Patents

Literature

88results about How to "To achieve the desired effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

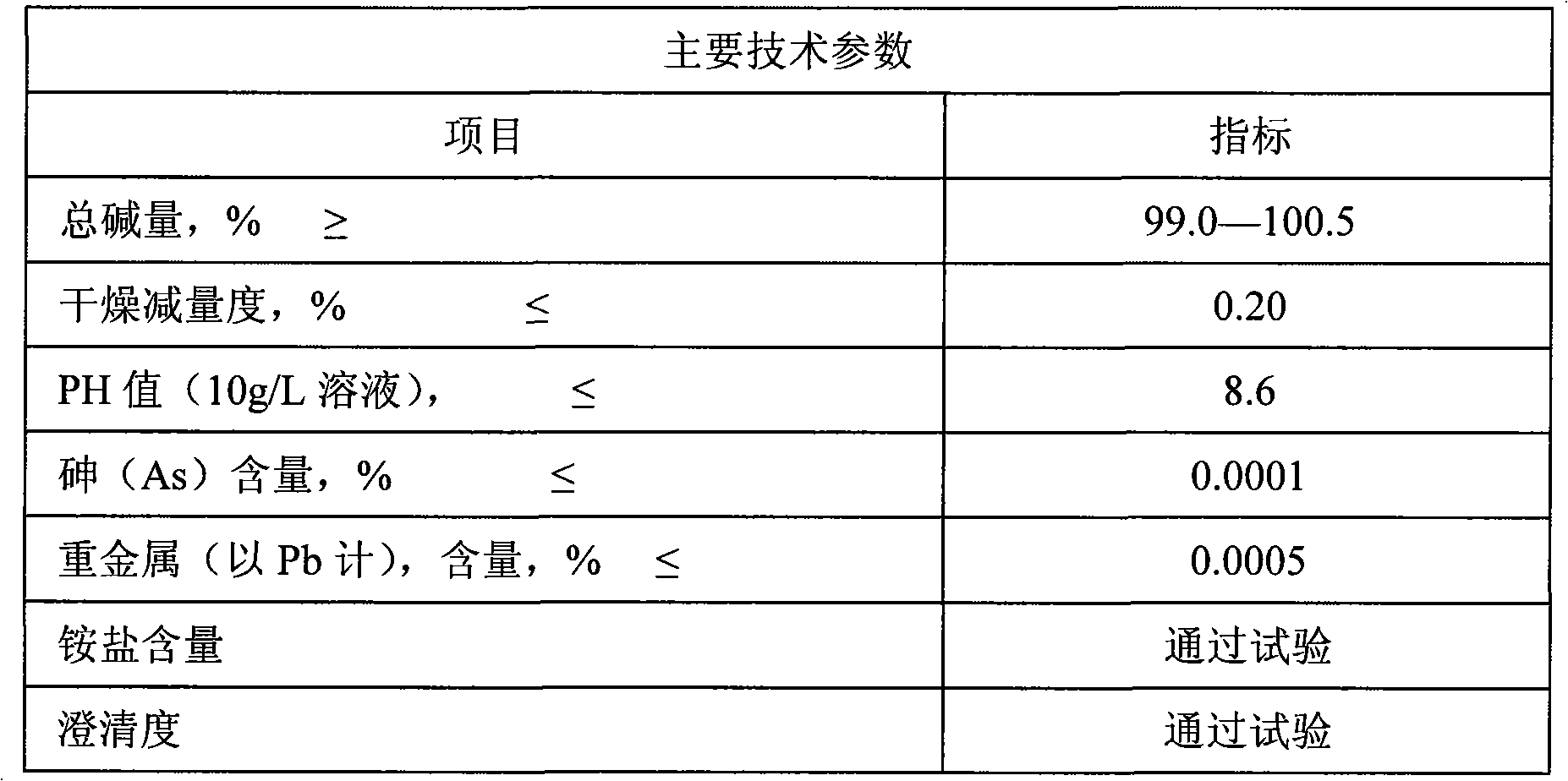

High-temperature no-dropping-point lubricating grease and production technique thereof

InactiveCN102051256ALong fatliquoring cycleWide adaptabilityLubricant compositionSulfonateSodium Bentonite

The invention relates to a high-temperature no-dropping-point lubricating grease and a production technique thereof. The high-temperature no-dropping-point lubricating grease is prepared from the following components in parts by weight: 13.7-84.4 parts of base oil, 5-15 parts of bentonite thickener, 5-50 parts of composite calcium sulfonate lubricating grease, 5-20 parts of tackifier, 0.5-1 part of antioxidant and 0.1-0.3 part of metal deactivator. The preparation method of the composite calcium sulfonate lubricating grease comprises the following steps: converting superhigh-base-number calcium sulfonate with a conversion agent at 60-100 DEG C for 20-60 minutes until the superhigh-base-number calcium sulfonate becomes obviously thickened, and heating to 140-180 DEG C to remove water. The high-temperature no-dropping-point lubricating grease has the advantages of long grease addition period and wide adaptability, and can be used in high-temperature positions; and at high temperature, the high-temperature no-dropping-point lubricating grease also has the advantages of no coking, light discolorment, less oil bleeding, low loss and longer service life.

Owner:辽宁海华科技股份有限公司

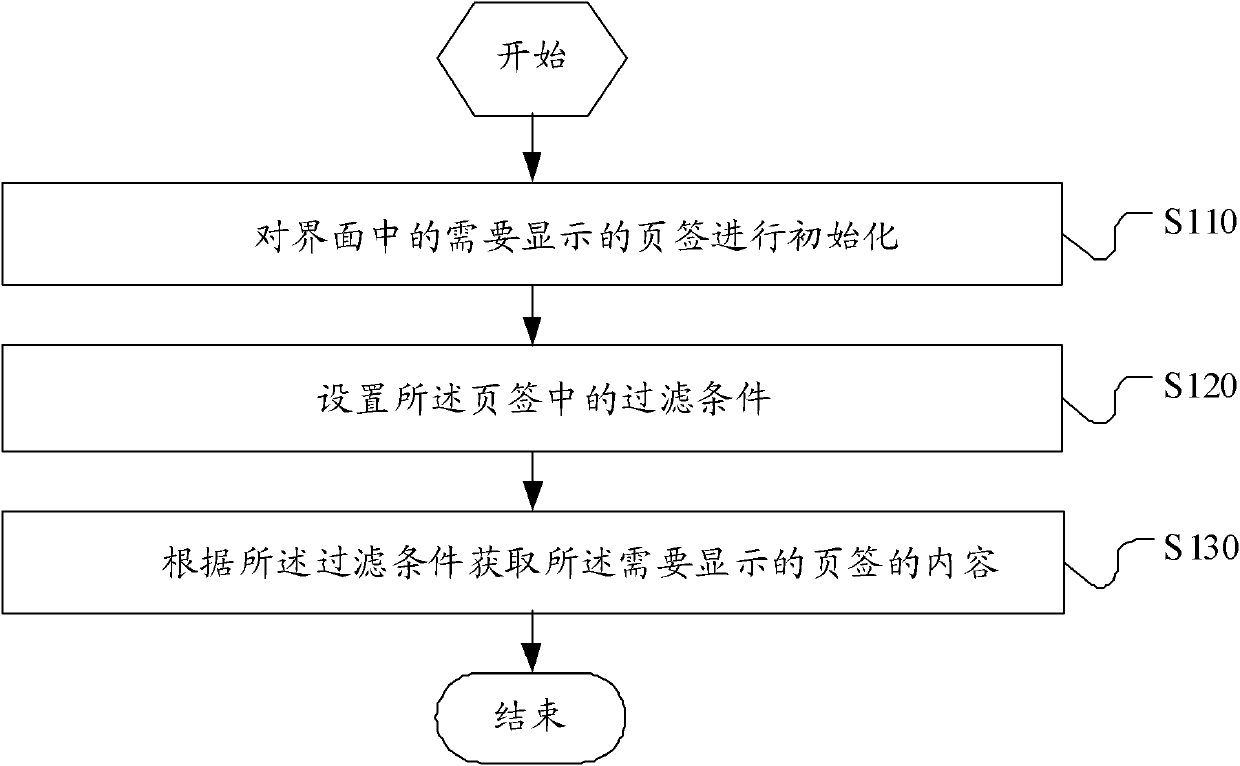

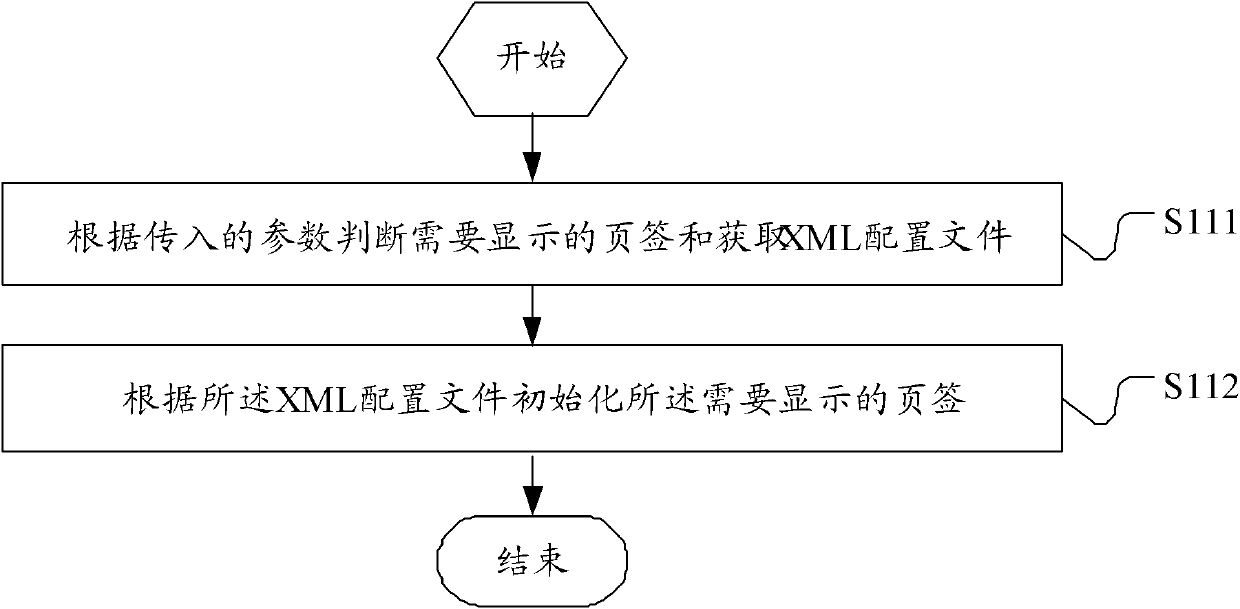

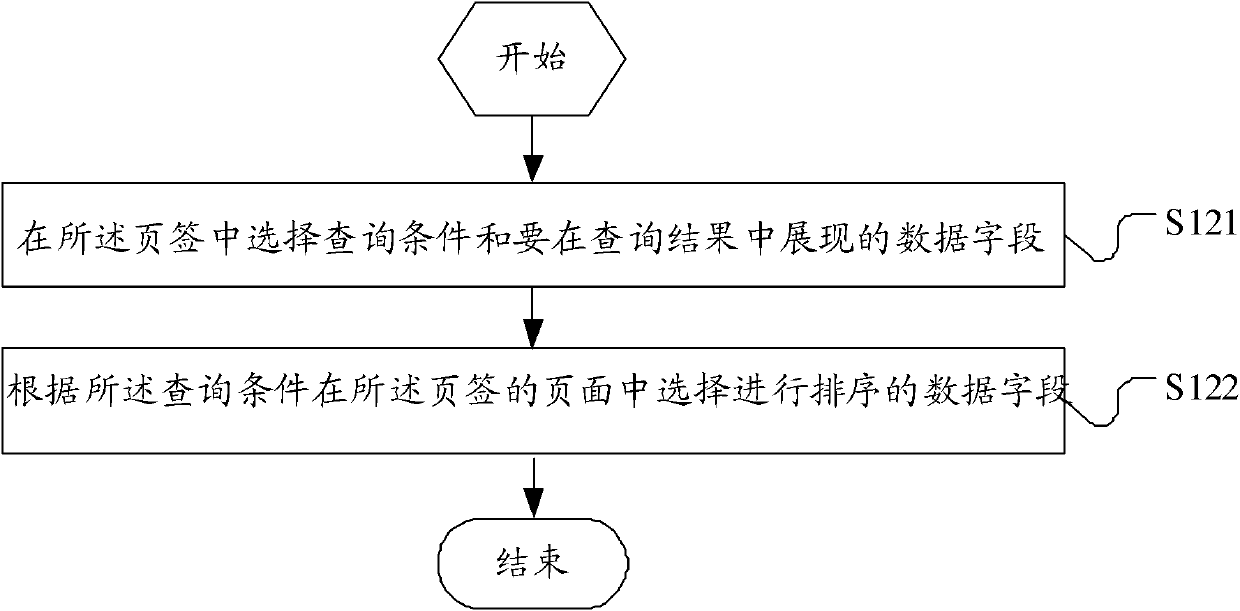

Common interface configuration method and computer

ActiveCN102567032ARich and flexible filtering methodsImprove experienceProgram loading/initiatingSpecial data processing applicationsOperating system

