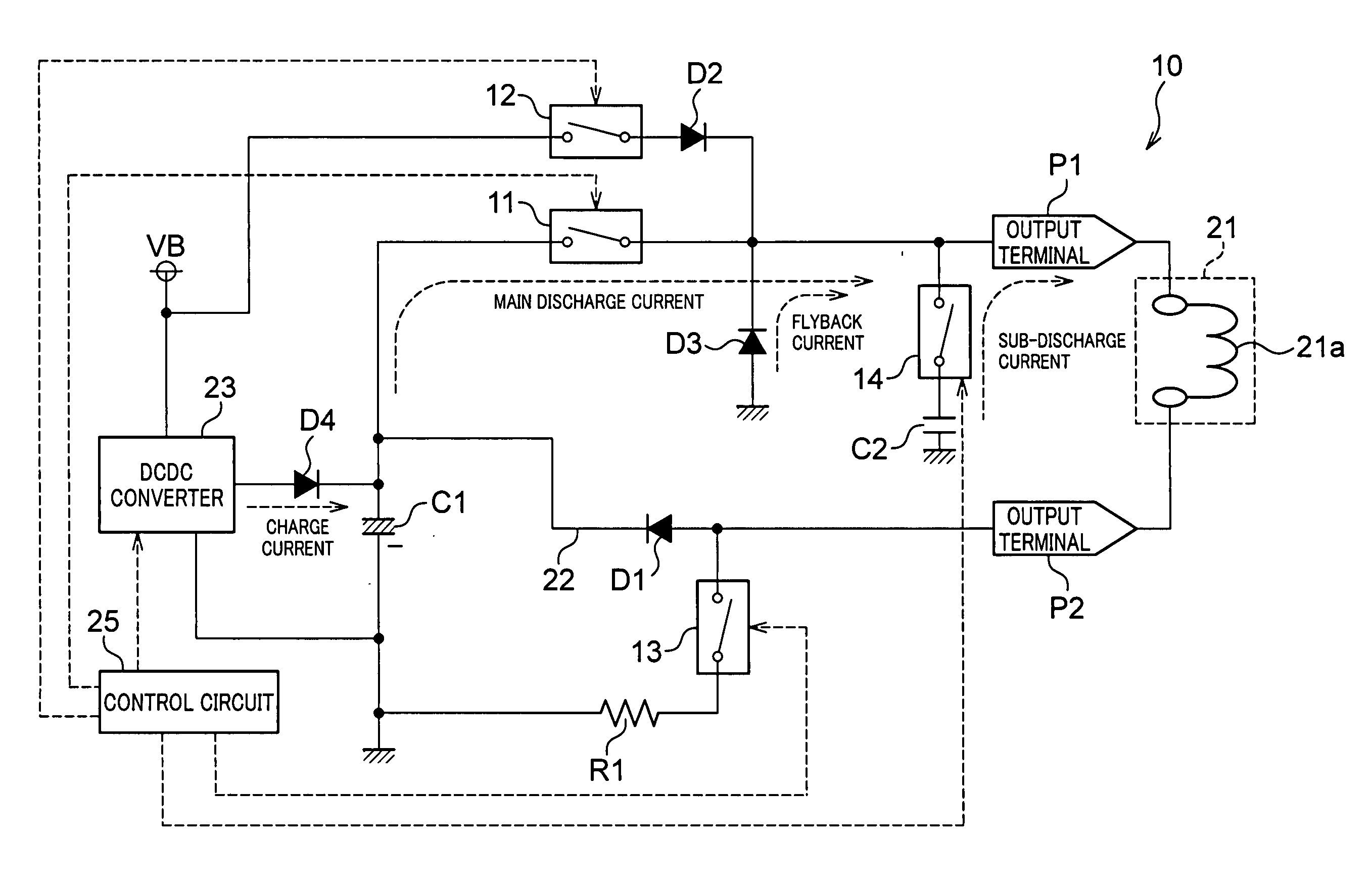

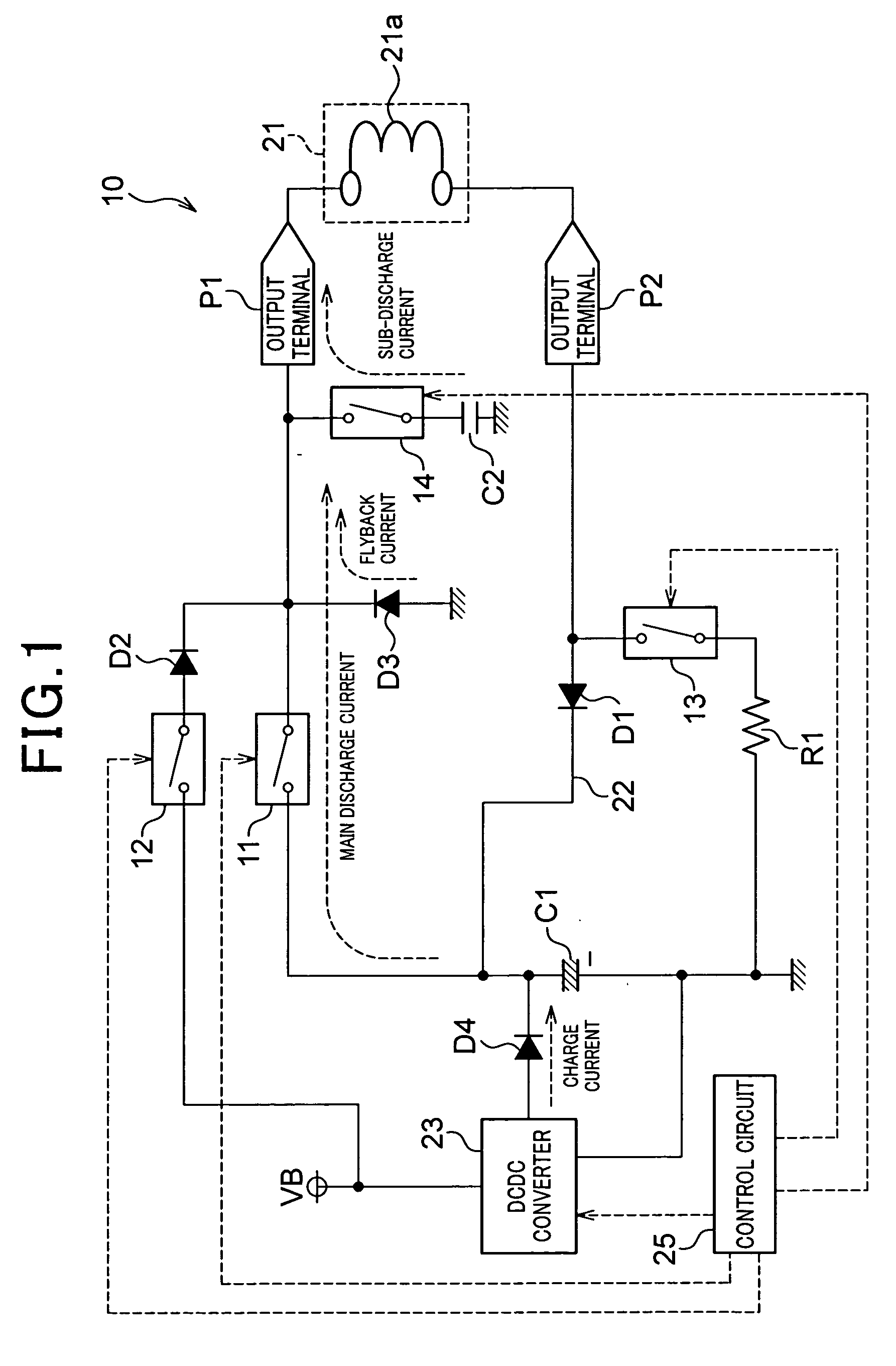

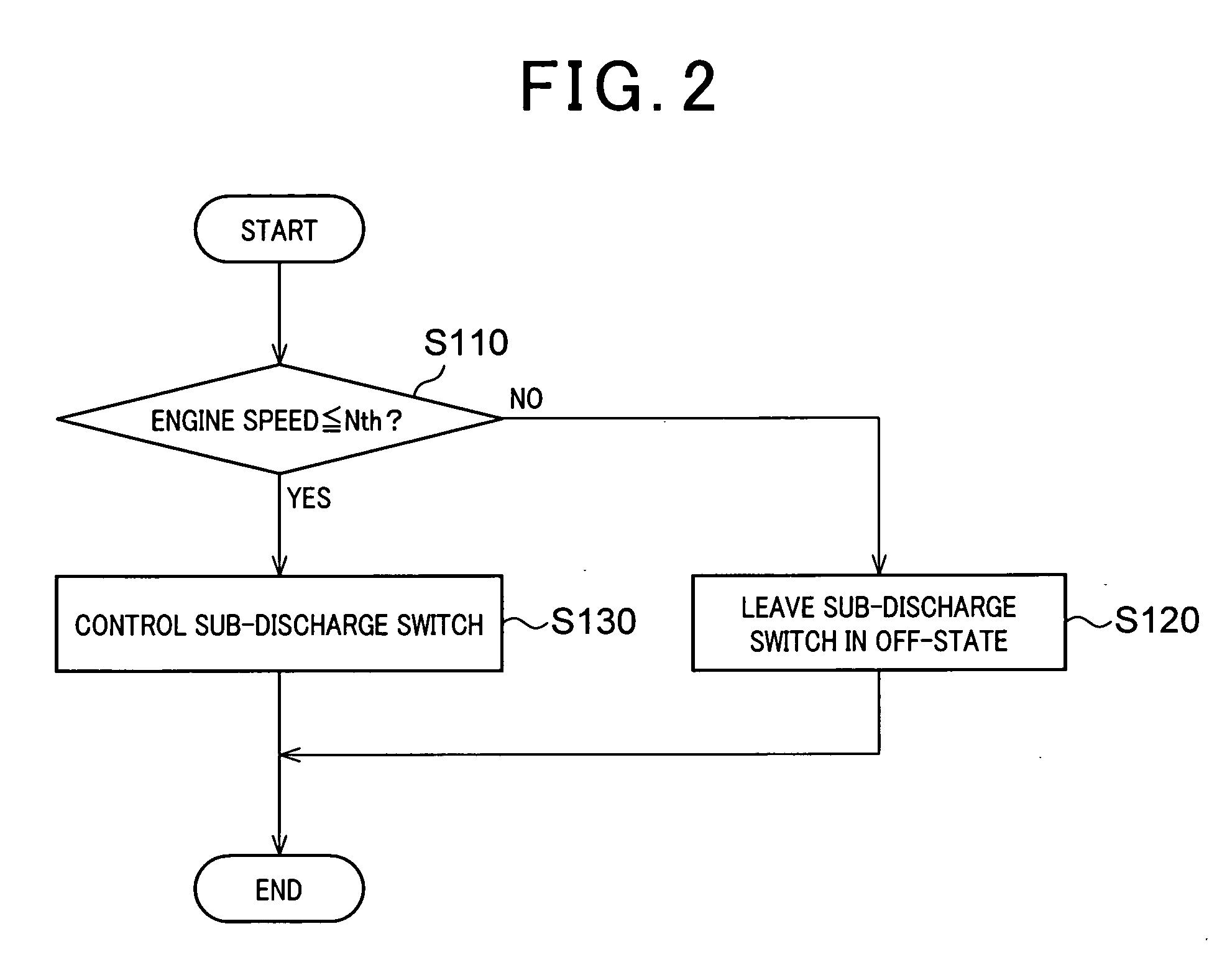

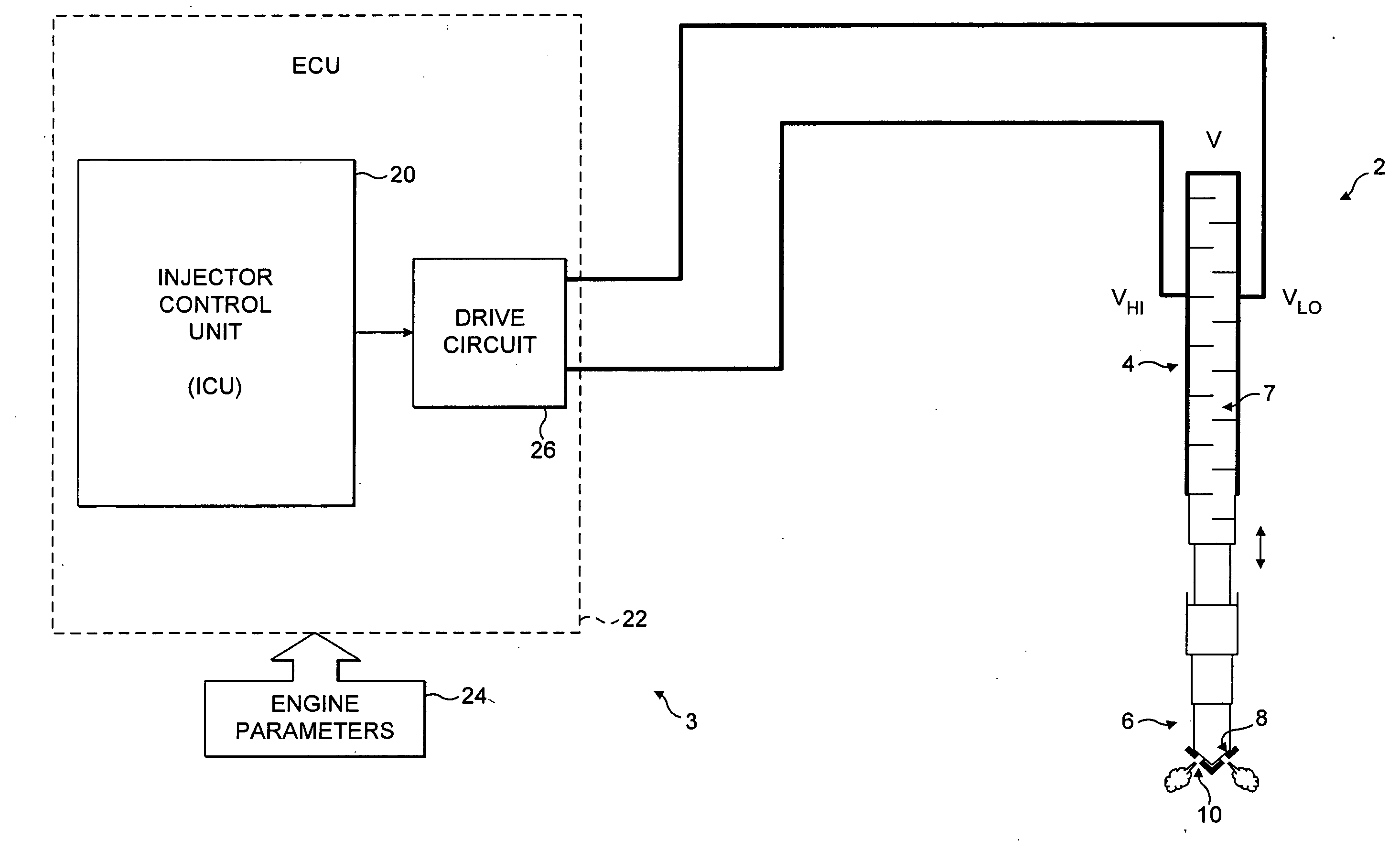

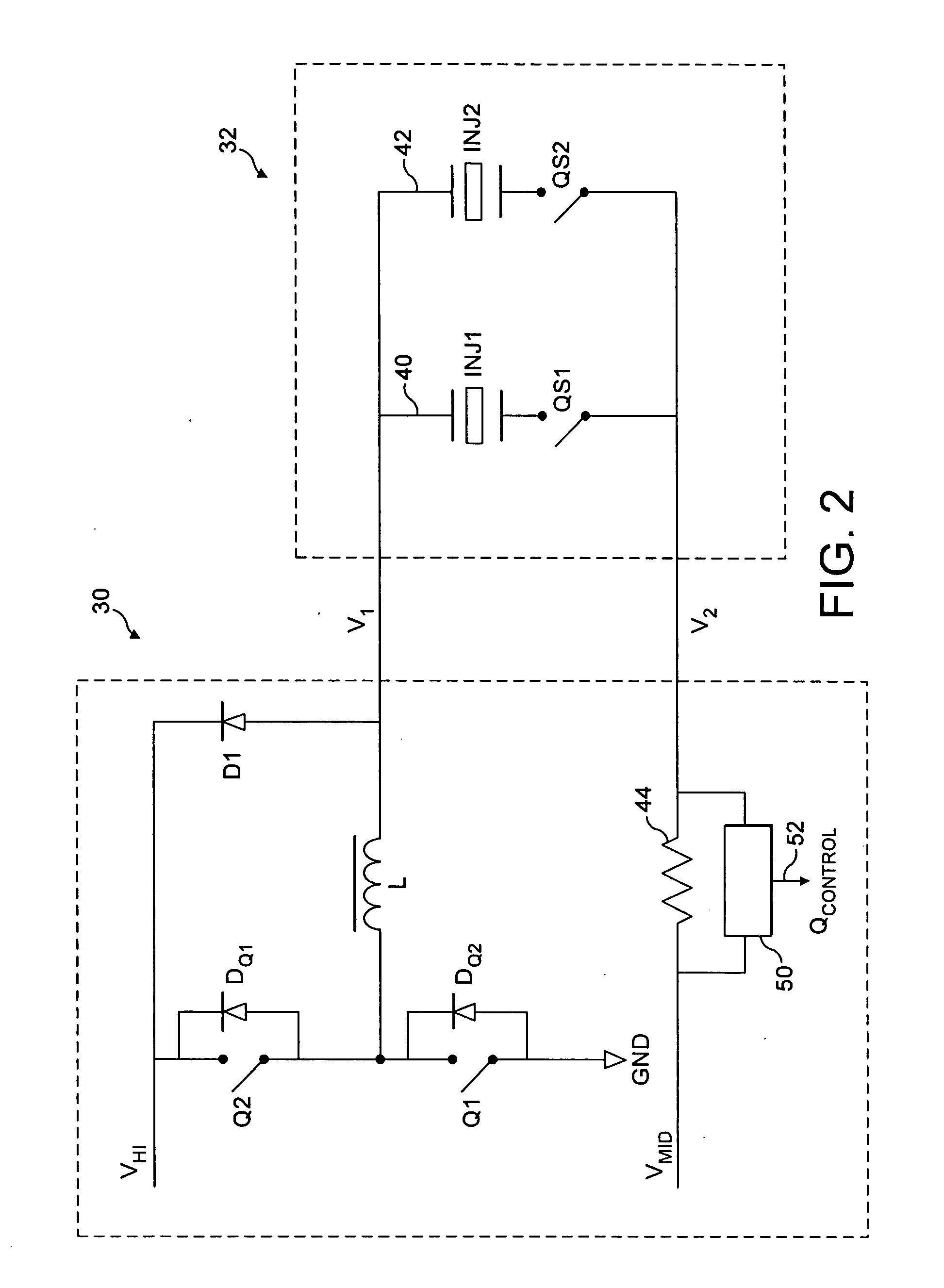

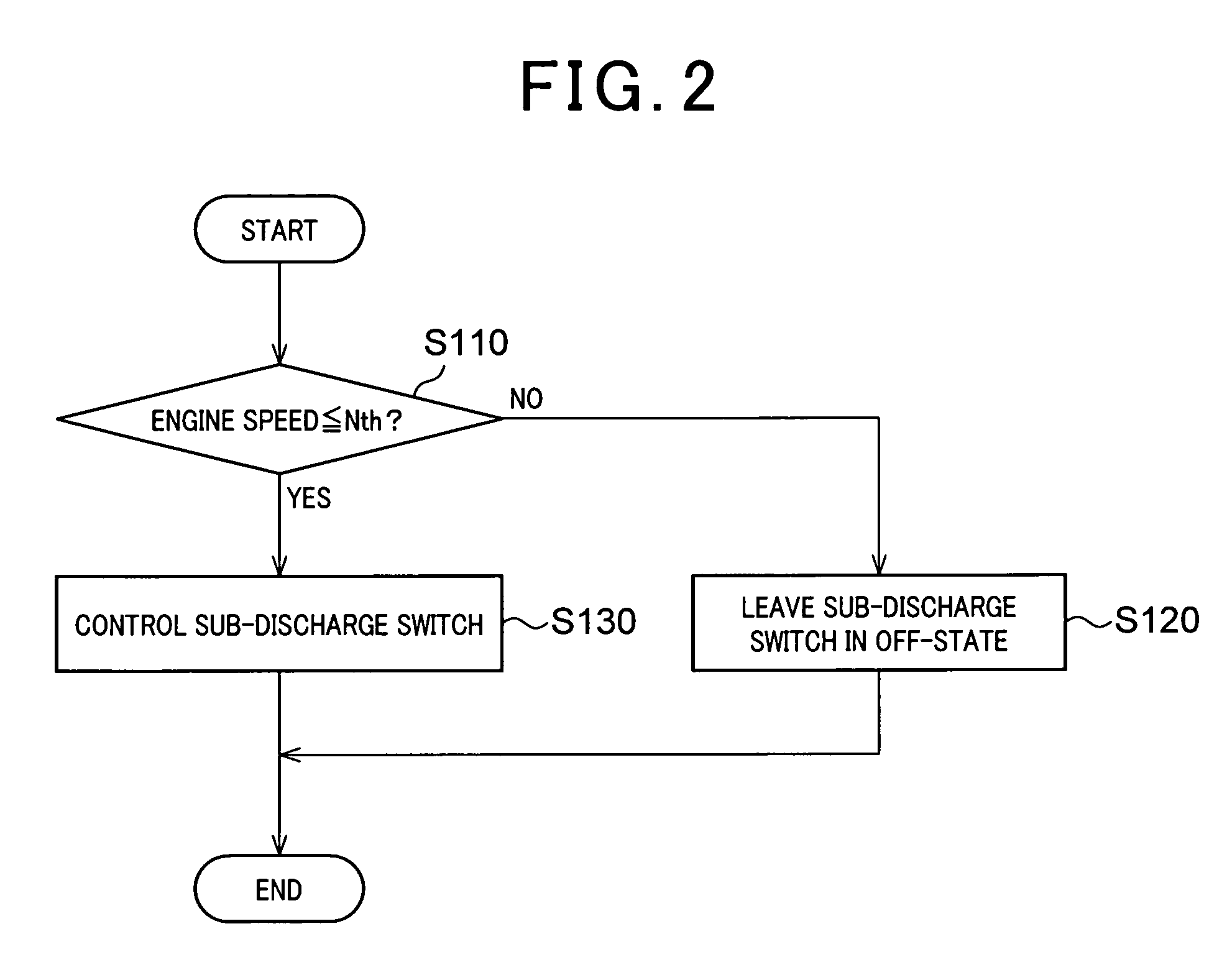

Apparatus for driving electromagnetic values

InactiveUS20080083895A1Reduce emission noiseOperating means/releasing devices for valvesElectrical controlMagnetic valveEngineering

An electromagnetic valve driving apparatus is provided for reducing emission noise generated when a discharge switching element is turned off. In the apparatus, a discharging capacitor stores electrical energy for performing discharge to a coil in an electromagnetic valve and charging means generates voltage from a power source voltage, which voltage is higher than that of the power source voltage. A discharge switching element is provided in series in a current path extending from the discharging capacitor to an up-stream side terminal of the coil. Controlling means turns on / off the discharge switching element. Circulating means is provided in the current path for circulation of current to the coil. Sub-discharging means is provided in the current path, for starting discharge to the coil when the discharge switching element is turned off, and for circulating current to the coil through the circulating means when the discharge to the coil is completed.

