Combined type steam discharge silencer

A muffler and combined technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve problems such as large investment, unfavorable maintenance and maintenance of equipment and pipelines, and difficulty in meeting environmental protection requirements for noise reduction, and achieve Convenient maintenance, simple structure and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

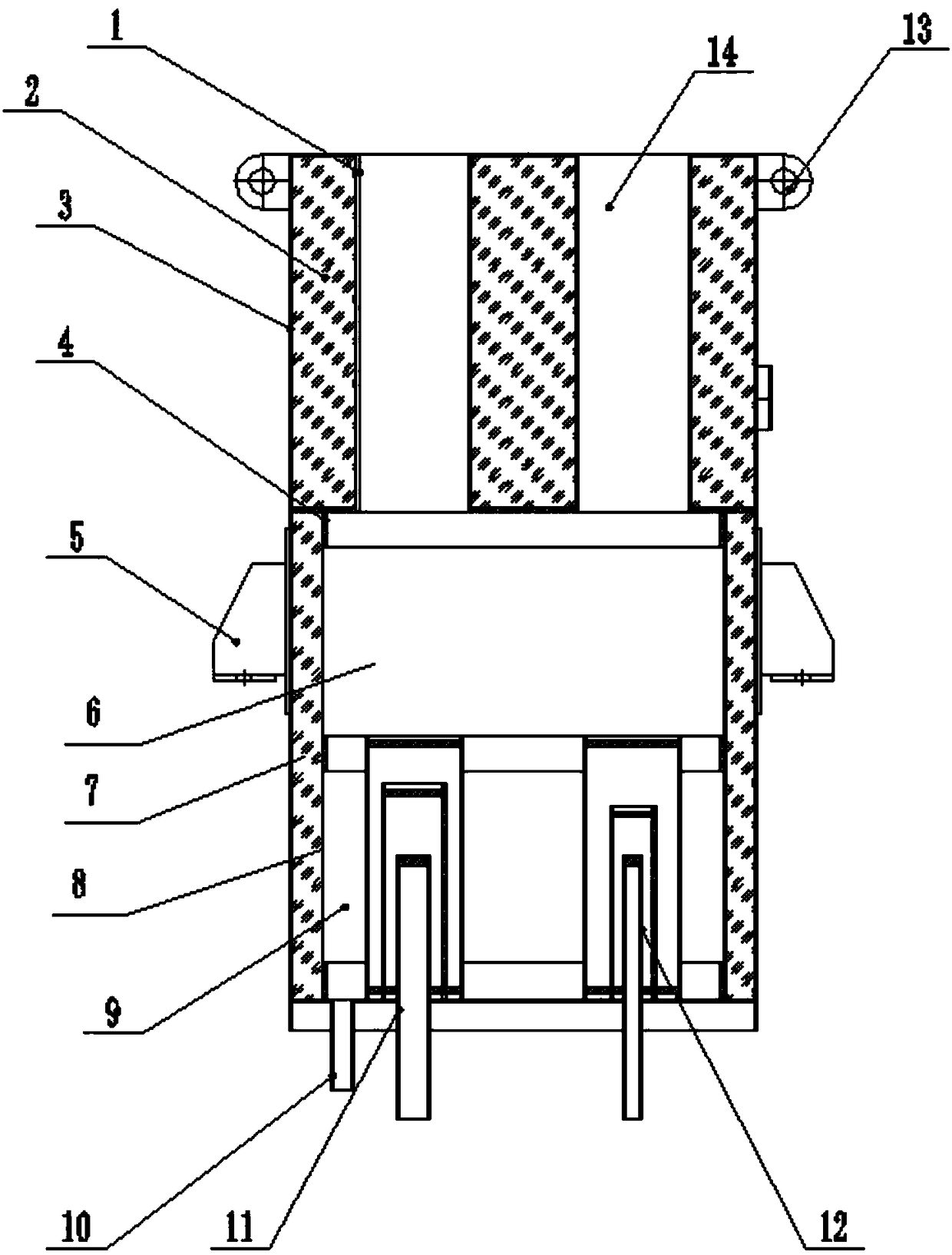