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

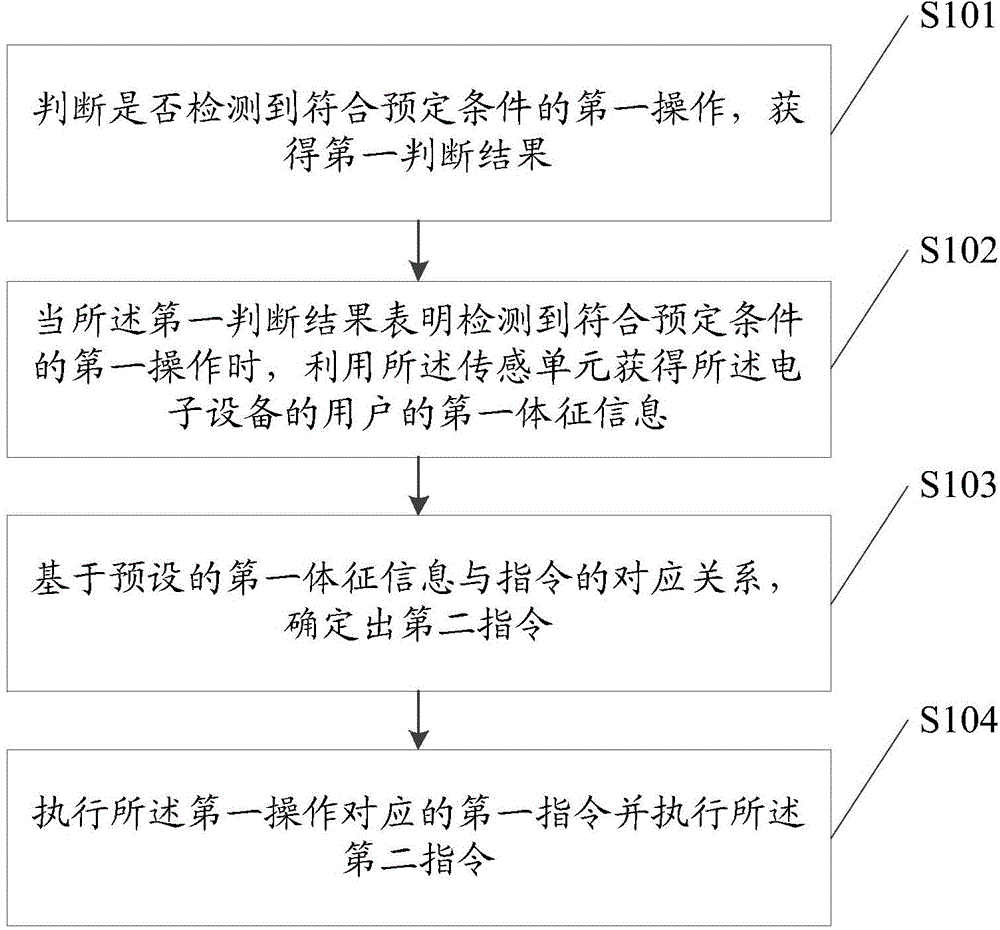

Information processing method and electronic device

ActiveCN104376241AEasy to operateTo achieve the desired effectDigital data authenticationInput/output processes for data processingInformation processingHuman–computer interaction

The invention discloses an information processing method and an electronic device. The method includes: judging whether first operation conforming to preset conditions is detected or not, and acquiring a first judgment result; when the first judgment result shows that the first operation conforming to the preset conditions is detected, utilizing a sensing unit to acquire first physical sign information of the electronic device; based on corresponding relationship between the preset first physical sign information and instructions, determining a second instruction; executing a first instruction corresponding to the first operation and executing the second instruction.

Owner:LENOVO (BEIJING) LTD

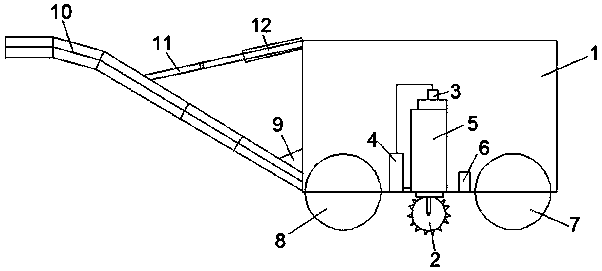

Milling machine capable of adjusting milling depth and using method thereof

ActiveCN107558341ATo achieve the desired effectPrevent rotationRoads maintainenceElectric machineryPulp and paper industry

The invention provides a milling machine capable of adjusting the milling depth. The milling machine comprises a milling machine frame, a milling rotor, an engine, a milling depth control device, a milling depth adjusting device, a walking motor, a front rolling wheel, a rear rolling wheel, a tail door, a recycling belt device, a connecting rod and an oil cylinder. Through the milling depth control device and the milling depth adjusting device of the pavement milling machine, the milling depth of the pavement can be accurately adjusted to achieve the ideal milling effect.

Owner:台州市黄岩裕盛聚酯模具厂

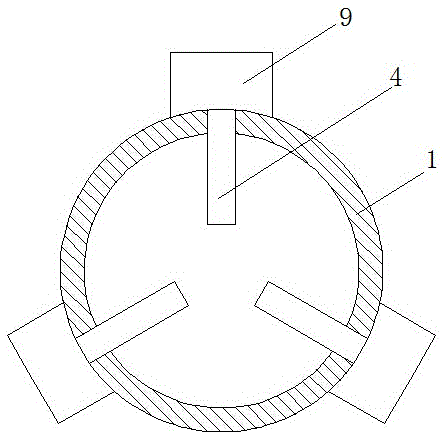

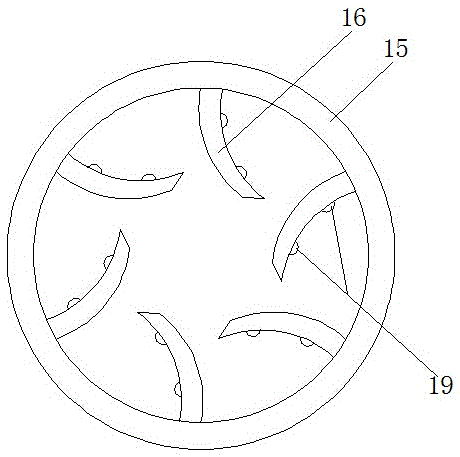

Printing and dyeing raw material mixing equipment based on synchronous mixing treatment

ActiveCN105582842AEasy heating temperatureTo achieve the desired effectRotating receptacle mixersTransportation and packagingEngineeringControl valves

The invention discloses printing and dyeing raw material mixing equipment based on synchronous mixing treatment, which comprises a mixing barrel, wherein three feeding ports extending into the mixing barrel are arranged on the mixing barrel, the three feeding ports are spirally symmetric relatively to the axis of the mixing barrel, and each feeding port is internally provided with a first control valve; and the three feeding ports are respectively connected with a feeding pipe extending toward the axis of the mixing barrel. According to the printing and dyeing raw material mixing equipment adopting the technical scheme, through the arrangement of the three feeding ports in the mixing barrel, three primary color dyes can be fed and mixed synchronously, so that the uniformity of color of the molded dyes is more ideal; according to the printing and dyeing raw material mixing equipment based on synchronous mixing treatment, in the mixing process of printing and dyeing raw materials, three primary color printing and dyeing raw materials can be fed and mixed synchronously, so that the mixing uniformity is obviously improved.