Owner:DENSO CORP

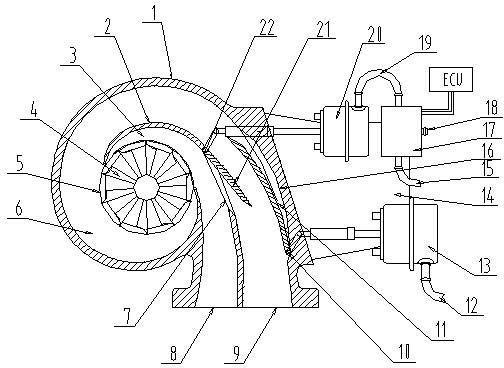

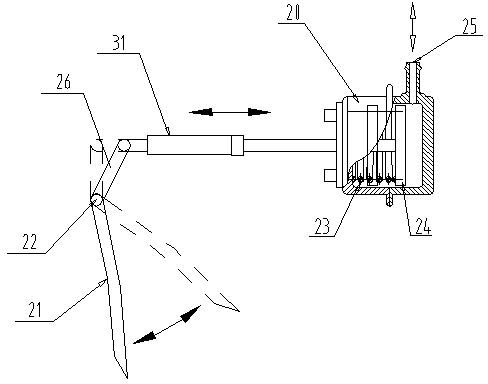

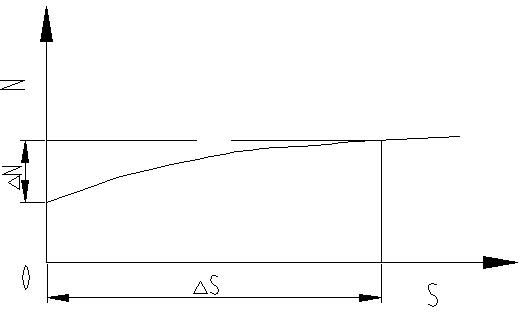

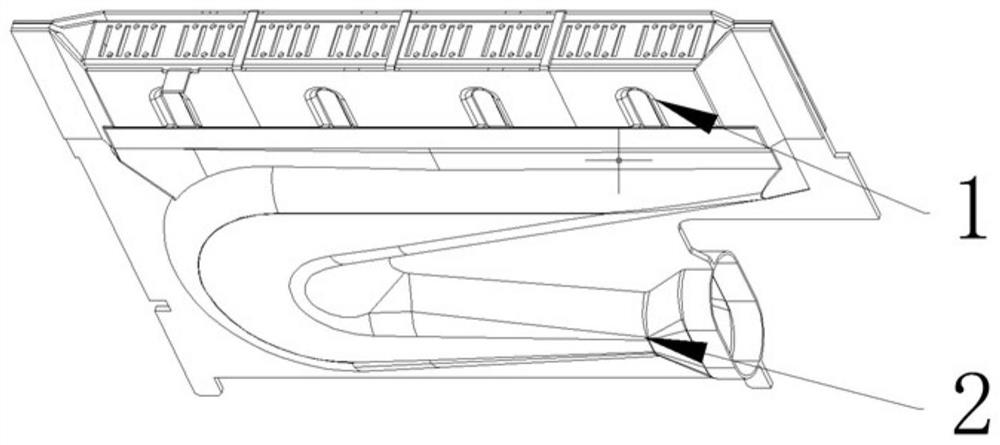

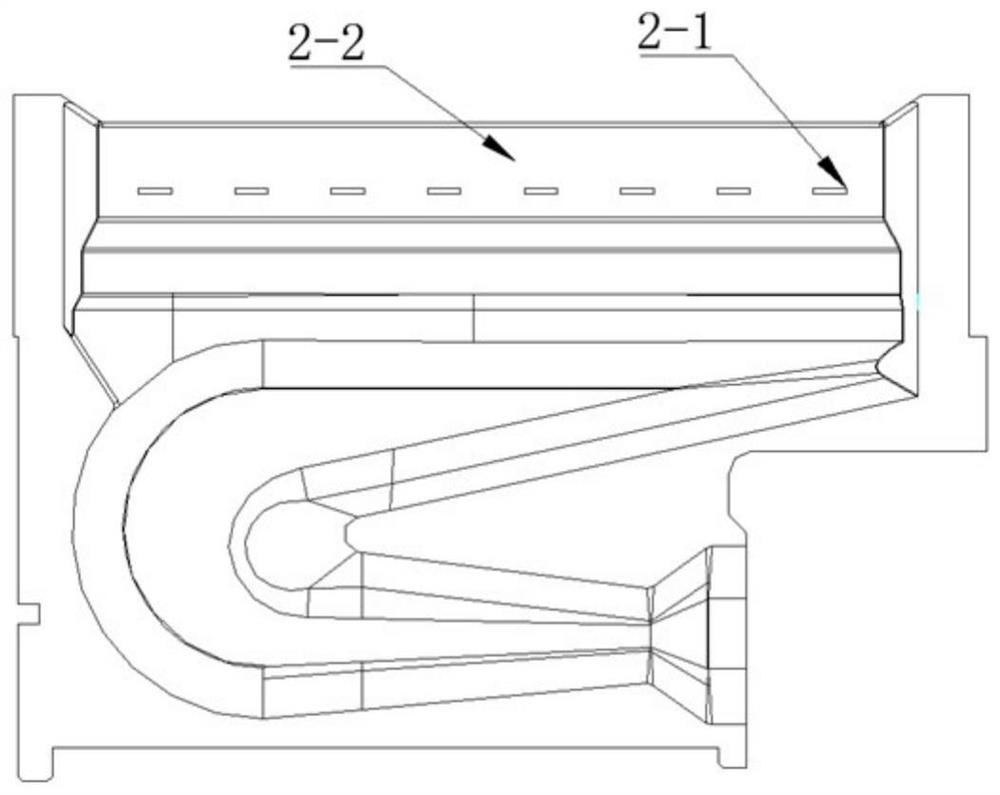

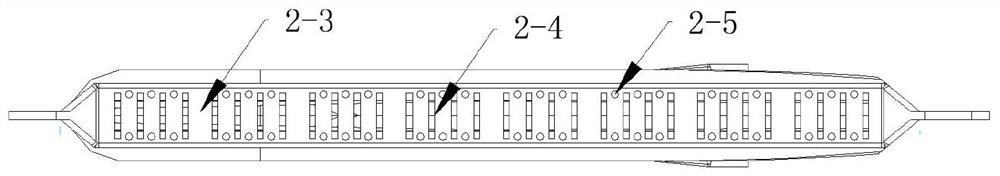

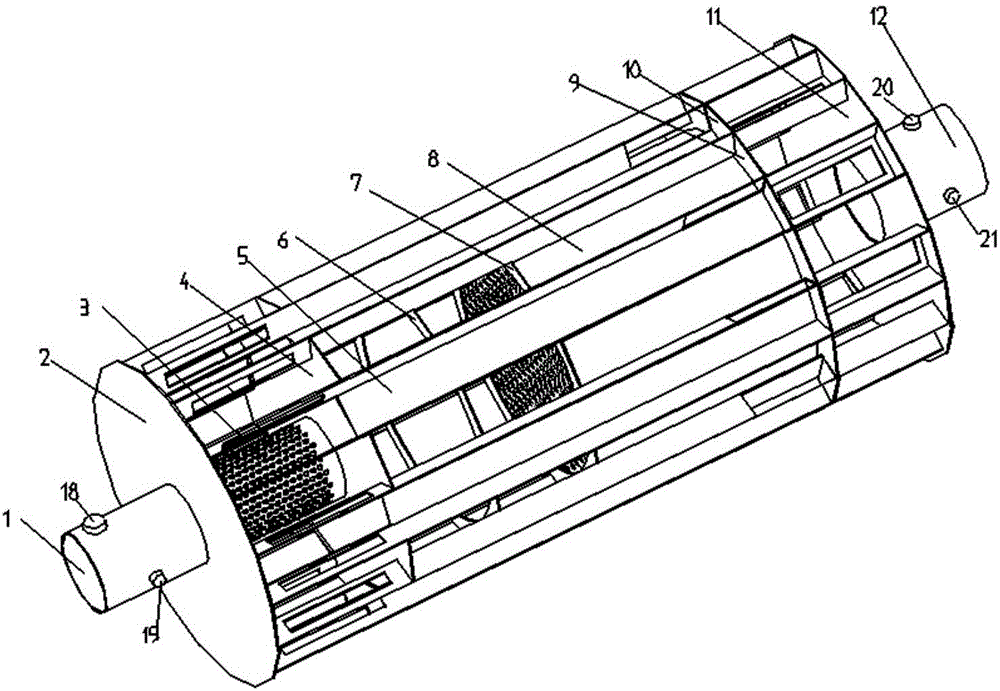

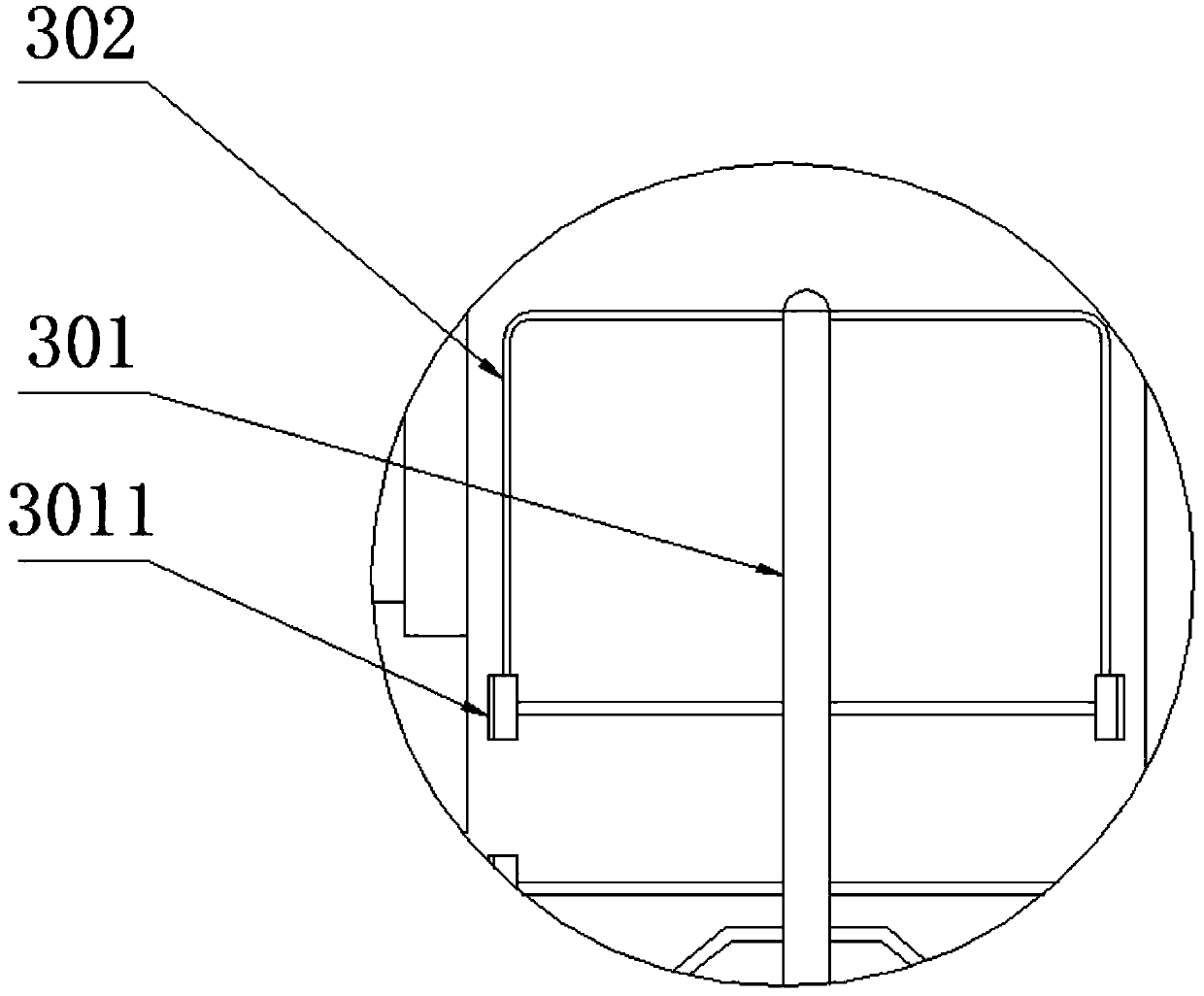

Staged flow-adjustable turbine shell

ActiveCN102536433AAvoid lateral flowReduce flow frictionInternal combustion piston enginesEngine componentsLow speedInlet flow

The invention discloses a staged flow-adjustable turbine shell, which comprises a turbine shell body. A turbine assembly and a waste gas inlet flow channel are mounted in the turbine shell body; an air inlet which is communicated with the waste gas inlet flow channel is arranged on the turbine shell body; an intermediate wall is disposed in the waste gas inlet flow channel and divides the waste gas inlet flow channel into an inner flow channel and an outer flow channel; a first valve device which can close the outer flow channel is disposed in the outer flow channel; and the intermediate wall is provided with a second valve device which can realize connection or disconnection of the inner flow channel and the outer flow channel. Waste gas energy is utilized sufficiently, rotation speed of a turbine rotor is increased, air inlet quantity of an engine in low speed work conditions is improved, so that the engine can apply more work, low speed torsion of the engine is increased, the low speed torque of the engine well matches with the low speed work conditions of the engine, and dynamic property and transient responsibility of the engine in low speed work conditions are improved.

Owner:康跃科技(山东)有限公司

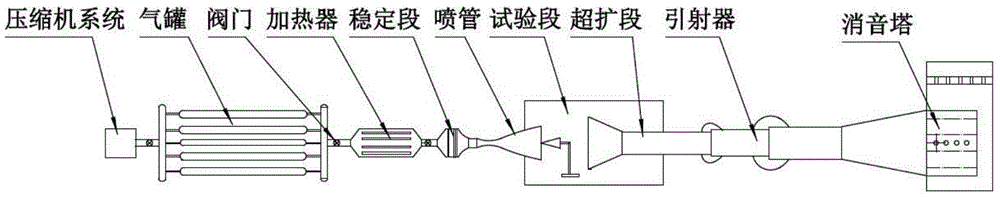

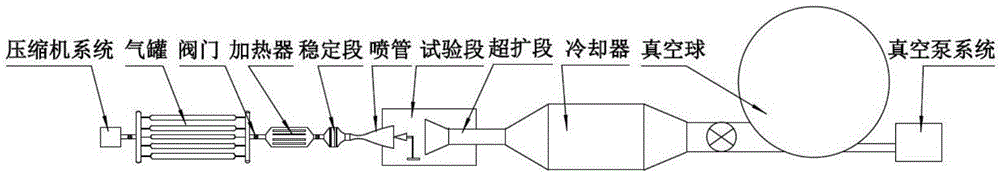

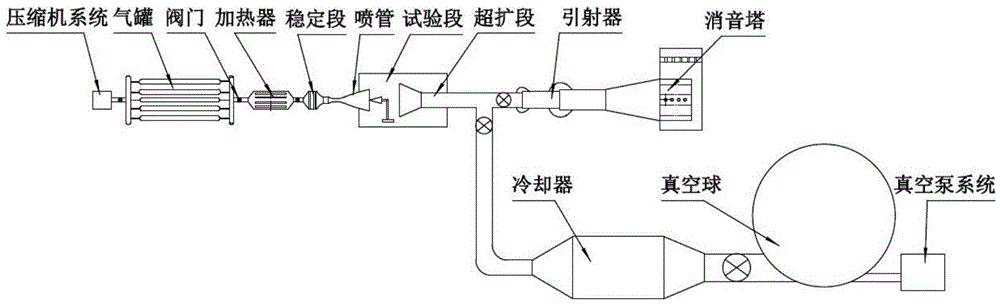

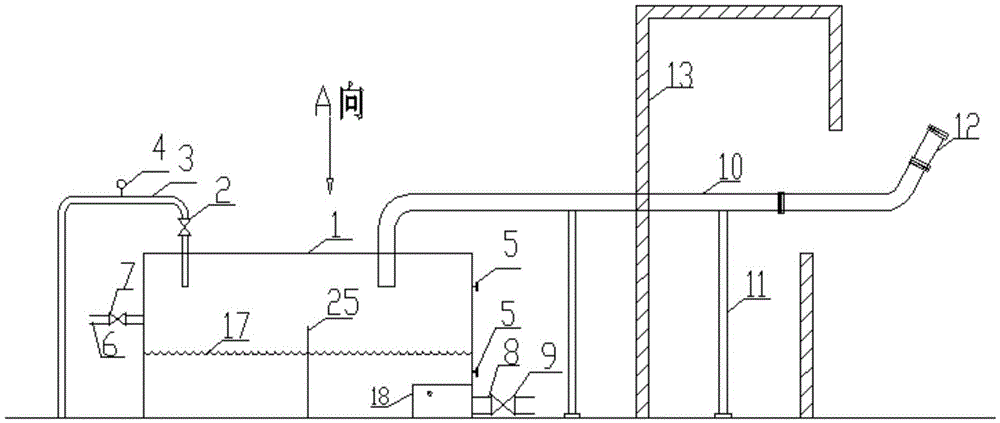

Energy-saving environment-friendly layout of large-scale routine hypersonic wind tunnel

ActiveCN105628331ASolve the problem of high exhaust noise and waste heat wasteReduce the impactAerodynamic testingTest segmentEngineering

The invention provides an energy-saving environment-friendly layout of a large-scale routine hypersonic wind tunnel. The system comprises a gas tank, a heater, a stabilization segment, a jet pipe, a test segment, an ultra-expanding segment and a heat exchanger, wherein the stabilization segment, the jet pipe, the test segment and the ultra-expanding segment are successively connected to form a major test wind tunnel assembly, the heat exchanger comprises an intermediate channel and a peripheral channel encircling the intermediate channel, an outlet of the ultra-expanding segment communicates with the intermediate channel of the heat exchanger, the gas tank communicates with the peripheral channel of the heat exchanger, and high-pressure gas in the gas tank is sent into the heater via the peripheral channel of the heat exchanger by means of a gas pipeline, then is sent into the stabilization segment after passing through the heater and is discharged through flowing through the intermediate channel of the heat exchanger after being tested in the major assembly of a test wind tunnel. According to the invention, energy consumption is reduced, the operation cost is decreased, at the same time, the influence on the environment is reduced, and the problems of large exhaust noise and waste of afterheat of a conventional hypersonic wind tunnel can be solved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

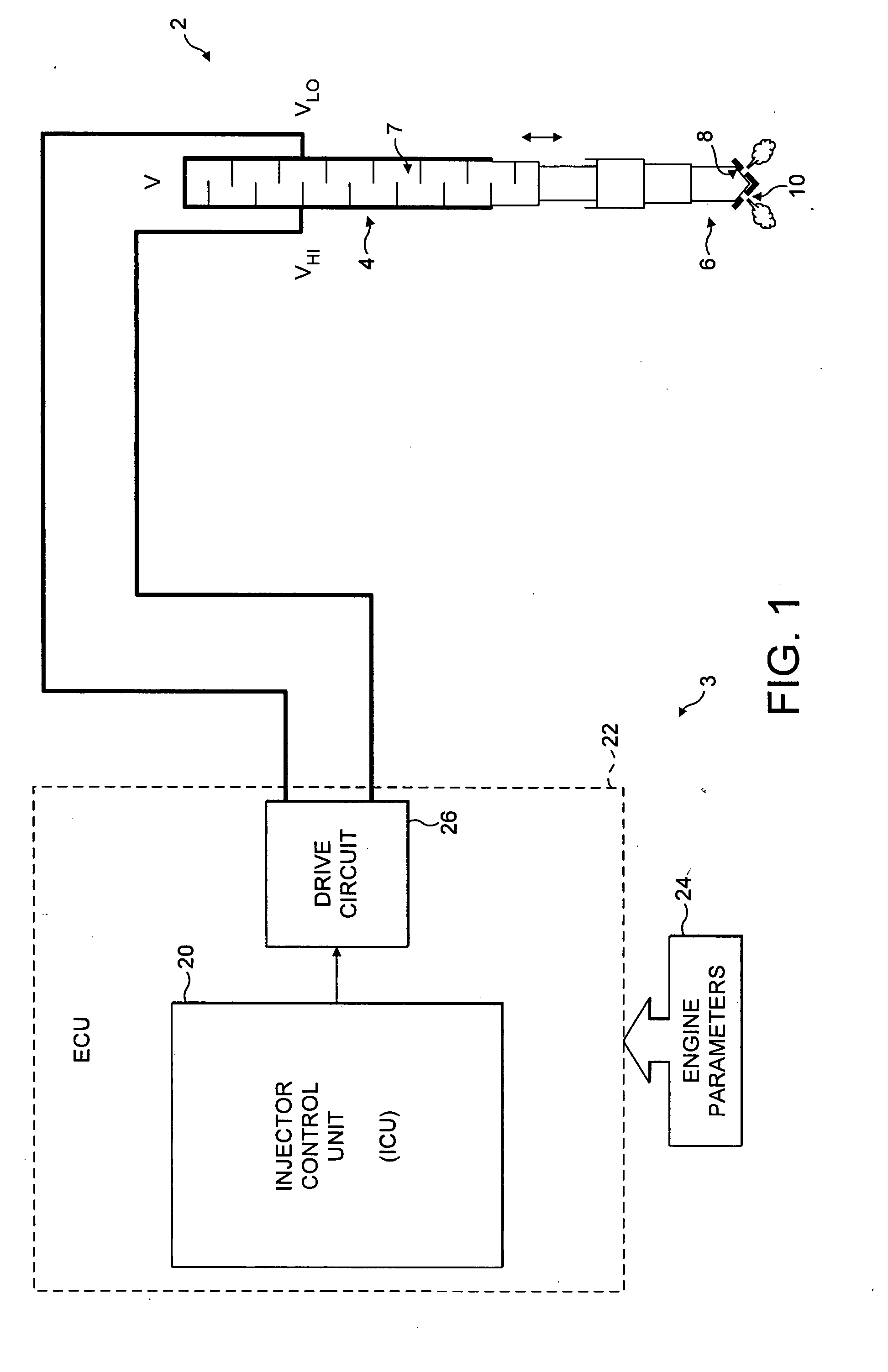

Method of operating a fuel injector

InactiveUS20070273246A1Lower the volumeReduce fuel consumptionElectrical controlPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

A method of operating a fuel injector having a piezoelectric actuator operable by applying a drive pulse thereto, wherein the drive pulse has a frequency domain signature. The method includes i) determining at least one resonant frequency of an injector installation in which the injector is received, in use, and ii) modifying the drive pulse such that a maximum of the frequency domain signature thereof is remote from the determined resonant frequency of the injector installation.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

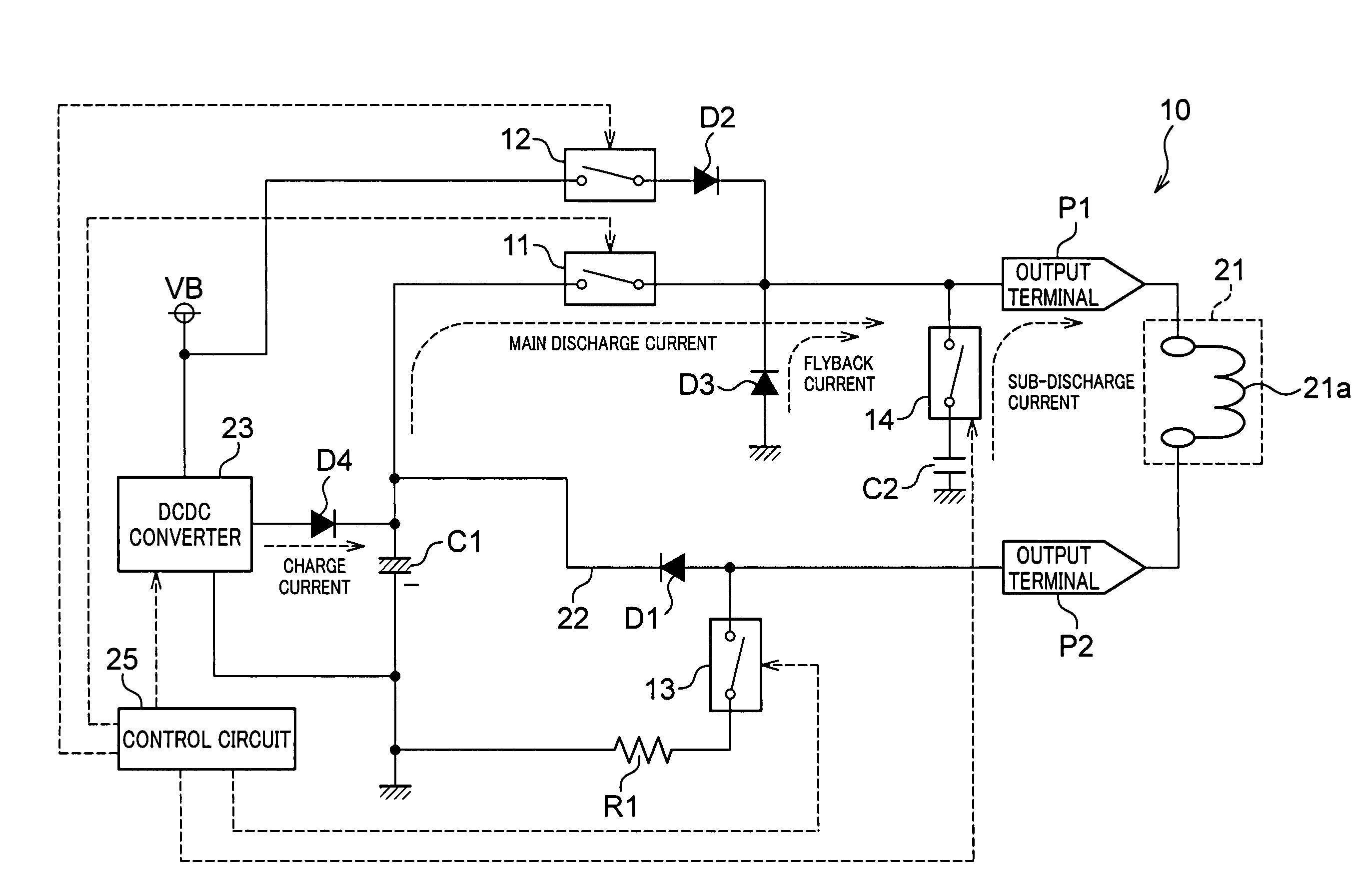

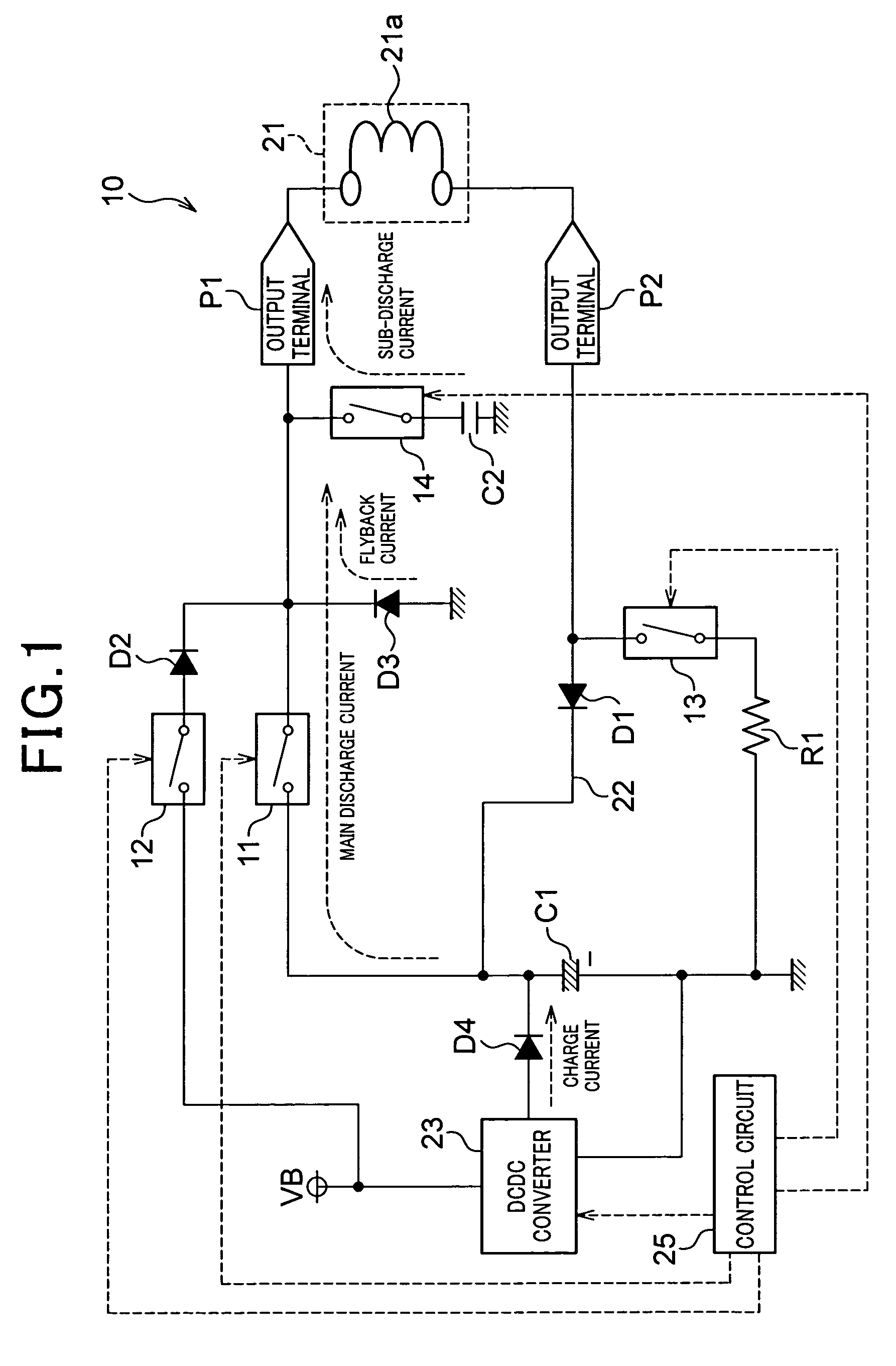

Drive of an electromagnetic valve with a coil by supplying high voltage from a discharging capacitor to the coil

InactiveUS7823860B2Reduce emission noiseOperating means/releasing devices for valvesElectrical controlSolenoid valveCirculating current

An electromagnetic valve driving apparatus is provided for reducing emission noise generated when a discharge switching element is turned off. In the apparatus, a discharging capacitor stores electrical energy for performing discharge to a coil in an electromagnetic valve and charging means generates voltage from a power source voltage, which voltage is higher than that of the power source voltage. A discharge switching element is provided in series in a current path extending from the discharging capacitor to an up-stream side terminal of the coil. Controlling means turns on / off the discharge switching element. Circulating means is provided in the current path for circulation of current to the coil. Sub-discharging means is provided in the current path, for starting discharge to the coil when the discharge switching element is turned off, and for circulating current to the coil through the circulating means when the discharge to the coil is completed.

Owner:DENSO CORP

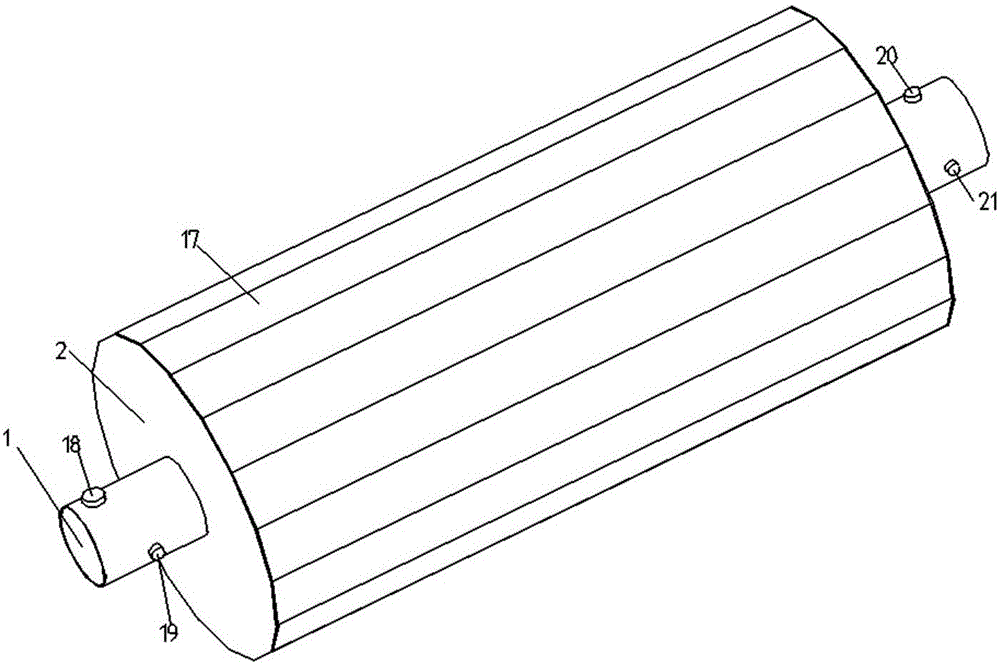

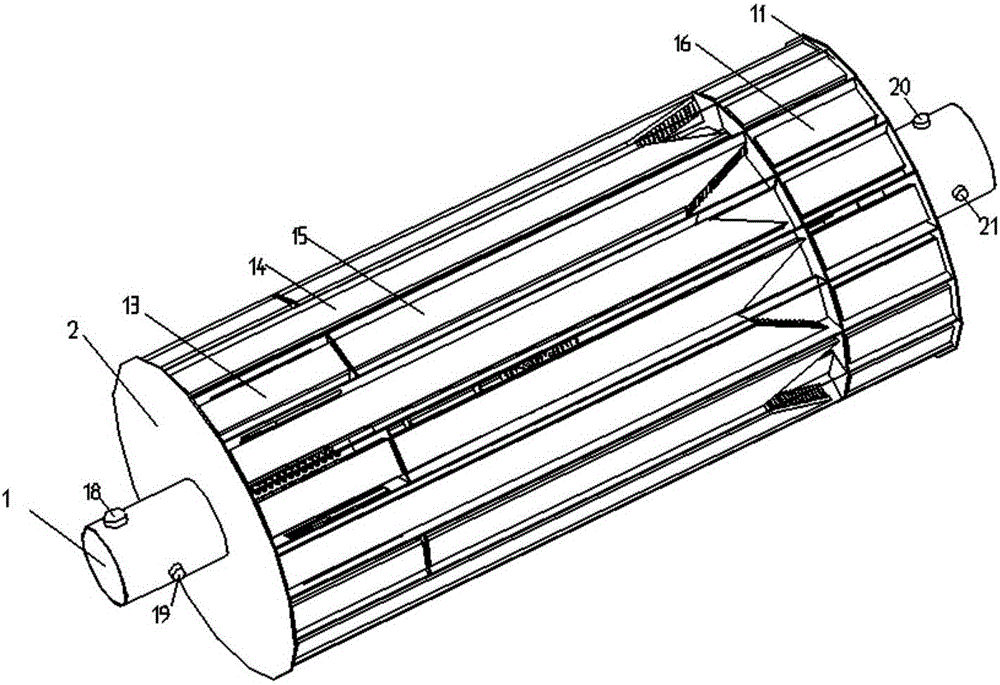

Muffler

InactiveCN101514649APracticalReduce volumeSilencing apparatusMachines/enginesLoss of resistanceAcoustic absorption

The invention discloses a novel muffler which not only can block off the transmission of acoustic waves and enable air flows to pass through, but also can eliminate emptying noise of a purification apparatus. Such a muffler is provided with a large amount of tiny pores and is capable of filtering the discharged air flows into countless small air flows, the gas pressure is reduced and the flow speed is diffusely diminished by reflecting partial acoustic waves to an acoustic source direction via an abrupt change location of acoustic characteristics within a pipeline, then secondarily passing the reflected acoustic waves through the pipeline and finally by acoustic absorption of an acoustic absorbing material of a filter at an inlet of a waste air compressor, thus achieving the aim of noise elimination in the end to thereby reduce environmental pollution and noises in industrial boundary. The invention has the advantages of small volume, large noise elimination quantity, small investment, simple structure, convenient installation, small loss of resistance and the like, and is wider in effective frequency band, extensive in application range and best in eliminating the middle / high frequency noises.

