Multistage pressure control complex muffler

A composite muffler and pressure-controlled chamber technology, which is applied to sound-producing equipment, instruments, etc., can solve the problem that ordinary mufflers cannot meet the requirements of high pressure and large flow, and cannot effectively solve the problems of high gas noise pollution and large flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

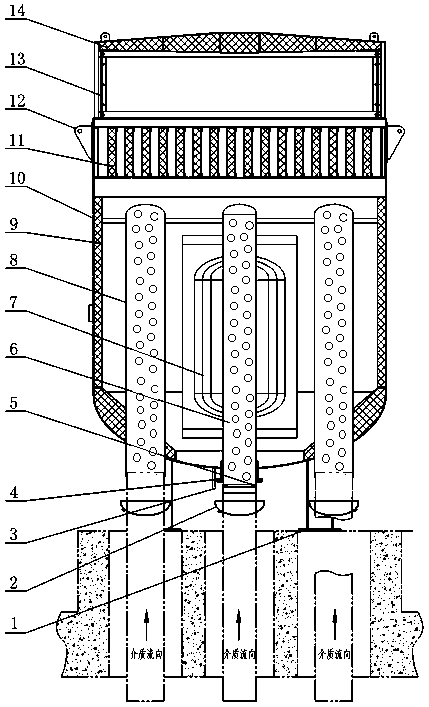

[0018] As shown in the figure, a multi-stage pressure control composite muffler includes a casing 10 that is sealed and connected through the legs 1 and fixedly installed outside the atmospheric exhaust port. The middle part of the inner cavity of the casing 10 is provided with a The main shunt pipe 6, the top of the main shunt pipe 6 is closed, and the lower end is fixedly connected to the atmospheric exhaust port. The lower end of the inner cavity of the main shunt pipe 6 is provided with a throttling orifice 5, which constitutes a primary pressure control structure; the wall of the main shunt pipe 6 There are a number of circular through holes from top to bottom, forming a secondary pressure control structure; the middle section of the main shunt pipe 6 is coaxially arranged and fixedly connected with a multi-layer pressure control cylinder 7, and the height and diameter of the multi-layer pressure control cylinder 7 are according to The sequence increases from the inside to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com