Compressed air heat-exchange system

A heat exchange system, a technology for compressing air, used in compressors, compressors with reversible cycles, lighting and heating equipment, etc., can solve problems such as pollution, heat waste, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

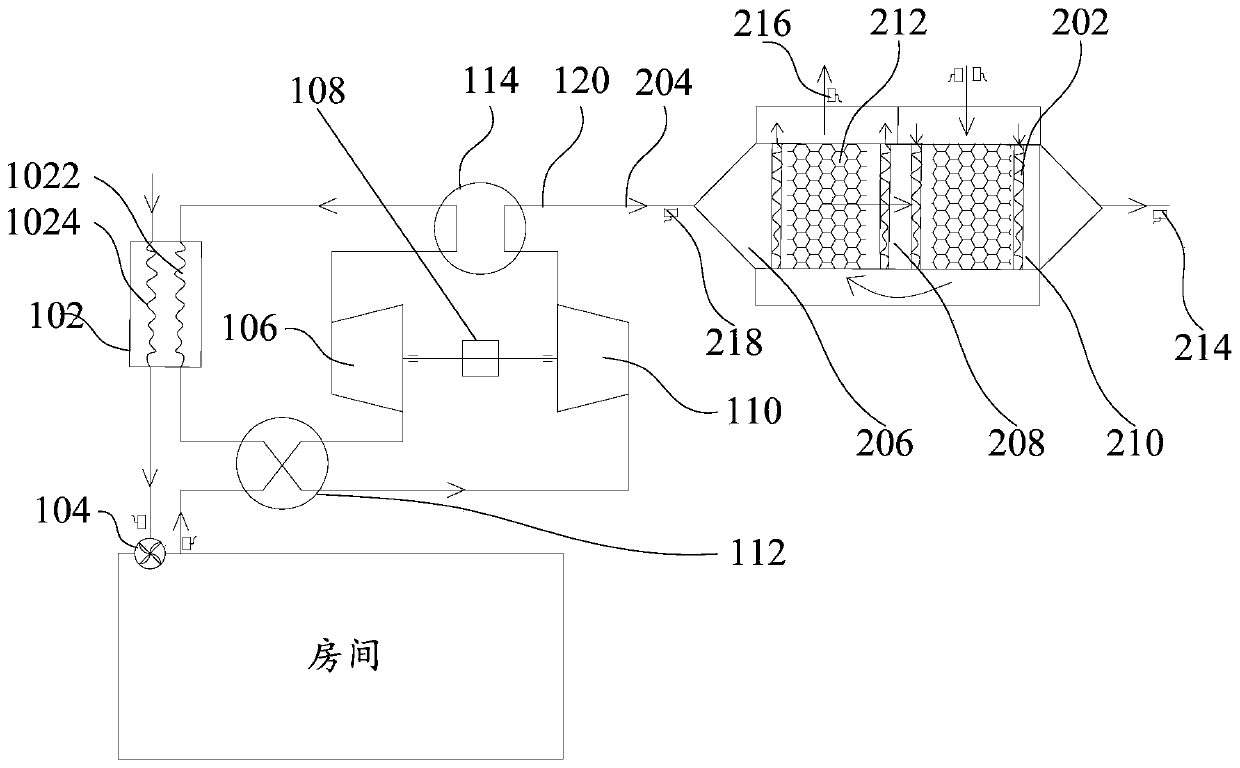

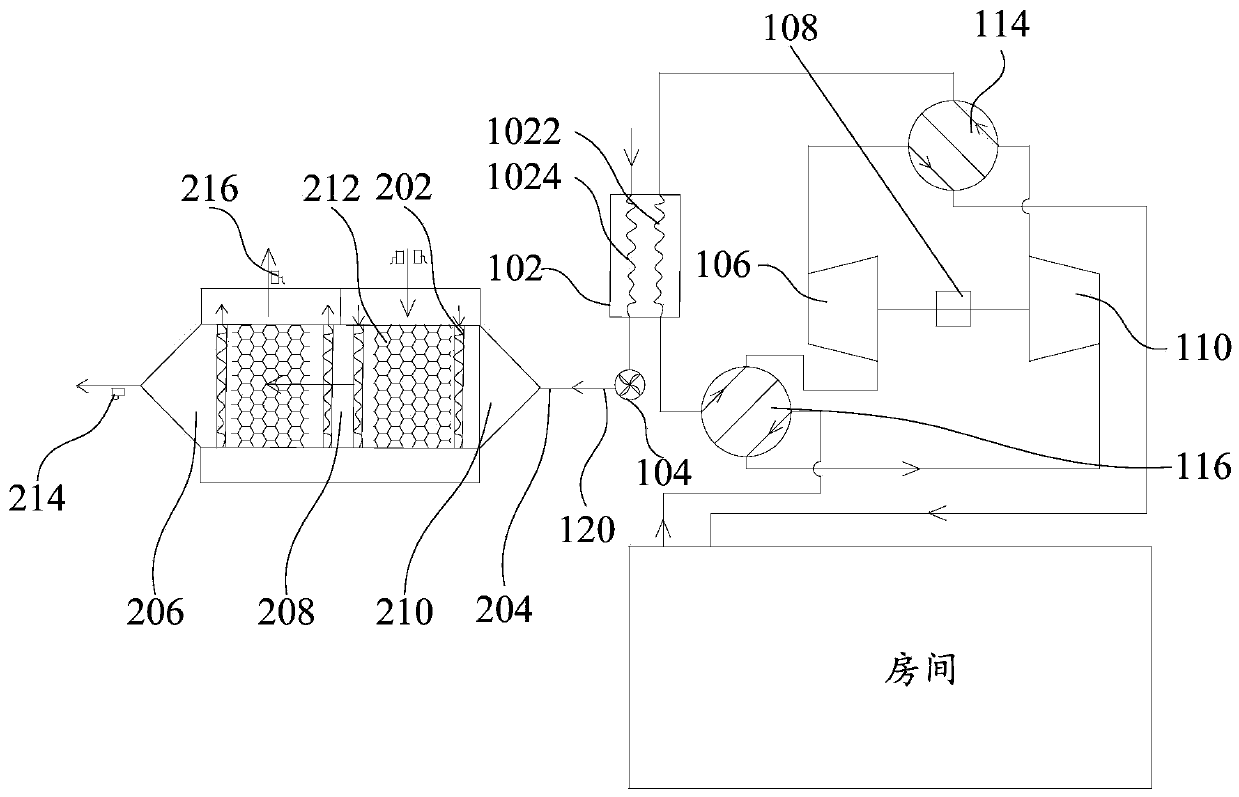

[0069] Such as figure 1 As shown, the compressed air heat exchange system according to the embodiment of the present application has an air outlet, an air return port, an exhaust port 120 and an air inlet. The air outlet and the air return port are used to communicate with the room. The mouth is used to communicate with the outside atmosphere.

[0070] The compressed air heat exchange system specifically includes: processor (see Figure 5 ), heat exchanger 102, pressurized expansion assembly and exhaust gas treatment device.

[0071] Among them, the processor is used to execute computer instructions.

[0072] The heat exchanger 102 includes a first flow path 1022 and a second flow path 1024 capable of heat exchange, the inlet of the second flow path 1024 communicates with the air inlet, and the first flow path 1022 communicates with the pressurization expansion assembly.

[0073] The pressurized expansion assembly specifically includes an expander 106 connected by a shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com