Thrust reverser gates having side openings

A technology of thrust reverser and reverse injection, which is applied in jet propulsion devices, machines/engines, high-efficiency propulsion technology, etc. It can solve problems such as weight reduction, complex device implementation, damage to turbojet engines, etc., and increase exhaust velocity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Typically and well known, a thrust reverser comprises at least one door adapted to be driven by an actuator or the like, the door being moved from a "closed door" position corresponding to the engine compartment operating in direct injection mode to a position corresponding to the engine compartment The "door open" position where the cabin operates in reverse injection mode.

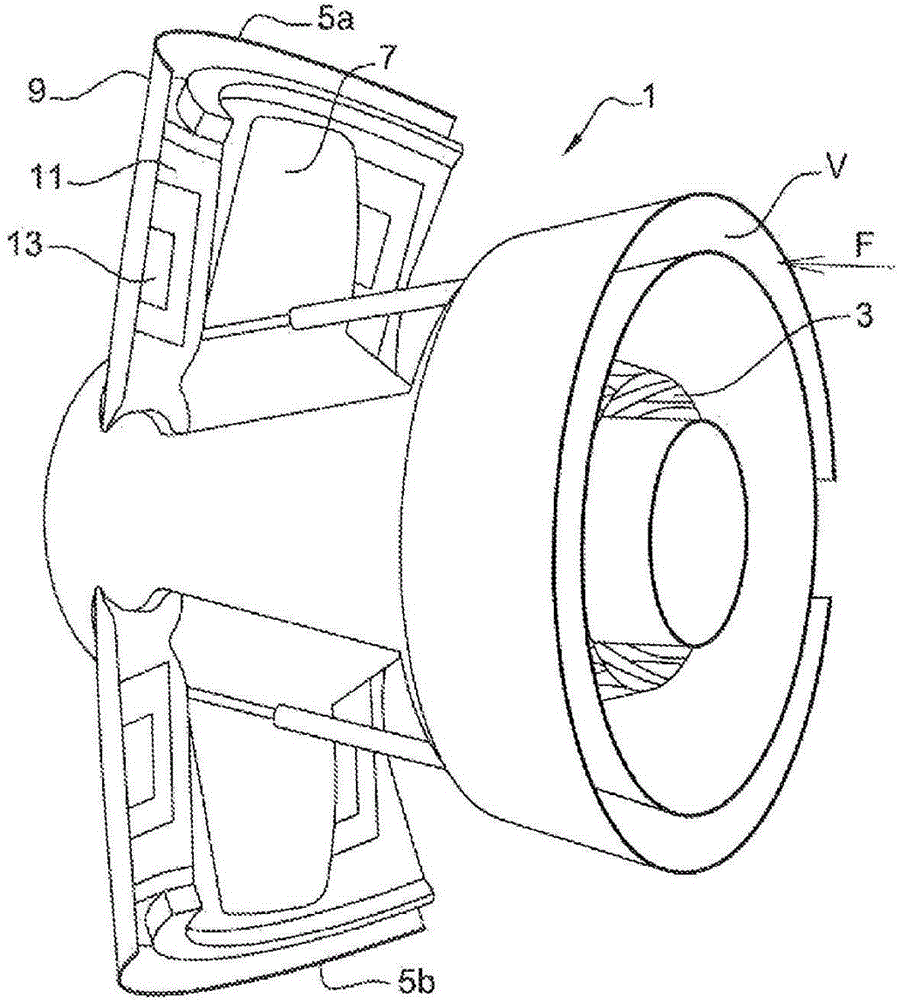

[0043] see figure 1 , showing a nacelle 1 of a turbojet engine 3 operating in reverse injection mode, a portal thrust reverser according to the invention comprising two doors 5a, 5b according to the invention.

[0044] The doors 5a and 5b are identical, and one of them is referred to as door 5 in the following description.