Owner:绍兴中漂印染有限公司

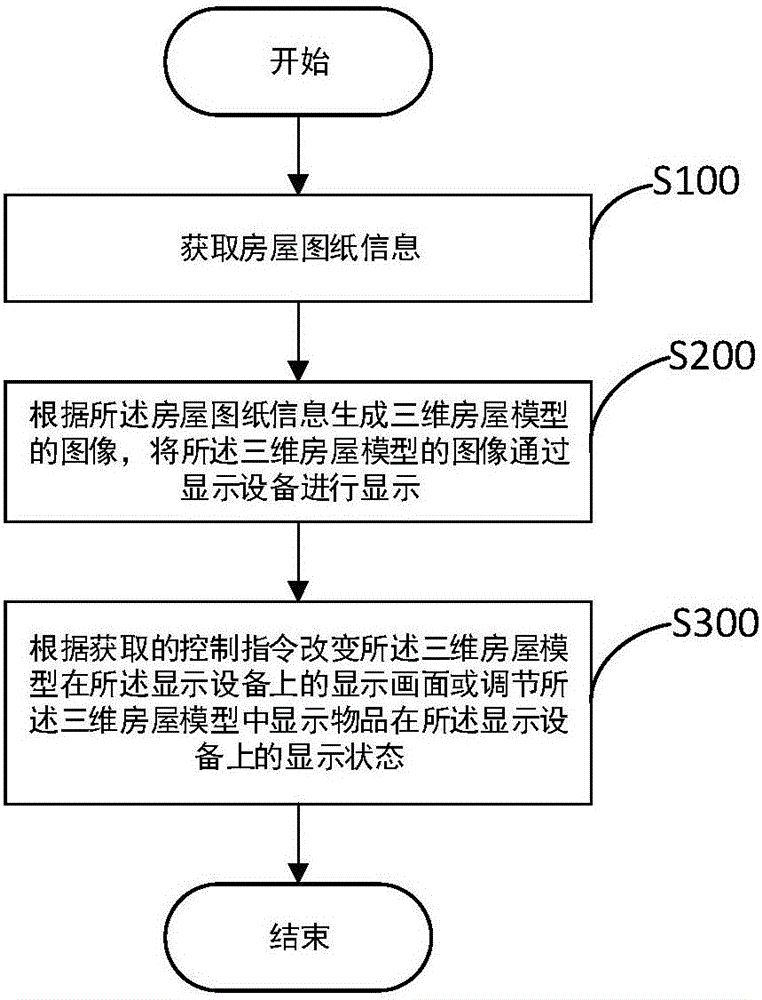

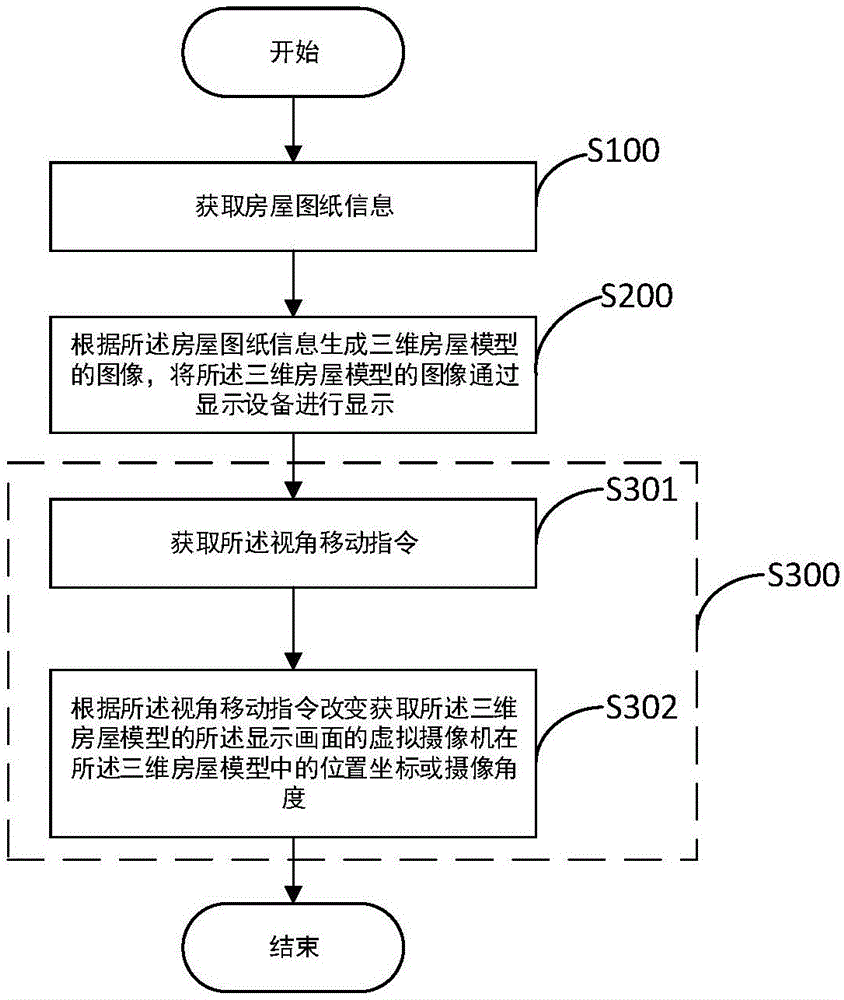

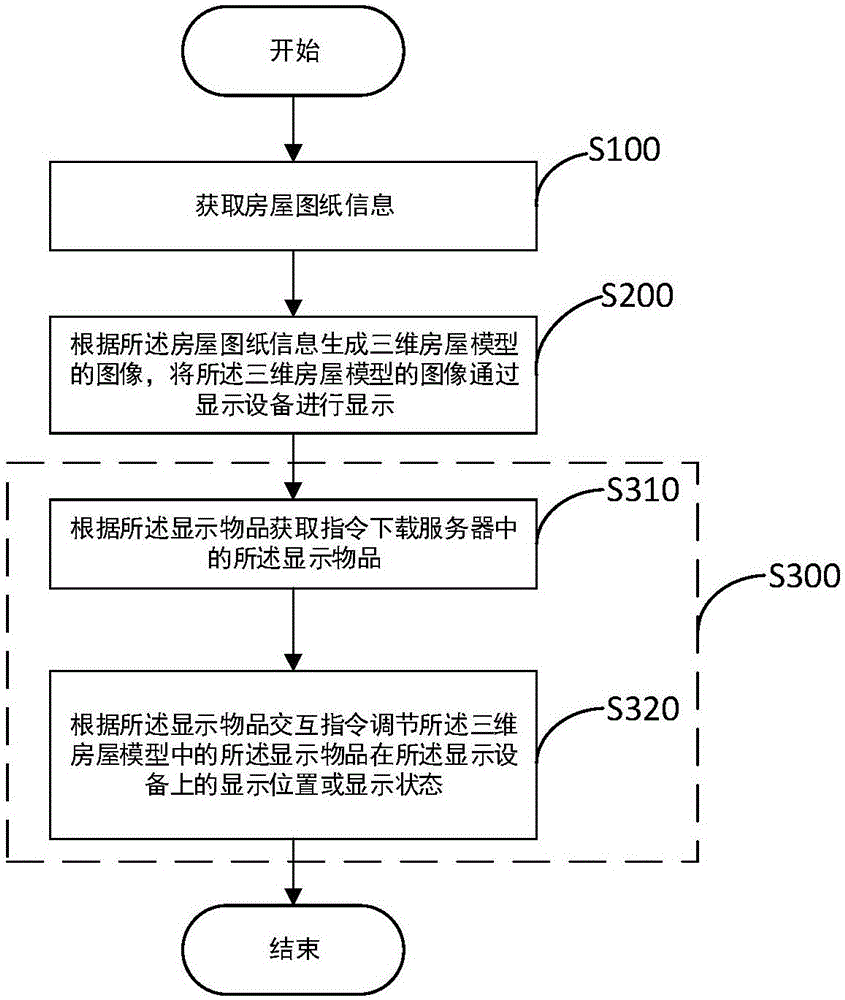

Data interactive method and device based on interactive roaming house decoration

ActiveCN106683177ATo achieve the desired effectExpected decoration effectBuying/selling/leasing transactions3D modellingComputer technologyDisplay device

The invention provides a data interactive method and device based on interactive roaming house decoration, and belongs to the field of computer technology. The data interactive method based on the interactive roaming house decoration includes acquiring house drawing information; generating an image of a three-dimensional house model according to the house drawing information, and displaying the image of the three-dimensional house model through a display device; changing the display state of the three-dimensional house model on the display device or adjusting the display state of display items in the three-dimensional house model on the display device according to an acquired control instruction; and generating a three-dimensional housing model through two-dimensional plane drawings, the three-dimensional housing model being capable of being edited by a user. The invention can achieve the desired decoration effect of the user without requiring a lot of expense or a lot of time and energy from the user.