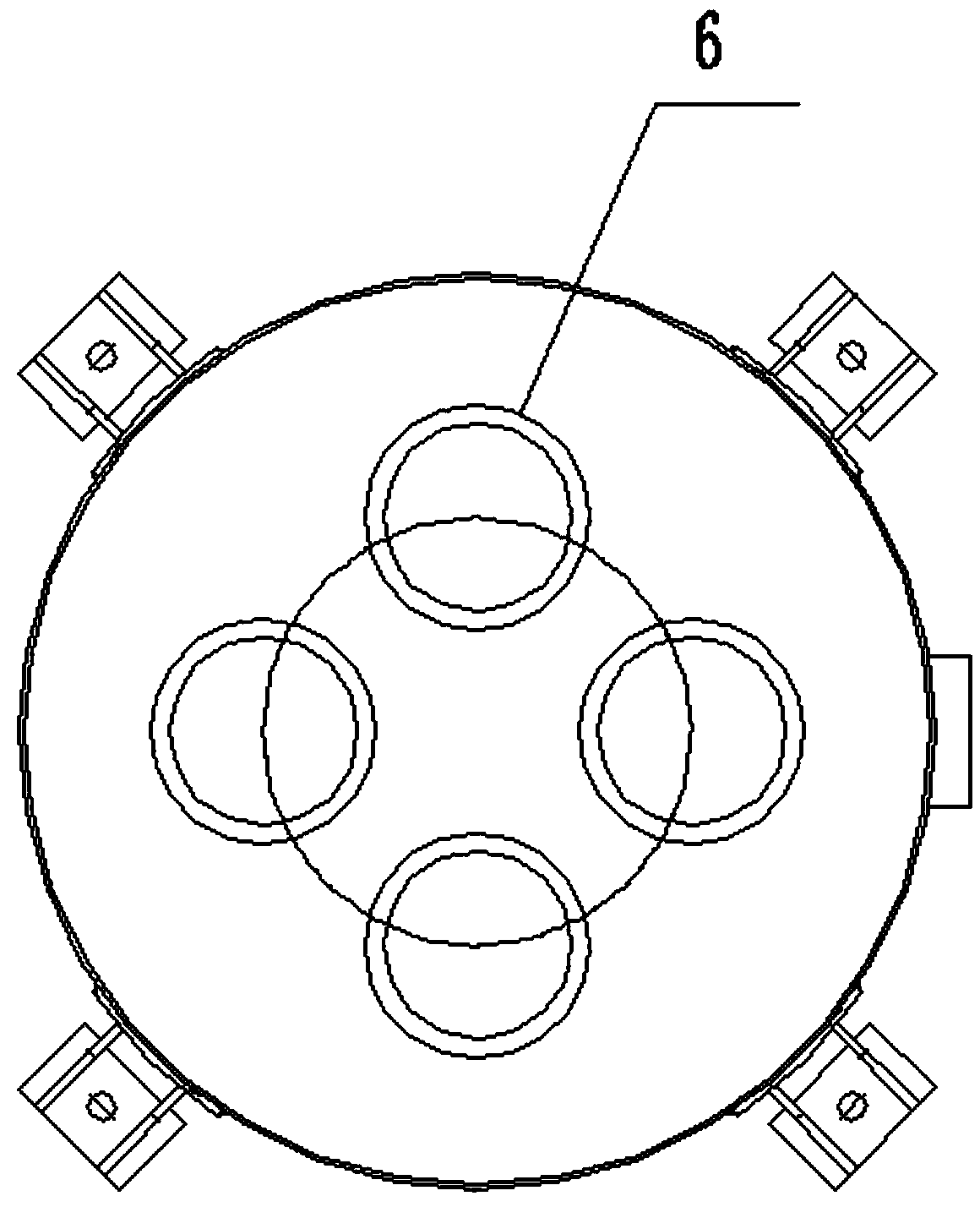

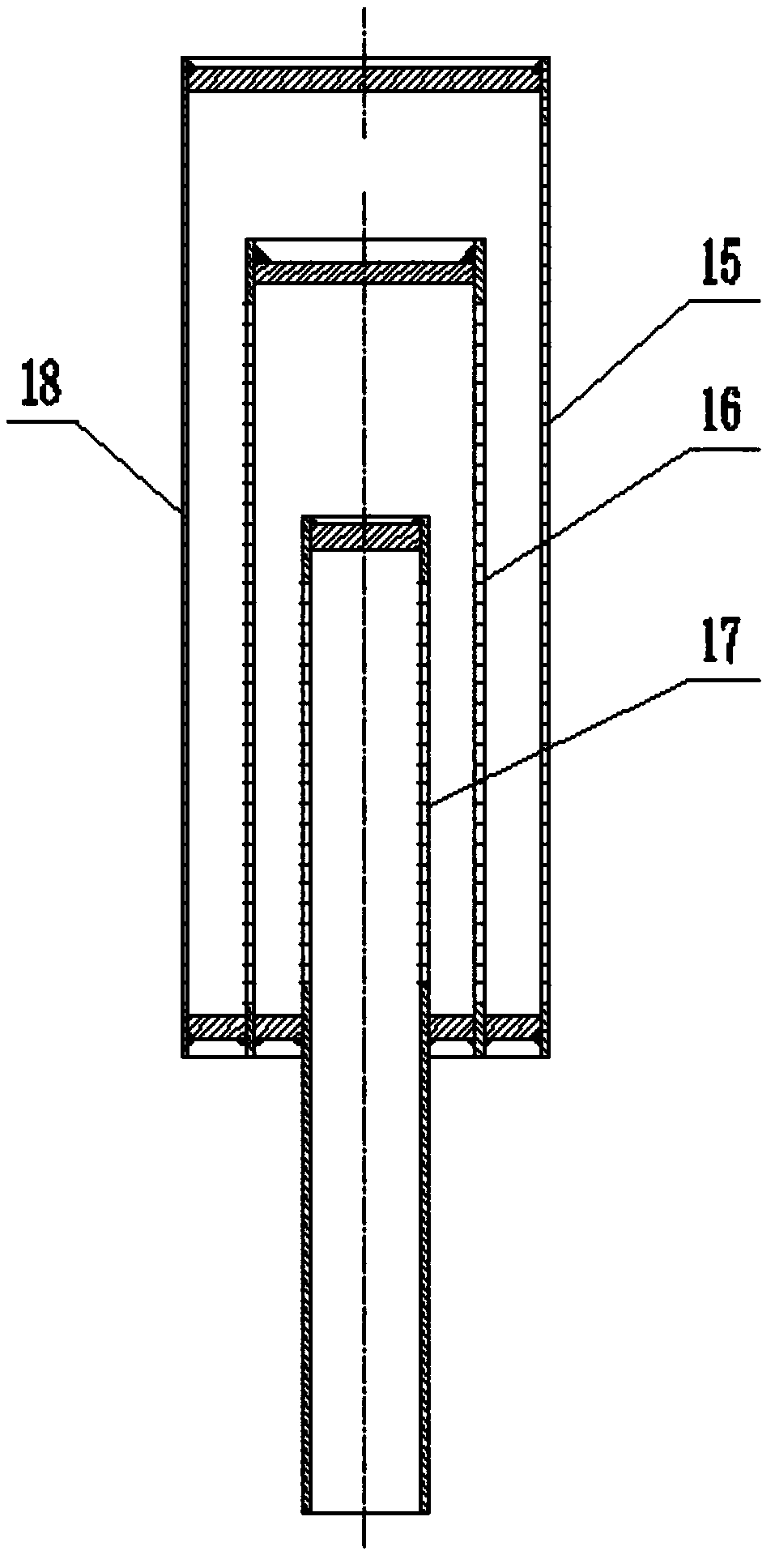

[0027] Refer to attached Figure 1-3 , a combined steam exhaust muffler, including a sound-proof cover 3 closed at the upper and lower ends, the sound-proof cover 3 is made of stainless steel, and a lifting lug 13 is provided on the outer upper part of the sound-proof cover 3, and the sound-proof cover 3 A support 5 is provided in the middle part of the outer side. The lower end of the sound-resistance cover 3 is provided with a drain port, and a drain pipe 10 is connected to the discharge port. The lower part of the sound-resistance cover 3 is provided with a first anechoic chamber 9, the middle part is provided with a second anechoic chamber 6, and the upper part is provided with a third anechoic chamber. The anechoic chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com