Owner:CAIHONG COLOUR KINESCOPE GENERAL FACTORY

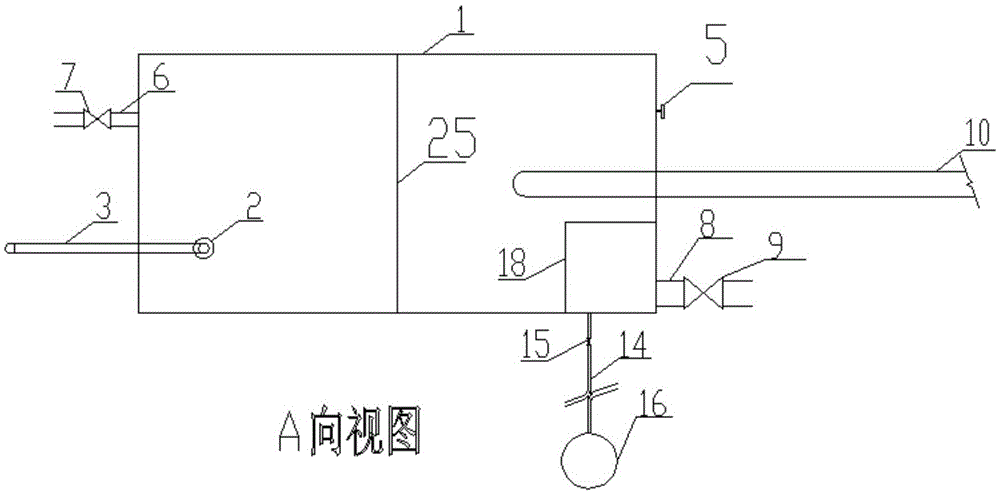

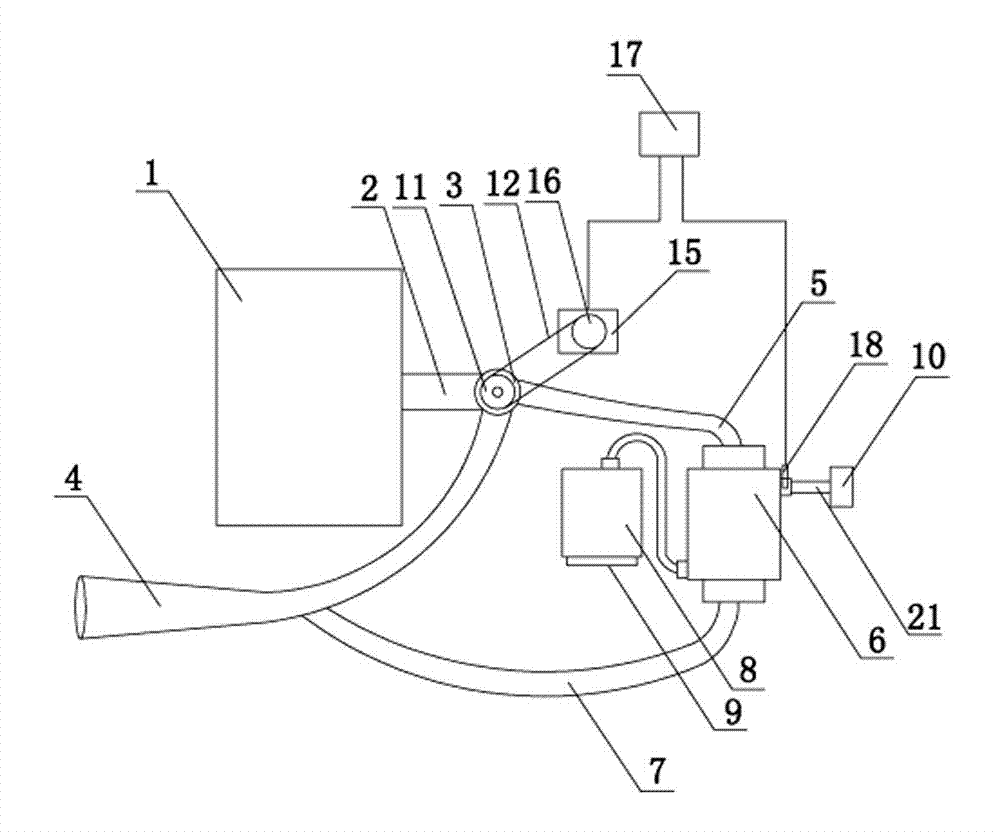

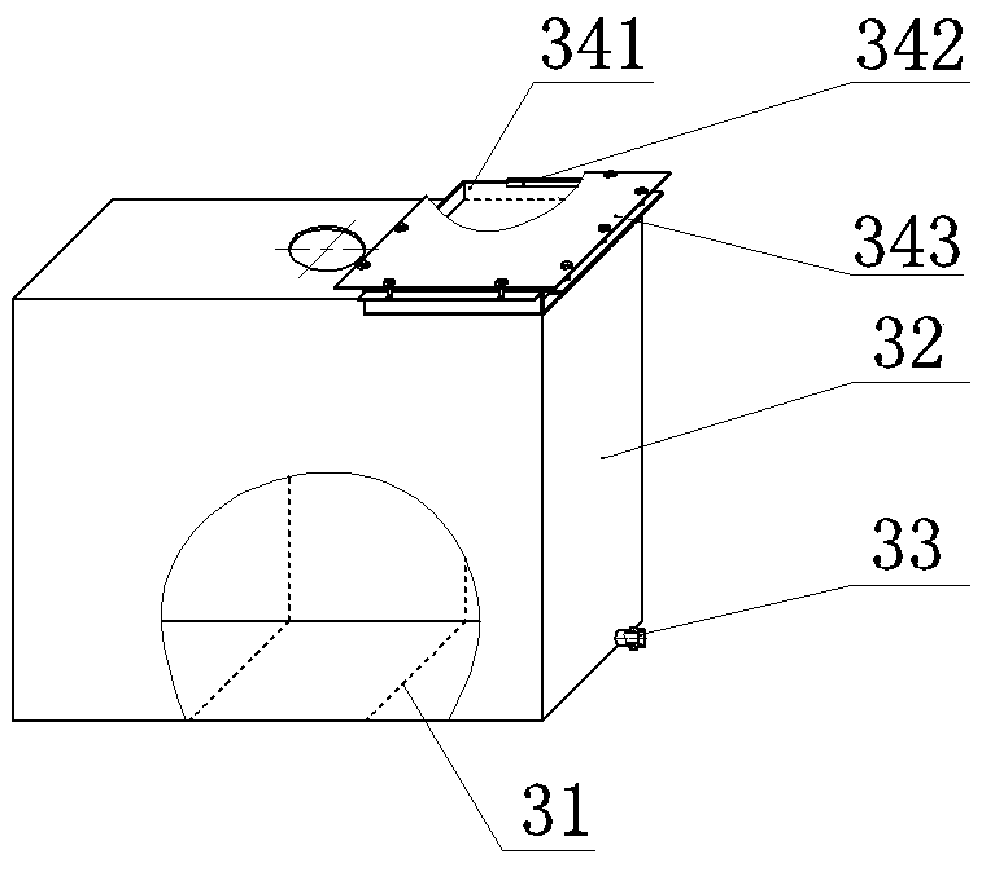

Steam blowing energy dissipation and pollutant removal discharging device

InactiveCN105618440ASmooth dischargeReduced emission energyCombination devicesDispersed particle filtrationAtmospheric airEngineering

The invention provides a steam blowing energy dissipation and pollutant removal discharging device. Steam blowing is needed during debugging after reconstructed, expanded and newly-constructed building electromechanical systems are installed. According to a steam blowing scheme, pressure is high, the quantity of steam is large, and the steam blowing path is long, so that at the steam blowing discharging tail end, the quantity of remaining steam is large, the pressure is high, pollutants are blown into the air, and a large cloud of smoke usually occurs at the same time. Thus, a filtering device is arranged in a main water tank, and a steam energy dissipation device is arranged at the tail end of a steam discharging pipe passing through the water tank. Blowing waste is treated in time at the blowing tail end of a system, steam discharging energy is reduced, and the steam is evenly discharged at a low speed. The steam blowing energy dissipation and pollutant removal discharging device is not only suitable for super high-rise buildings but also applicable to other buildings with regulations of noise or steam discharging requirements.

Owner:SHANGHAI INSTALLATION ENG GRP

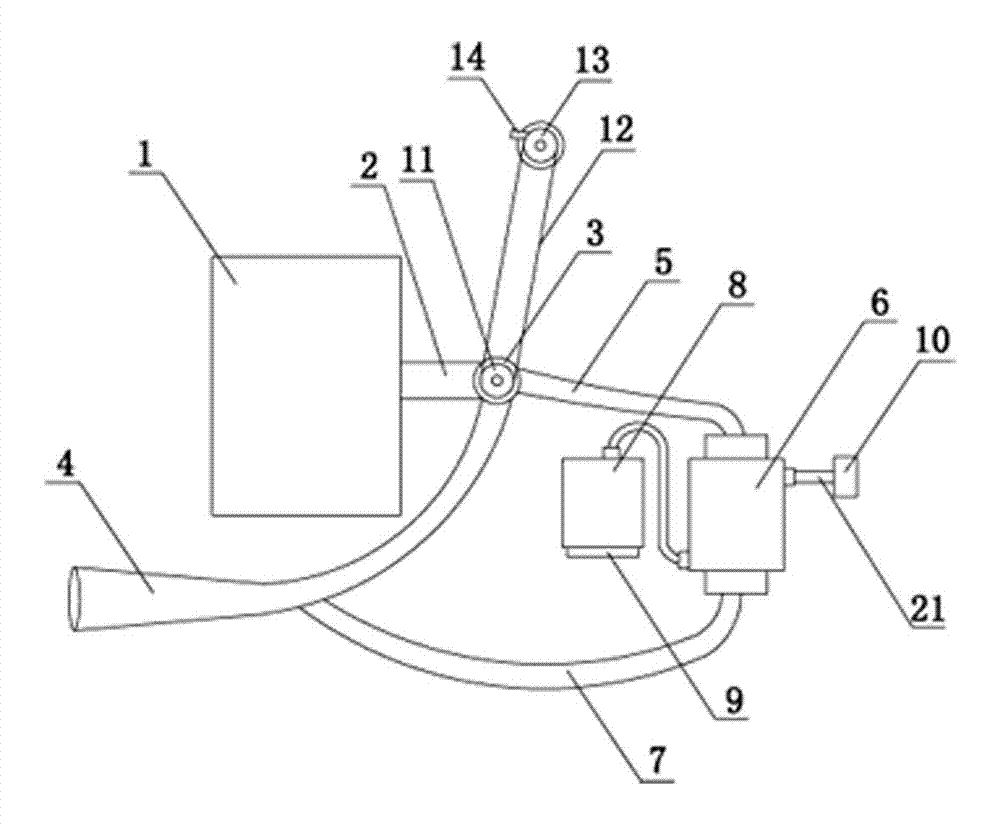

Tail gas warming device of motor bicycle and warming clothing applied to same

InactiveCN102785733AWide applicabilityReduce emission noiseCycle equipmentsEngineeringHeat exchanger

The invention discloses a tail gas warming device of a motor bicycle and warming clothing applied to the same. The tail gas warming device comprises a heat exchanger and a fan. An air outlet of the fan is connected onto an air inlet of the heat exchanger through an air guide pipe, an air outlet of the heat exchanger is connected with an air outlet connector through the air guide pipe, an exhaust front pipe is connected at the position of an engine tail gas outlet of the motor bicycle, the tail end of the exhaust front pipe is connected with one inlet of the three-way flow dividing valve, and the other two outlets of the three-way flow dividing valve are respectively connected onto an exhaust tail pipe and a branch gas tail pipe. The tail end of the branch gas front pipe is connected onto a hot fluid inlet of the heat exchanger, and a branch gas back pipe is connected with a hot fluid outlet of the heat exchanger. An adjusting device used for poking and rotating a valve switch is arranged on the three-way flow dividing valve. The warming temperature of the tail gas warming device can be adjusted simply by the gas flow degree of the three-way flow dividing valve to enable a human body to obtain optimum warming temperature. Therefore, adaptability of the tail gas warming device is expanded, and the tail gas warming device overcomes the shortcoming in the prior art that the warming device is wasted and left unused for most time.

Owner:陈涧忠

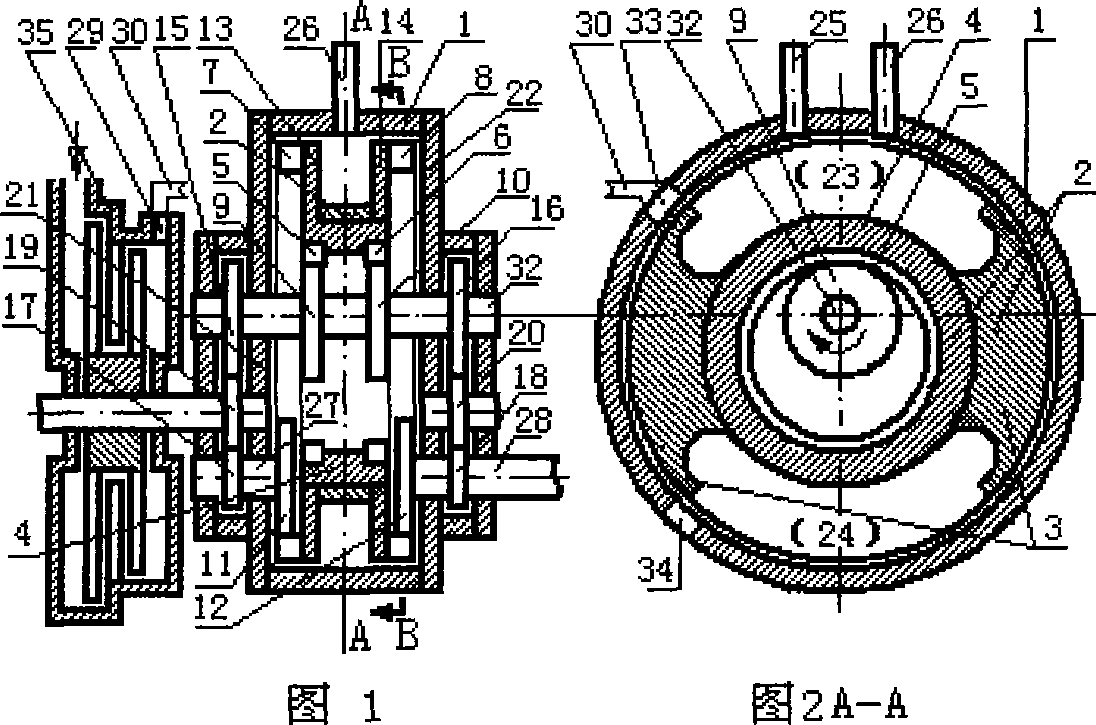

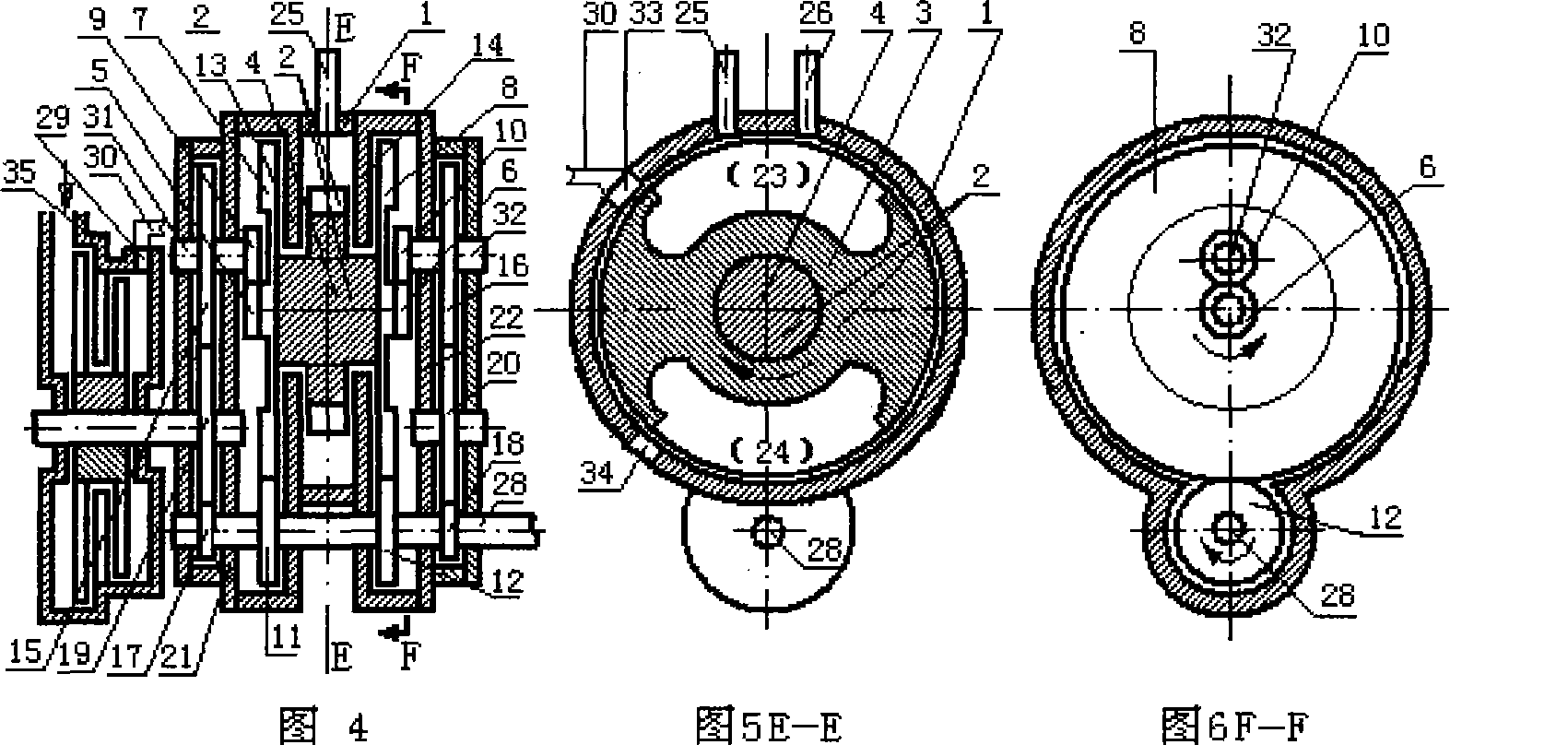

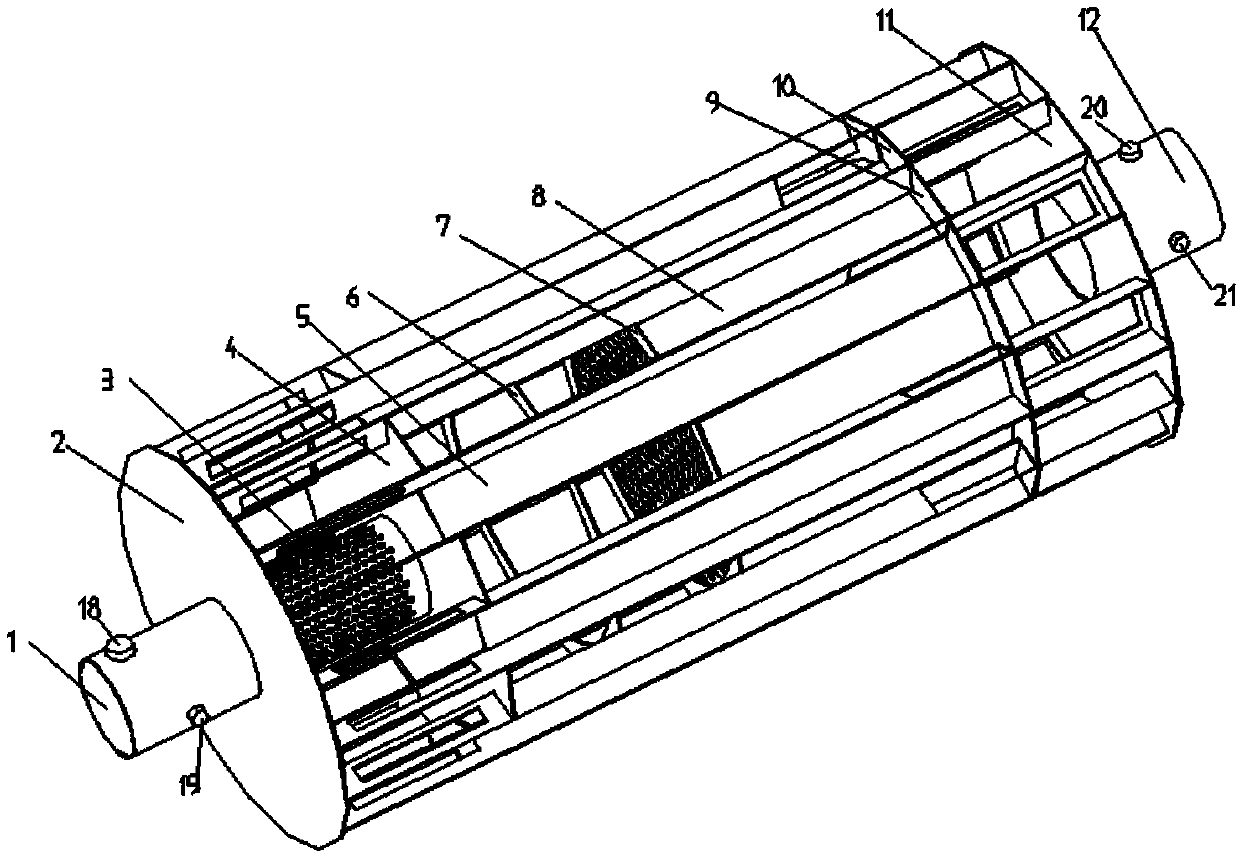

Constant volume type piston rotor engine

InactiveCN101509419AImprove work efficiencyReduce emission noiseInternal combustion piston enginesAir compressionGear drive

The invention relates to an isasteric piston rotor engine, wherein a piston rotor is arranged in a cylinder, the piston rotor is consists a piston and a button stem, the piston rotor is respectively connected with a chief shaft and an eccentric shaft by a wheel gearing; the piston divides the cylinder into at least one air chamber, the two ends of the cylinder are sealed by a cylinder cap which is fixed at the cylinder or the piston rotor, an air inlet, an air outlet, an oil injection nozzle and a spark plug are arranged at the cylinder; an air compression device is arranged for providing compressed air for the air chamber; the blast air in the air chamber acts on the piston rotor to cause the rotor to perform circular motion around the eccentric shaft, and power is output by the chief shaft; as the air capacity of the chamber is invariable, the expansion pressure of the high temperature air in the air chamber can not be reduced when working, namely, the discharged working air can be introduced into the air chamber of the duplex type cylinder to work one more time to realize the reutilization of the working air; the engine can be made into an external combustion engine by adding or reducing a relative device.

