Float valve tower cleaning system and cleaning method

A cleaning system and valve tower technology, applied in the valve tower cleaning system and the cleaning field, can solve the problems of decreased processing capacity, shortened inspection and maintenance time, and floating valve jammed trays, etc., and achieves high operational flexibility and shortens inspection and maintenance. Time, avoid the effect of dismantling and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

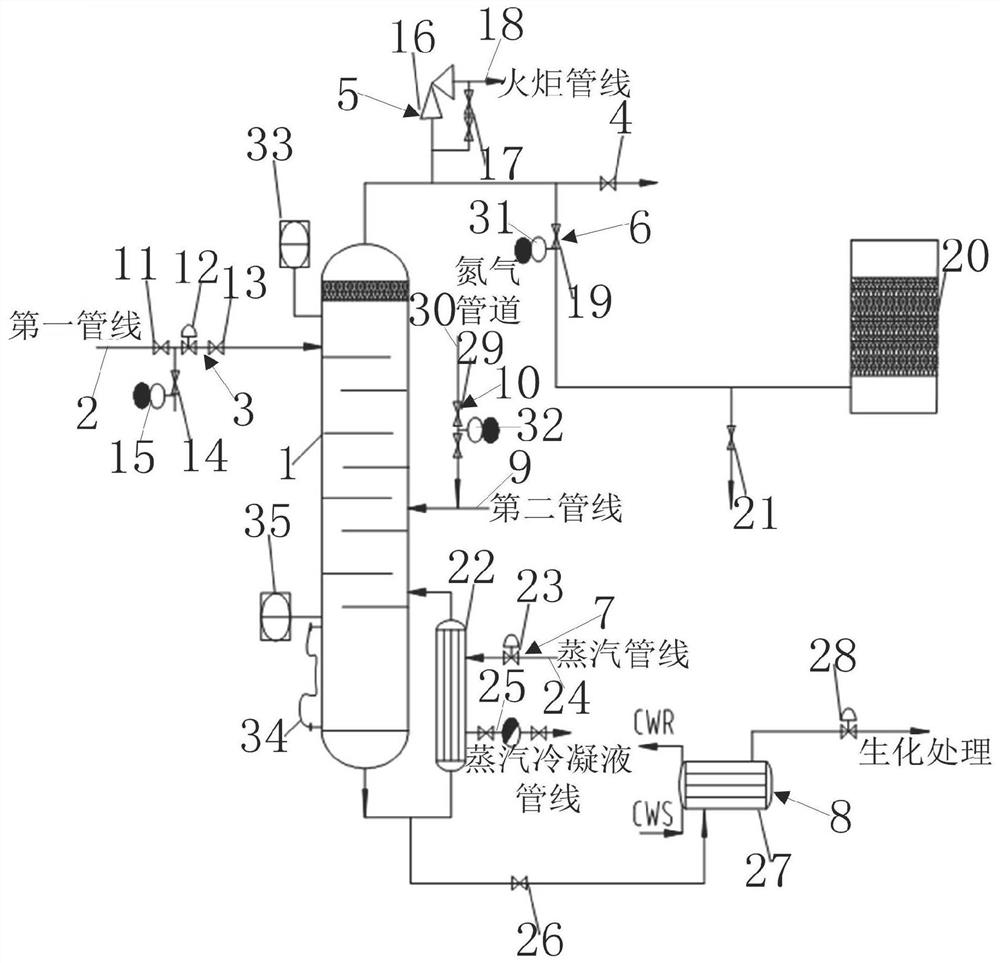

[0075] like figure 1 As shown, a floating valve tower cleaning system includes: a central control unit, an evaporation unit and a cooling unit that are connected in sequence; the controlled end of the central control unit is connected to the control end of the evaporation unit of the central control unit; the evaporation unit includes a float The valve tower, the return line is connected to the top of the float valve tower, the control valve group is installed on the return line, the DN50 demineralized water pipeline and the demineralized water valve are installed between the reflux control valve and the front valve of the return control valve, and the “8” blind is installed. plate (blind position during normal operation, and open position before cleaning the float valve tower). A gas phase outlet valve is installed at the outlet of the gas phase pipeline of the float valve tower. The gas phase pipeline is provided with a safety valve and a safety valve bypass. The other end o...

Embodiment 2

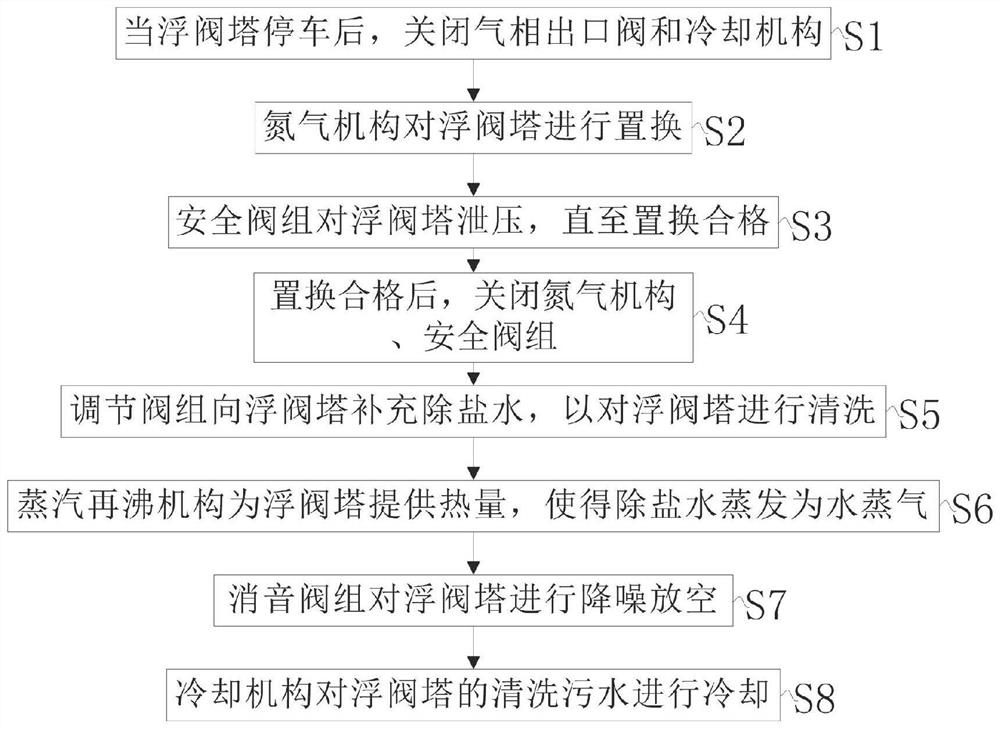

[0077] A kind of valve tower cleaning system of Embodiment 1, further, when the valve tower is stopped, close the gas phase outlet valve of the valve tower gas phase pipeline and the liquid phase outlet valve of the float valve tower, and open the nitrogen two-way valve to the float valve tower ( Replacement), the pressure is relieved through the bypass of the safety valve, and the nitrogen content ≥ 99.5% is regarded as qualified for the replacement.

[0078] When cleaning the float valve tower, close the front valve of the backflow control valve, open the back valve of the backflow control valve, and the demineralized water valve to control the flow of the cleaning water source through the backflow control valve. When cleaning the float valve tower, the remote transmission pressure of the float valve tower is controlled by adjusting the inlet valve of the muffler. A guide shower is installed from the gas phase of the float valve tower to the low point of the muffler pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com