Steam blowing energy dissipation and pollutant removal discharging device

An emission device and energy dissipation technology, which is applied in the direction of combination device, cleaning hollow objects, dispersed particle separation, etc., can solve the problems of high pressure, high steam surplus, large steam volume, etc., achieve low speed, reduce emission noise, uniformity The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

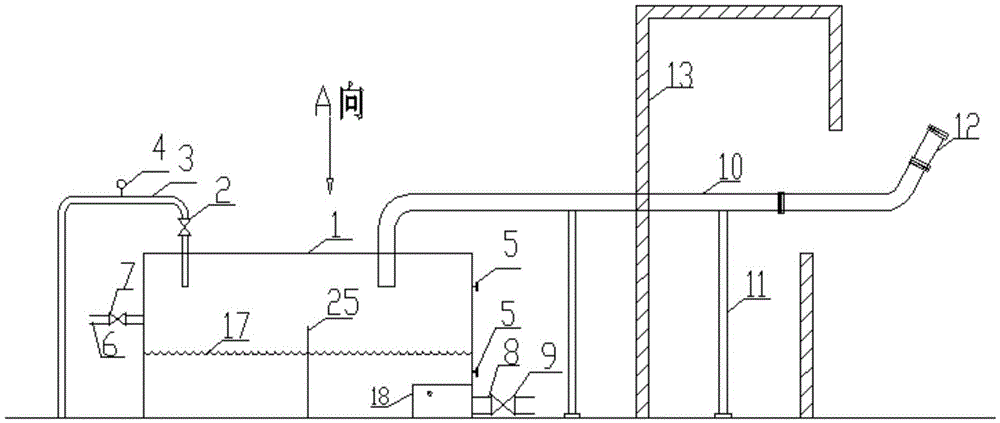

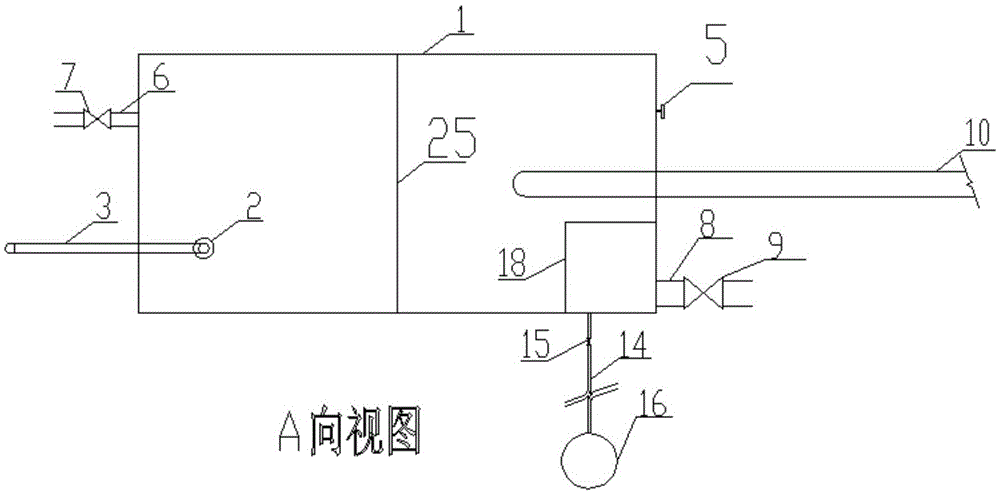

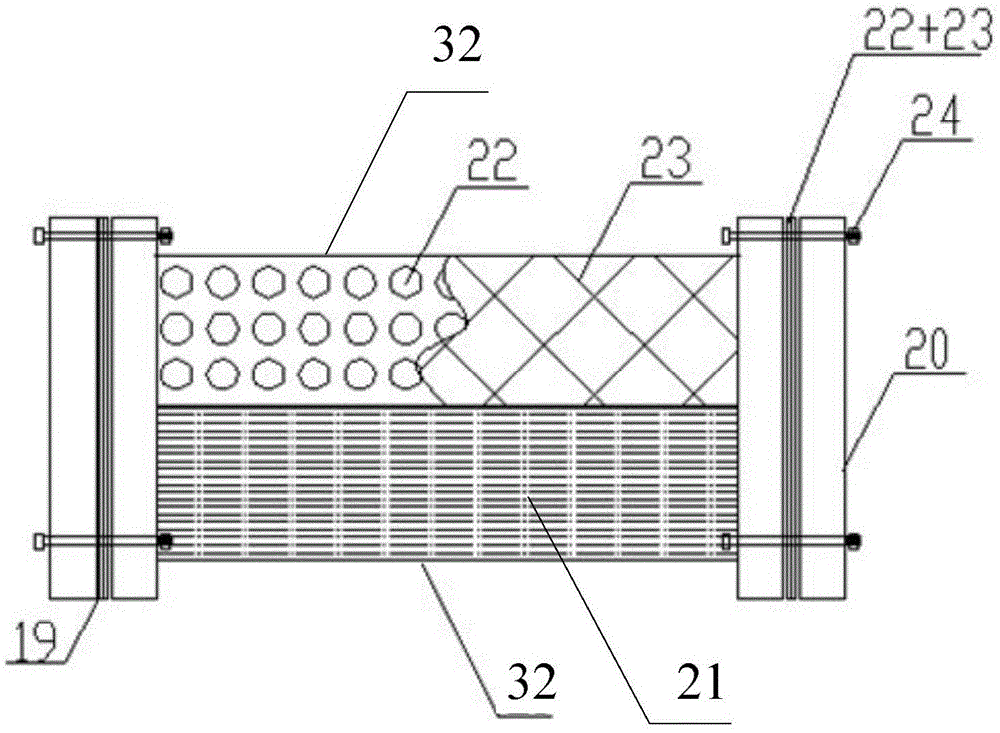

[0027] Such as Figure 1~3 As shown, the present invention provides a steam purging energy dissipation and decontamination discharge device, comprising:

[0028] A closed water tank main body 1; specifically, the size of the water tank main body 1 can be 4m×2m×2m, and the material can be 10mm thick steel plate;

[0029] The steam inlet pipe 3, the water supply pipe 6, the steam outlet pipe 10 and the sewage discharge pipe 8 arranged on the main body of the water tank; the diameter of the sewage discharge pipe 8 is Ф219, which is located at the lower part of the discharge end of the water tank main body 1; preferably The diameter of the steam outlet pipe is enlarged to Ф219. This design increases the diffusion area of the steam,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com