Owner:管土改

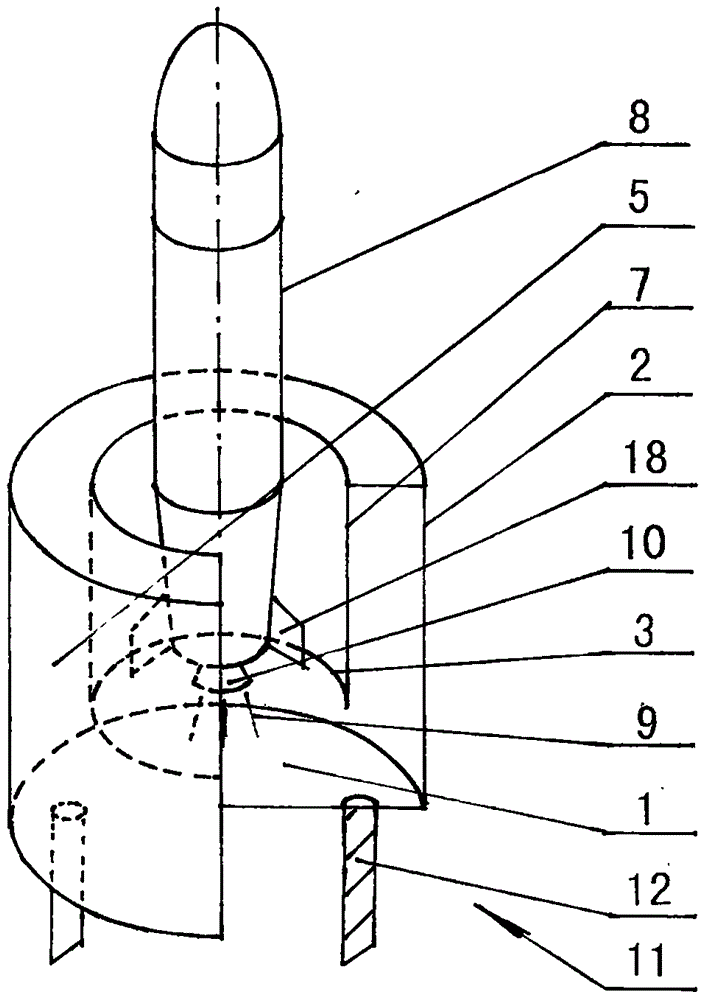

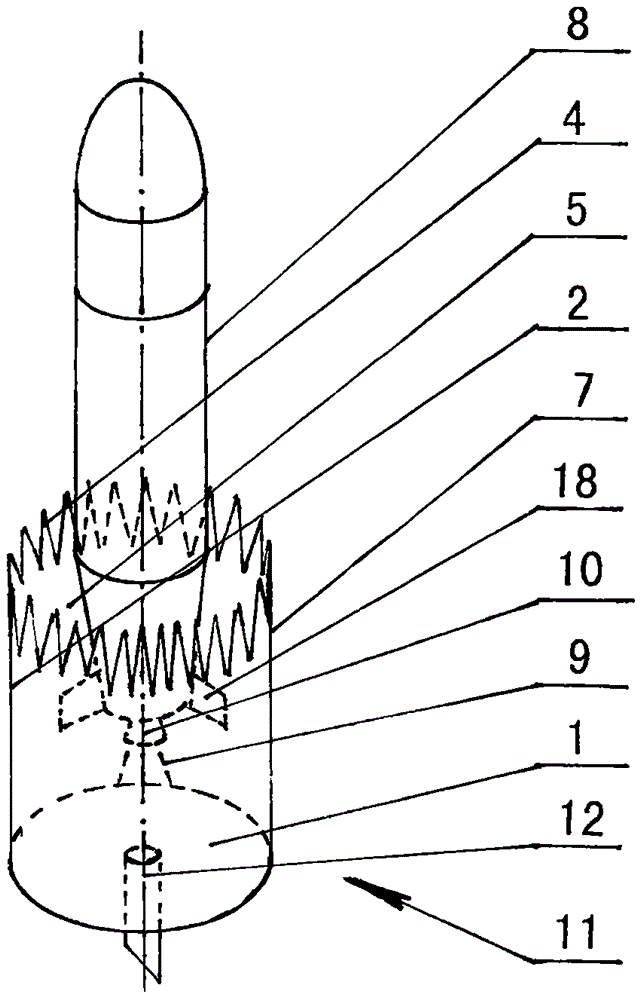

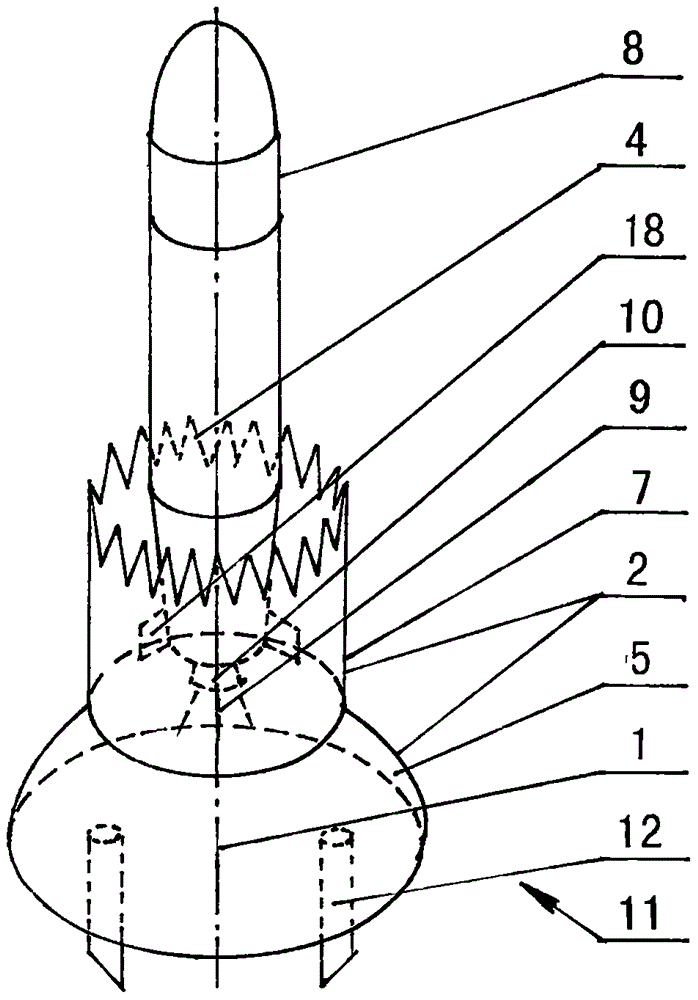

Reverse thrust seat for rocket launching

InactiveCN106123688AIncrease reverse thrustAcceleration is too smoothRocket launchersRocket launchHigh pressure

The invention relates to a reverse thrust seat for rocket launching. The reverse thrust seat comprises a bottom (1), a wall (2), a round hole (3) or a sawtooth hole (4), a cavity (5) and a cylinder (7). The wall (2) and the bottom (1) of the cylinder (7) of the reverse thrust seat (11) is hermetically connected to form the cavity (5). The lower end of a rocket (8) is placed in the horizontal reverse thrust seat (11). The rocket (8) is coaxially arranged on the reverse thrust seat (11). Piles, arranged on the lower surface of the reverse thrust seat (11) and fixed to the reverse thrust seat (11), extend into the horizontal ground, and are clung to the ground. A cover seat (13) is arranged at the periphery of the lower end of the rocket, and is used for preventing hot air flow (9) from burning the rocket (8) out. Kinetic energy of the high-pressure hot air flow (9), emitted to the surrounding by the rocket (8) and sprayed horizontally, is collected by the reverse thrust seat (11) with the wall (2), is stored in the cavity (5), and is converted into energy for thrusting the rocket up, so that more energy is saved, and the weight of the rocket can be reduced.

Owner:杨富云

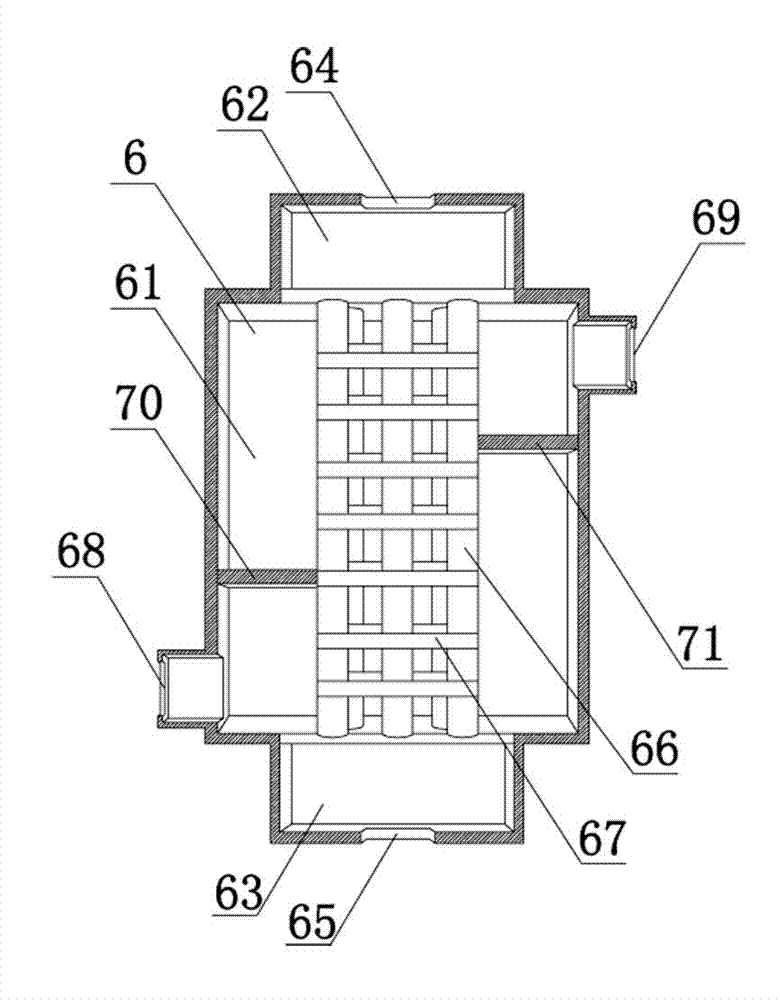

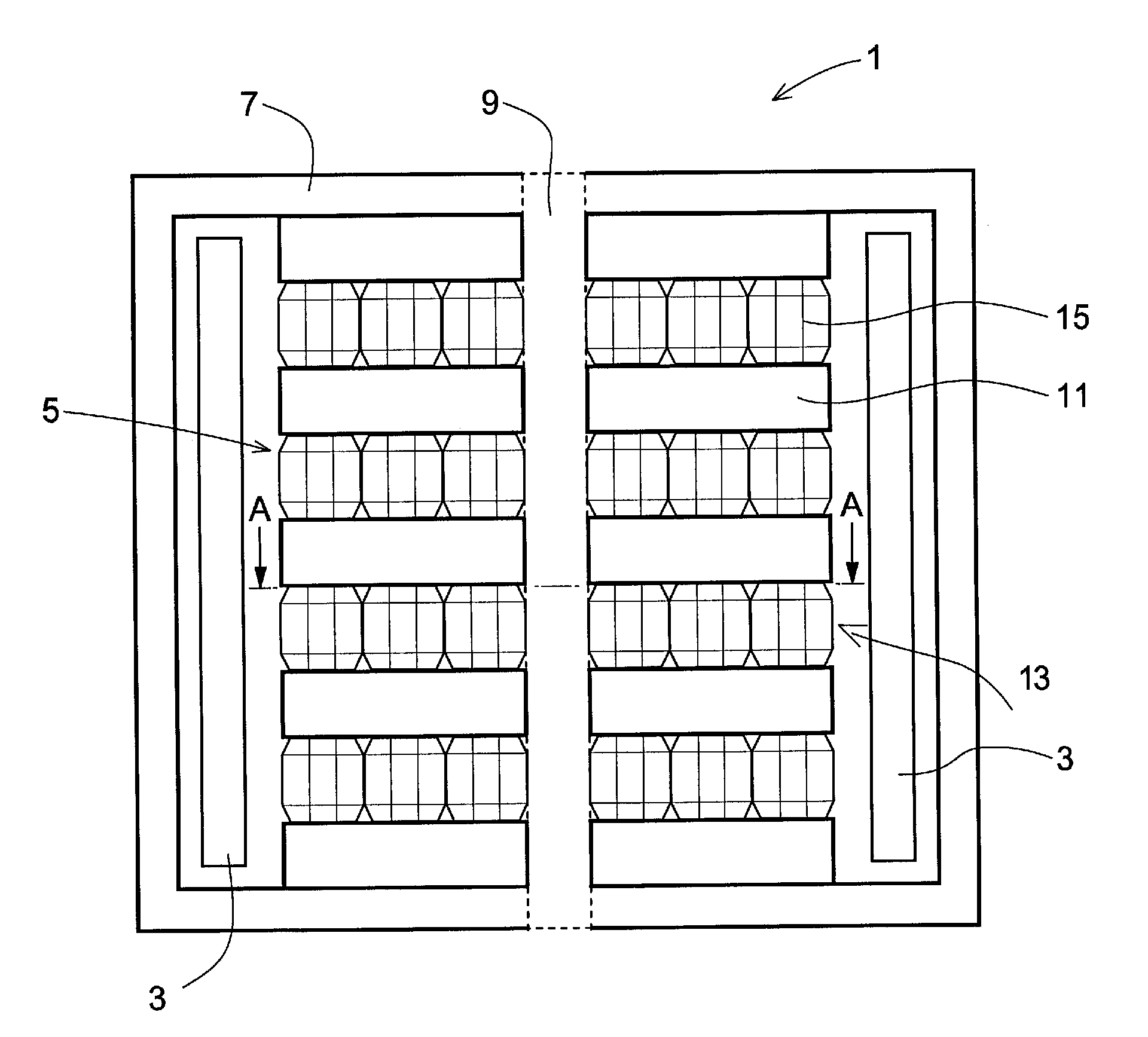

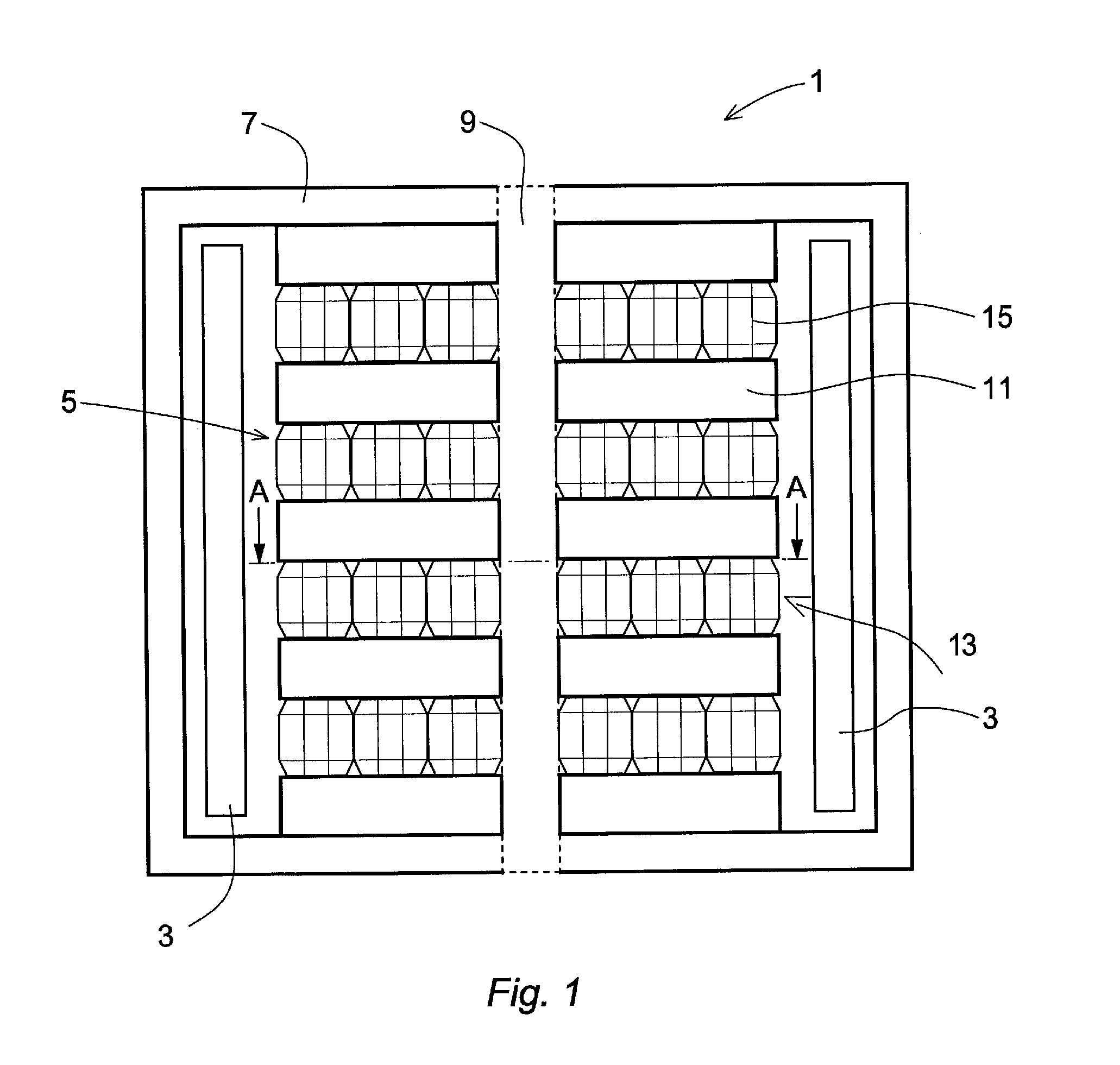

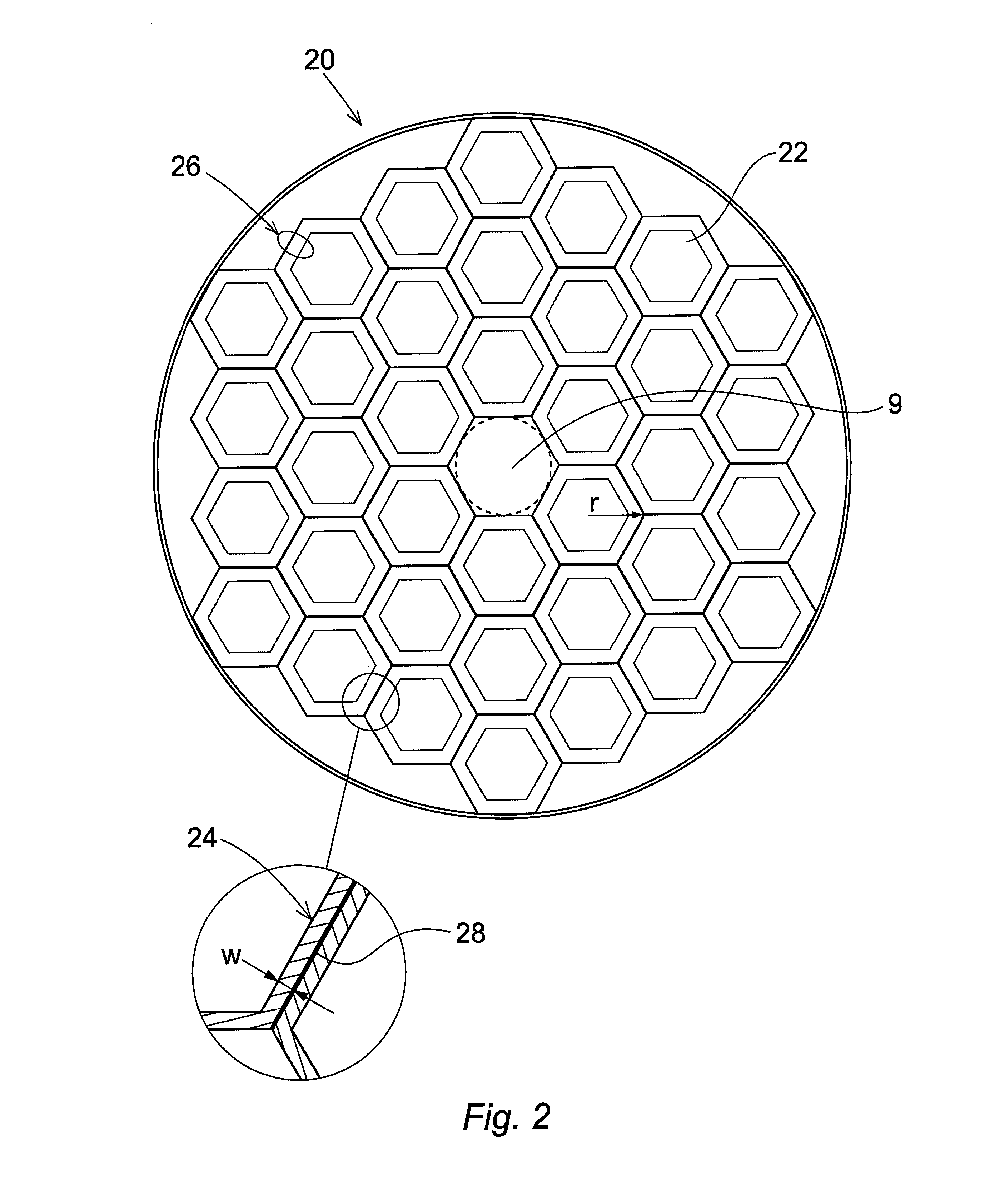

Induction device

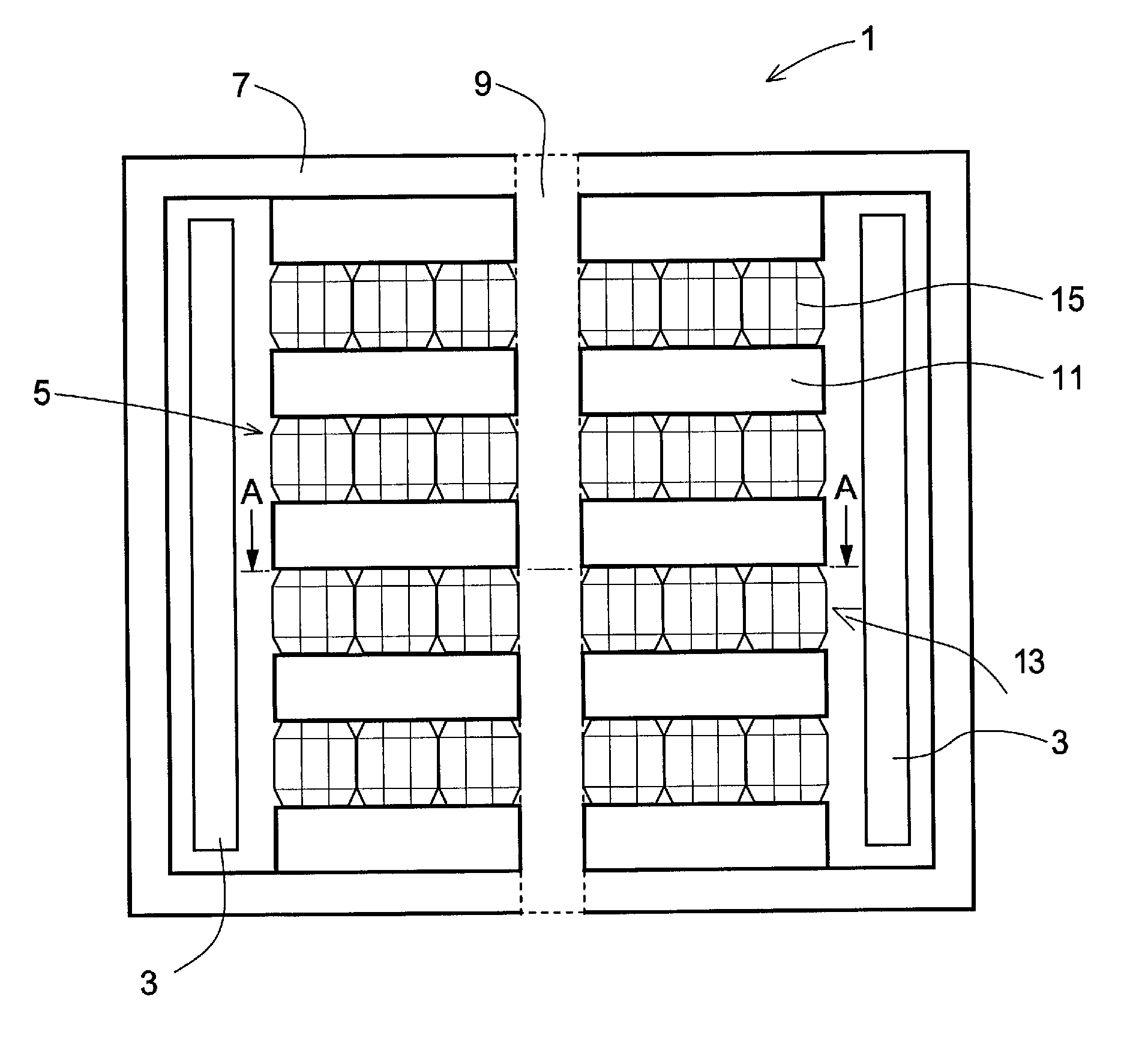

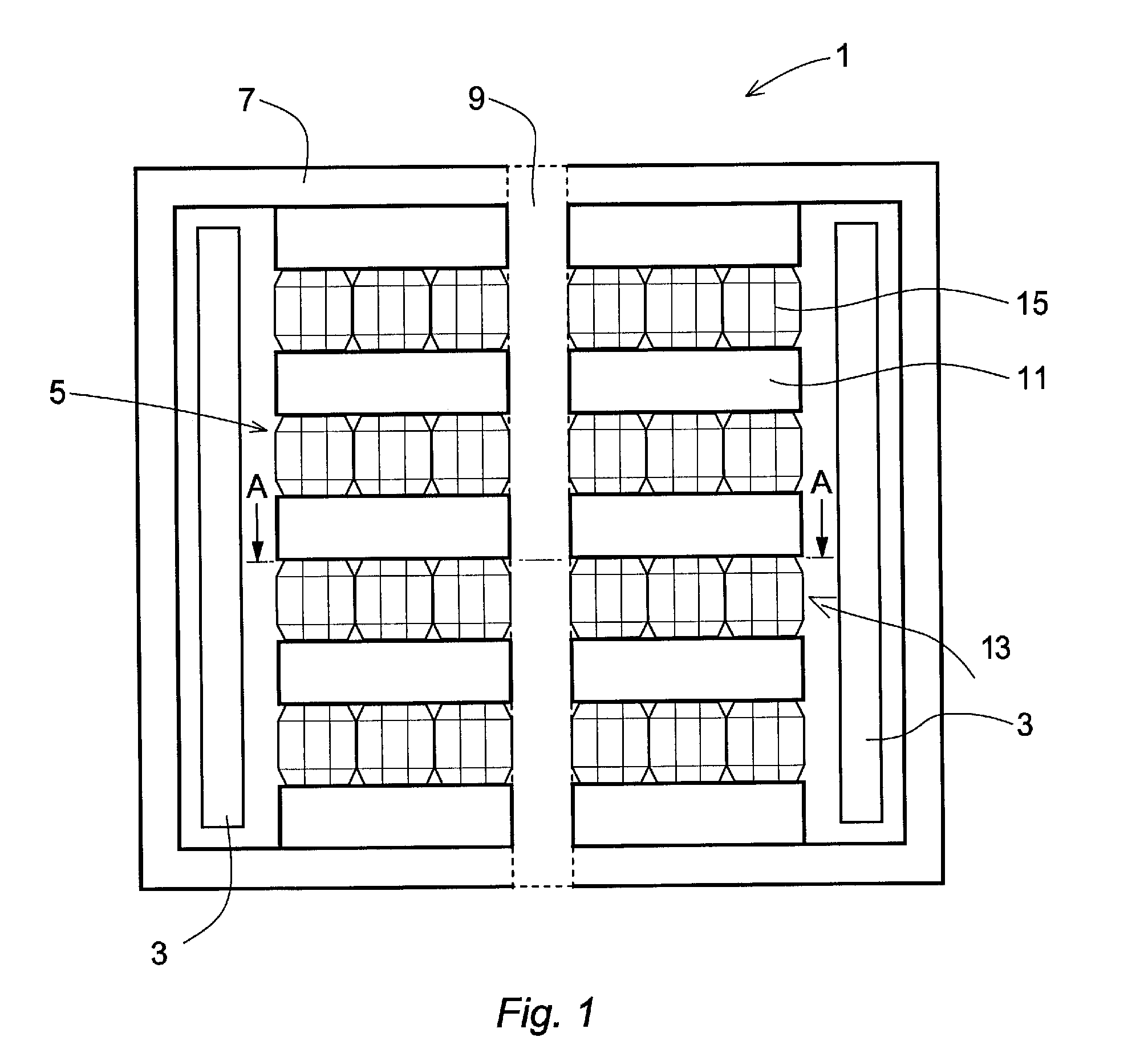

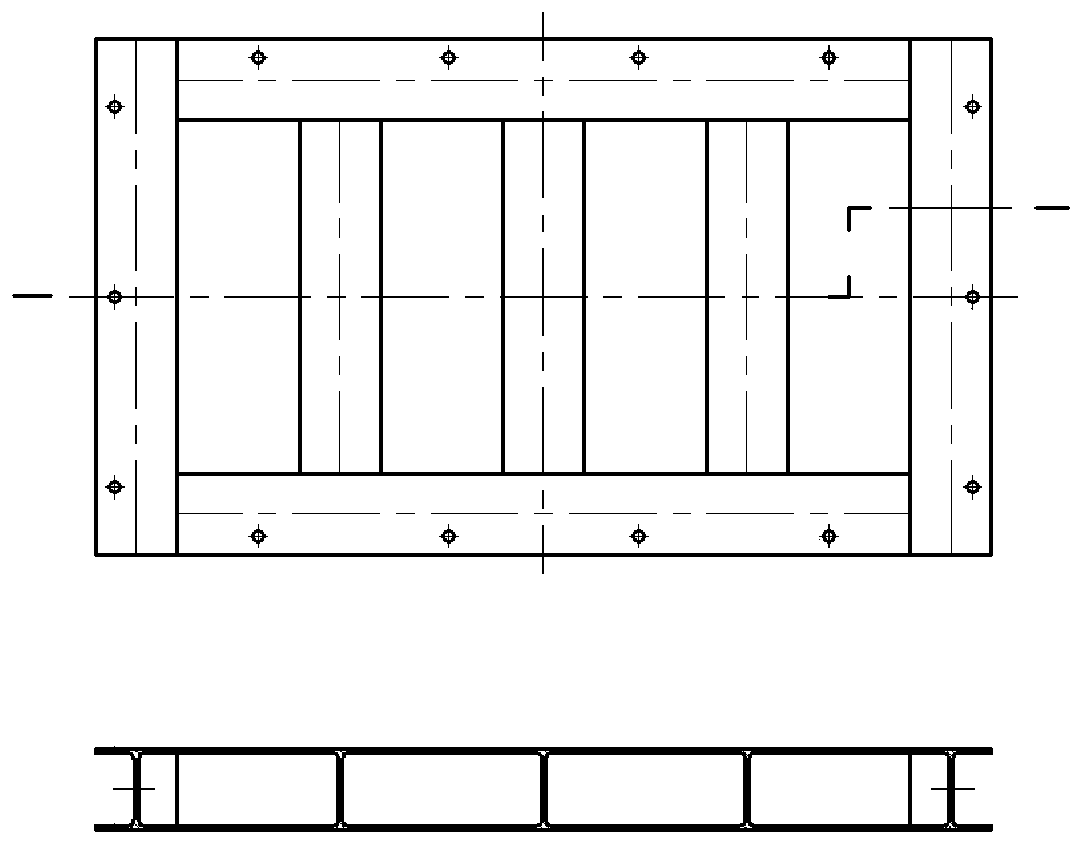

InactiveUS8115584B2Reduce noiseIncrease stiffnessTransformers/inductances coolingTransformers/inductances noise dampingEngineeringHigh pressure

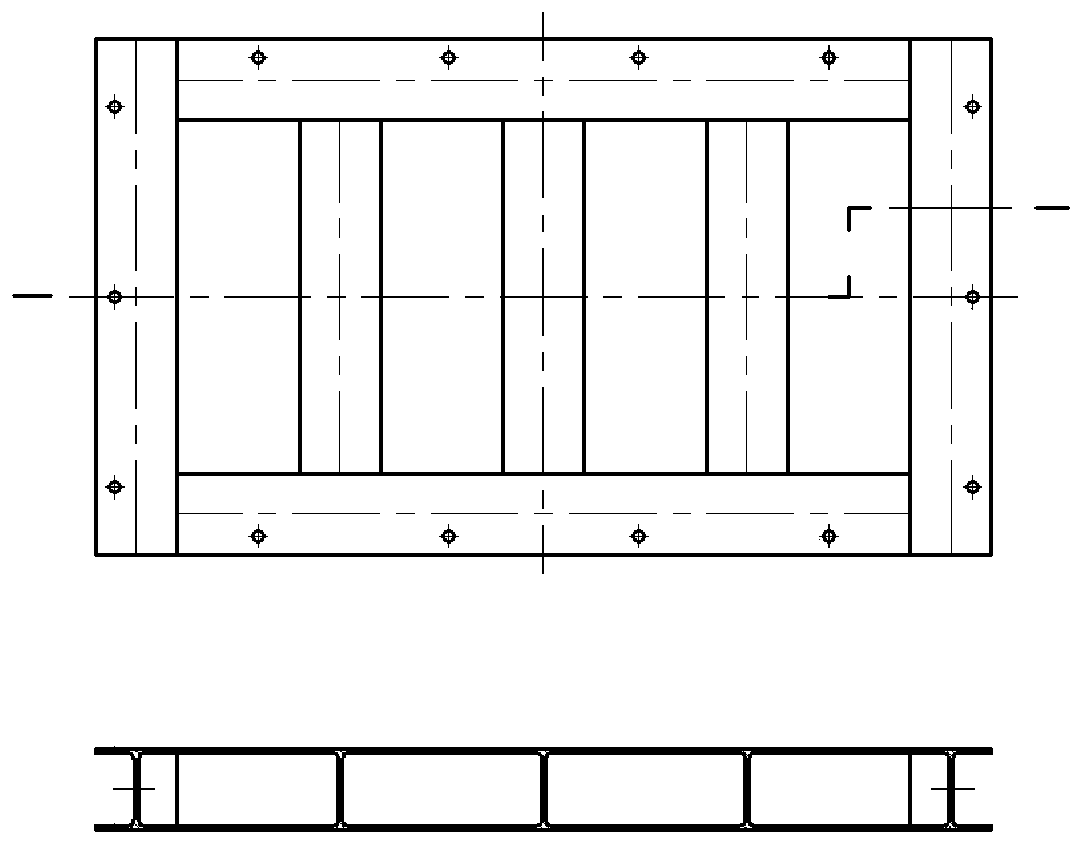

An induction device for association with high voltage electric transmission systems having at least one core frame and at least one winding arranged around said core frame. The induction device has at least one magnetic core leg arranged in said core frame. The core frame includes a stack of core segments of a magnetic material being cooled by cooling medium, arranged in compression in the core frame, core gaps being arranged to separate the core segments, and a plurality of spacers, arranged in the core gaps between the core segments, with a cross section of hexagonal shape, having an upper and a lower end-face being in contact with the core segments. The spacers in at least one of the core gaps are arranged densely packed so as to form a compact filling in the core gap.

