Vehicle-mounted tail gas temperature difference power generation heat exchanger

A heat exchanger and thermoelectric power generation technology, which is applied in exhaust gas treatment, exhaust devices, engine components, etc., can solve problems affecting the application of thermoelectric power generation devices, volume and shape limitations of thermoelectric power generation devices, and space constraints, so as to save chassis Space, good noise reduction performance, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

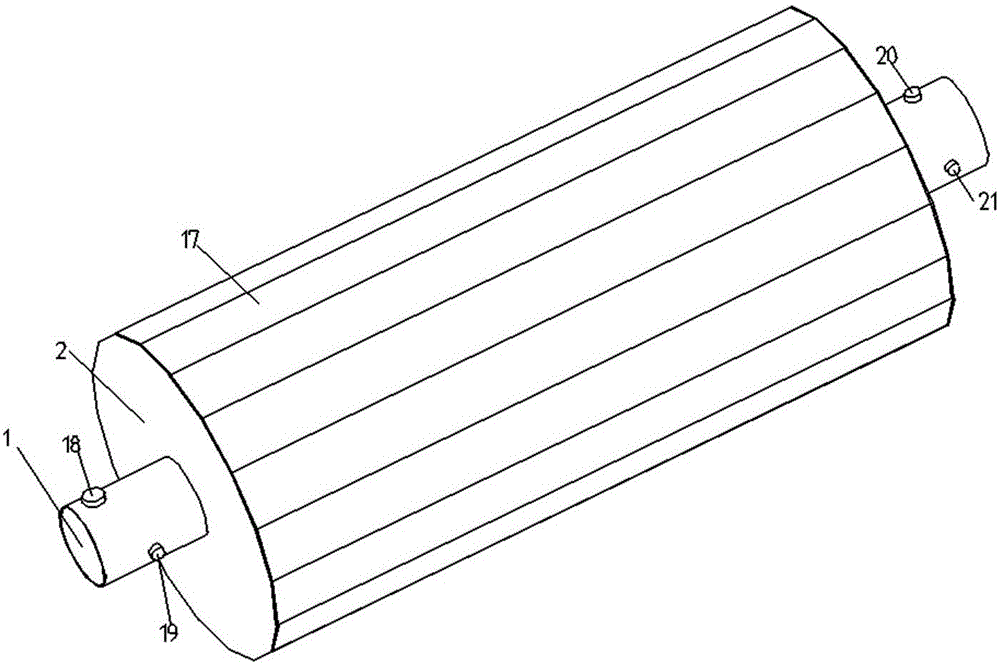

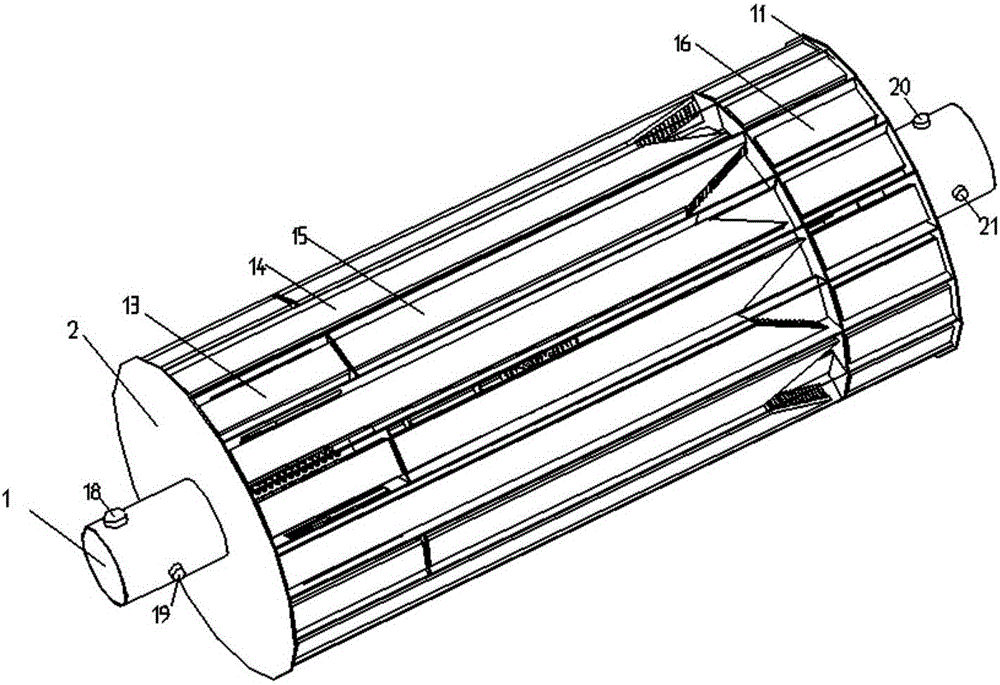

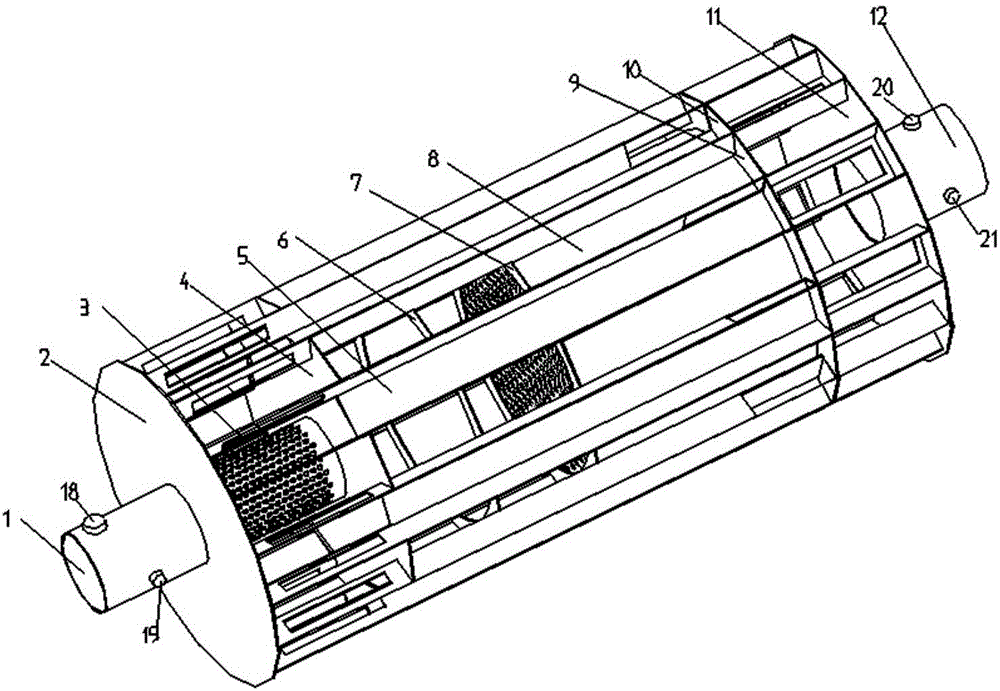

[0033] The invention provides a vehicle-mounted exhaust temperature difference power generation heat exchanger device integrating SCR function and noise reduction function, including SCR (Selective Catalytic Reduction Converter), noise reduction device, heat exchange fins, frame and base plate. The outer partitions at both ends of the heat exchanger and the circumferentially arranged frame form the installation base. The heat exchange fins are arranged circularly along the outer side of the frame, the base plate and the thermoelectric module are installed in sequence on the outer side, and the SCR catalytic converter and the noise reduction device are installed inside. The two ends of the heat exchanger are respectively provided with air inlet and outlet, and a plurality of partitions are arranged inside. The noise reduction device includes a noise reduction baffle, a porous pipe, and a complex channel composed of openings on the frame, internal baffles and holes inside the SC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com