Combustor fire grate, combustor and water heater

A burner and fire row technology, applied in the field of burners, can solve the problems of unstable combustion flame smoke, combustion resonance and fire off, and high carbon monoxide emissions, so as to improve comfort and safety, improve stability, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

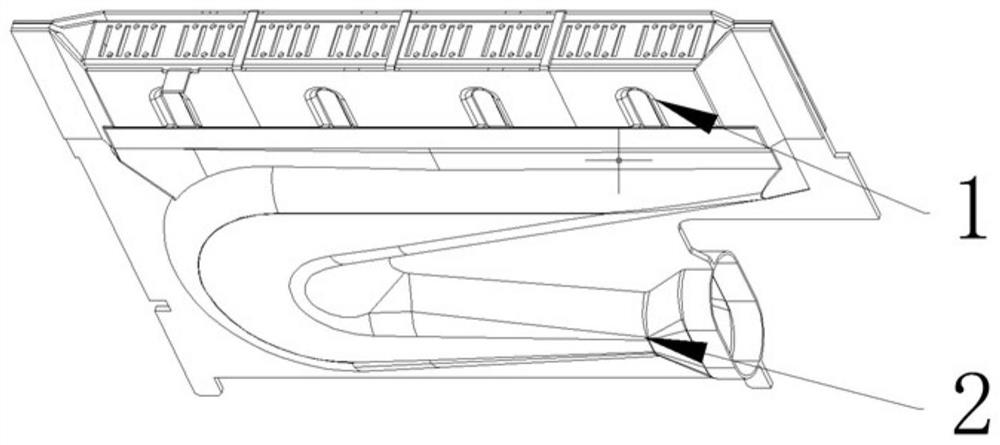

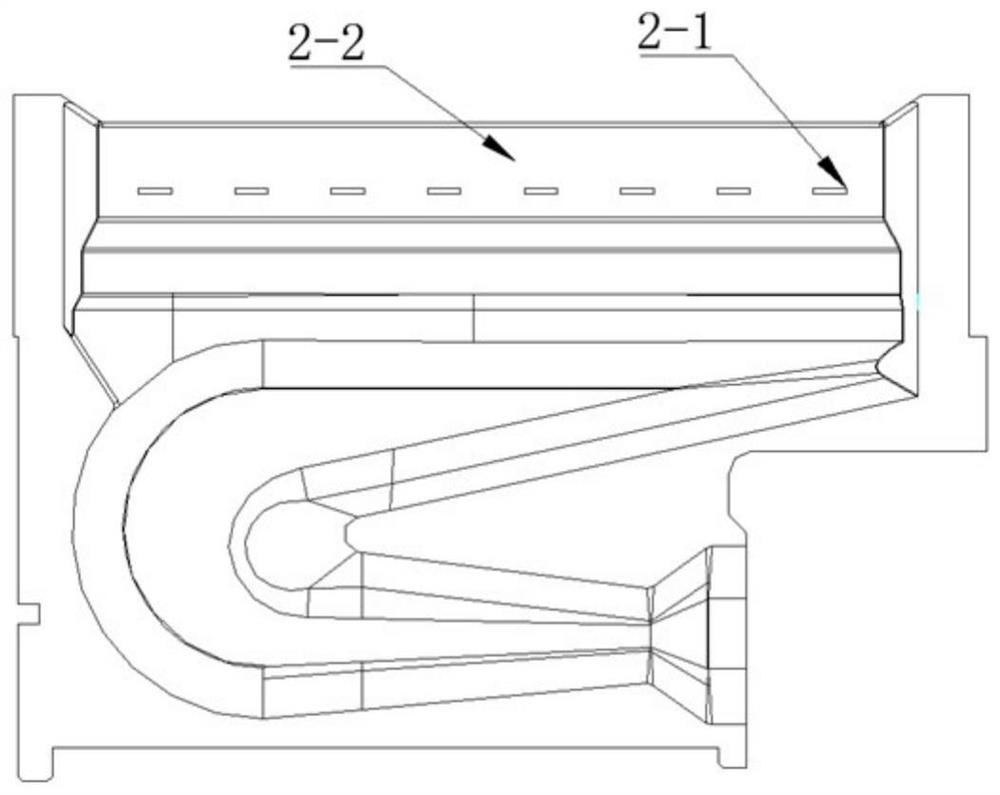

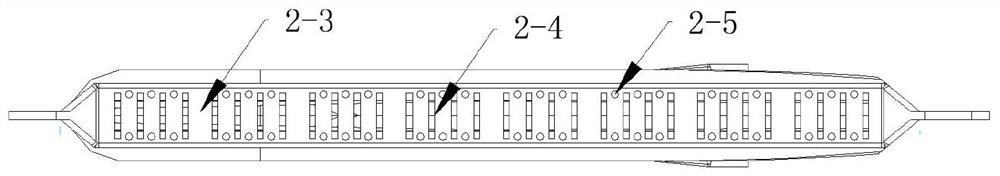

[0061]A burner row, such asFigure 1-4As shown, including the premix cavity 2 and the flame flame 1, the premix chamber 2 includes a cavity and an out-of-end end, and the end surface of the fire end is provided with a plurality of strip of the long flaps 2-4 that are parallel to each other, and a plurality of circles are also provided Fire holes 2-5, two circular flakes 2-5 are a circular flake group, and the long strip flakes 2-4 and the circular flake set are arranged in the longitudinal direction of the fire surface 2-3. The side 2-2 of the fire end is opened with a plurality of parallel arranged side flakes 2-1 for discharging part of the gas. The two stable flakes 1 are fixed to both sides of the hot end of the premixing cavity. The area of the circular flakes 2-5 is smaller than the area of the side flakes 2-1.

[0062]The long strip flavor 2-4 almost through the width direction of the fire surface 2-3, and the two circular flakes of the circular flake group are formed at both...

Embodiment 2

[0067]In this first embodiment, the improvement in the basis of Example 1, the first reinforcing rib between the side surface of the flame piece and the outlet end, and the first reinforcing rib is fitted to the side surface of the fire end. The circular fire hole as the sub-finger hole is replaced with a square hole, and the square hole is one, and is in the central region of the fire surface unit between the adjacent two long flaps.

Embodiment 3

[0069]In this first embodiment, an improvement made on the basis of Example 1, replaced with an elliptical hole as an elliptical aperture as a circular fire hole of the sub-finifier, and the resilience is arranged between the adjacent two long flakes. One long strip flame in Example 1 was in a multi-segment form in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com