Energy-saving environment-friendly layout of large-scale routine hypersonic wind tunnel

A hypersonic, energy-saving and environment-friendly technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of high exhaust noise, waste heat waste, etc., to reduce the impact on the environment, reduce operating costs, and save energy The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below with reference to the accompanying drawings.

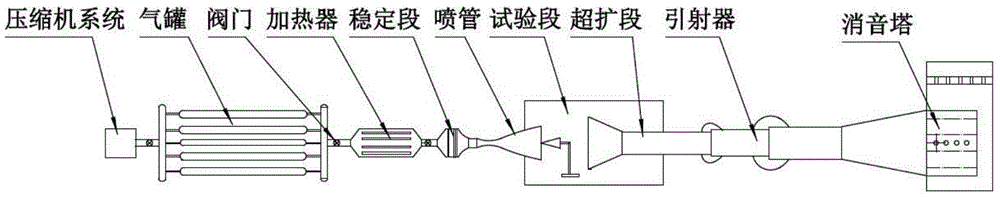

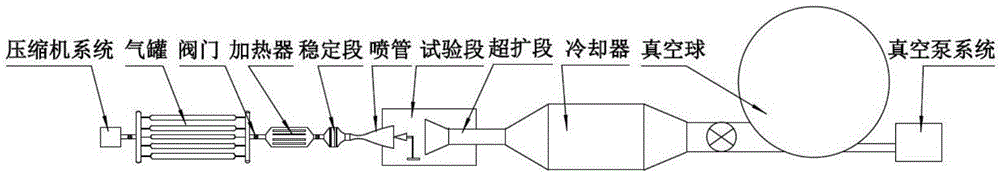

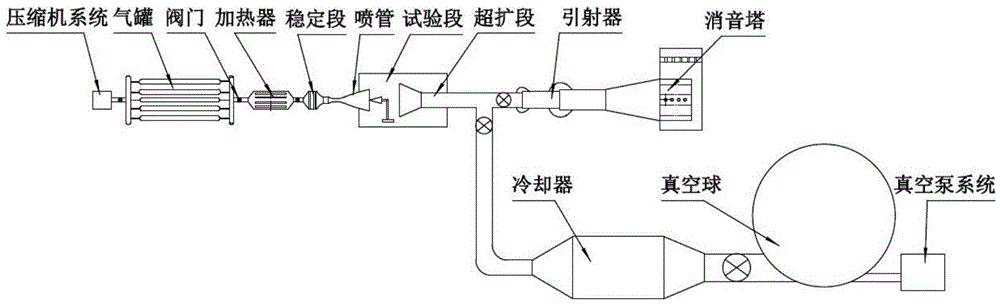

[0018] The layout scheme of the present invention is as Figure 4 shown. The heat exchanger 7 includes an intermediate channel and a peripheral channel surrounding the intermediate channel. First, the high-pressure gas from the gas tank 1 is sent into the peripheral channel of the heat exchanger 7, and then sent into the heater 2 by means of a gas pipeline. In the heater 2 The heated high-pressure gas is sent into the stable section 3, flows through the nozzle 4, the test section 5 and the super-expansion section 6 in turn, flows into the middle channel of the heat exchanger 7, and then passes through the ejector 8 and the water ring pump group 9 is exhausted into the atmosphere. Alternatively, via the vacuum bulb 10 , it is exhausted to the atmosphere by the vacuum pump system 11 .

[0019] This layout is an improvement on the existing layout. The main chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com