Owner:ABB POWER GRIDS SWITZERLAND AG +1

Combustor fire grate, combustor and water heater

InactiveCN112443840AImprove stabilityImprove comfortGaseous fuel burnerThermodynamicsCombustion noise

The invention relates to the technical field of combustors, in particular to a combustor fire grate, a combustor and a water heater. The combustor fire grate comprises a premixing cavity, wherein thefire outlet end of the premixing cavity is provided with a fire outlet face, the fire outlet face is provided with fire outlet holes, the fire outlet holes comprise a plurality of main fire holes anda plurality of auxiliary fire holes, all the main fire holes are arranged in parallel, and the auxiliary fire holes are formed between every two adjacent main fire holes among part or all of the mainfire holes. According to the combustor, the auxiliary fire holes are formed between every two adjacent main fire holes in the fire outlet face 2-3 of the unique premixing cavity, so that the main fireholes and the auxiliary fire holes are basically formed alternately, good fire transferring and flame stabilizing performance is achieved, combustion noise is lowered, the combustion discharge amountis reduced, better performance experience is brought to consumers, the using comfort of the water heater is improved, moreover, the emission of carbon monoxide can be effectively reduced, and the usesafety of the water heater is improved.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

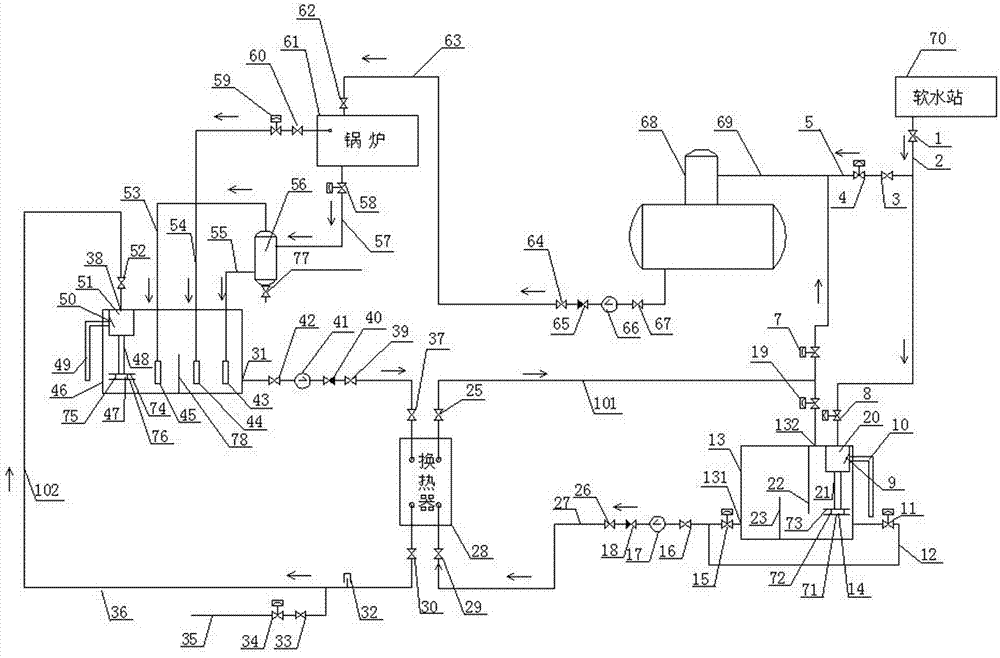

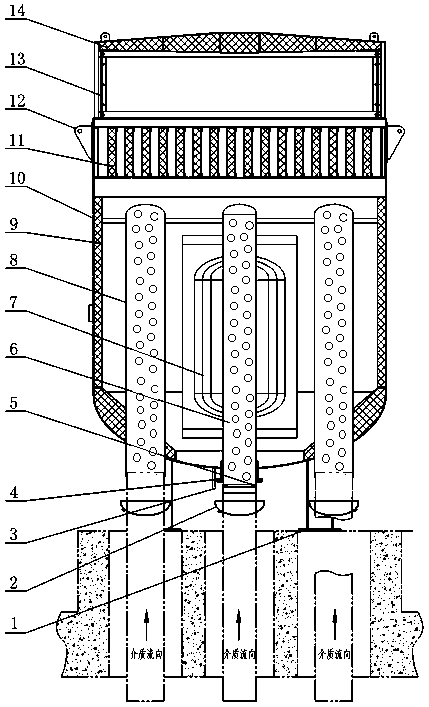

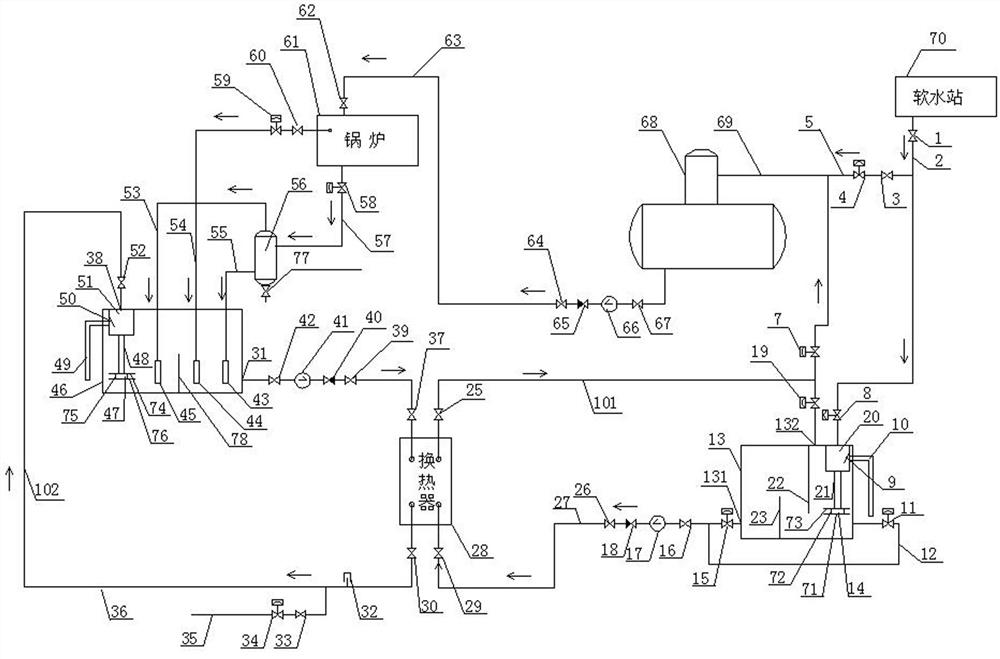

Boiler blow-off heat energy recycling utilization system

ActiveCN107973356AExtended service lifeReduce failureWater treatment parameter controlSpecific water treatment objectivesThermal energyPlate heat exchanger

The invention provides a boiler blow-off heat energy recycling utilization system, and belongs to the technical field of boiler blow-off heat energy utilization. The boiler blow-off heat energy recycling utilization system comprises a soft water station, a boiler, a deaerator connected with the boiler, and a demineralized water circulation device communicating with the soft water station, whereindemineralized water generated by the soft water station flows into the demineralized water circulation device, and then flows through the deaerator, and then is transported to the boiler; a buffer tank communicating with the bottom of the boiler; a sewage recycling device respectively communicating with the boiler and the buffer tank; and a heat exchanger respectively connected with the demineralized water circulation device and the sewage recycling device, wherein the demineralized water and sewage respectively flow through the heat exchanger, and heat is transferred from the sewage to the demineralized water. According to the system, the demineralized water and the sewage generated by the boiler blow-off respectively flow through the heat exchanger in a circular and uninterrupted mode, so that heat energy of the sewage is fully utilized to preheat the demineralized water.

Owner:CHINA TOBACCO HENAN IND

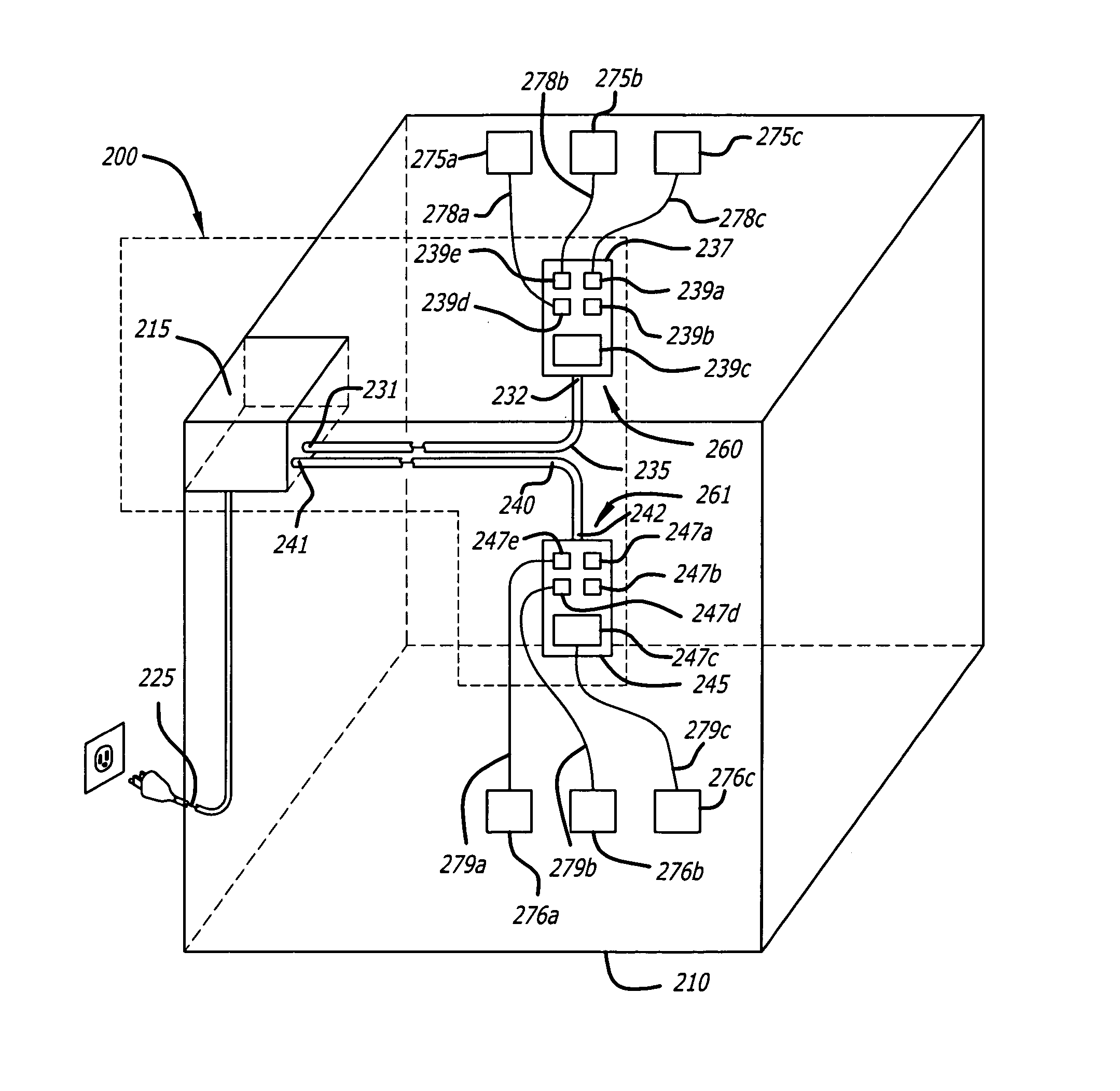

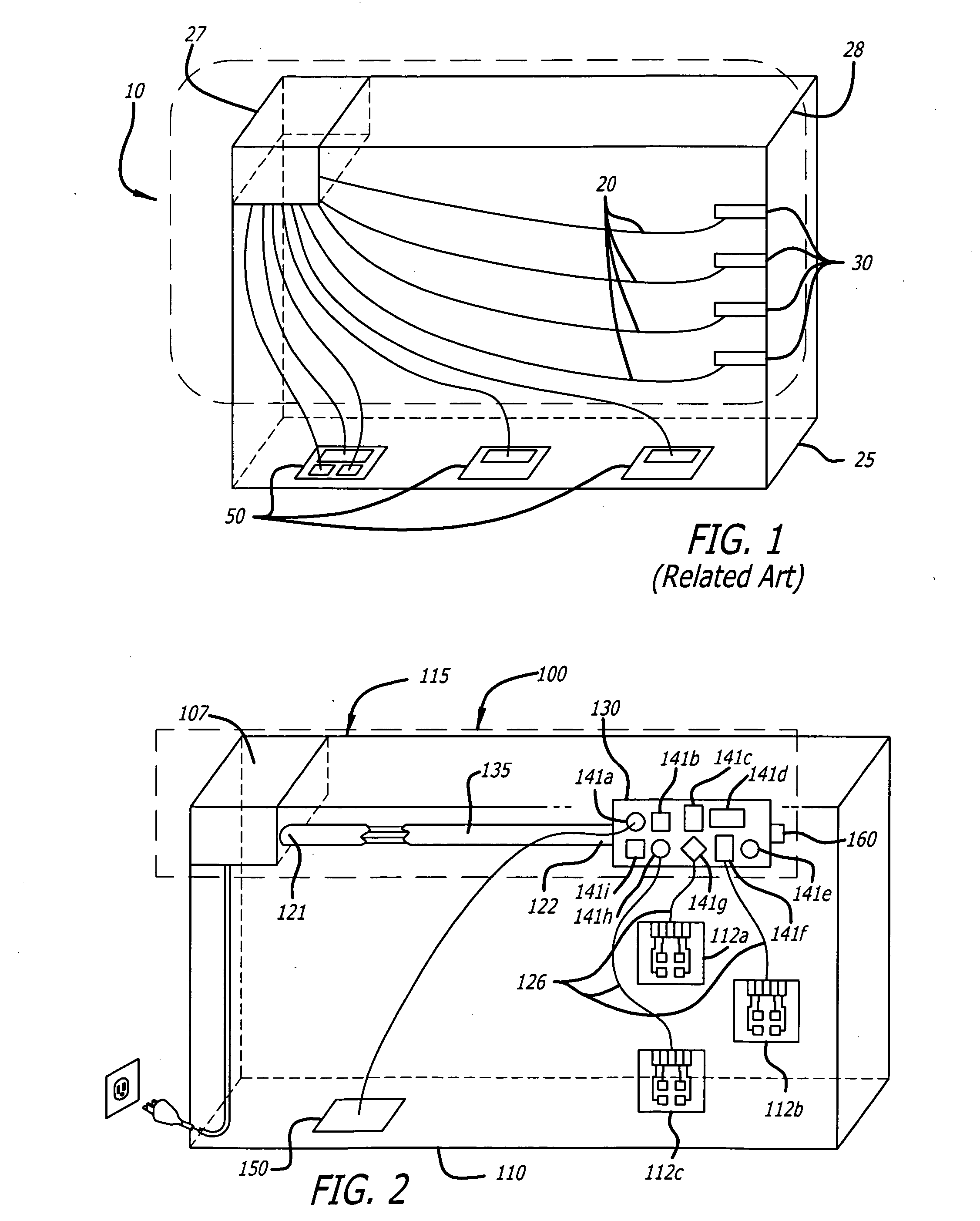

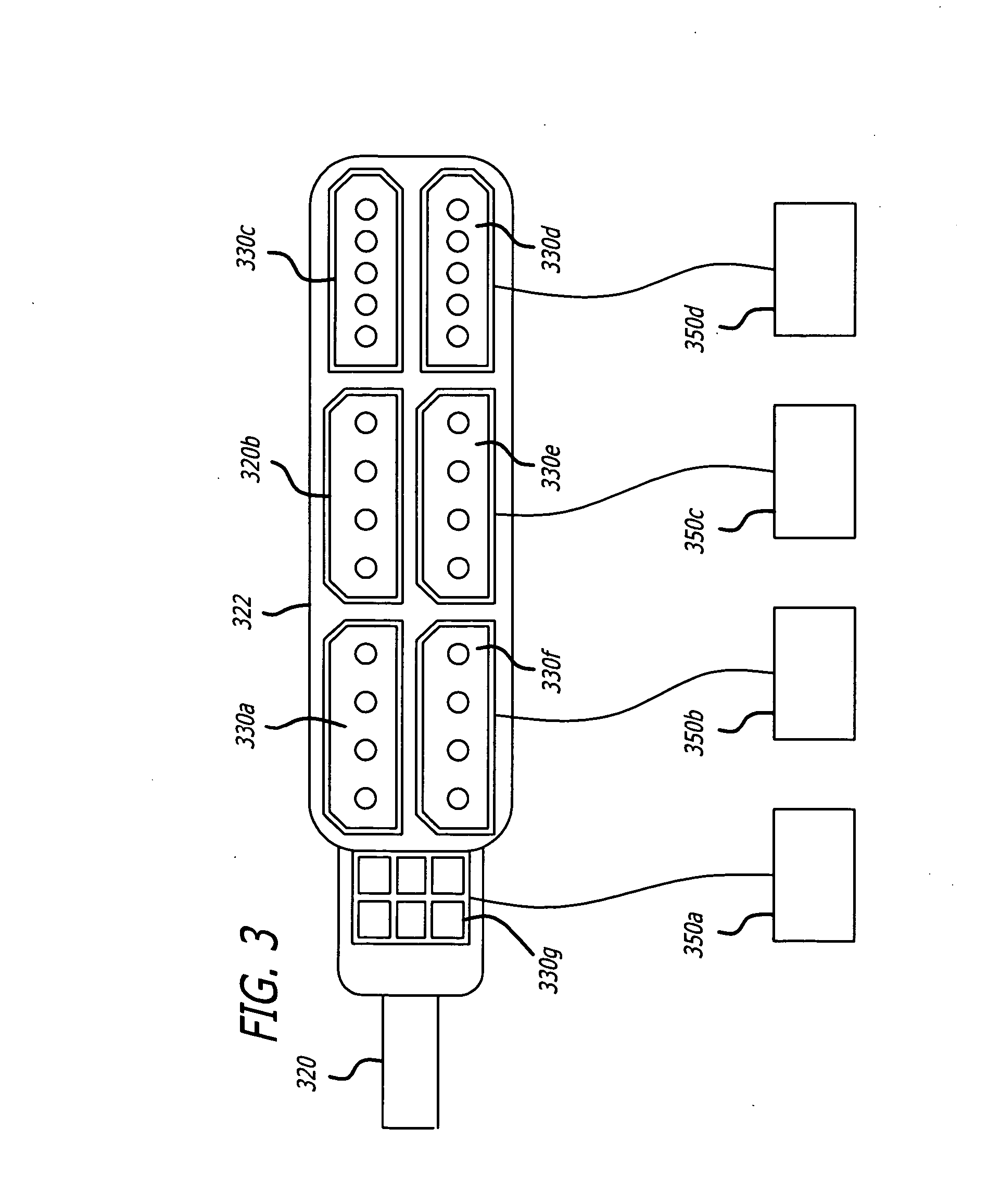

Computer power supply and cable

InactiveUS20070029880A1Reduce wiringReduce cable clutterPrinted circuit detailsDigital data processing detailsElectricityEngineering

A power supply apparatus is disclosed to provide power to a plurality of electrical components inside a computer housing. The power supply apparatus comprises a power supply module to convert electrical power to at least one power level. At least one power distribution panel is disposed within the computer housing. At least one wiring harness is electrically coupled at a first end of the at least one wiring harness to the at least one power distribution panel. The at least one wiring harness at a second end connects to the power supply module to transfer the at least one power level to the at least one power distribution panel. The at least one power distribution panel provides electrical adapters to transfer the at least one power level to cables that are coupled between the electrical adaptors and the plurality of electrical components.

Owner:KIM JINSEOK

Vehicle-mounted tail gas temperature difference power generation heat exchanger

InactiveCN106762036AImprove compatibilityReduce emission noiseInternal combustion piston enginesSilencing apparatusPower generation systemAutomotive emissions

The invention provides a vehicle-mounted tail gas temperature difference power generation heat exchanger. The heat exchanger comprises a mounting base body. A device having the SCR function and a device having the noise reduction function are integrated into the mounting base body at the same time so that heat energy in high-temperature tail gas of an automobile engine can be recycled; and meanwhile, in the heat exchange process of the heat exchanger, compatibility between an automobile tail gas temperature difference power generation system and a tail gas emission system is improved. By means of the vehicle-mounted tail gas temperature difference power generation heat exchanger, the SCR function and the noise reduction function can be integrated; the problem that multiple devices are in tandem arrangement in the link of tail gas treatment is thoroughly solved; the integration degree is high; arrangement is easy to conduct; and a temperature difference power generation device can be applied to a commercial vehicle conveniently.

Owner:WUHAN UNIV OF TECH

Induction Device

InactiveUS20110227683A1Reduce noiseIncrease stiffnessTransformers/inductances coolingTransformers/inductances noise dampingHigh pressureConductor Coil

An induction device for association with high voltage electric transmission systems having at least one core frame and at least one winding arranged around said core frame. The induction device has at least one magnetic core leg arranged in said core frame. The core frame includes a stack of core segments of a magnetic material being cooled by cooling medium, arranged in compression in the core frame, core gaps being arranged to separate the core segments, and a plurality of spacers, arranged in the core gaps between the core segments, with a cross section of hexagonal shape, having an upper and a lower end-face being in contact with the core segments. The spacers in at least one of the core gaps are arranged densely packed so as to form a compact filling in the core gap.