Owner:四川讯视科技有限公司

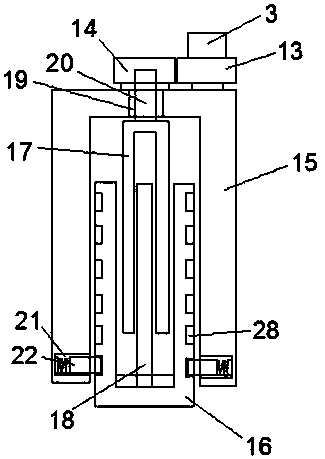

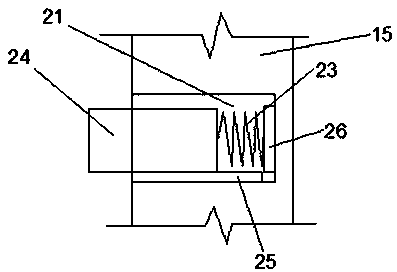

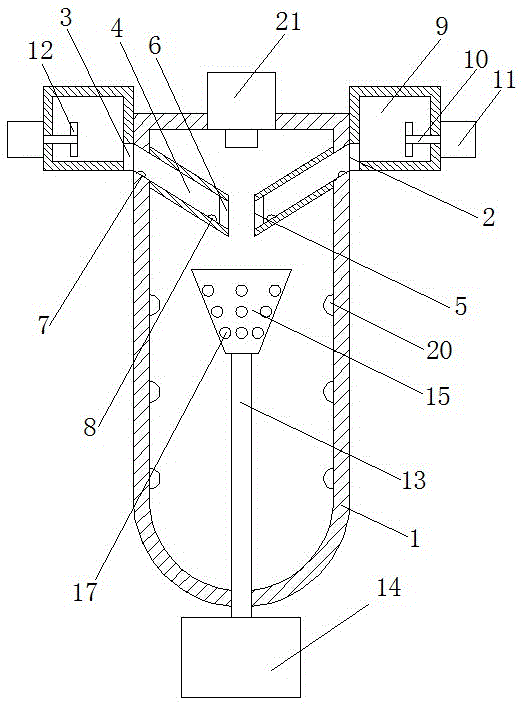

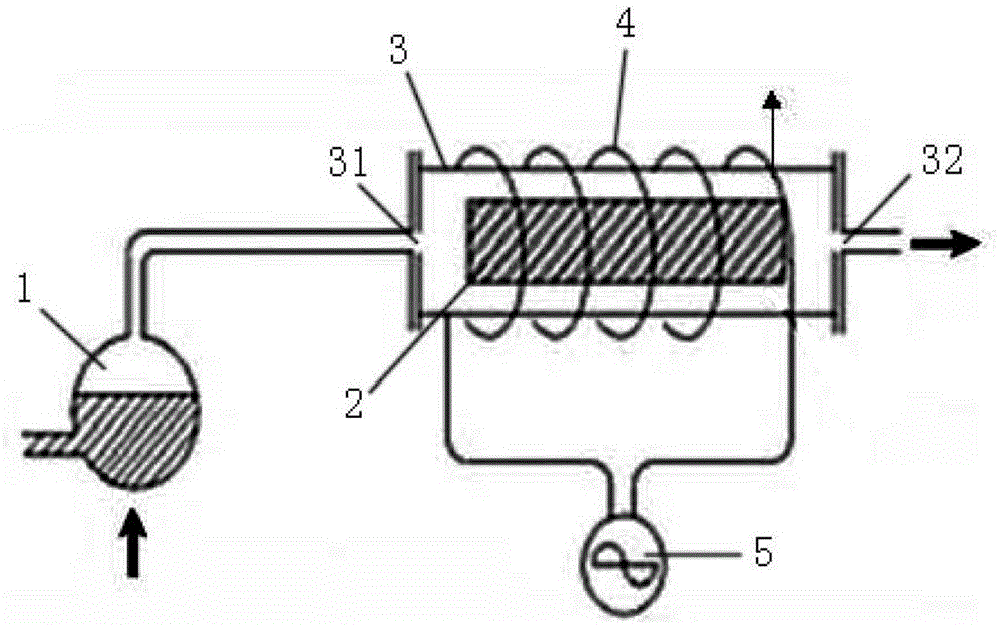

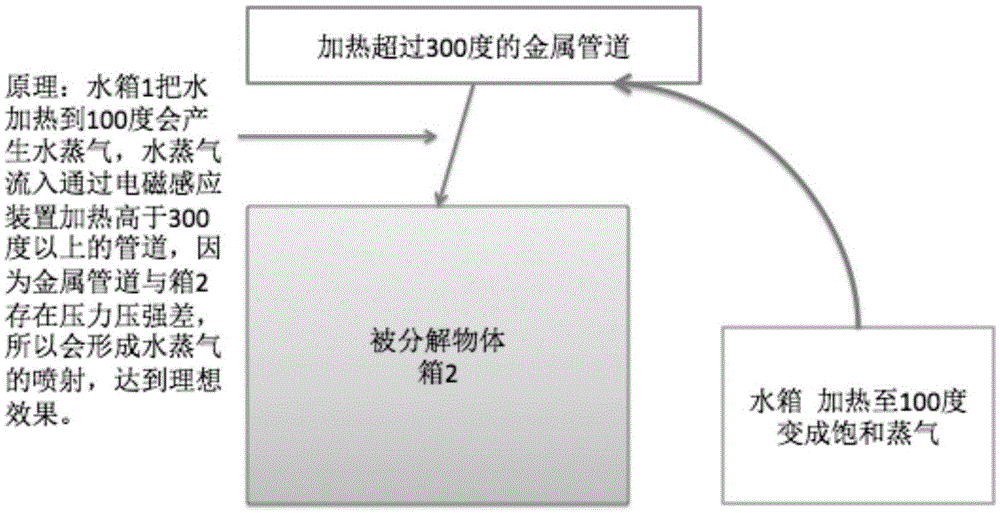

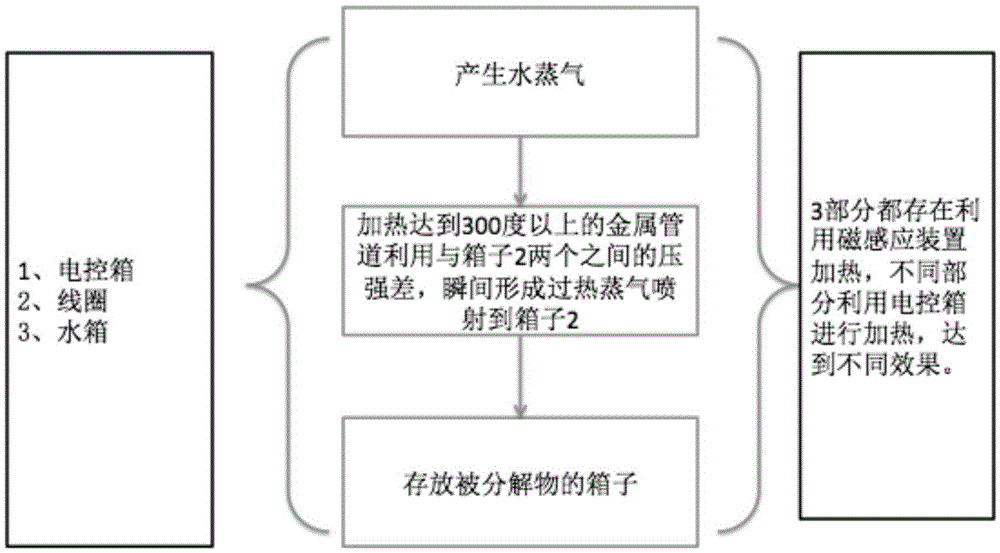

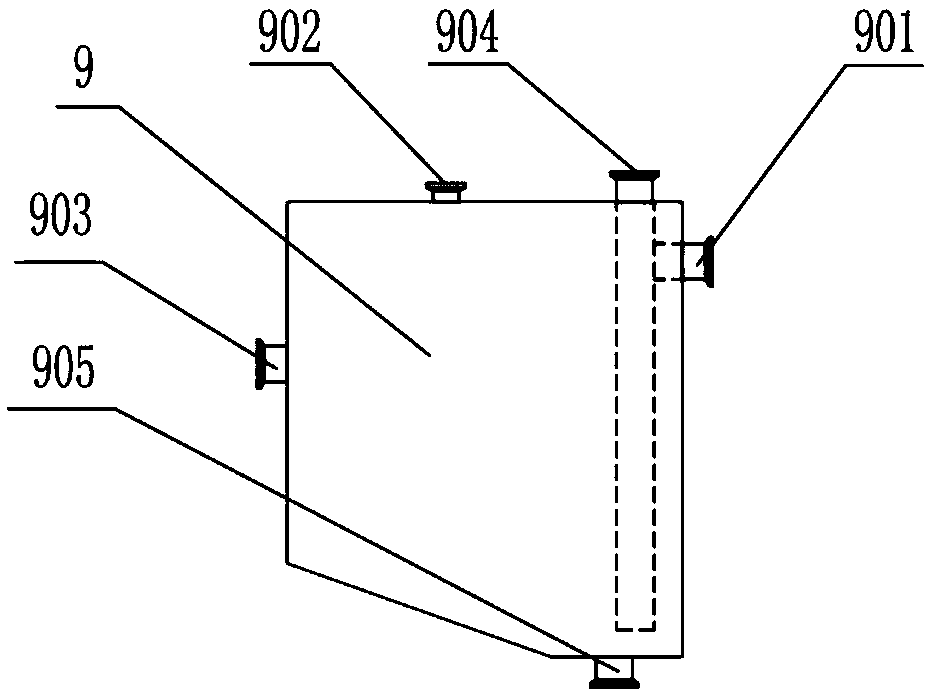

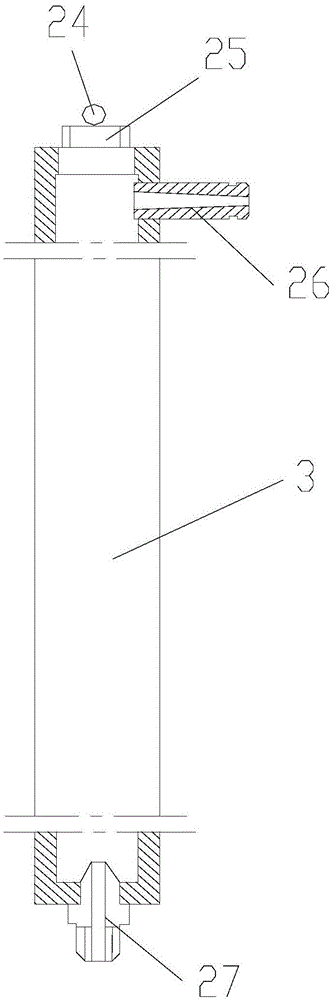

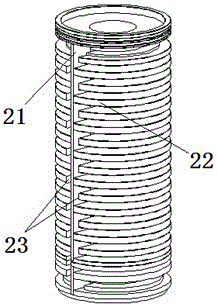

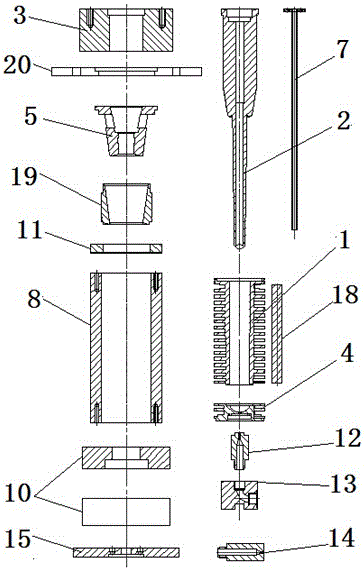

Program-controlled electromagnetic induction heating device and method for processing waste battery by using device

ActiveCN105576317AHeating evenlyEnvironmentally friendlyInduction heatingWaste accumulators reclaimingElectricityHeating effect

The invention discloses a program-controlled electromagnetic induction heating device. The program-controlled electromagnetic induction heating device is characterized by comprising a water tank, a metal pipeline and an accommodating tank, wherein a steam inlet and a steam outlet are respectively arranged at the two ends of the metal pipeline, the steam inlet is communicated with the water tank, a coil is wound outside the metal pipe, the two ends of the coil are electrically connected with an electric control box, the accommodating box is arranged in the metal pipeline, and a plurality of through holes are formed on the accommodating box. The invention also discloses a method for processing a waste battery by using the program-controlled electromagnetic induction heating device. In the program-controlled electromagnetic induction heating device, a mode of electromagnetic induction heating is adopted to heat the water tank and the metal pipeline, the electric control box is used for controlling a heating effect, and the program-controlled electromagnetic induction heating device has the advantages of environmental friendliness, high heating efficiency and heating uniformity.

Owner:GUANGZHOU BAOSHI WIRELESS POWER SUPPLYING TECH CO LTD

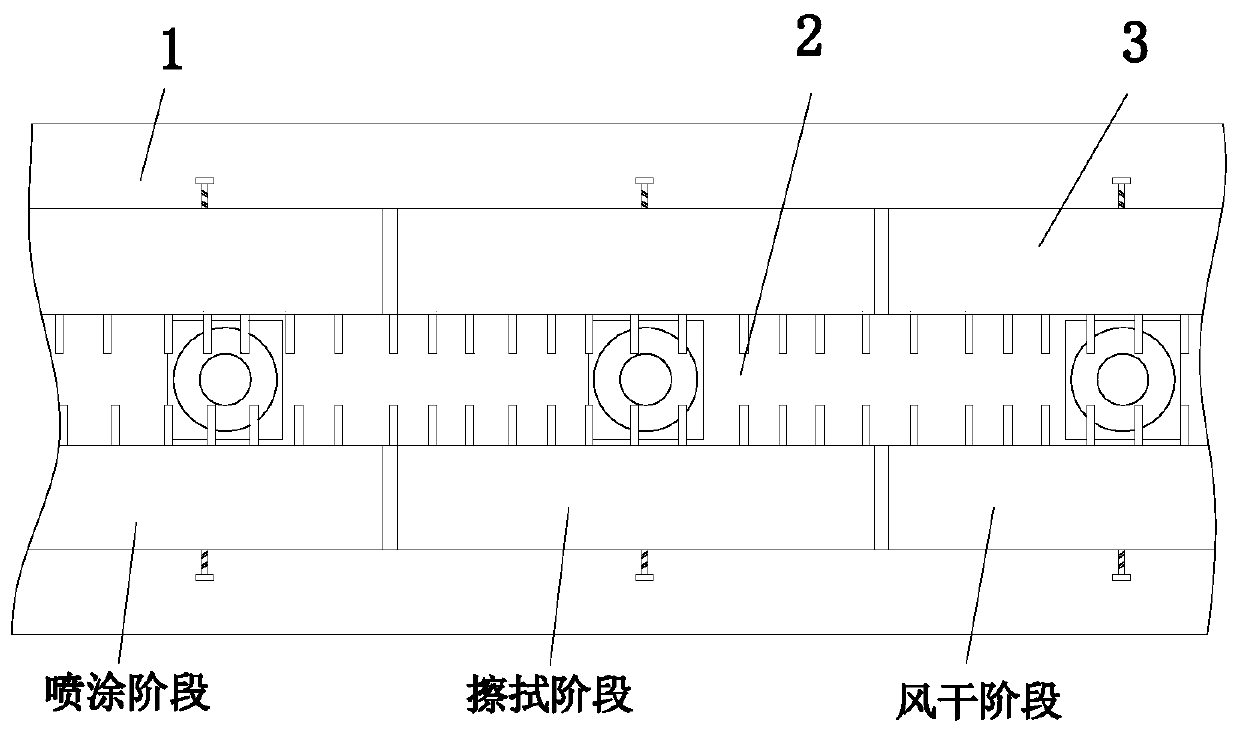

Ceramic product external surface treatment system and method

ActiveCN110385776ARealize the function of processingImplement different processing functionsCeramic shaping apparatusMetallurgyTreatment period

The invention relates to a ceramic product external surface treatment system and method. The system comprise a bottom plate, a conveying device and surface treatment devices, a groove is formed in themiddle of the bottom plate, the conveying device is arranged in the groove, the surface treatment devices are arranged above the conveying device, and the surface treatment devices are symmetricallyarranged on the bottom plate. The problems that when existing equipment is used for treating the ceramic surface, deformation adjustment cannot be carried out according to the shape of the ceramic surface, and the treatment device cannot be matched with the ceramic, so that ceramic glazing is uneven and the ceramic firing effect is influenced can be solved, meanwhile, the problems that a step-by-step processing mode is generally adopted, and brushing, wiping and air drying equipment are needed for processing respectively, so that long ceramic surface treatment period, high using cost and the like are caused are solved, and the ceramic product external surface treatment system and method have the advantages of being low in using cost, high in working efficiency and the like.

