Reverse thrust seat for rocket launching

A rocket launch and rocket technology, applied in the field of thrust reversers, can solve the problems of waste of combustion agent and oxidant energy, increase of rocket mass, and insufficient utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

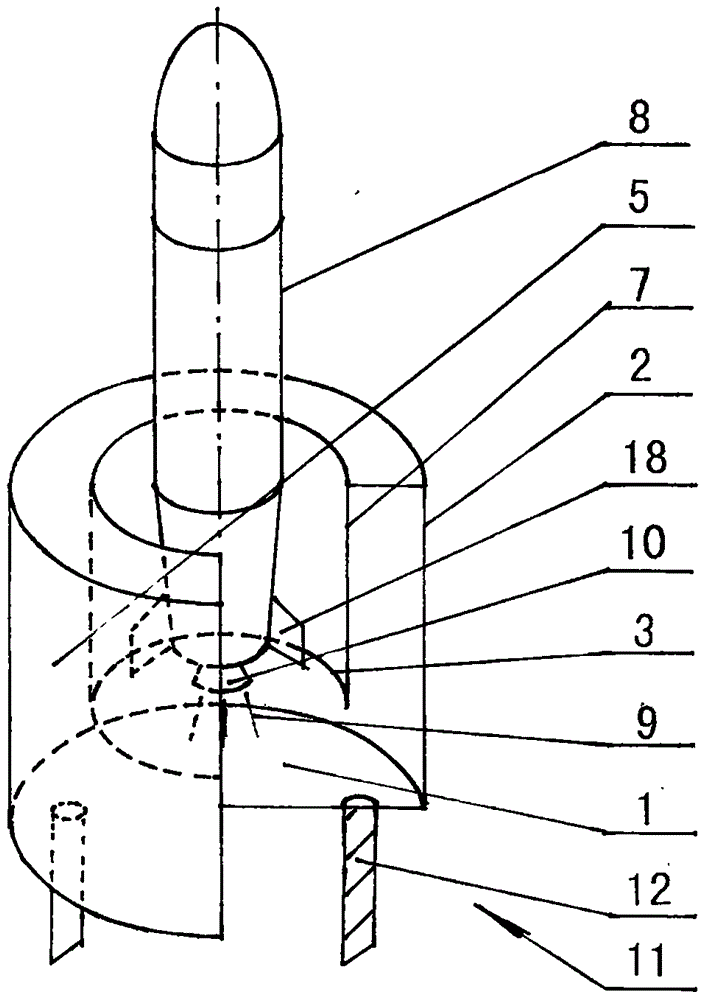

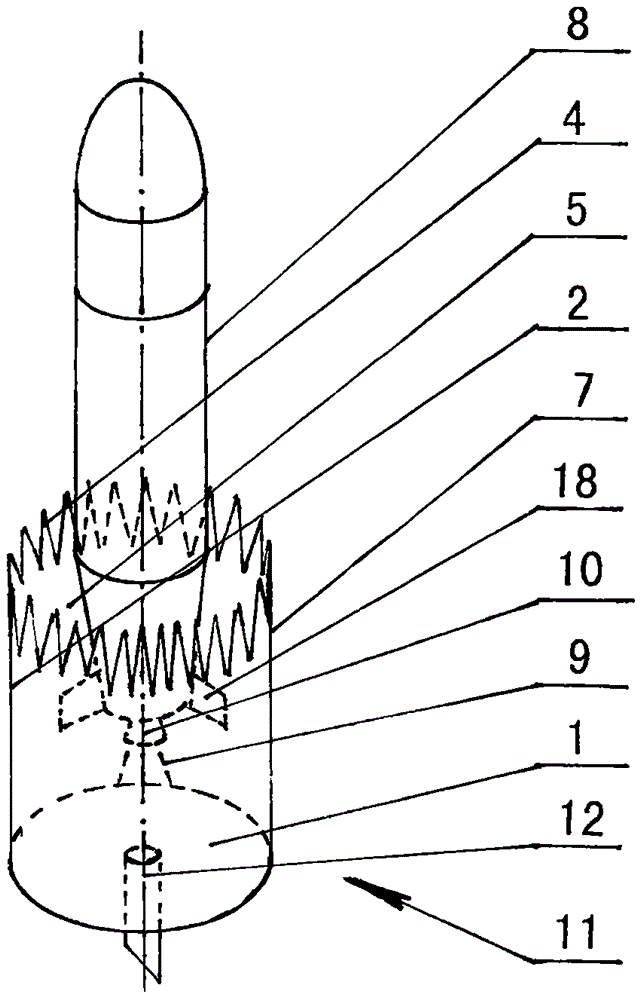

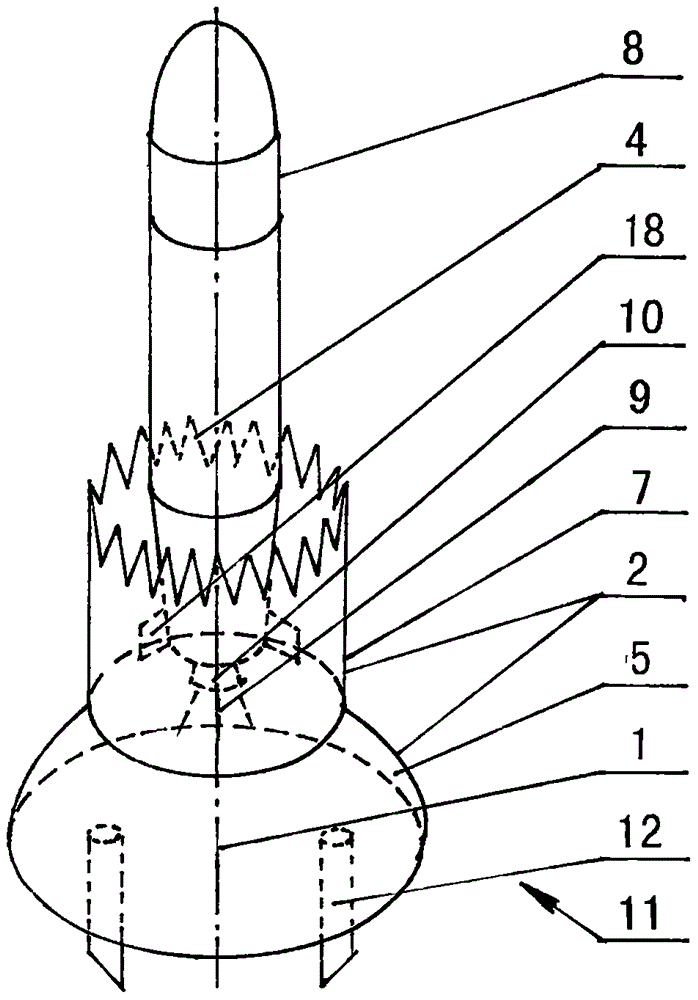

[0025] figure 1 Middle is to see the structural diagram of the anti-thrust seat (11) that 1 / 4 is cut off inside, the anti-thrust seat (11) is placed in the wall (2) of the large cylinder by the tube (7) of the small cylinder, and the two upper The port is connected with an annular wall and closed, the lower port of the wall (2) is sealed and connected with the edge of the disc-shaped bottom (1), the rocket (8) stands in the tube (7), and the nozzle (10) of the rocket is in the Between the circular mouth (3) and the bottom (1) of the tube (7), and the rocket (8), the tube (7), the wall (2) and the bottom (1) are coaxial; by the tube (7), the circle The space between the shaped mouth (3), the wall (2) and the bottom (1) is the cavity (5); the high-pressure hot air flow (9) initially ejected from the nozzle of the rocket (8) first fills the cavity (5), and then Pressure gradually builds up in the chamber (5), and at the same time a small amount of high-pressure hot air (9) leaks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com