Owner:ABB POWER GRIDS SWITZERLAND AG +1

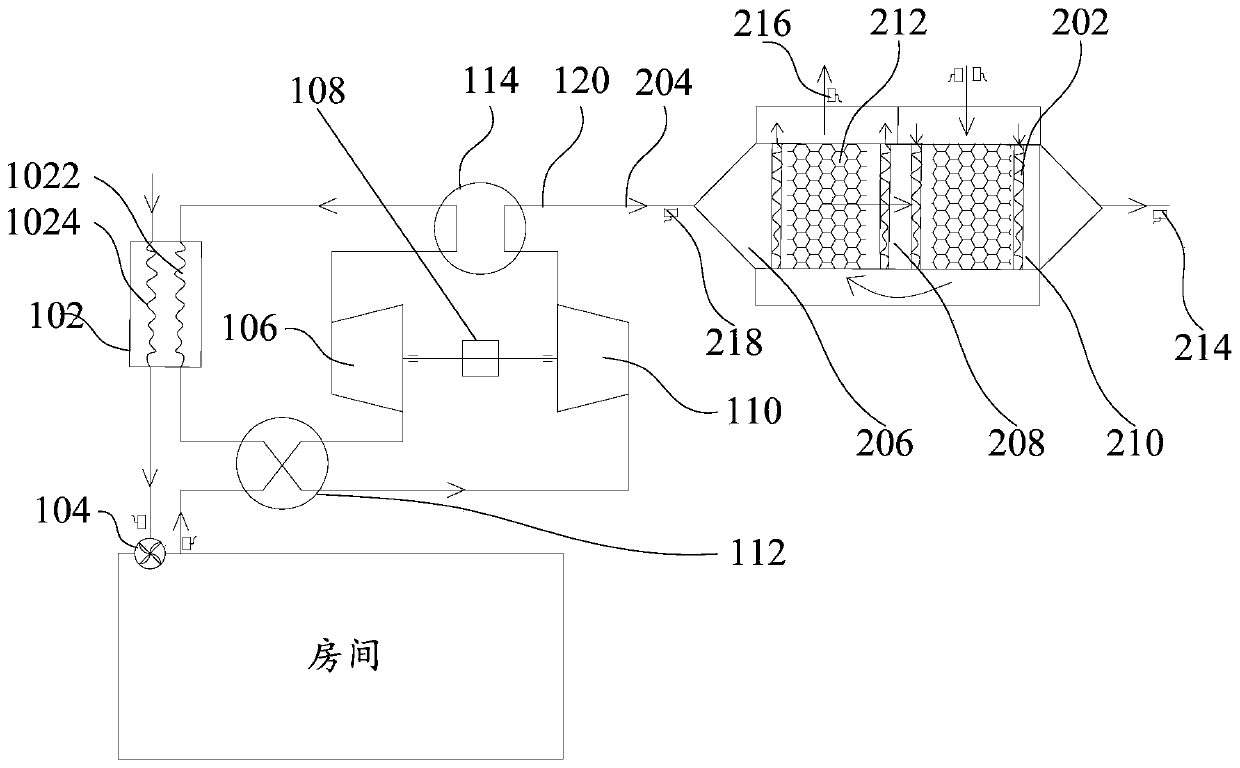

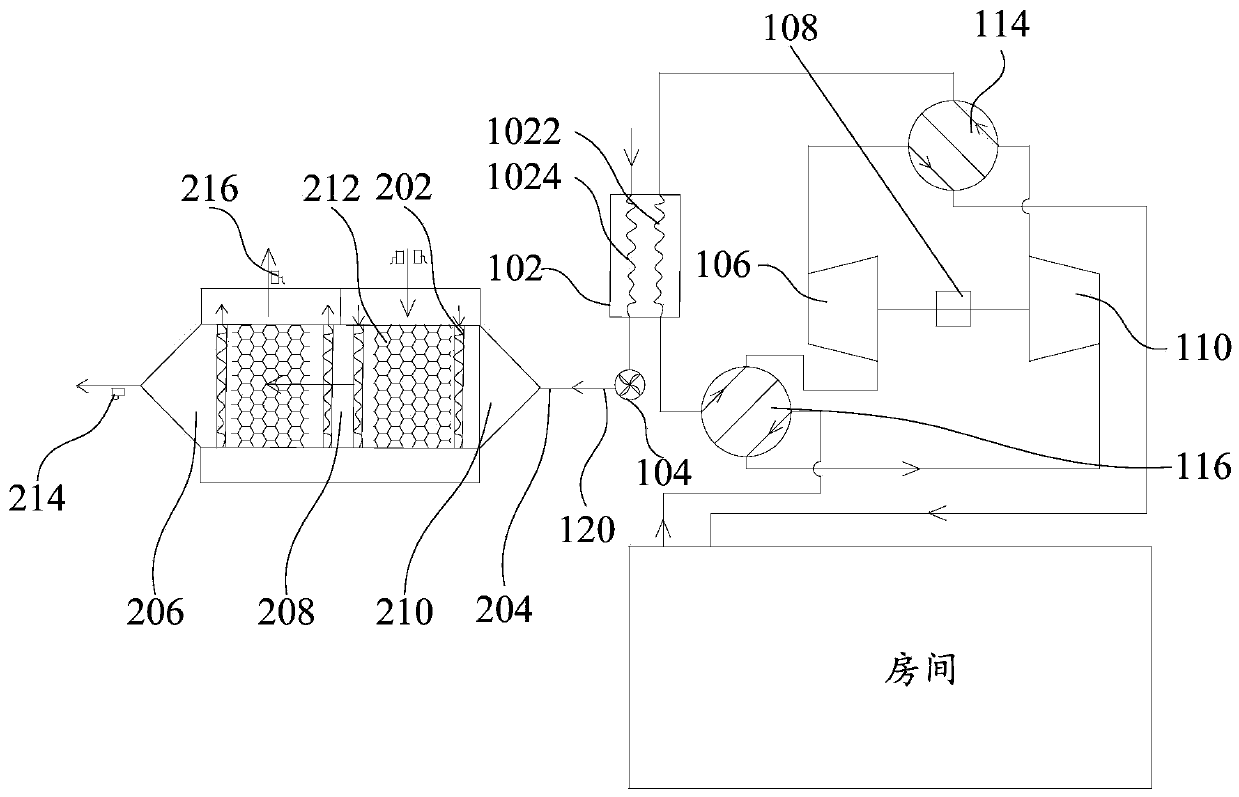

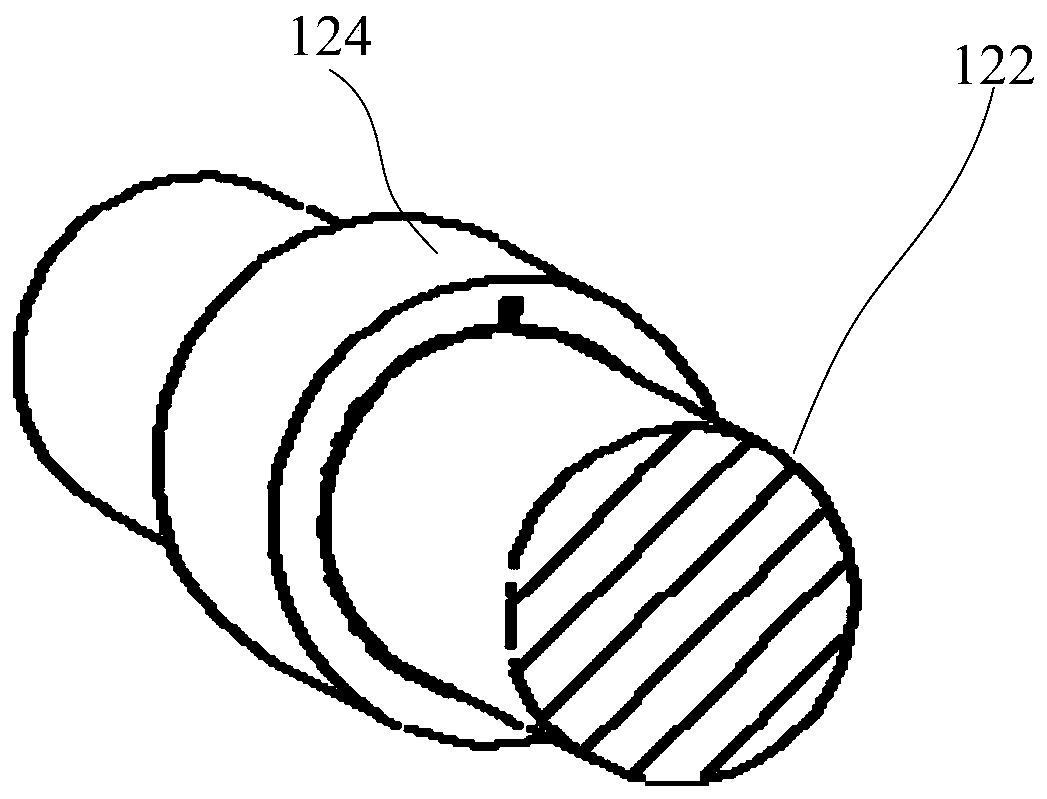

Compressed air heat-exchange system

InactiveCN110864470ALow costReduce pollutionMechanical apparatusFluid circulation arrangementEngineeringGas exchange

The invention provides a compressed air heat-exchange system. The compressed air heat-exchange system comprises a processor, a heat-exchanger, a pressurization expanding assembly and a tail gas treatment device, wherein the pressurization expanding assembly is electrically connected to the processor; air flow paths are arranged between the heat exchanger and the pressurization expanding assembly as well as between the heat exchanger and an indoor ventilation opening, so that the pressurization expanding assembly is controlled by the processor to carry out indoor heating or refrigeration; the tail gas treatment device is connected with an exhaust port and comprises an air cavity and heat-exchange tubes arranged in the air cavity and used for delivering liquid; and after high-temperature gasis exhausted into the air cavity, the high-temperature gas exchanges heat with the heat-exchange tubes to heat the liquid and is then exhausted outdoors. By the adoption of the technical scheme, thetail gas treatment device comprises the air cavity and the heat-exchange tubes in the air cavity, and the high-temperature gas exhausted via the exhaust port can exchange heat with the normal-temperature or low-temperature liquid in the heat-exchange tubes to heat the liquid after entering the air cavity, so that the utilization rate of tail gas is increased, and heat waste is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

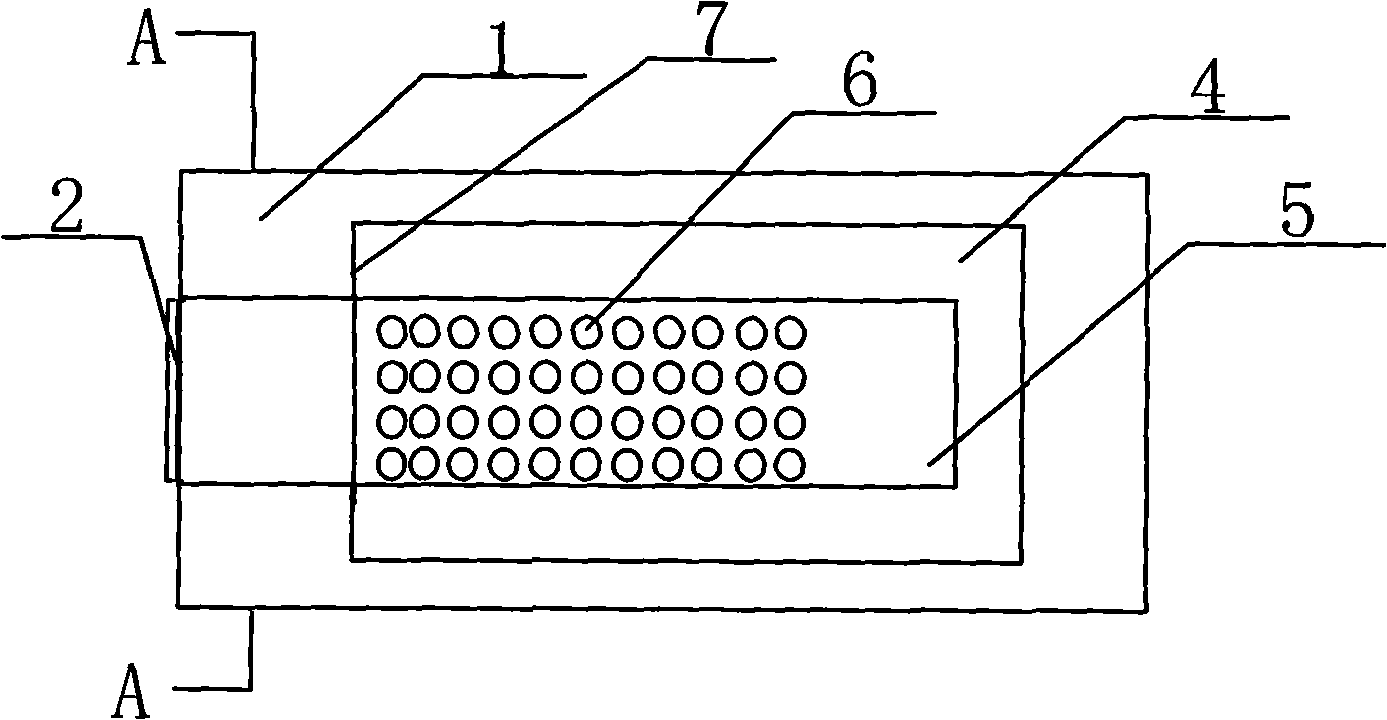

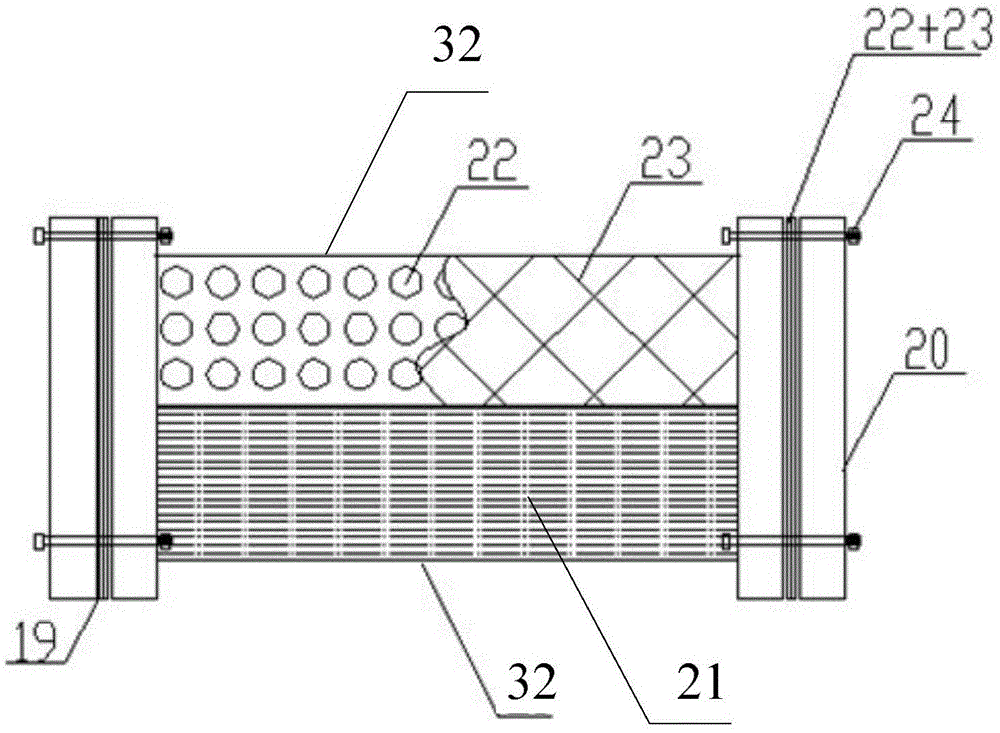

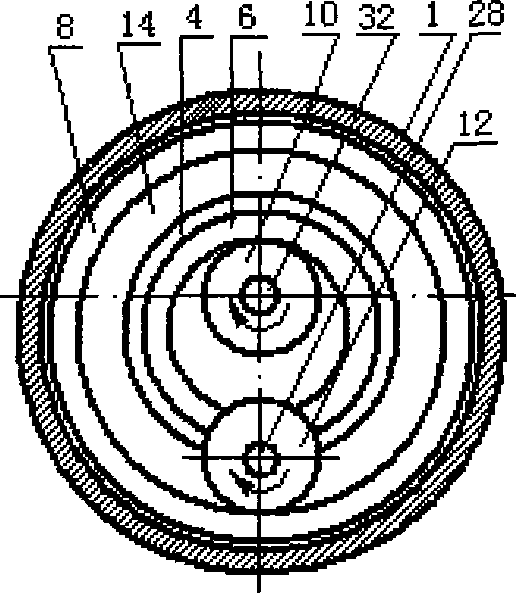

Multistage pressure control complex muffler

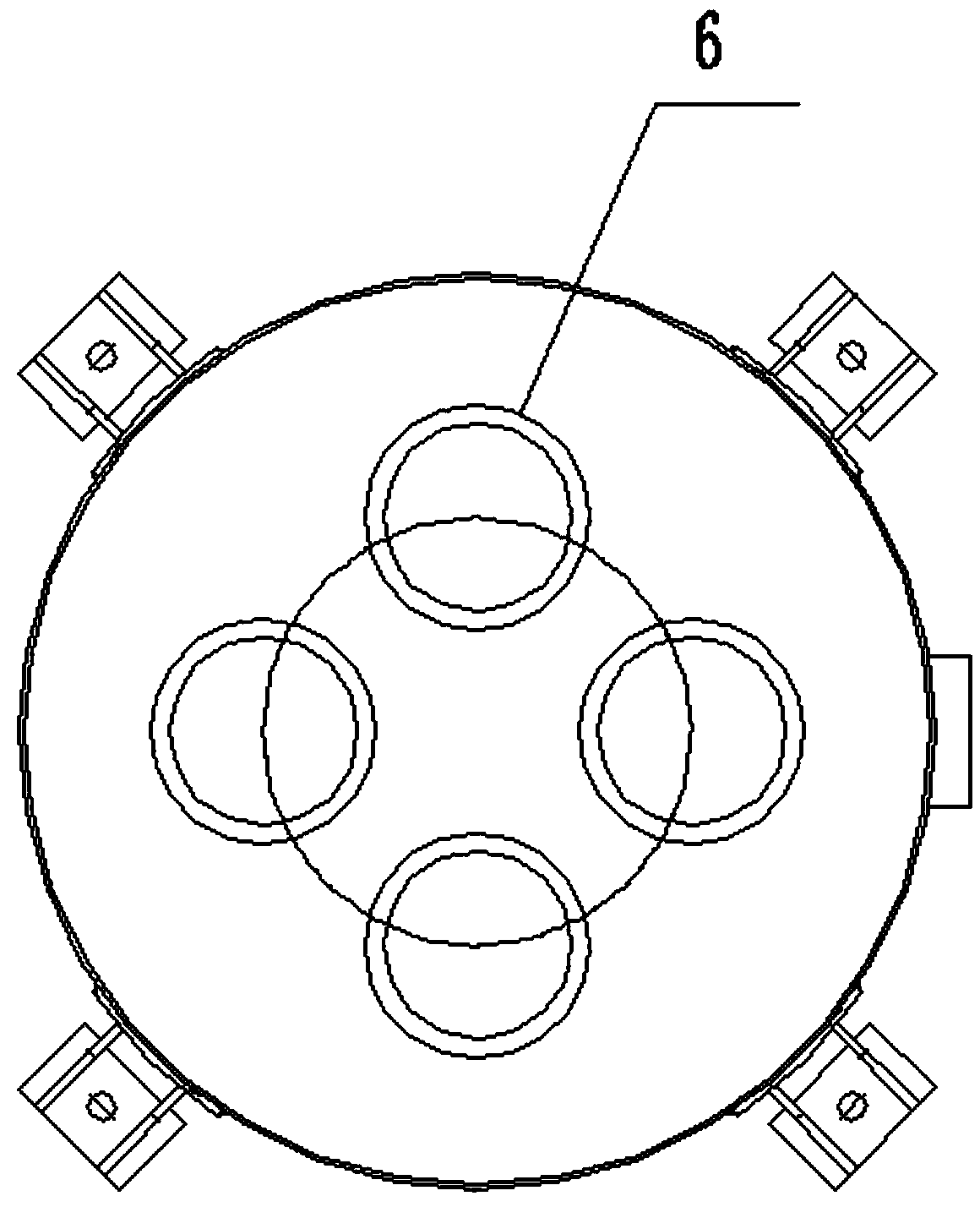

PendingCN109767747AReduce emission noiseAvoid strong jet noiseSound producing devicesNoise pollutionSound Absorber

The invention discloses a multistage pressure control complex muffler. A restriction orifice plate is arranged at the lower end of an inner cavity of a main manifold in a casing; a plurality of roundholes are spread on the wall part of the main manifold from top to bottom to form a second-stage pressure control structure; multiple layers of pressure control cylinders are coaxially arranged and are fixedly connected with the outer part of the main manifold; a plurality of round through holes are distributed on the wall of the pressure control cylinder of each layer from top to bottom; the round through holes in the walls of two adjacent layers of pressure control cylinders are staggered distributed in a spaced manner; a second manifold is arranged in the casing to form a fourth-stage pressure control structure; large pressure drop exhausted by an atmosphere exhaust opening is dispersed to bear, so that air current discharged from the atmosphere exhaust opening is changed from pressurejump evacuation into pressure gradient evacuation, and further strong jet noise produced by large pressure drop exhaust is avoided; gas is jetted from small holes and is assisted with a resistance sound absorber for further absorbing sound, the internal pressure drop process of equipment can be controlled, atmospheric emission noise is reduced, the noise spectrum quality is improved, and a noise pollution control goal is achieved; the multistage pressure control complex muffler meets the use requirements of an atmospheric exhaust regulating valve for nuclear power on high pressure and mass flow and has good muffling effect.

Owner:ZHENJIANG EAST CHINA ELECTRIC POWER EQUIP FACTORY CO LTD

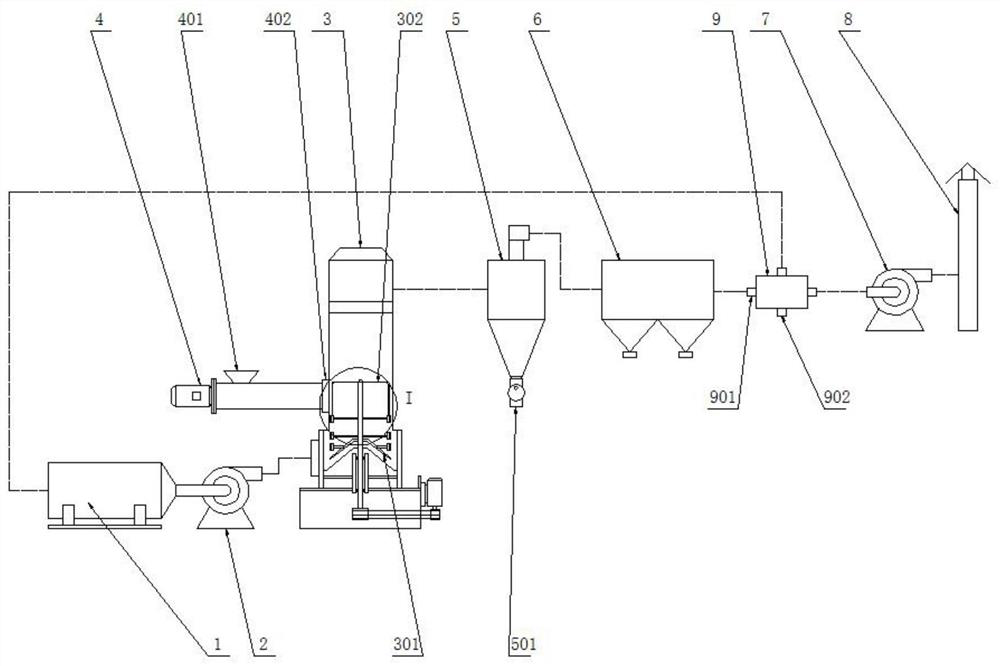

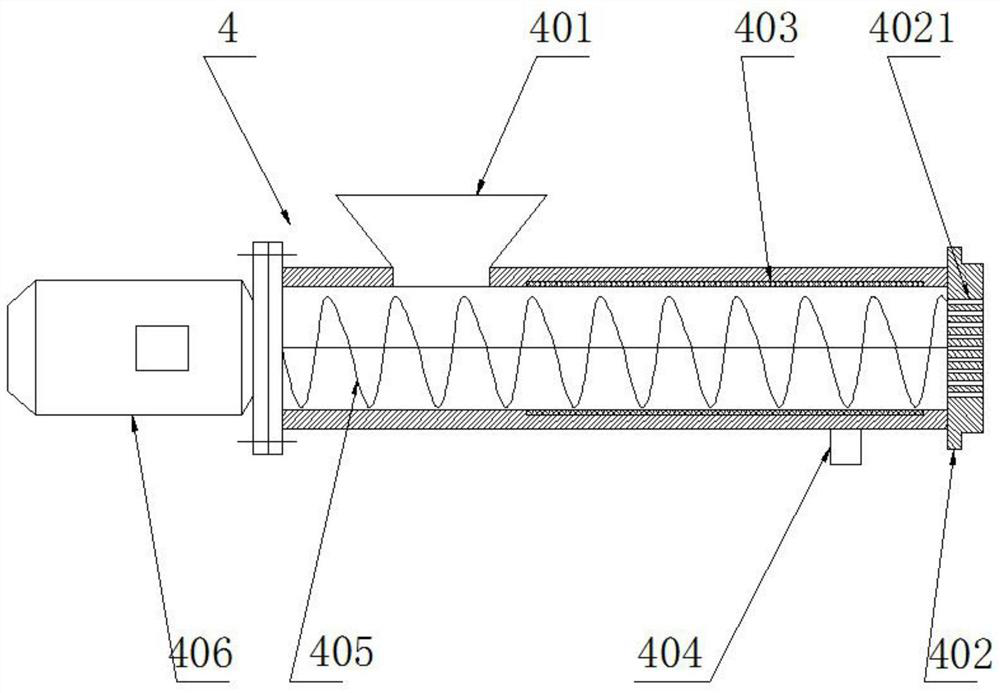

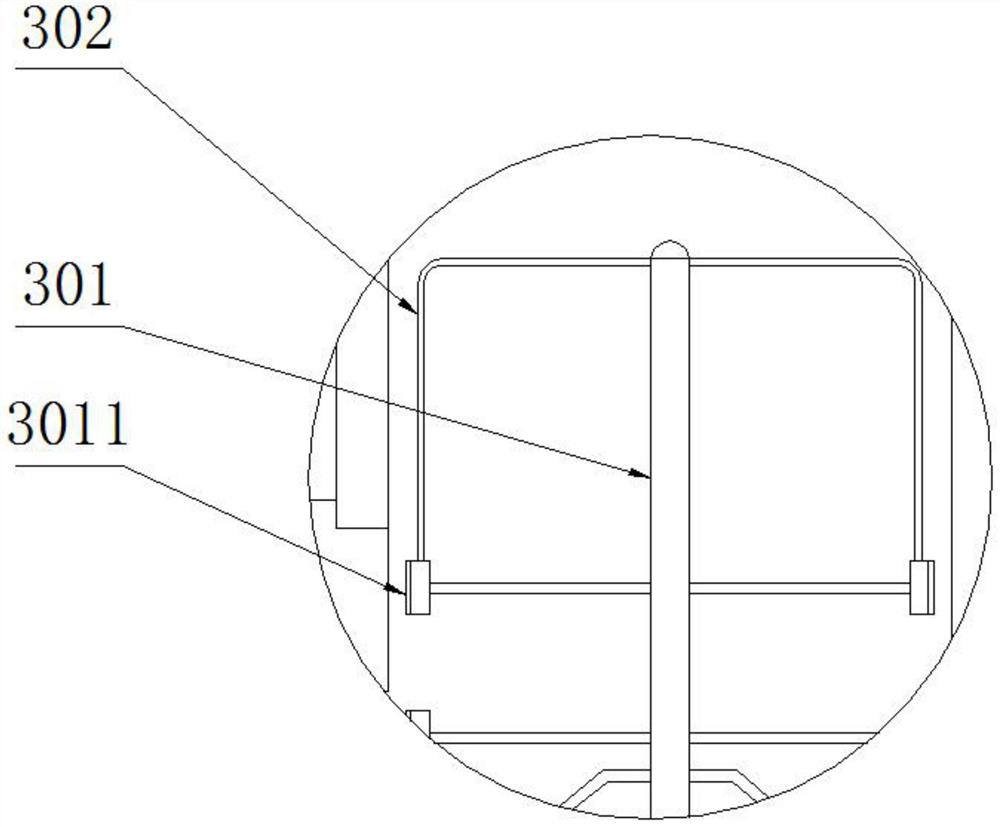

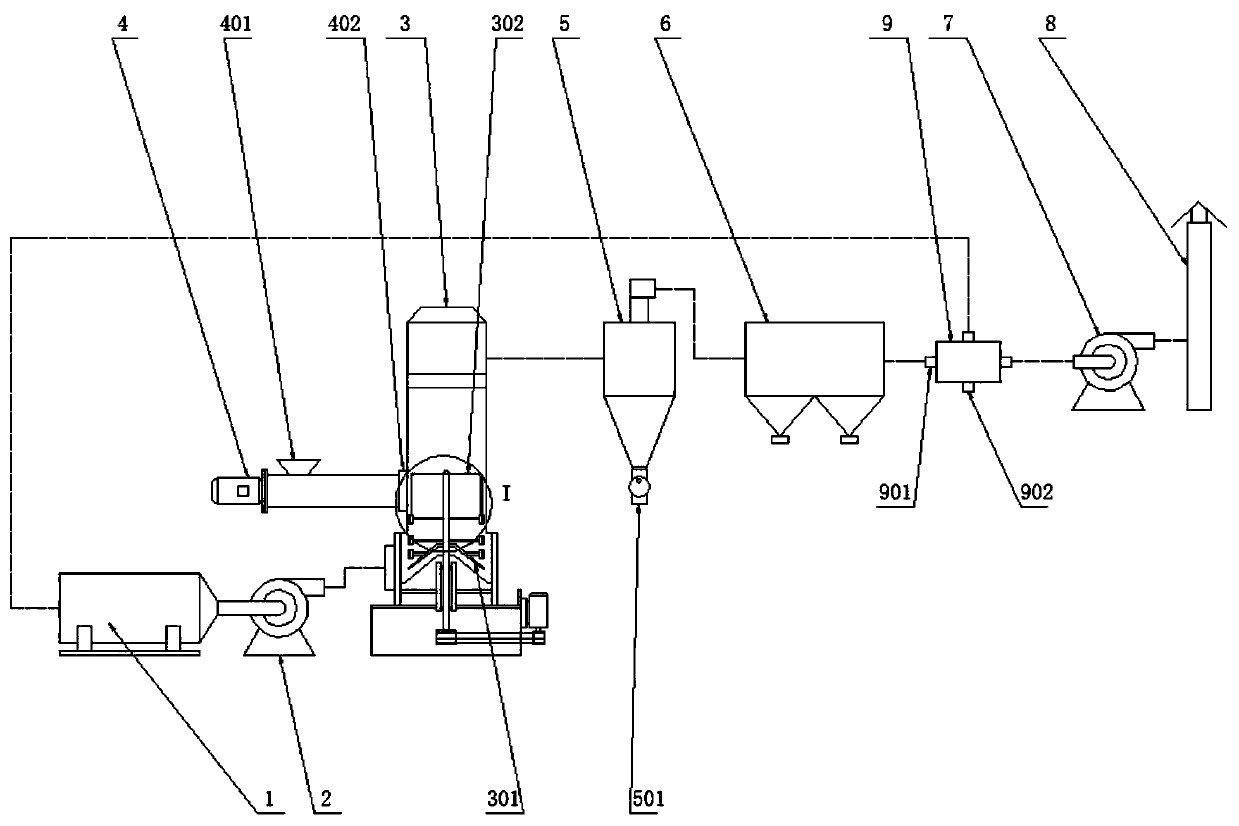

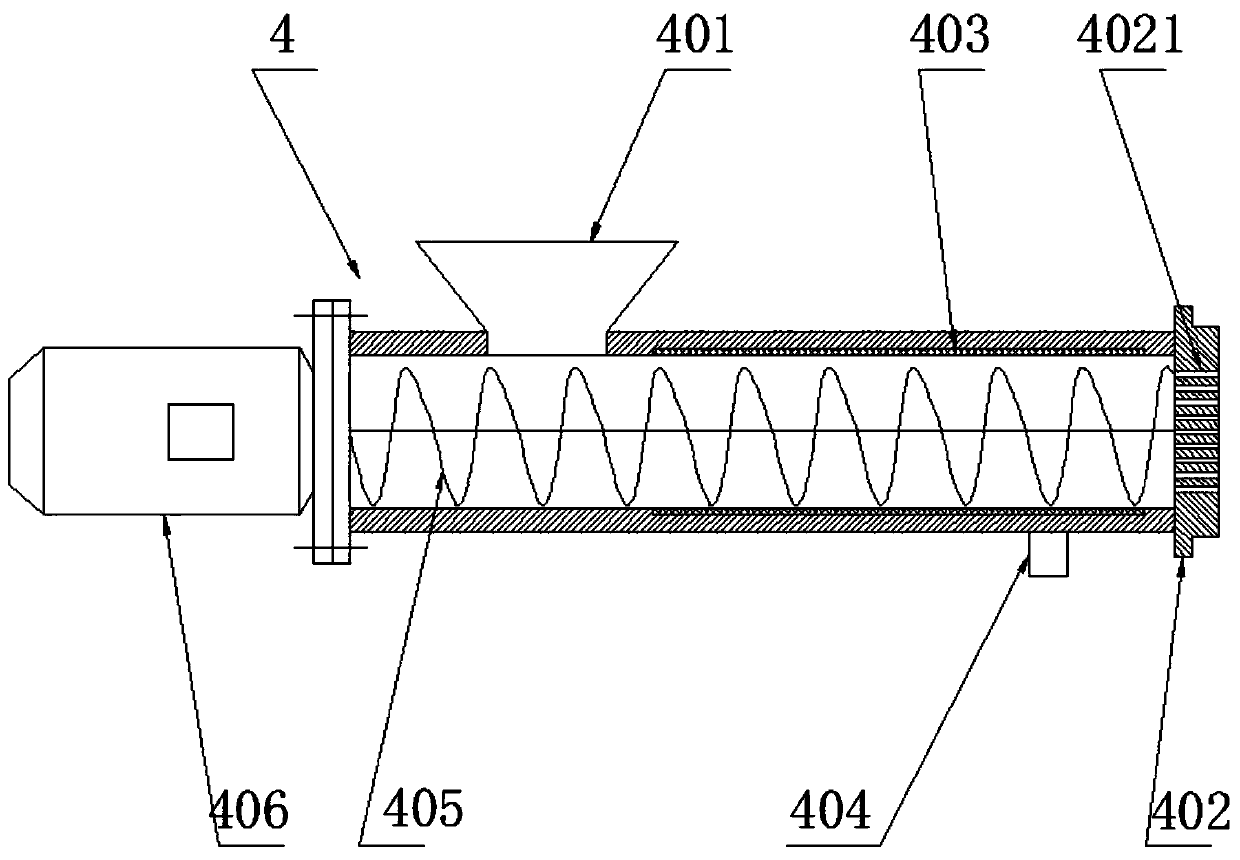

A feed milk powder drying device

ActiveCN111250241BEasy to dryEfficient Mass-to-Heat ConversionDrying solid materials without heatDrying gas arrangementsHigh humidityElectric machinery

The invention discloses a feed milk powder drying device, belonging to the technical field of feed milk powder production equipment, comprising an air heater, a blower, a drying tower, a cyclone separator, a bag filter and an induced draft fan connected in sequence through pipelines, the drying tower A screw feeder is provided on the side wall, and the screw feeder includes a main cylinder body, a feeding port, an extruding plate, a screw shaft and a deceleration motor, and the deceleration motor drives the screw shaft to rotate in the main cylinder The material input from the feeding port is transported to the extruding plate at the discharge end of the main cylinder, and the extruding plate is detachably installed on the feeding hole on the side wall of the drying tower, and the extruding plate is provided with several Through the discharge holes on both sides, the material is extruded into the inner cavity of the drying tower through the discharge holes. The feed milk powder drying device of the present invention can quickly dry feed milk powder materials with relatively high humidity, thereby improving production efficiency.