Owner:景德镇饶玉陶瓷文化传播有限公司

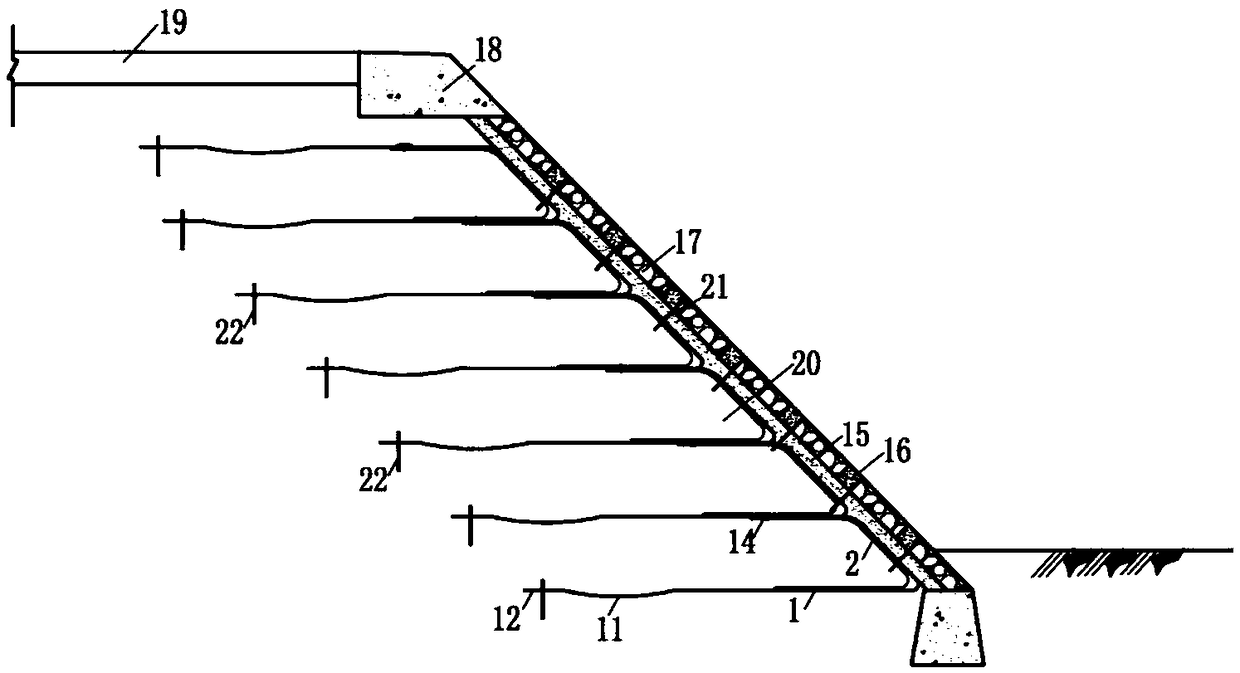

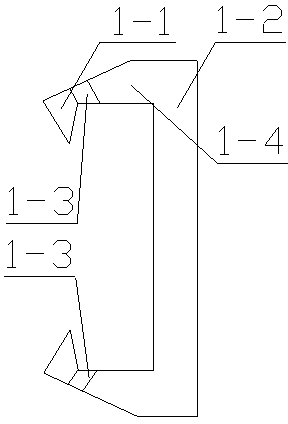

Geogrid steep slope embankment structure with wrapped faces and construction method thereof

The invention discloses a geogrid steep slope embankment structure with wrapped faces. A plurality of geogrid layers with the wrapped faces are arranged on the free face of a side slope in a vertically-stacked mode, thick gravel cushion adjusting layers and square grid precast blocks are sequentially laid on the outer sides of the geogrid layers with the wrapped faces, and the square grid precastblocks are filled with grait; and each geogrid layer with the wrapped face comprises a geogrid, wherein the section of each geogrid is of a trapezoidal-groove structure with one side open, and the closed end of each geogrid is located on the free face of the side slope. The tail end of the each geogrid is fixed to a roadbed, and a geotechnical cloth is laid on the inner wall of each geogrid and filled with a gravelly soil roadbed filler. The problems that in the laying process of the geogrids, soil nearby the free face is difficult to compact, and the labor and time are wasted in grid stretching are solved through a geogrid reinforcement soil structure which better facilitates the geogrids to give full play to the reinforcement property and thus improve the stability of the reinforced steep slope embankment, and a matched construction technology.

Owner:新疆维吾尔自治区交通规划勘察设计研究院

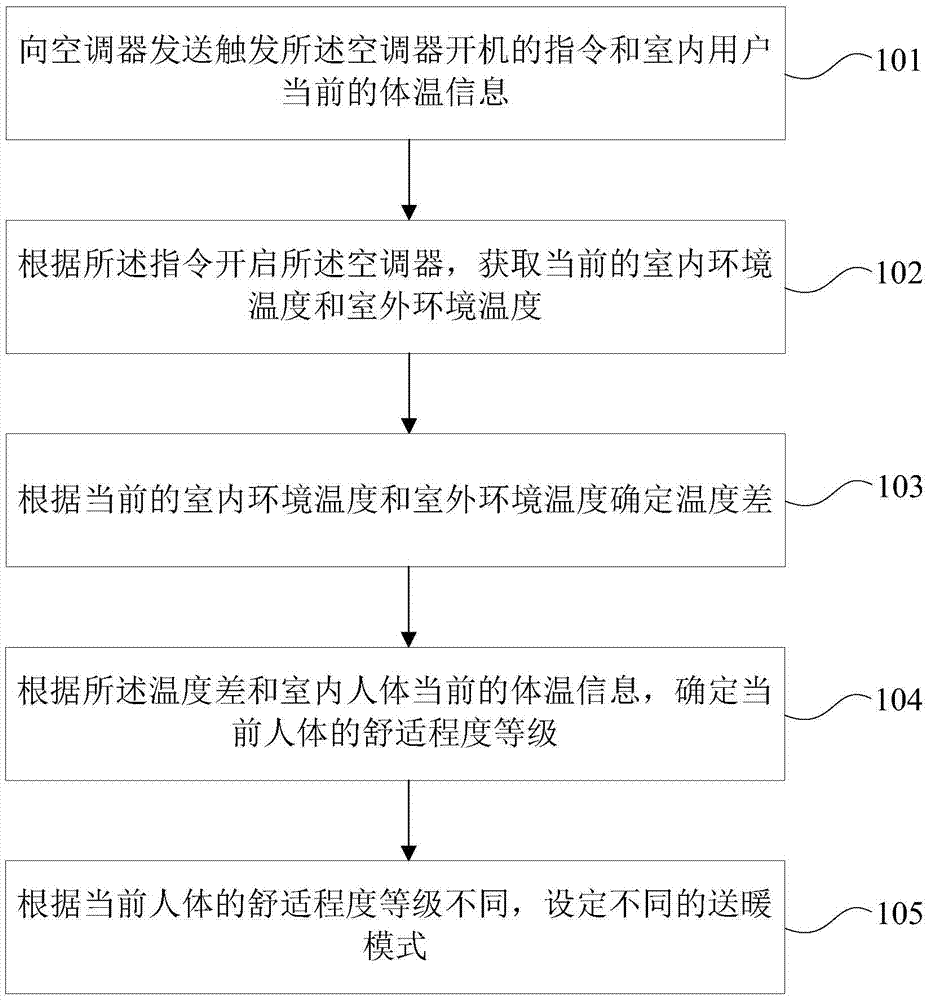

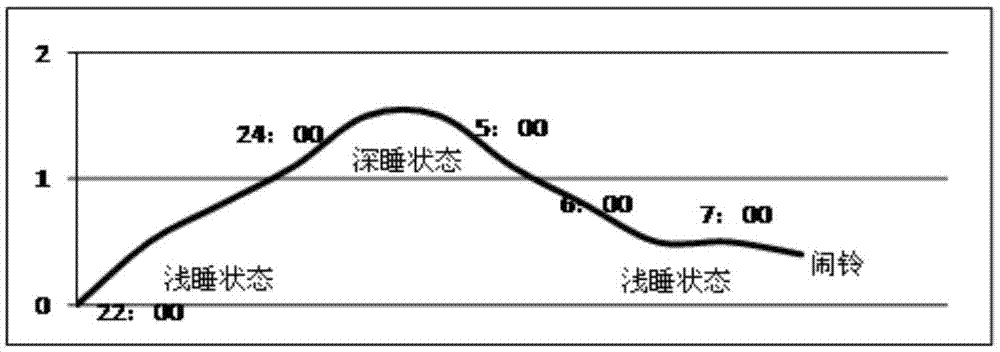

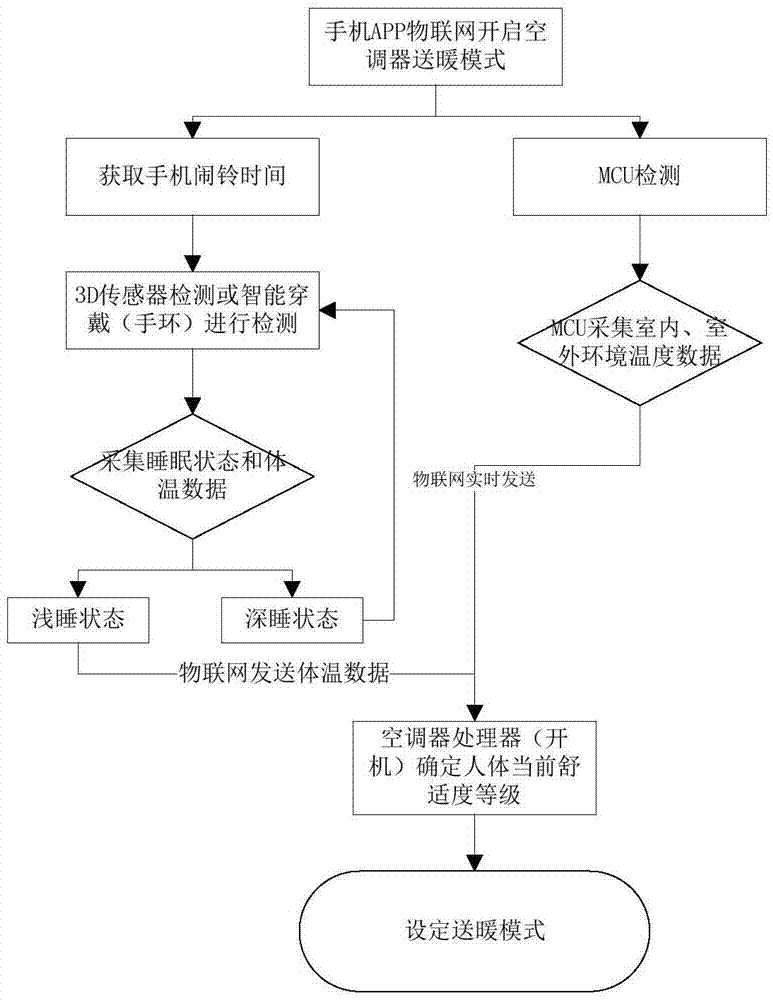

Air-conditioner heating control method and device

ActiveCN107101318AImprove efficiencyMeet needsMechanical apparatusSpace heating and ventilation safety systemsTemperature differenceHeat control

The invention discloses an air-conditioner heating control method and a device. The air conditioner heating control method comprises the steps of sending an instruction for triggering an air conditioner to start up and the current body temperature information of an indoor user to the air conditioner, starting up the air conditioner according to the instruction, acquiring the current indoor environment temperature and the outdoor environment temperature, determining a temperature difference according to the acquired current indoor environment temperature and the outdoor environment temperature, determining the current comfort degree level of a human body according to the temperature difference and the current body temperature information of the human body, and setting different heating modes according to different current comfort degree levels of the human body. The air-conditioner heating control method provided by the invention can maximally bring comfortable experience for the user, is beneficial to meeting the user demand, and achieves an ideal effect for the user.

