Constant volume type piston rotor engine

A rotary engine and piston technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., to achieve the effects of high work efficiency, simple structure, and low emission noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

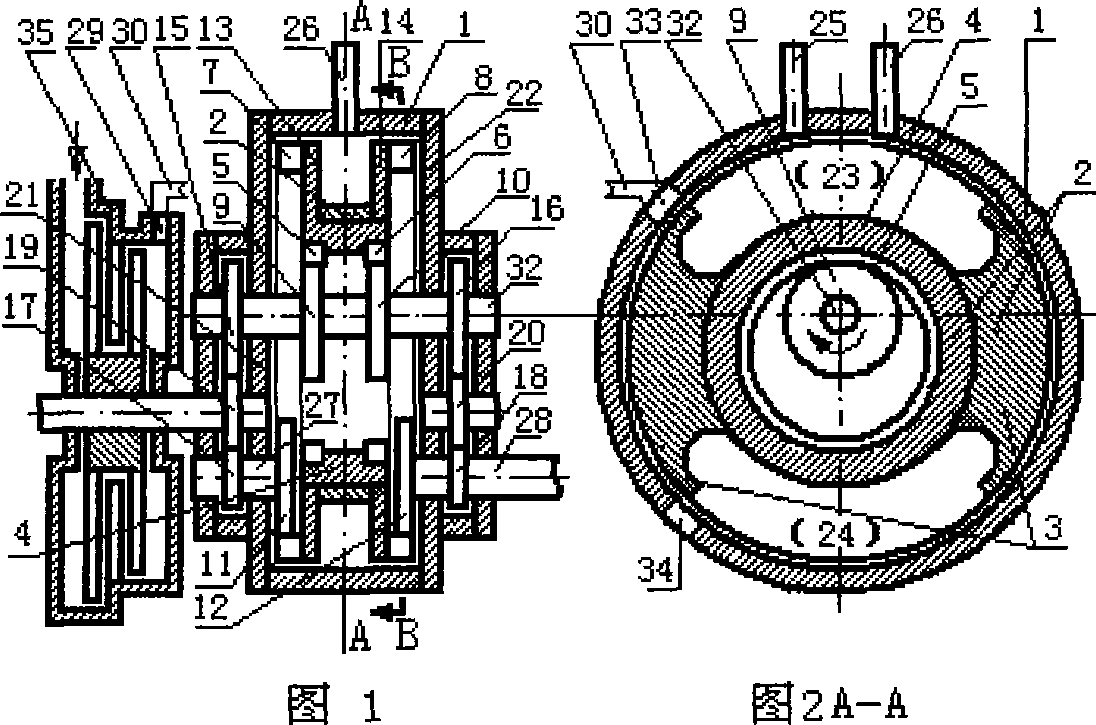

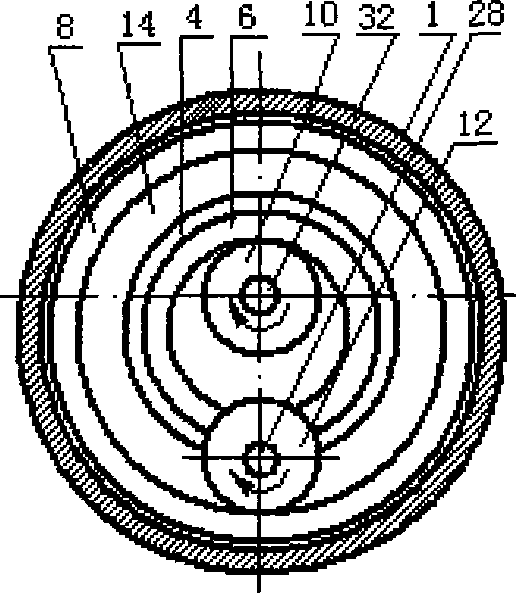

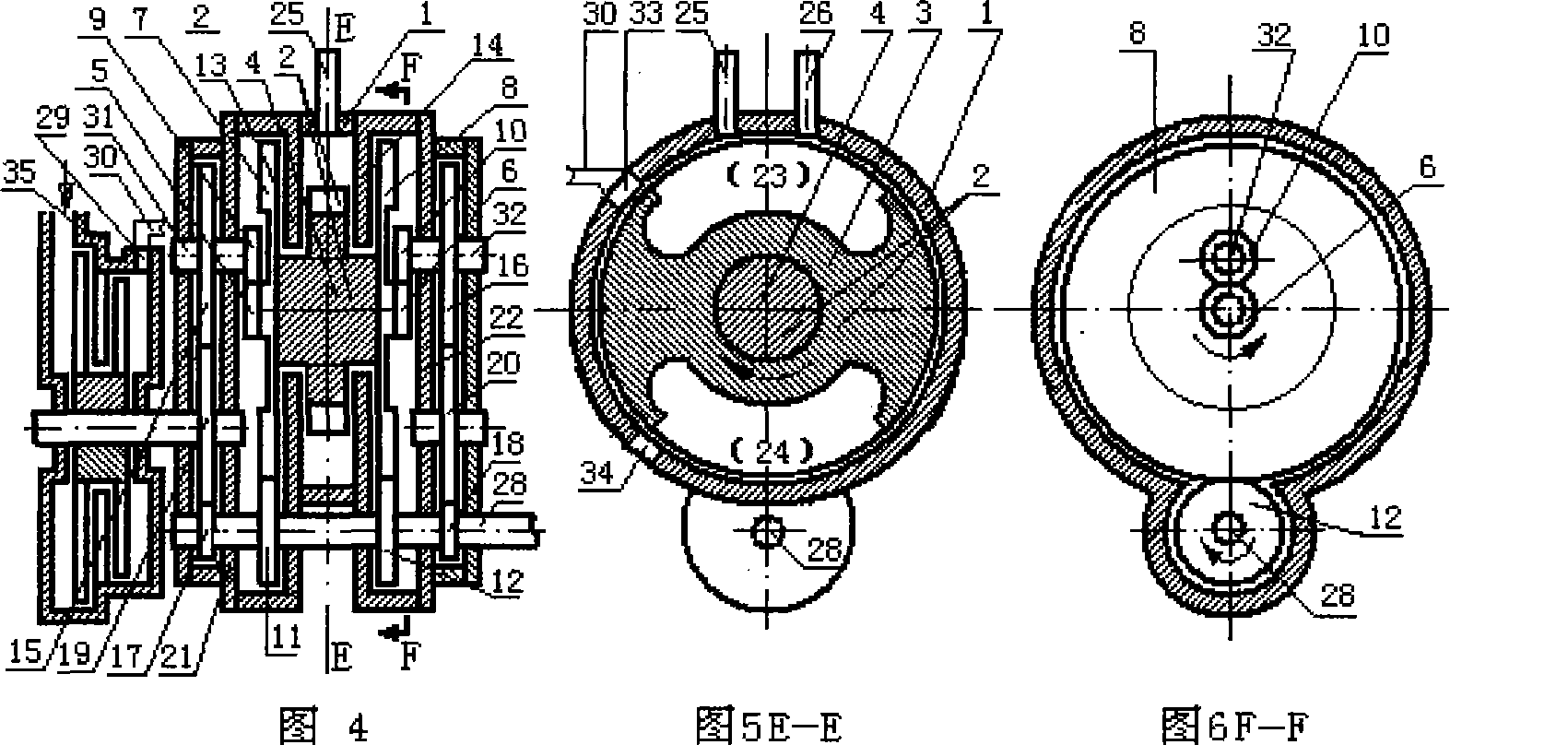

[0029] In the embodiment shown in FIG. 1 , a piston rotor 2 is arranged in a circular cylinder block 1 . The piston rotor 2 shown in FIG. 2 is composed of a bipolar piston 3 and a hollow stem 4 . The core column 4 of the piston rotor passes through the cylinder heads 13, 14 located at both ends of the cylinder block 1, the cylinder covers 13, 14 are fixed to the piston rotor 2, and the two ends of the piston rotor 2 are located on the inner diameter of the core column 4 Center ring gears 5, 6 are set, power output ring gears 7, 8 are respectively arranged on the periphery of the outer plane of the cylinder head 13, 14, and the center ring gears 5, 6 and the power output ring gears 7, 8 are center; main shaft 27, 28 and eccentric shaft 32 are set, wherein, main shaft 27, 28 is a semi-axis, and the axis centers of said main shaft 27, 28 and eccentric shaft 32 are on the same straight line as the center of piston rotor 2, and said main shaft 27 . 10 and secondary feedback gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com