Owner:河北维果生物科技有限公司

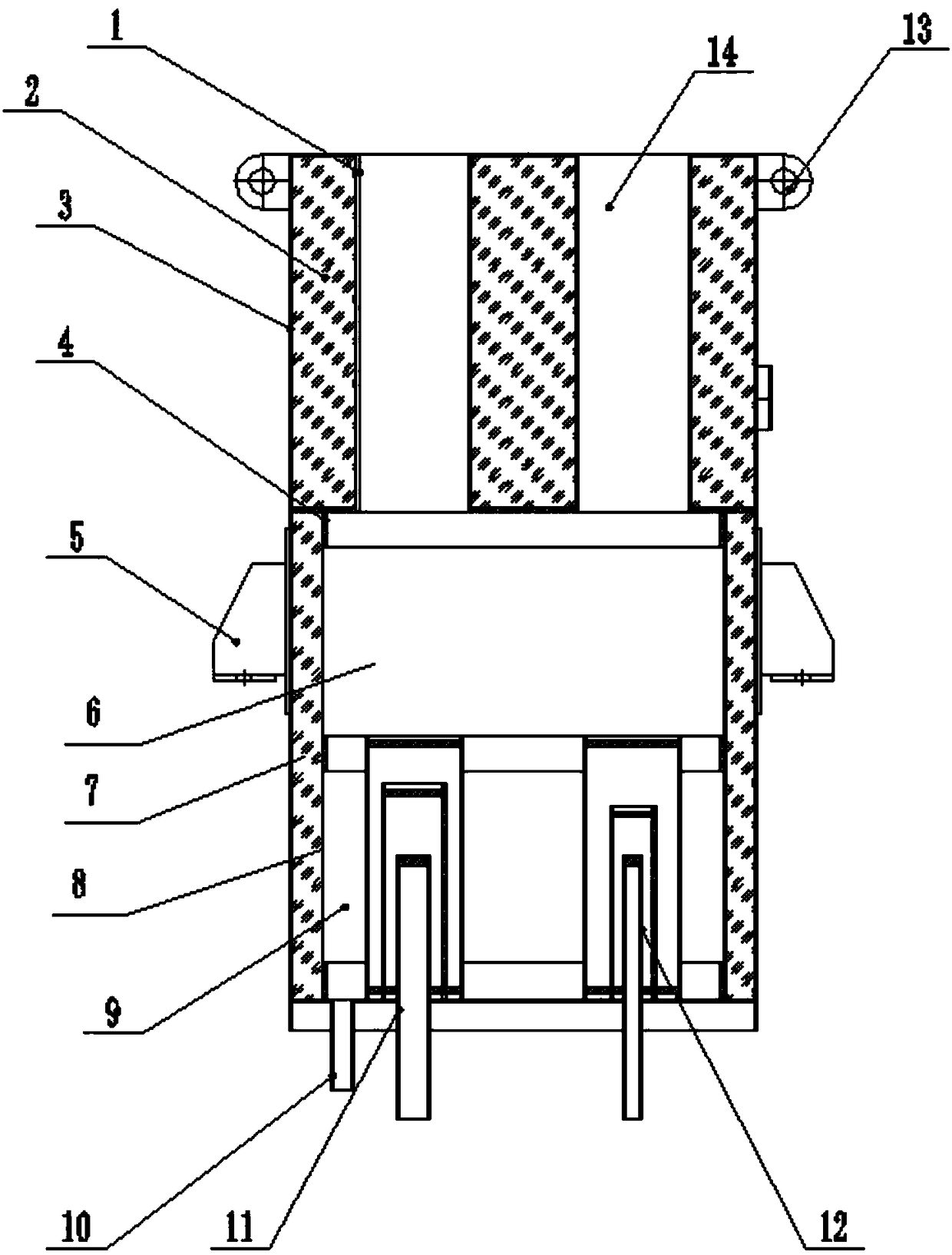

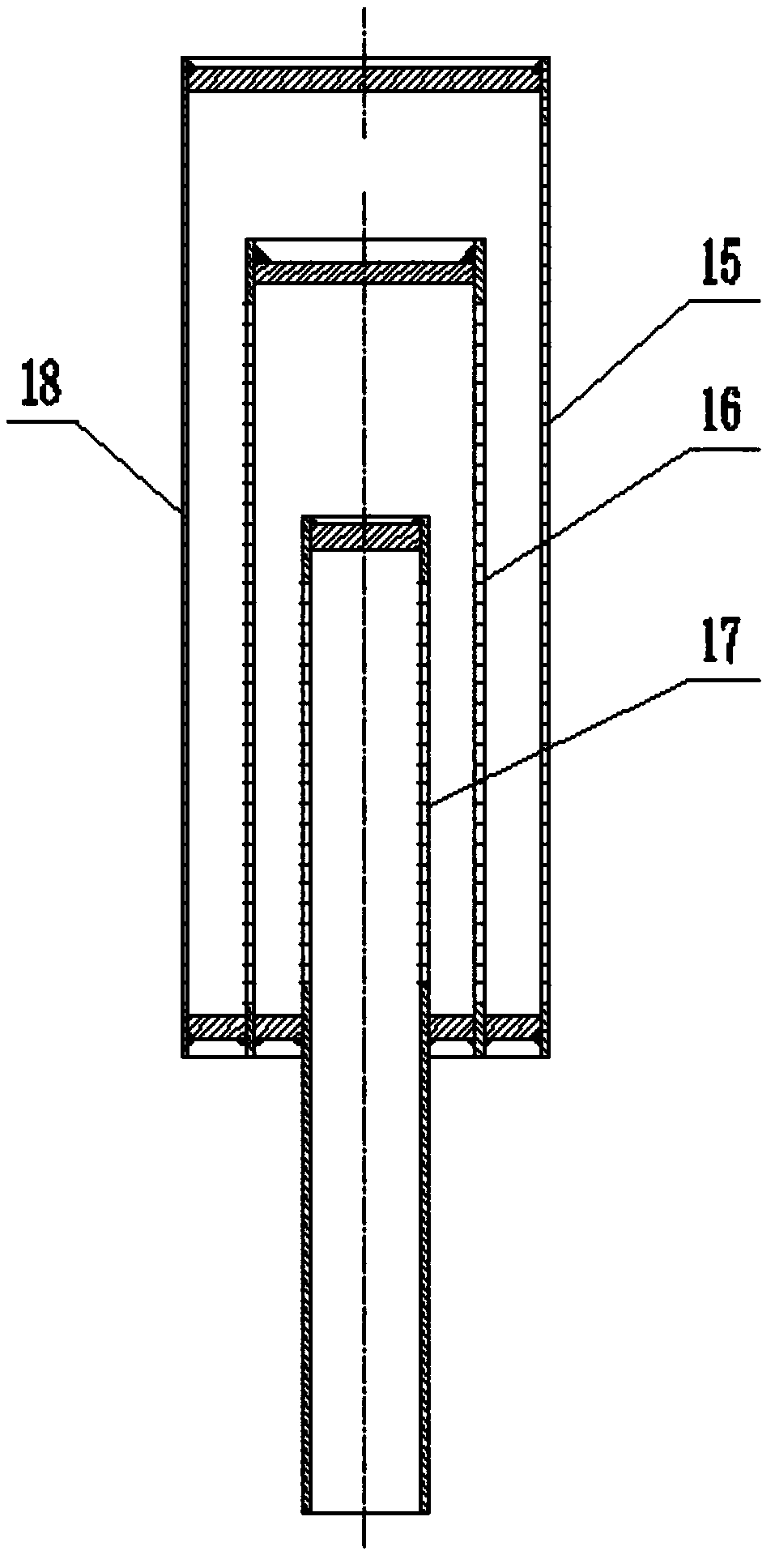

Combined type steam discharge silencer

PendingCN108331991AReduce emission noiseThe purpose of strengthening the noise cancellationPipe elementsEngineeringAnechoic chamber

The invention discloses a combined type steam discharge silencer. The silencer comprises a sound blocking cover which is closed at the upper end and the lower end, a drainage opening is formed in thelower end of the sound blocking cover, a first anechoic chamber is arranged at the lower part in the sound blocking cover, the middle part of the sound blocking cover is provided with a second anechoic chamber, and the upper part of the sound blocking cover is provided with a third anechoic chamber; inner cylinder bodies made of hole plates are arranged, and the inner cylinder bodies, sound absorption bodies and the sound blocking cover form a cover shell together; at least two vertically-arranged sound absorbing cylinders are arranged in the third anechoic chamber, the upper end of each soundabsorbing cylinder communicates with the outside of the sound blocking cover, and the lower ends of the sound absorption cylinders communicate with the second anechoic chamber; sound absorption cavities are formed between the sound absorption cylinders and the sound blocking cover, and the sound absorption cavities are filled with sound absorption bodies; and at least two vertically-arranged multi-stage flow-control type silencer bodies are arranged in the inner cylinder body of the first anechoic chamber, and each multi-stage flow-control type silence body is provided with a steam inlet pipeextending out of the lower end of the sound blocking cover. By means of the multi-stage flow-control type silencer bodies, most of noise can be eliminated during the primary silencing for first time,and the silencing effect is finally achieved through the secondary silencing and the tertiary silencing.

Owner:连云港宇泰电力设备有限公司

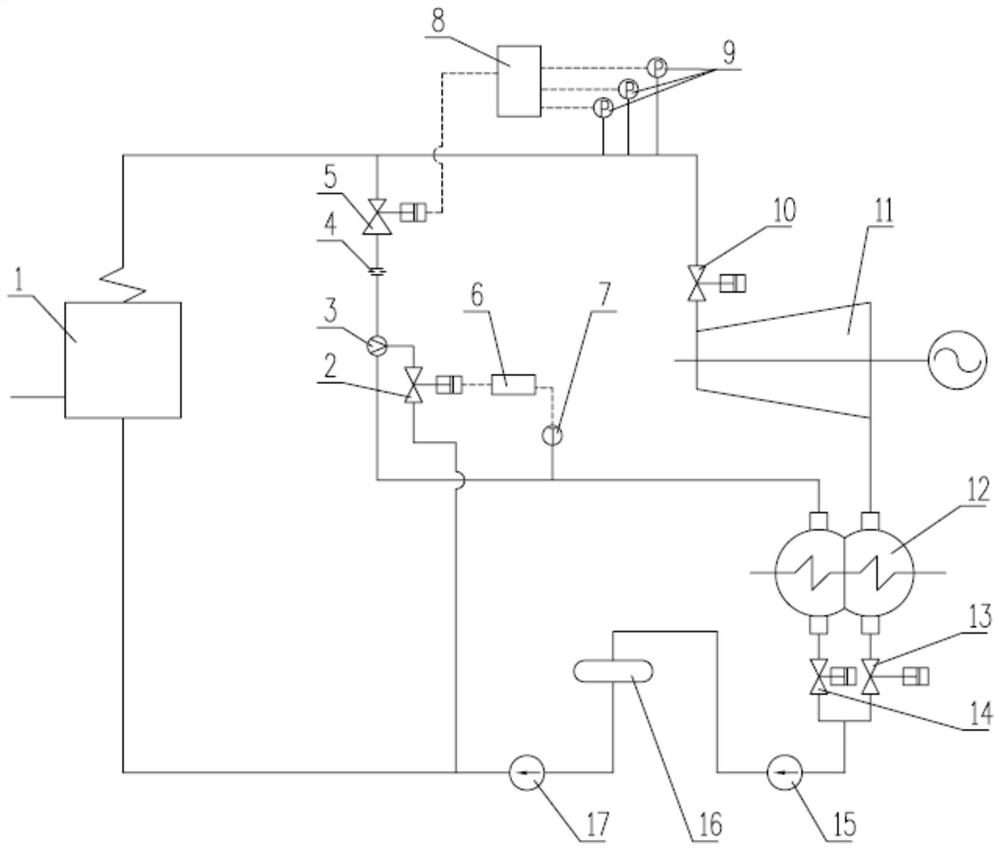

Steam supply system for dynamic performance test of turbo-generator set

ActiveCN108757064BStable operating loadImprove operating conditionsEngine testingSafety/regulatory devicesSteam pressureProcess engineering

The invention discloses a steam supply system for testing the dynamic performance of a turbo-generator set, which includes a boiler, a main steam valve, a turbo-generator set, a double-pressure condenser and a pump set, and the boiler is sequentially connected with the main steam valve, steam The turbine generator set, the steam inlet on the low-pressure side of the dual-pressure condenser and the pump set are connected in circulation to form a closed-loop working circuit; a branch is connected to the pipeline between the boiler and the main steam valve, and the branch is provided with a pressure reducing valve, A flow-restricting orifice and a desuperheater; the end of the branch is connected to the steam inlet of the high-pressure side of the dual-pressure condenser; the outlet of the high-pressure side of the dual-pressure condenser is connected to the pump set. During the dynamic performance test of the steam turbine generator set, according to the deviation and change rate of the steam pressure in front of the main steam valve and the set value, the pressure reducing valve is automatically opened or reduced to maintain the steam pressure in front of the main steam valve within the required range.

Owner:中国船舶重工集团公司第七〇三研究所无锡分部

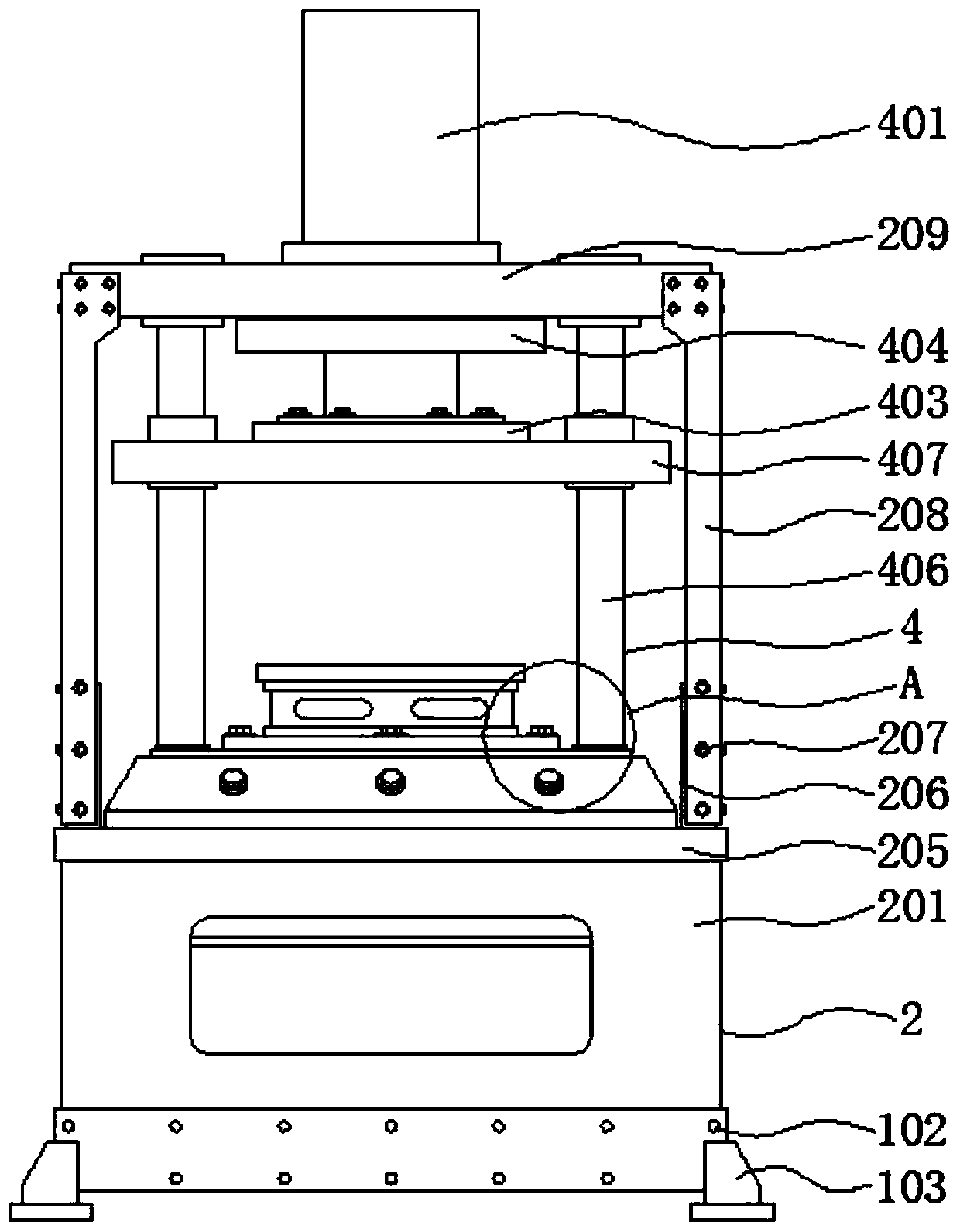

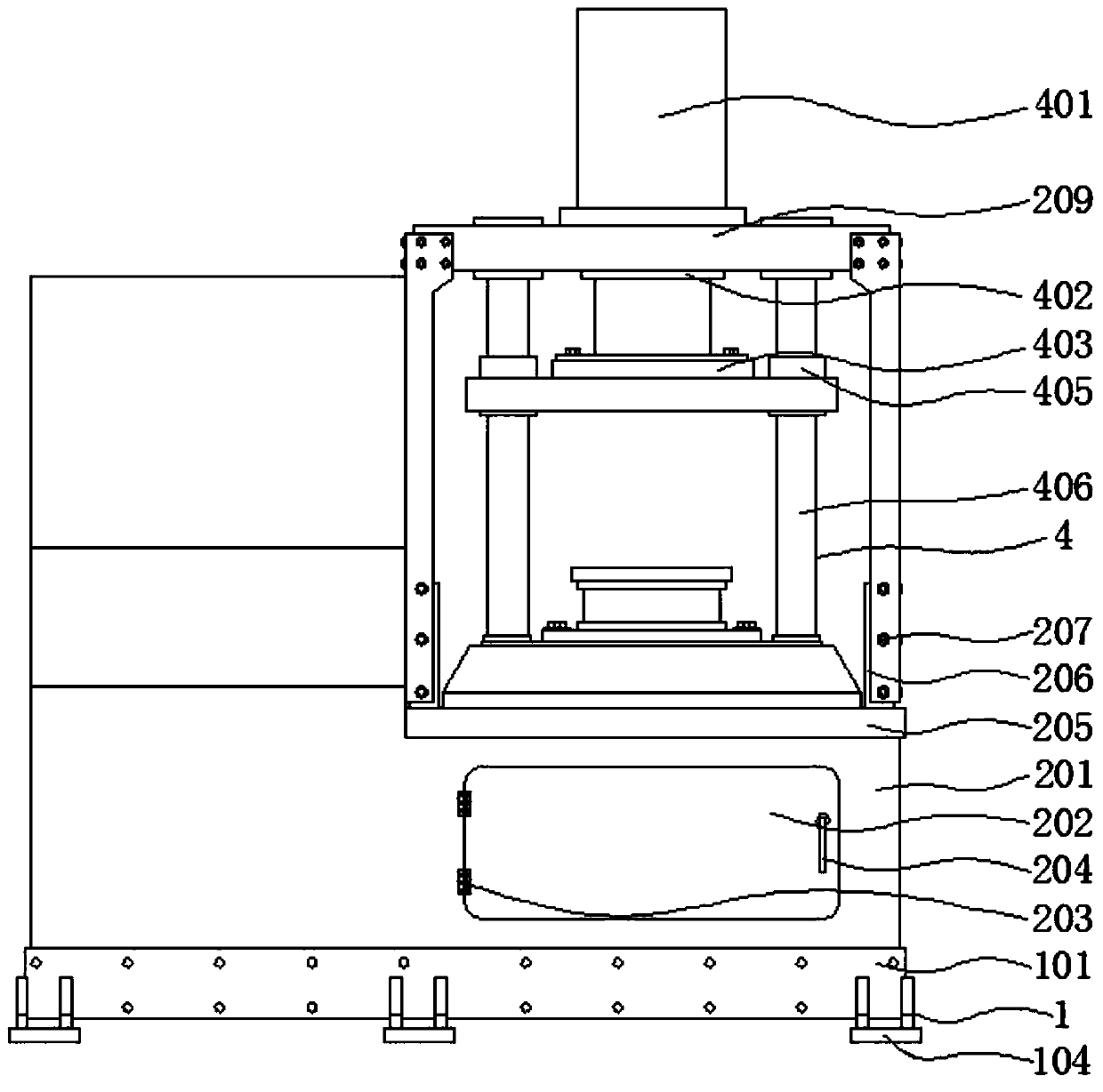

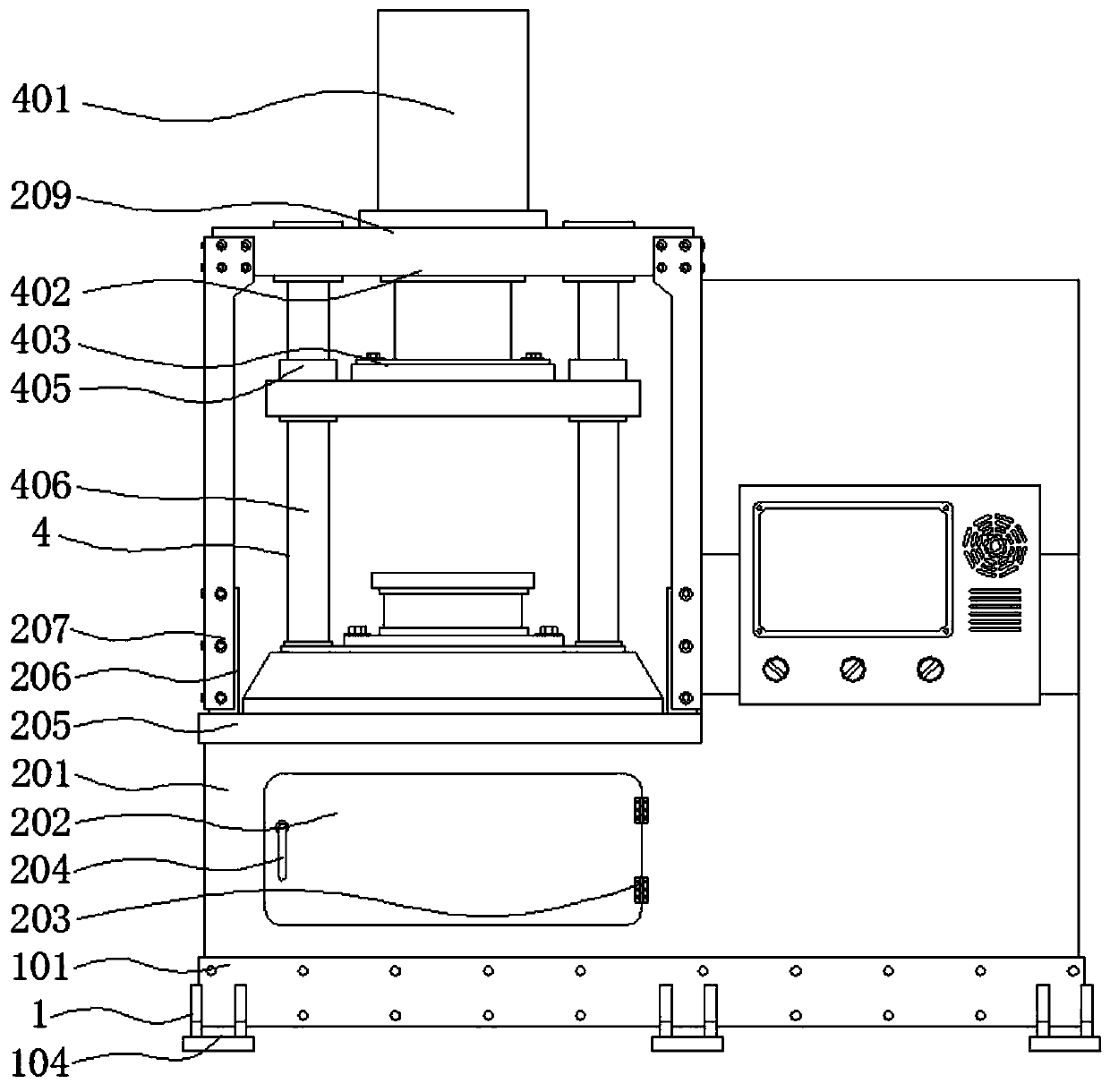

Pressing method of four-column hydraulic machine

InactiveCN111231394AReduce noiseReduce temperature risePress ramControl engineeringProcess engineering

The invention discloses a pressing method of a four-column hydraulic machine, and relates to the technical field of hydraulic machines, in particular to the pressing method of the four-column hydraulic machine. The pressing method of the four-column hydraulic machine comprises a supporting base and a hydraulic mechanism, a main body frame is arranged above the supporting base, a machining base isarranged in the middle of the upper portion of the main body frame, and the hydraulic mechanism is arranged above the machining base; and the hydraulic mechanism comprises a hydraulic column, a fixingsleeve, a mounting panel, a light supplementing lamp, sliding sleeves, a guide column and a pressing panel, wherein the light supplementing lamp is arranged in front of the fixing sleeve, the mounting panel is arranged below the hydraulic column, and the sliding sleeves are arranged in the left end and the right end of the pressing panel. According to the pressing method of the four-column hydraulic machine, the system overall control does not contain a proportional servo valve or proportional pump link, the servo-driven hydraulic machine has the advantages of being capable of saving energy,low in noise, small in temperature rise, good in flexibility, high in efficiency, convenient to maintain and the like, and the servo-driven hydraulic machine can save electricity by 30%-70% compared with a traditional hydraulic machine according to different machining processes and production takts.