Owner:GREE ELECTRIC APPLIANCES INC

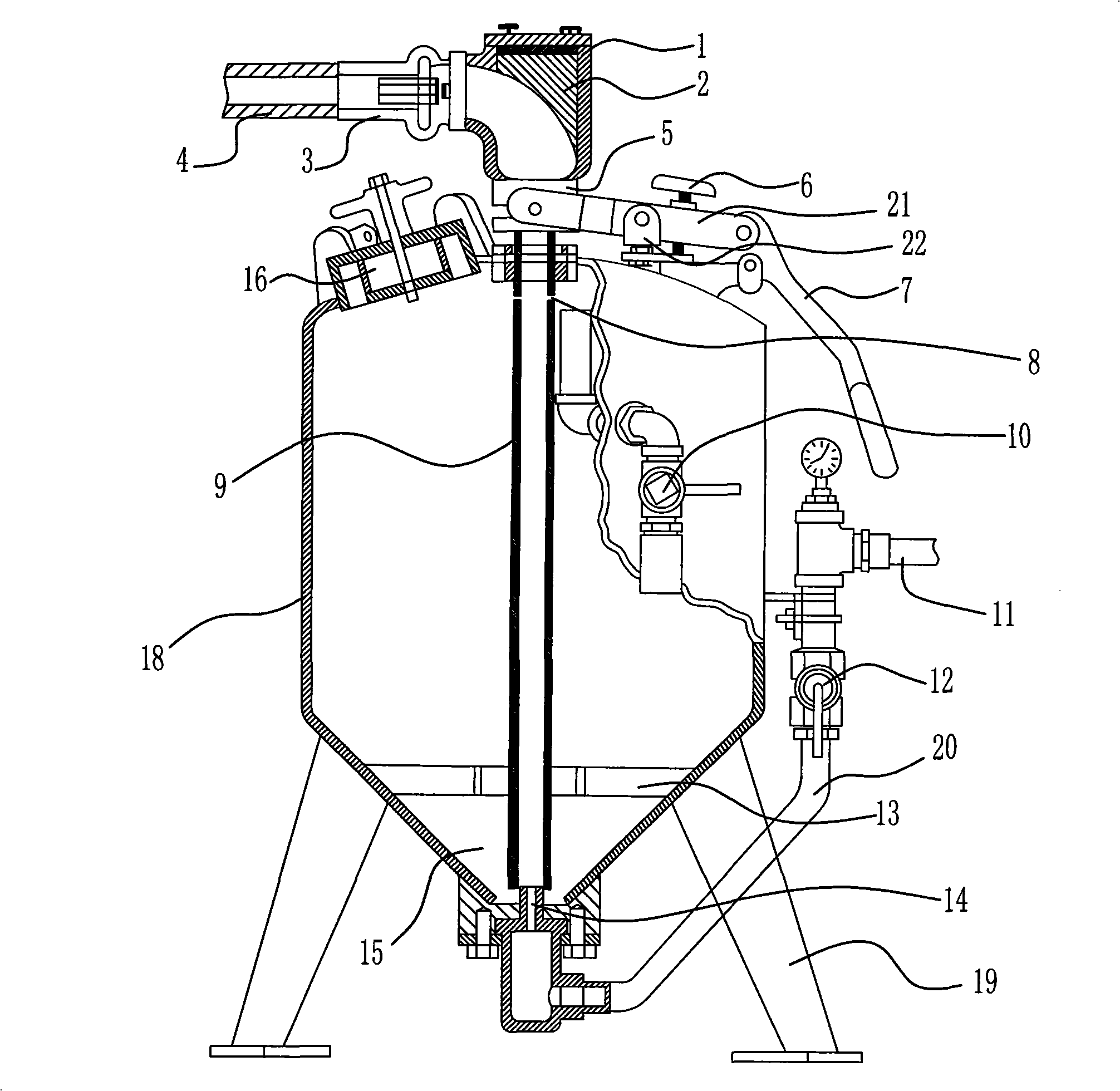

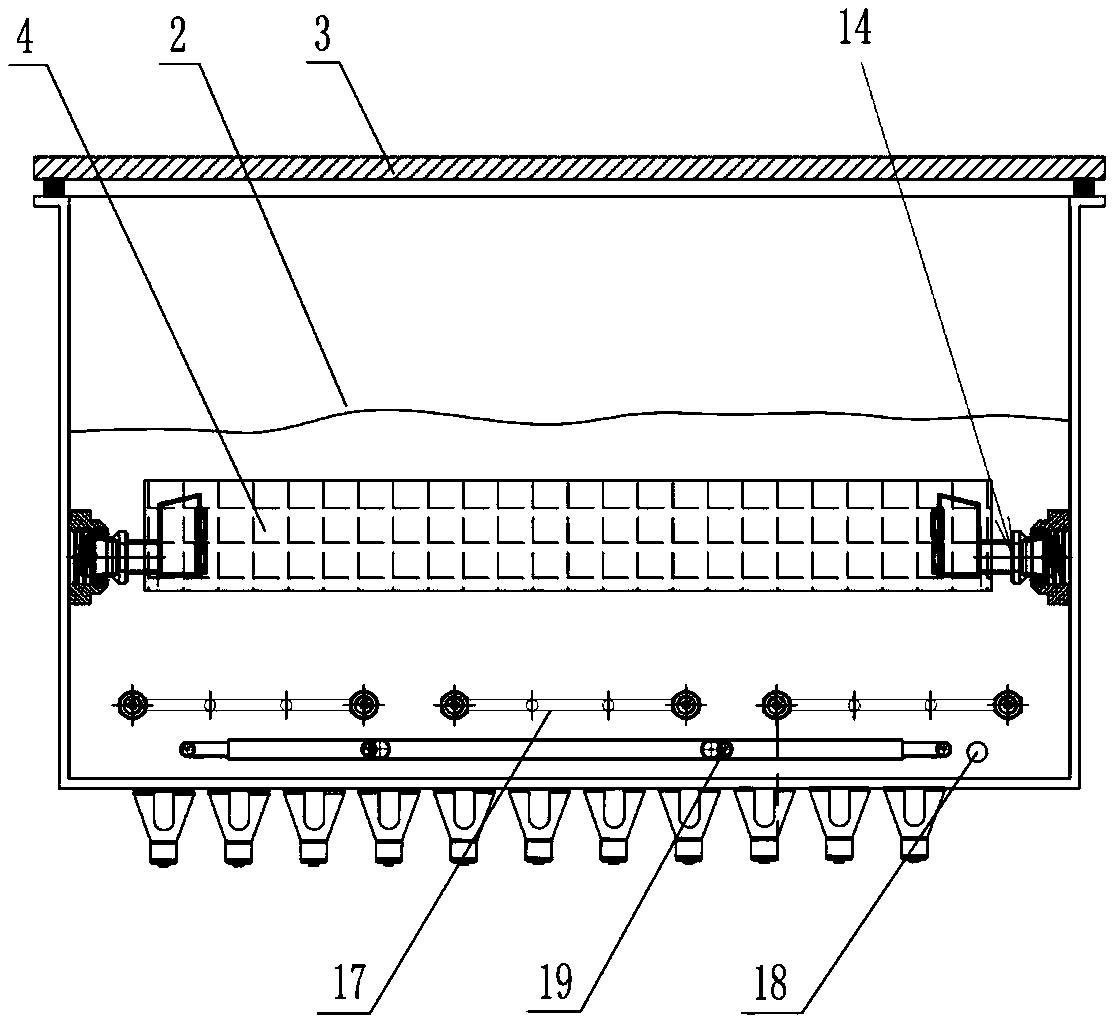

Environmental-protecting type high-efficient cleaning system

The invention relates to a cleaning system. The main cleaning machine of the cleaning system comprises a tank body which is communicated with a water source and is supported by arm braces. An air input nozzle is extended into the bottom of the tank body in a sealed mode and the lower port of the nozzle is communicated with an air holder and an air compressor through pipelines and control valves; the top surface of the tank body is provided with a cleansing medium adding port and the adding port is spirally connected with a cover in a sealed mode; an input pipe is extended into the tank body along the top of the tank body, the lower port of the input pipe is opposite to the upper port of the nozzle, and the input pipe is in movable fit with the tank body in a sealing mode; an output pipe inside the tank body is provided with exhaust holes, and the top end of the output pipe outside the tank body is hinged with a flow regulating mechanism; the upper port of the output pipe is fixedly connected with a crossover sub which is fixedly connected with an output elbow; an outlet of the output elbow is fixedly connected with a pipe coupling port which is fixedly connected with a spray feeding pipe; and the spray feeding pipe is communicated with a spray gun; and an air pressure release valve fixedly assembled on the outer wall of the tank body is communicated with the inside of the tank body. The cleaning system can be applied to a plurality of trades, and has the advantages of environmental protection, economical efficiency, and high efficiency.

Owner:衡钟龙

Full-automatic oolong tea production equipment

ActiveCN102669317ASmooth connectionIncrease productivityPre-extraction tea treatmentSingle processMolding machine

The invention discloses full-automatic oolong tea production equipment comprising a feeding hopper, a sunning device, a green leaf rocking device, an enzyme deactivation device, a kneading device, an automatic molding machine, a combined drying device and a control box for controlling all the parts, wherein the feeding hopper, the sunning device, the green leaf rocking device, the enzyme deactivation device, the kneading device, the automatic molding machine and the combined drying device are sequentially connected. According to the invention, machining equipment of each single process is sequentially connected to be combined to form a whole system; the machining equipment of two adjacent processes can be better engaged; when the full-automatic oolong tea production equipment is used, fresh tea can be automatically and sequentially subjected to the processes of sunning, green leaf rocking, enzyme deactivation, kneading, molding and the like to finally prepare a finished product; and the full-automatic oolong tea production equipment can be completely automatically operated, not only has high production efficiency, but also greatly reduces the labor cost.

