Boiler blow-off heat energy recycling utilization system

A boiler sewage and sewage recycling technology, which is applied in boiler cleaning devices, control/control systems, heating water/sewage treatment, etc., can solve problems such as fluctuation of boiler water discharge, easy vibration and shock, and incomplete utilization of heat energy. , to reduce boiler failure, prolong service life, reduce vibration and shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

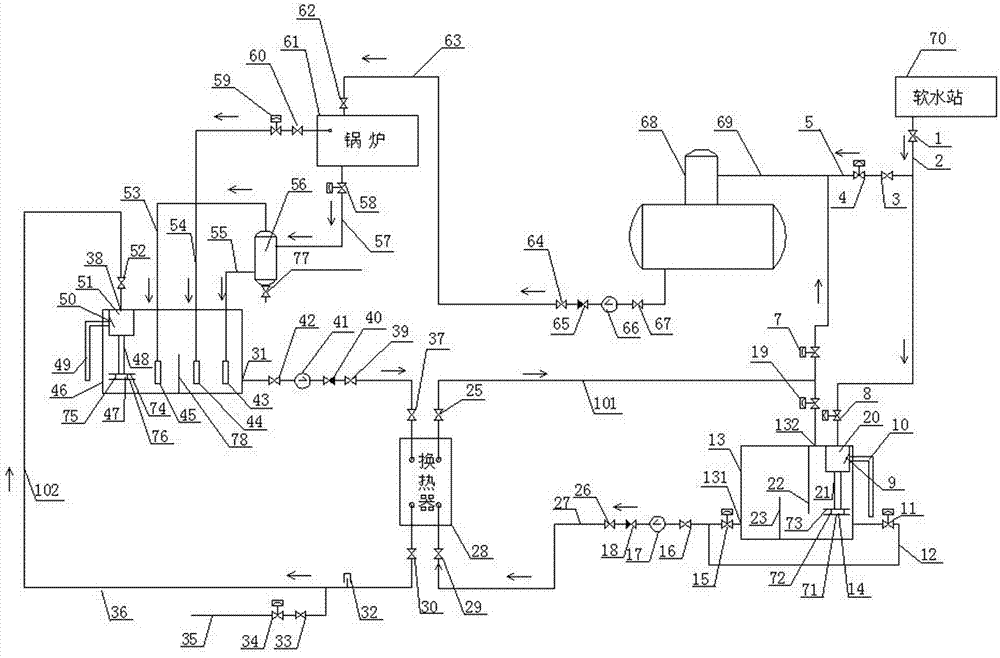

[0025] Such as figure 1 As shown, the present invention includes a boiler 61 , a buffer tank 56 , a deaerator 68 , a water softener station 70 , a softened water circulation device 101 , a sewage circulation device 102 and a heat exchanger 28 .

[0026] The deaerator 68 is connected to the boiler 61, and the demineralized water circulation device 101 is connected to the demineralized water station 70. The demineralized water produced by the deaerator station 70 flows into the demineralized water circulation device 101, and then passes through the deaerator 68 before being transported to the boiler 61. The buffer tank 56 communicates with the bottom of the boiler 61 , and impurities and sewage discharged from the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com