Owner:太田机械江苏有限公司

Vehicle exhaust air temperature difference power generation heat exchanger

InactiveCN106762036BAchieve purificationReduce emission noiseInternal combustion piston enginesSilencing apparatusTemperature differenceProcess engineering

Owner:WUHAN UNIV OF TECH

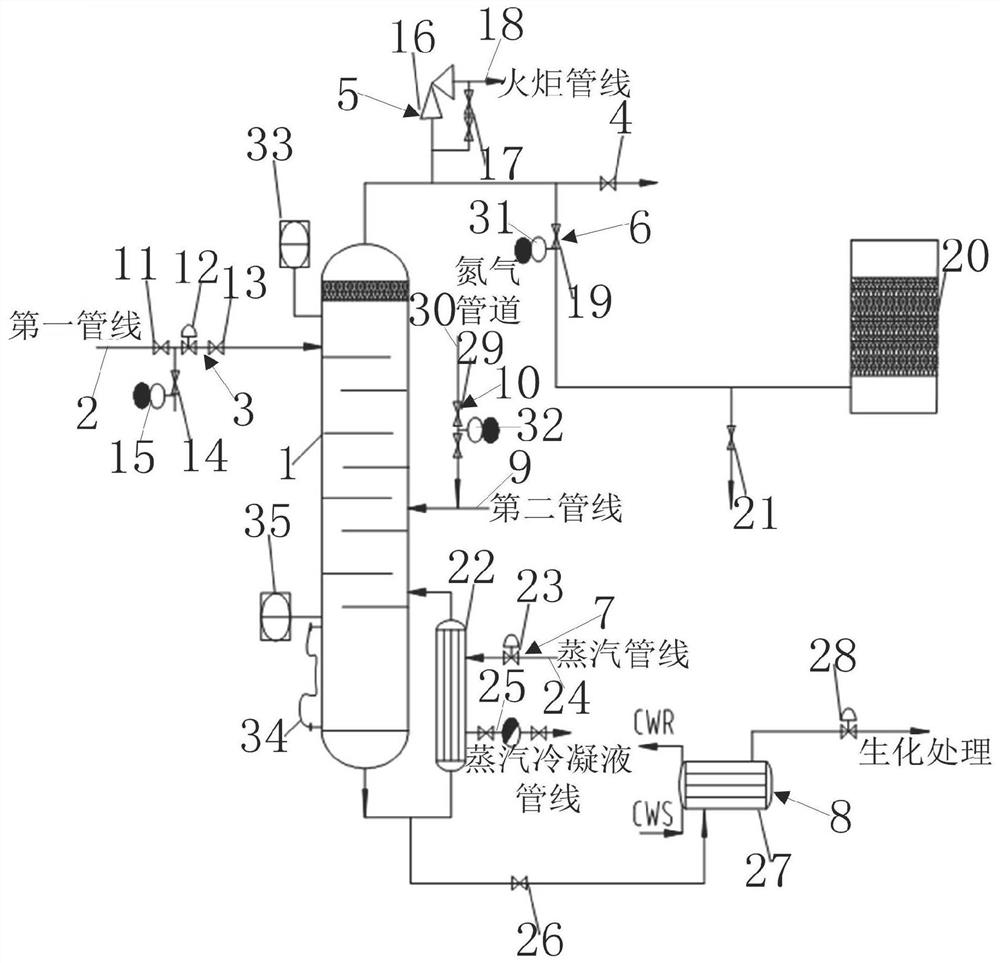

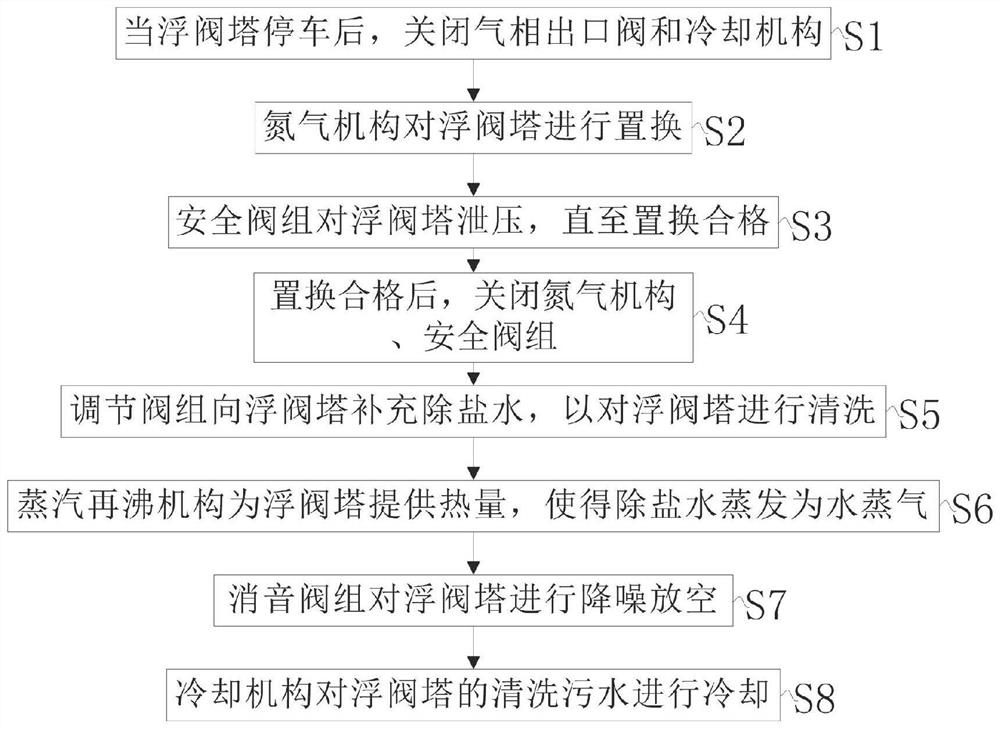

Float valve tower cleaning system and cleaning method

PendingCN114769245AImprove heat transfer performanceImprove efficiencyDistillation regulation/controlHollow article cleaningMarine engineeringNitrogen gas

The invention provides a floating valve tower cleaning system and method, and the floating valve tower cleaning system comprises a floating valve tower, a first pipeline, a regulating valve group, a gas phase outlet valve, a safety valve group, a silencing valve group, a steam reboiling mechanism, a cooling mechanism, a second pipeline and a nitrogen mechanism, the first pipeline is connected with the top of the floating valve tower through a pipeline by virtue of the adjusting valve group, the gas phase outlet valve is connected with the top of the floating valve tower through a pipeline, and the safety valve group is connected with the pipeline between the gas phase outlet valve and the floating valve tower through a pipeline; the noise reduction valve group is connected with a pipeline between the gas phase outlet valve and the safety valve group through a pipeline, the steam reboiling mechanism and the cooling mechanism are respectively connected with the bottom of the float valve tower through pipelines, the second pipeline is connected with the middle of the float valve tower, and the nitrogen mechanism is connected to the second pipeline.

Owner:河南开祥精细化工有限公司

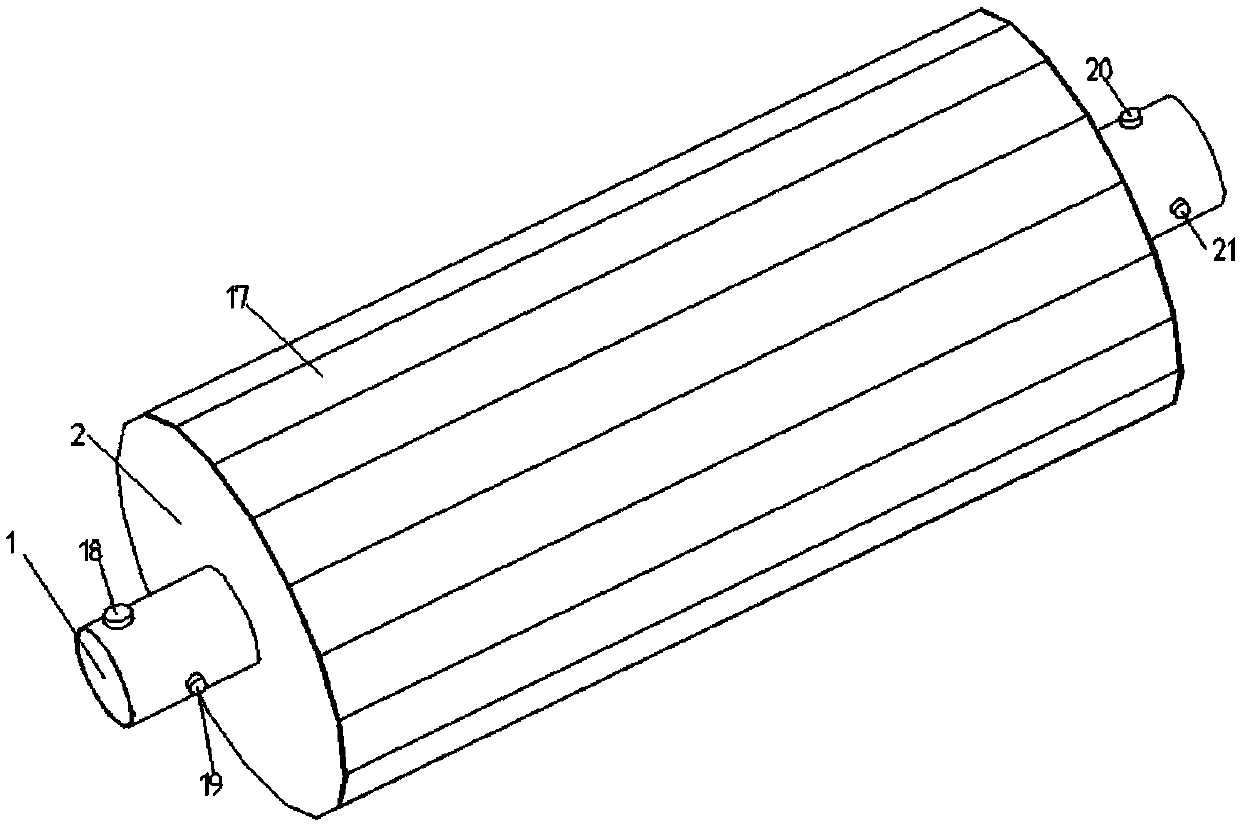

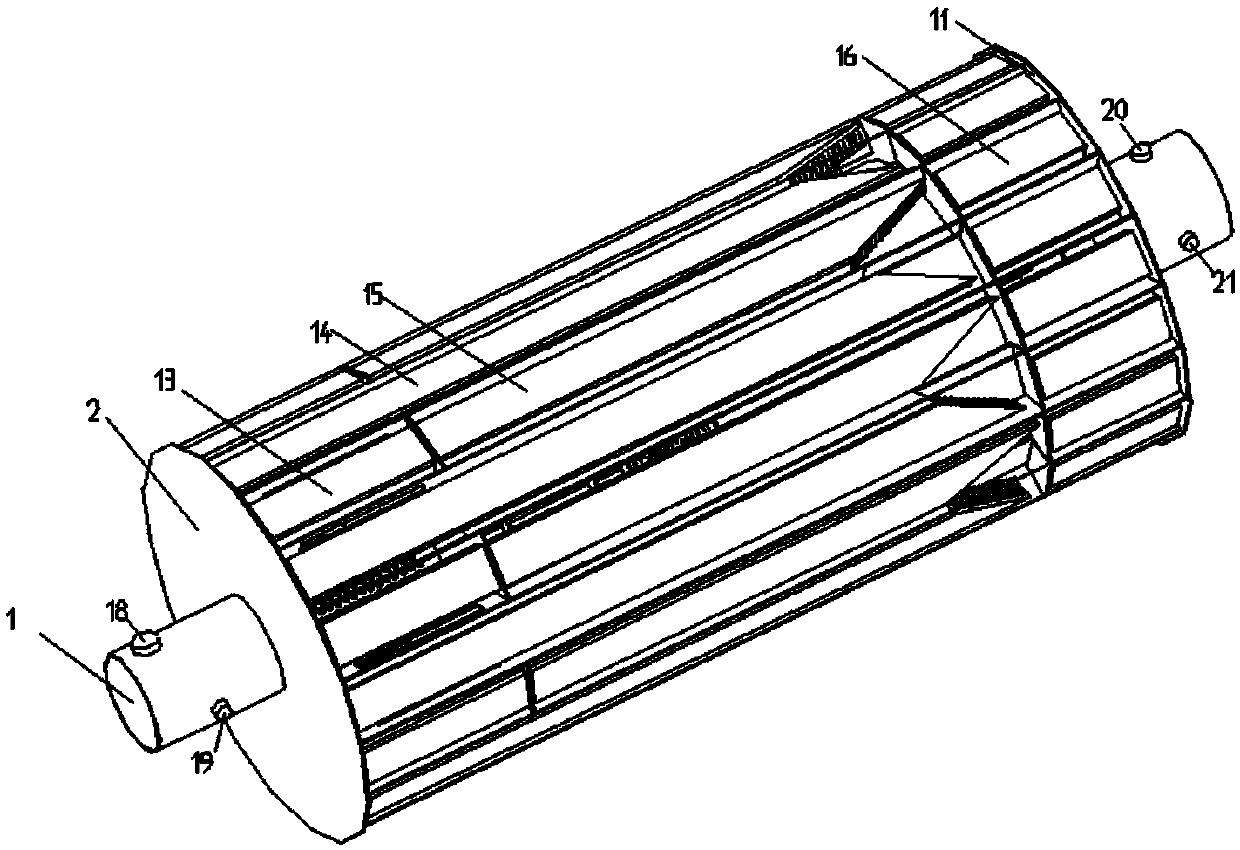

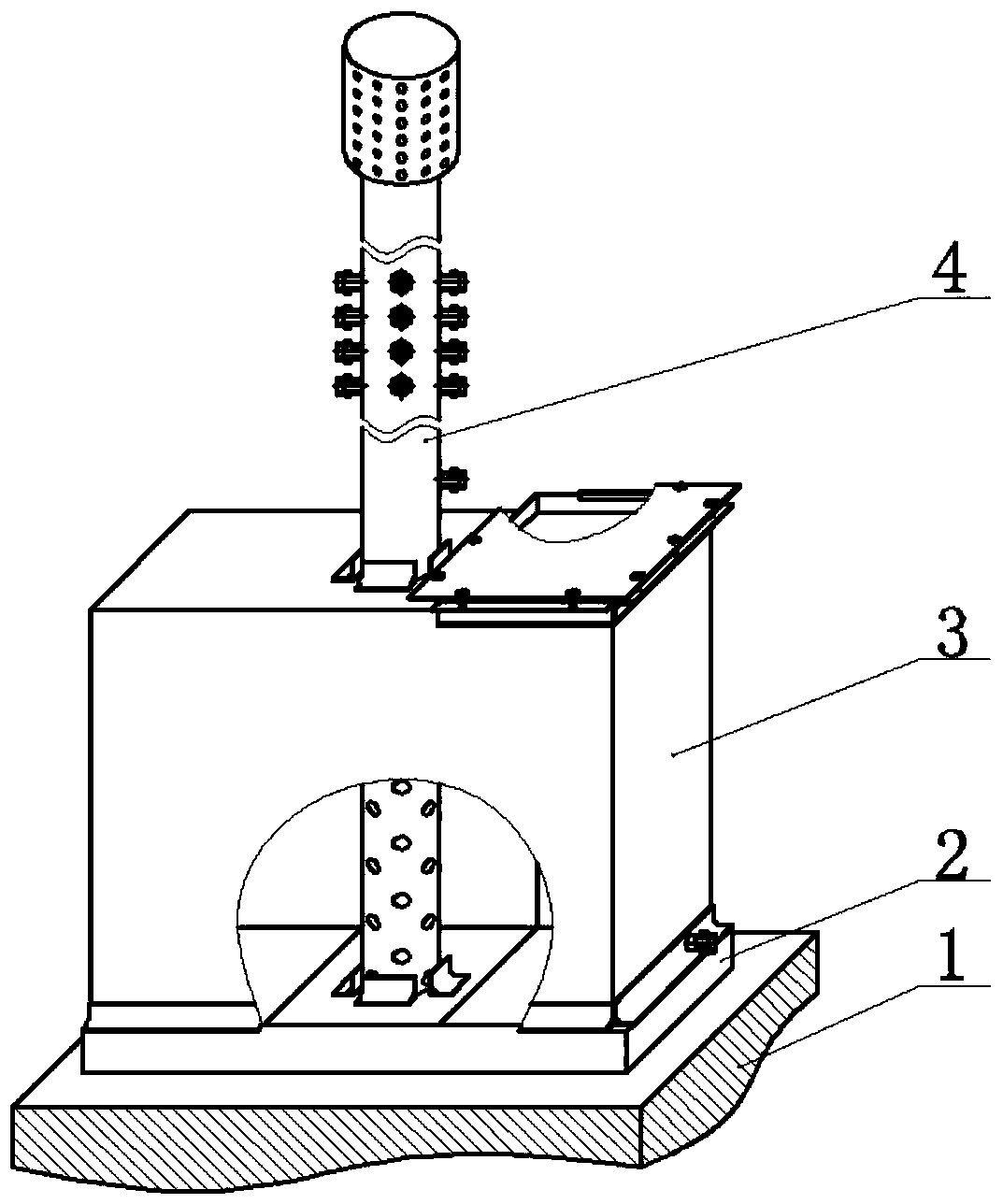

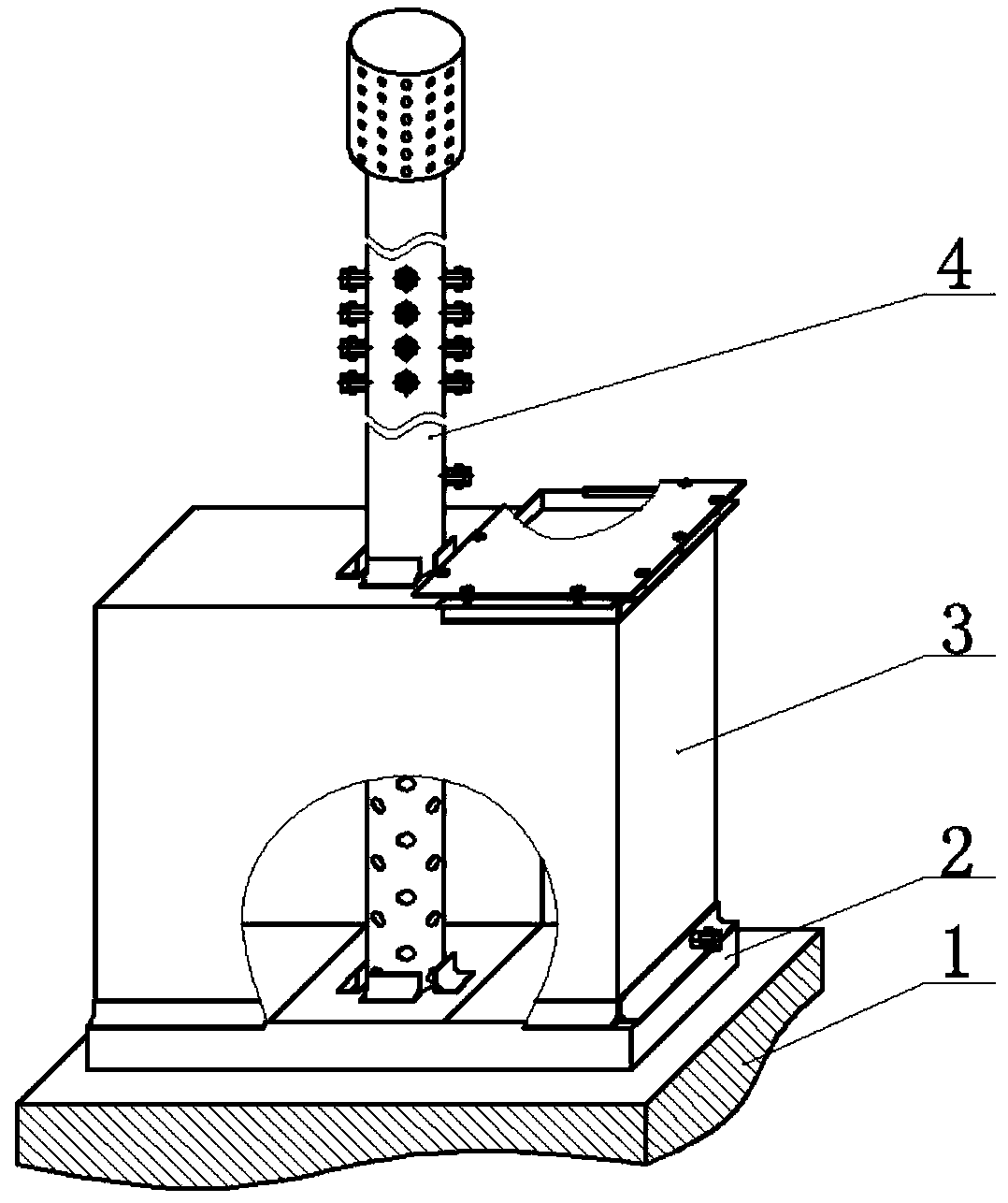

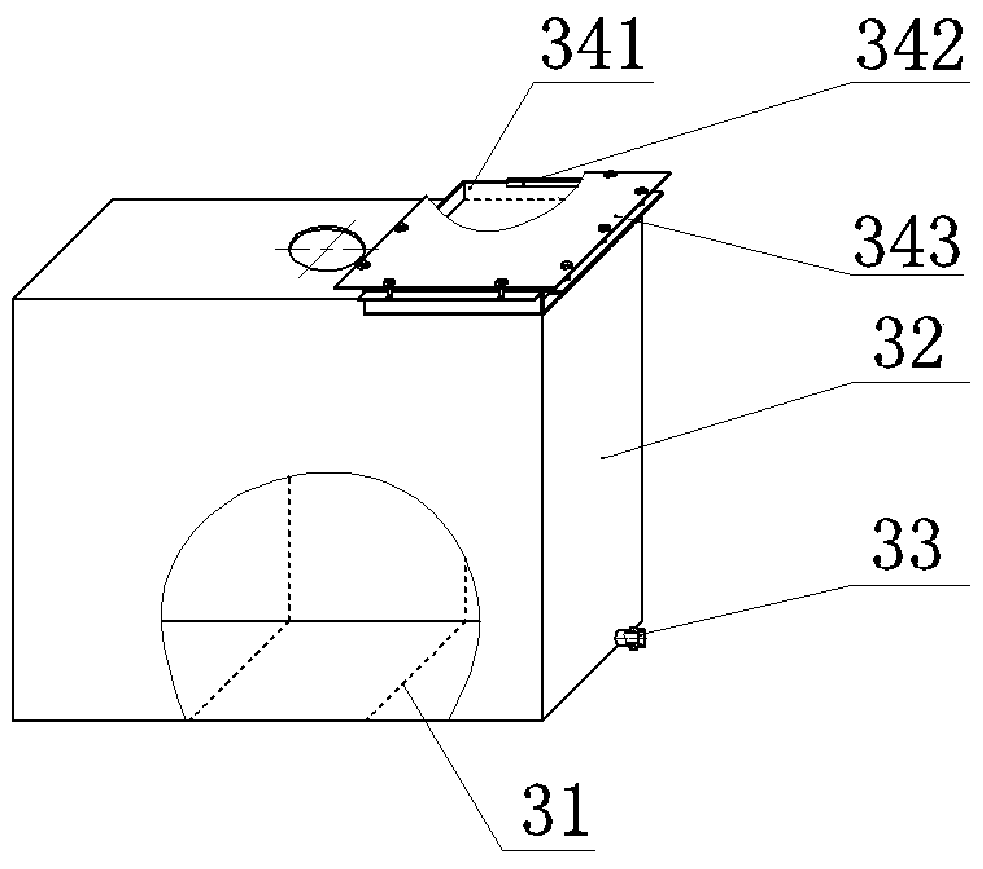

A normal temperature, low temperature flammable and explosive medium emptying device

ActiveCN109973250BReduce discharge rateReduce emission noiseRocket engine plantsThermodynamicsEngineering

A normal temperature and low temperature flammable and explosive medium emptying device comprises a concrete foundation (1), a profile steel support (2), a collecting box (3) and an emptying cylinderassembly (4); the profile steel support (2) is fixed on the concrete foundation (1); the collecting box (3) is fixed on the profile steel support (2); the emptying cylinder assembly (4) is fixed on the collecting box (3); the emptying cylinder assembly (4) comprises an emptying cylinder (41), a shock tube structure (42), a medium discharge port (43), a nitrogen mixing port (44) and a silencing device (45); and after a liquid or gas flammable and explosive medium enters from the medium discharge port (43), the gas flammable and explosive medium and nitrogen gas entering from the nitrogen mixingport (44) are mixed and then discharged from the silencing device (45), and the liquid flammable and explosive medium passes through the shock tube structure (42), then enters the collecting box (3),becomes a gas flammable and explosive medium after absorbing heat in the collecting box (3) and then is mixed with nitrogen gas entering from the nitrogen mixing port (44) and discharged from the silencing device (45).

Owner:XIAN AEROSPACE PROPULSION INST

A boiler blowdown thermal energy recycling system

ActiveCN107973356BExtended service lifeReduce failureWater treatment parameter controlSpecific water treatment objectivesBoiler blowdownSoftened water

The invention provides a boiler blowdown heat energy recycling system, which belongs to the technical field of boiler blowdown heat energy utilization. A boiler blowdown thermal energy recycling system, comprising a water softening station, a boiler, and a deaerator connected to the boiler, characterized in that it also includes: a softened water circulation device, connected to the softening water station, and the water softening station generates The demineralized water flows into the demineralized water circulation device, and then is transported to the boiler after passing through the deaerator; the buffer tank is connected with the bottom of the boiler; the sewage circulation device is connected with the boiler and the buffer The tanks are respectively connected; the heat exchanger is connected with the demineralized water circulation device and the sewage circulation device respectively, the demineralized water and the sewage flow through the heat exchangers respectively, and the demineralized water is treated by the sewage heat transfer. The invention makes the demineralized water and the sewage produced by boiler blowdown respectively circulate and flow through the heat exchanger continuously, fully utilizes the heat energy of the sewage, and preheats the demineralized water.

Owner:CHINA TOBACCO HENAN IND

Normal temperature and low temperature flammable and explosive medium emptying device

ActiveCN109973250AReduce discharge rateReduce emission noiseRocket engine plantsNitrogenRoom temperature

A normal temperature and low temperature flammable and explosive medium emptying device comprises a concrete foundation (1), a profile steel support (2), a collecting box (3) and an emptying cylinderassembly (4); the profile steel support (2) is fixed on the concrete foundation (1); the collecting box (3) is fixed on the profile steel support (2); the emptying cylinder assembly (4) is fixed on the collecting box (3); the emptying cylinder assembly (4) comprises an emptying cylinder (41), a shock tube structure (42), a medium discharge port (43), a nitrogen mixing port (44) and a silencing device (45); and after a liquid or gas flammable and explosive medium enters from the medium discharge port (43), the gas flammable and explosive medium and nitrogen gas entering from the nitrogen mixingport (44) are mixed and then discharged from the silencing device (45), and the liquid flammable and explosive medium passes through the shock tube structure (42), then enters the collecting box (3),becomes a gas flammable and explosive medium after absorbing heat in the collecting box (3) and then is mixed with nitrogen gas entering from the nitrogen mixing port (44) and discharged from the silencing device (45).

Owner:XIAN AEROSPACE PROPULSION INST

Feed milk powder drying device

ActiveCN111250241AEasy to dryEfficient Mass-to-Heat ConversionDrying solid materials without heatDrying gas arrangementsBiotechnologyAgricultural science

The invention discloses a feed milk powder drying device, and belongs to the technical field of feed milk powder production equipment. The feed milk powder drying device comprises an air heater, an air blower, a drying tower, a cyclone separator, a bag-type dust remover and an induced draft fan which sequentially communicate with one another through pipelines, wherein a spiral feeder is arranged on a side wall of the drying tower, and comprises a main cylinder body, a feeding port, a material extruding plate, a spiral shaft and a speed reducing motor; the speed reducing motor drives the spiralshaft to rotate in the main cylinder body to convey materials fed from the feeding port to the material extruding plate at the discharging end of the main cylinder body; the material extruding plateis detachably mounted on a feeding hole in a side wall of the drying tower; a plurality of discharging holes penetrating through two sides are formed in the material extruding plate; and the materialsare extruded into a cavity of the drying tower through the discharging holes. The feed milk powder drying device can quickly dry feed milk powder materials with relatively high humidity, and the production efficiency is improved.

Owner:河北维果生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com