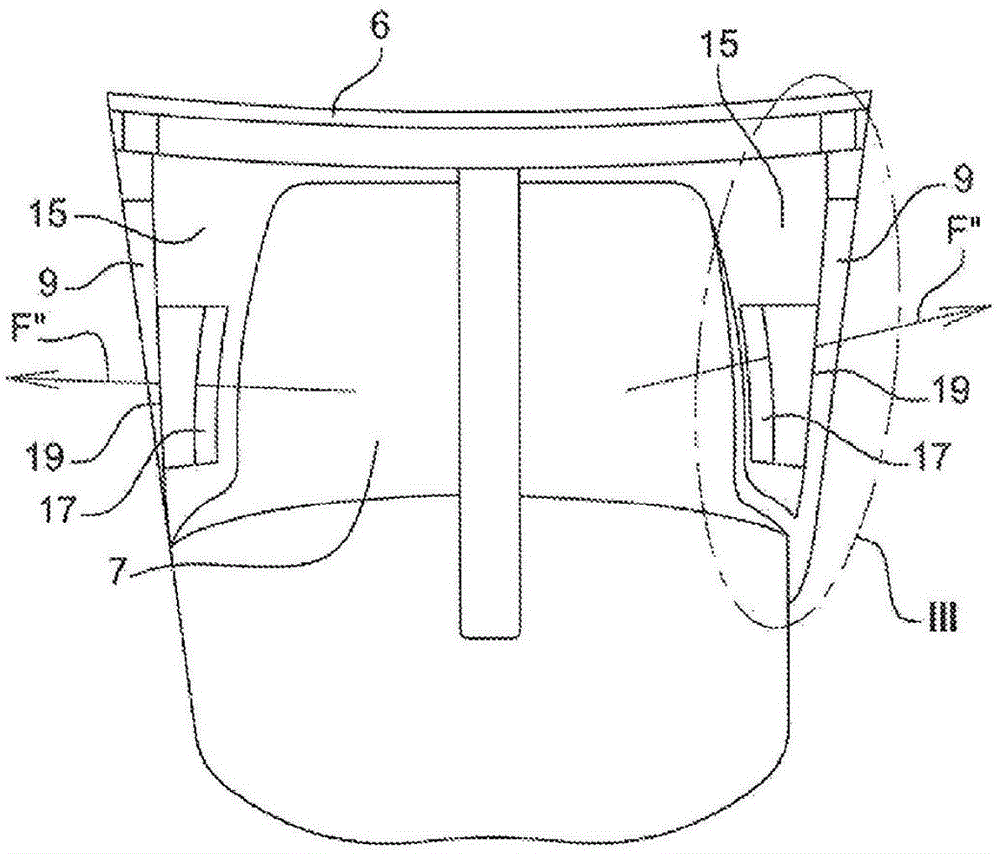

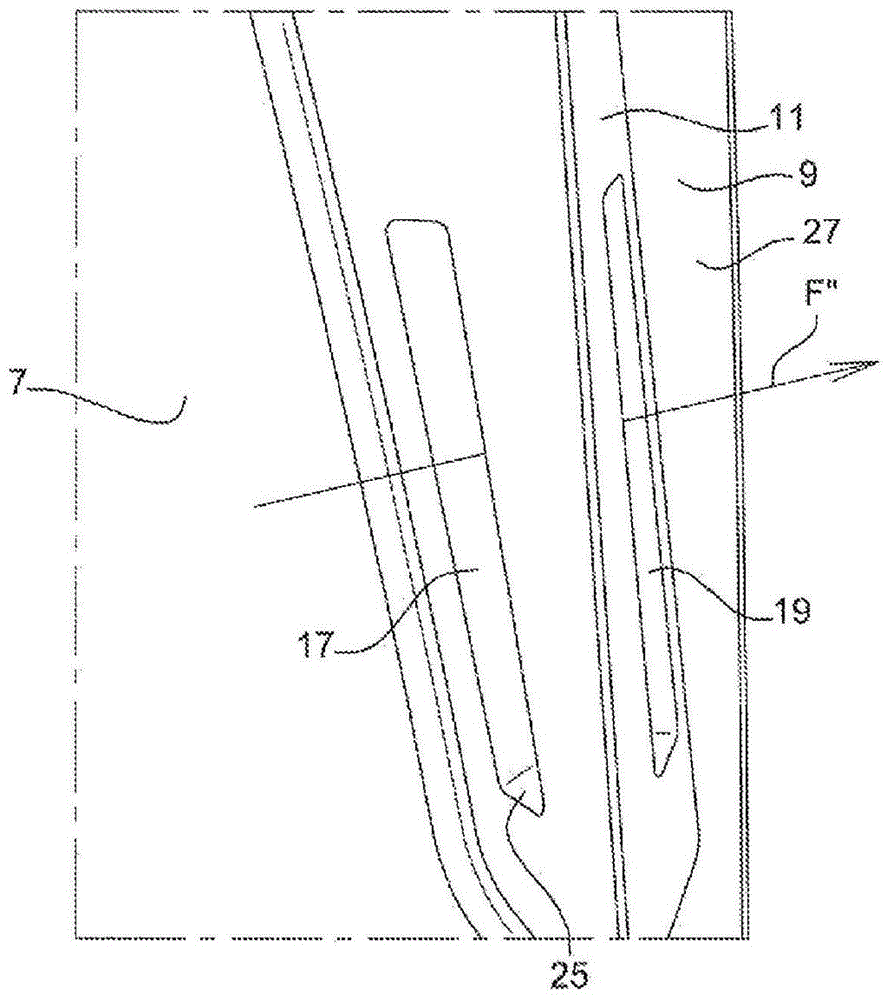

[0045] The door 5 according to the invention is constructed in such a way that the inner wall 7 is connected to the outer wall 9 by a side wall 11 and according to the invention the door 5 comprises a deflection device 13 .

[0046]For the direct injection mode of the nacell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com