Owner:FUJIAN ANXI YUNHE MECHANICS

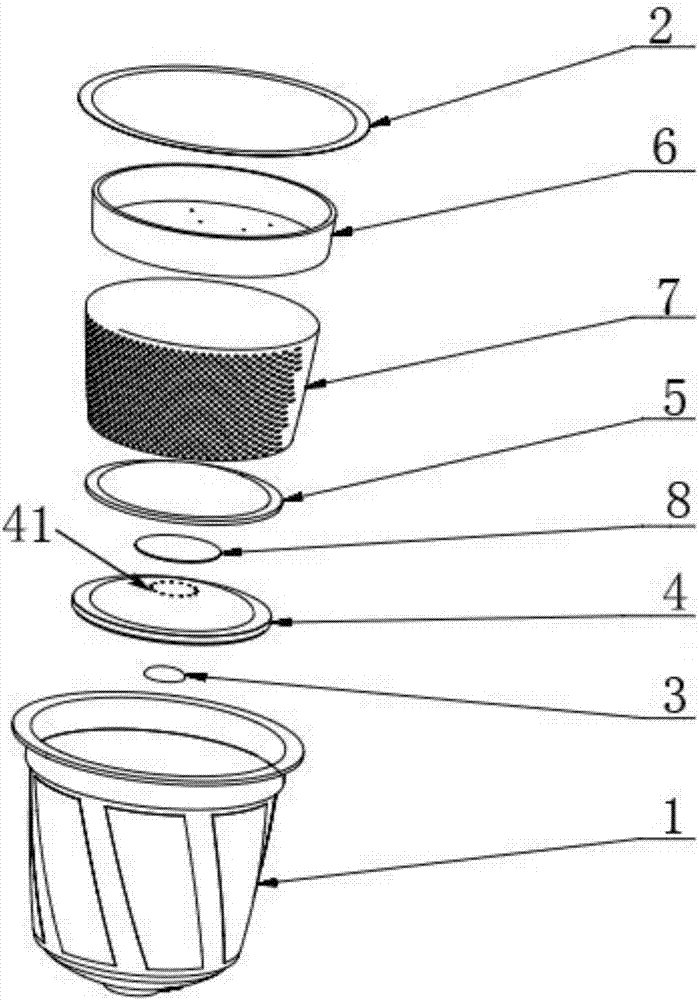

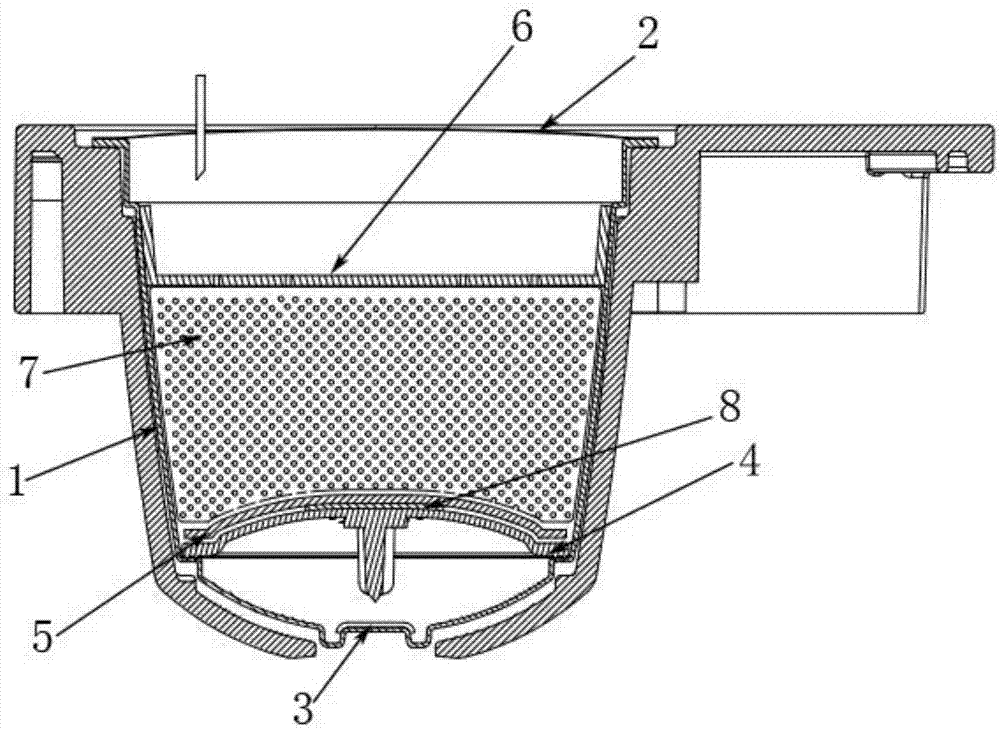

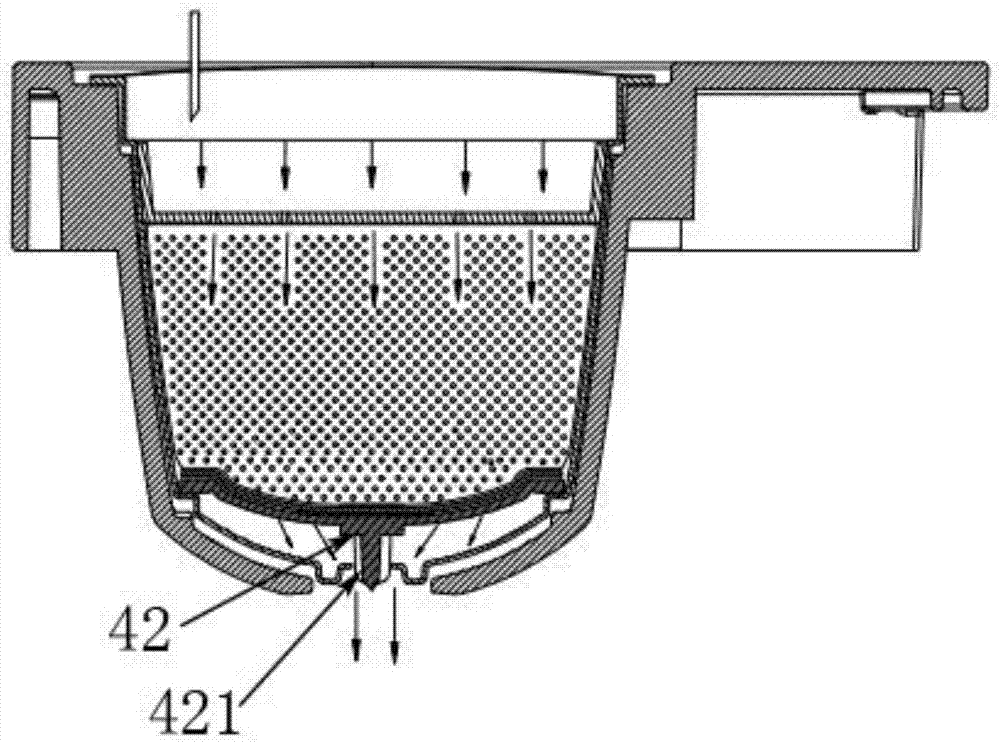

Beverage container pierced by internal deformation and beverage preparation method thereof

ActiveCN106983369AMeet the needs of different extraction pressuresAchieve the purpose of piercingBeverage vesselsEngineeringContamination

The invention discloses a beverage container priced by internal deformation and a beverage preparation method thereof. The container comprises a cup body, a material storage area arranged in the cup body, a top end seal member arranged on the top of the cup body and a bottom end seal member arranged on the bottom end of the cup body, wherein a filter pan in an arch shape is arranged between the bottom end seal member and the material storage area; the right upper part, corresponding to the a puncturing needle bottom end seal member, of the bottom end of the filter pan is provided with a puncturing needle. According to the beverage container pierced by the internal deformation and the beverage preparation method thereof, the expected effect can be achieved with lower cost; liquid directly reaches a cup when the liquid flows out from a capsule, so as to avoid the problems of contamination and odor tainting because the liquid flows through multiple channels; by using filter structures with different air permeability, the extraction pressure of the capsule is controlled to satisfy the requirements of the different extraction pressures of a plurality of Italy-typed and America-typed capsules.

Owner:SHENZHEN DINGJIA HONGSI BEVERAGE TECH CO LTD

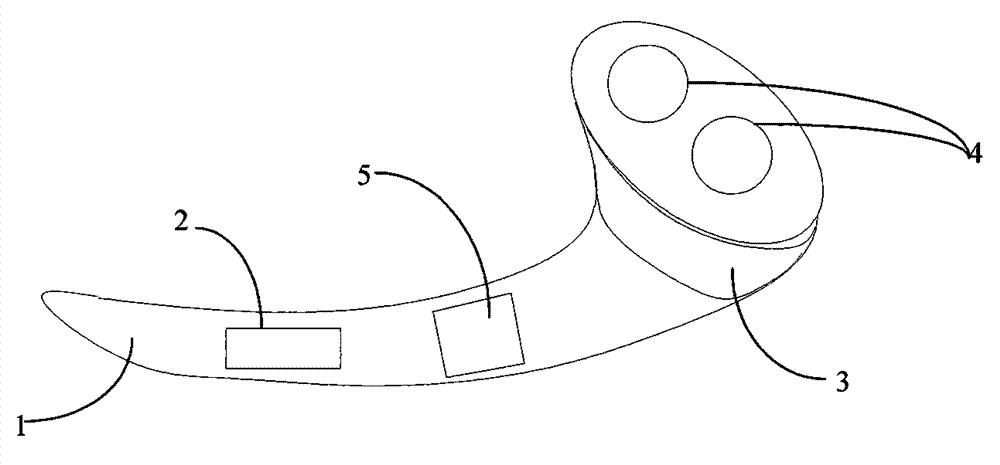

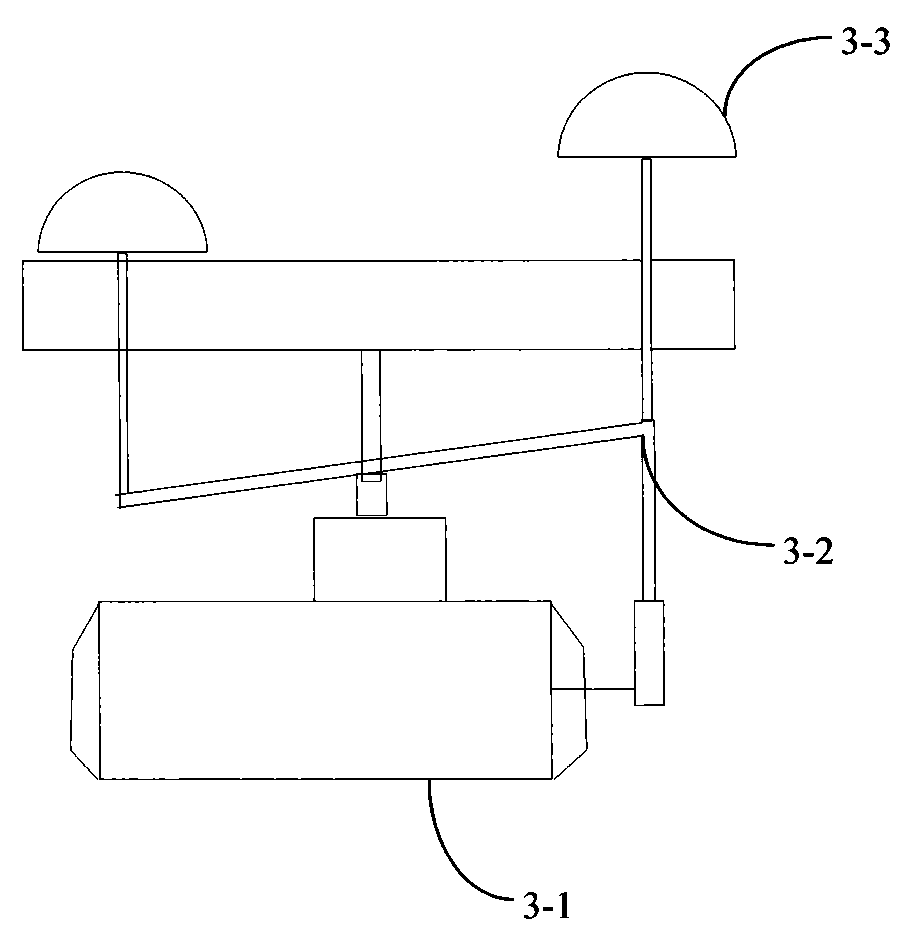

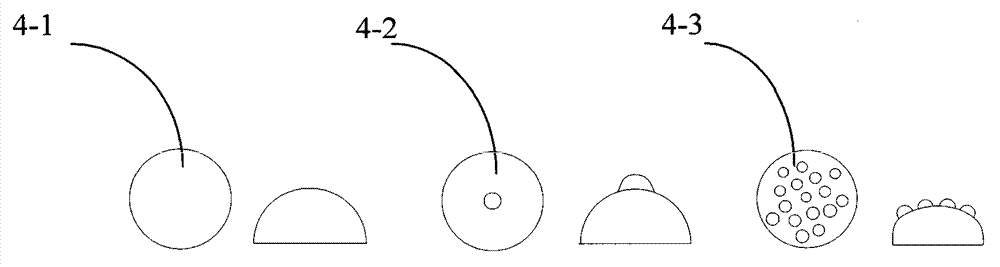

Massage device for neurology department

InactiveCN103919674ASimple structureReasonable designVibration massageNeurology departmentDisplay device

The invention discloses a massage device for the neurology department. Two structures of the massage device for the neurology department are provided. According to the first structure of the massage device for the neurology department, the massage device comprises a handle, a frequency control device, a vibration device, massage heads and a display device. According to the second structure of the massage device for the neurology department, the massage device comprises a support, a first shell, a second shell, a hinge, a massage face, massage heads, a lock catch, a control device, an inflation adjusting button, a speed changing button and a switch. The frequency control device and the display device are installed on the handle, the massage heads are arranged at the top end of the handle, the vibration device is arranged between the handle and the massage heads, and the vibration device is connected with the massage heads. According to the massage device for the neurology department, the frequency control device is adopted, various frequencies and various intermittent frequencies are achieved, a user can adjust the frequency as needed, stepless speed regulation is achieved, and therefore the effect needed by a patient can be achieved; in addition, the dual-vibrating replaceable massage heads are adopted, different massage heads can be replaced according to different parts, needing massage, of the patient, and the purpose that a massager is multipurpose is achieved.

Owner:朱守莲

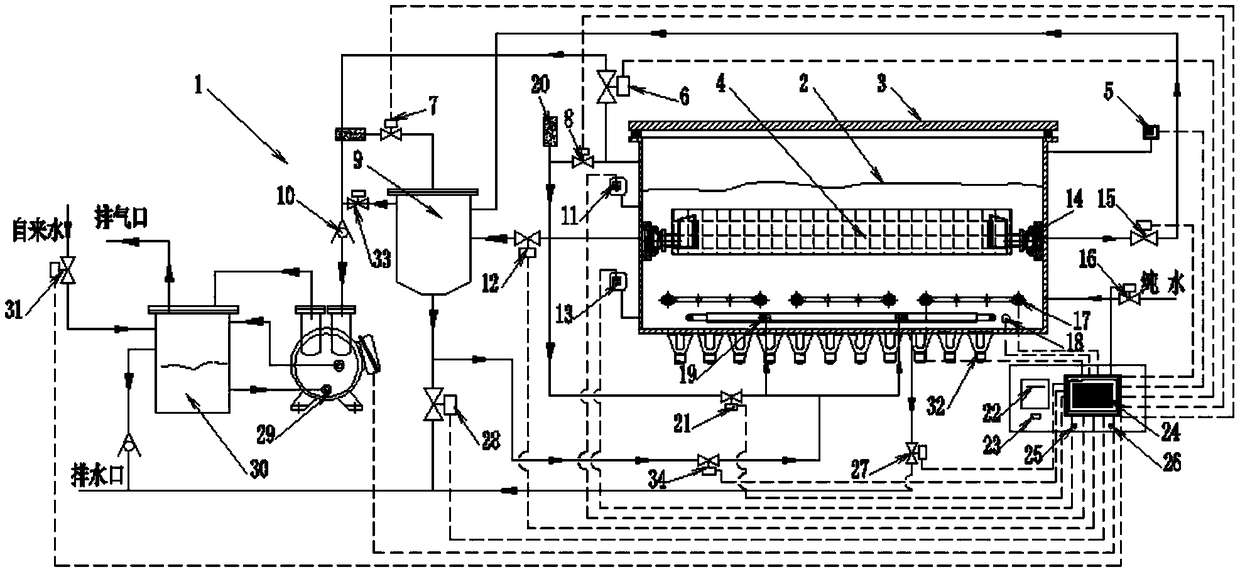

Cleaning method of multistage variable-voltage pulse cleaning system

PendingCN108714589AImprove cleaning efficiencyGuaranteed cleaning qualityCleaning using liquidsVacuum pumpingVoltage pulse

The invention provides a cleaning method of a multistage variable-voltage pulse cleaning system. The cleaning method mainly comprises the following working procedures that firstly, liquid supplementing is carried out, wherein an object to be cleaned is placed in a cleaning cabin, a cleaning cabin cover is closed, and then a cleaning liquid is supplemented; secondly, heating is carried out, whereinwhen the cleaning liquid reaches a set liquid level, a heater is started to enable the temperature to rise to 45-55 DEG C; thirdly, vacuum pulse tank pumping is carried out, wherein a tank pumping valve is opened, a vacuum pump is started for pressure pumping, when high negative pressure is formed inside a vacuum tank, a gas-breaking valve is opened firstly, then a pulse valve is opened, the cleaning liquid is instantly poured into the vacuum tank, and forward pulse flushing is formed; fourthly, vacuum pulse pumping back is carried out, wherein the tank pumping valve, the gas-breaking valve and the pulse valve are closed, a vacuum-pumping valve is opened, the vacuum pump is started for pressure pumping, when high negative pressure is formed inside the cleaning cabin, a tank breaking valveand the pulse valve are opened, the cleaning liquid in the vacuum tank is instantly reversely flushed into the cleaning cabin, and reverse pulse flushing is formed. According to the cleaning method,labor is saved, the operation is simple and convenient, and the cleaning effect is good.

Owner:深圳市美雅洁技术股份有限公司

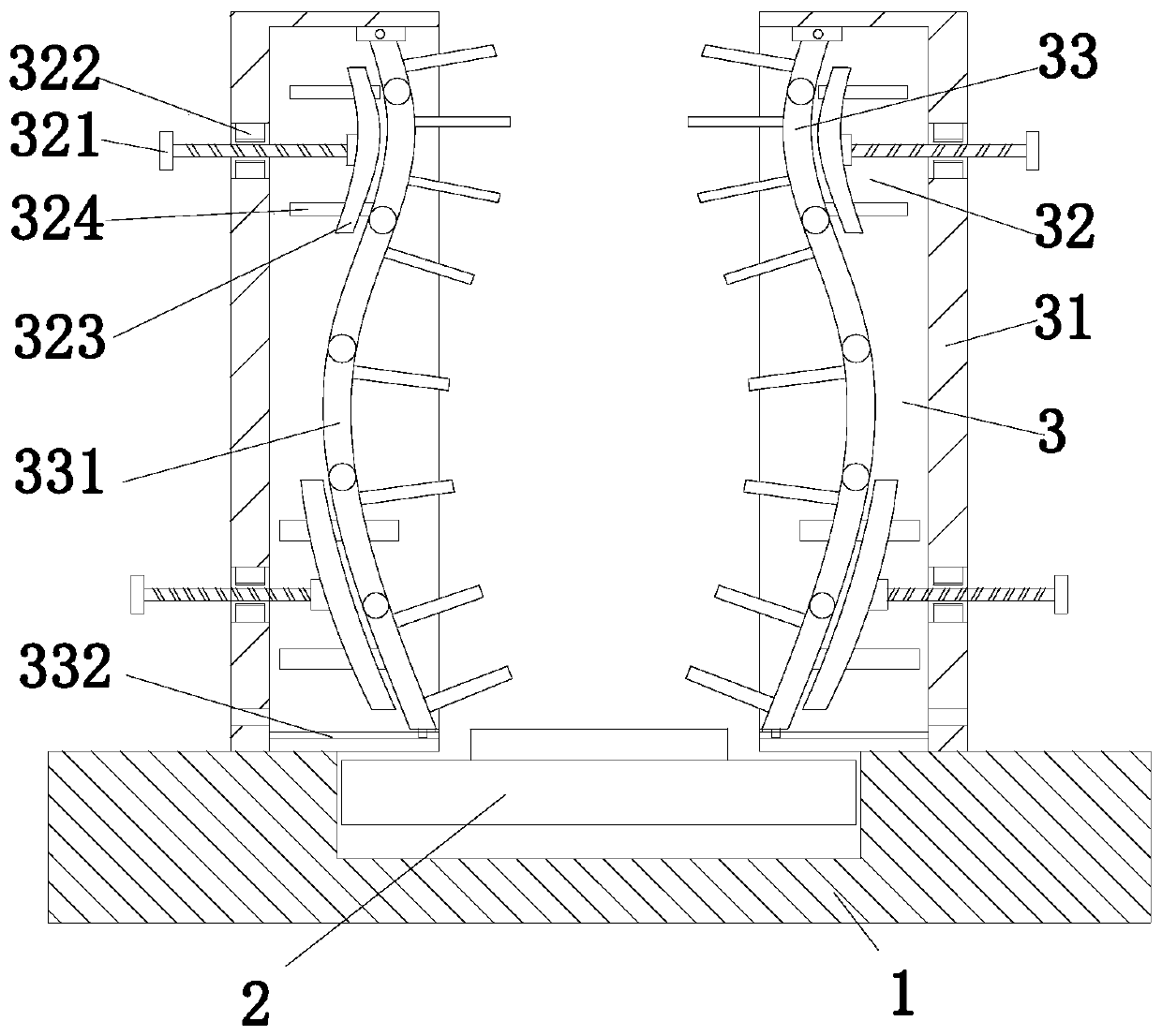

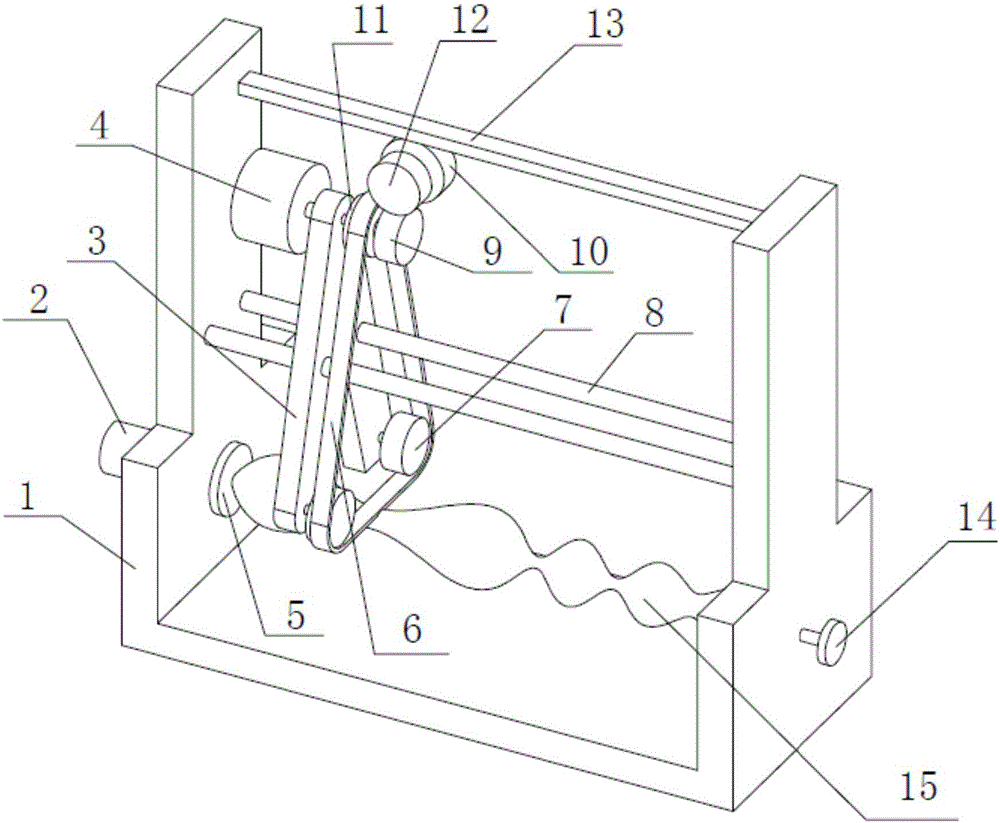

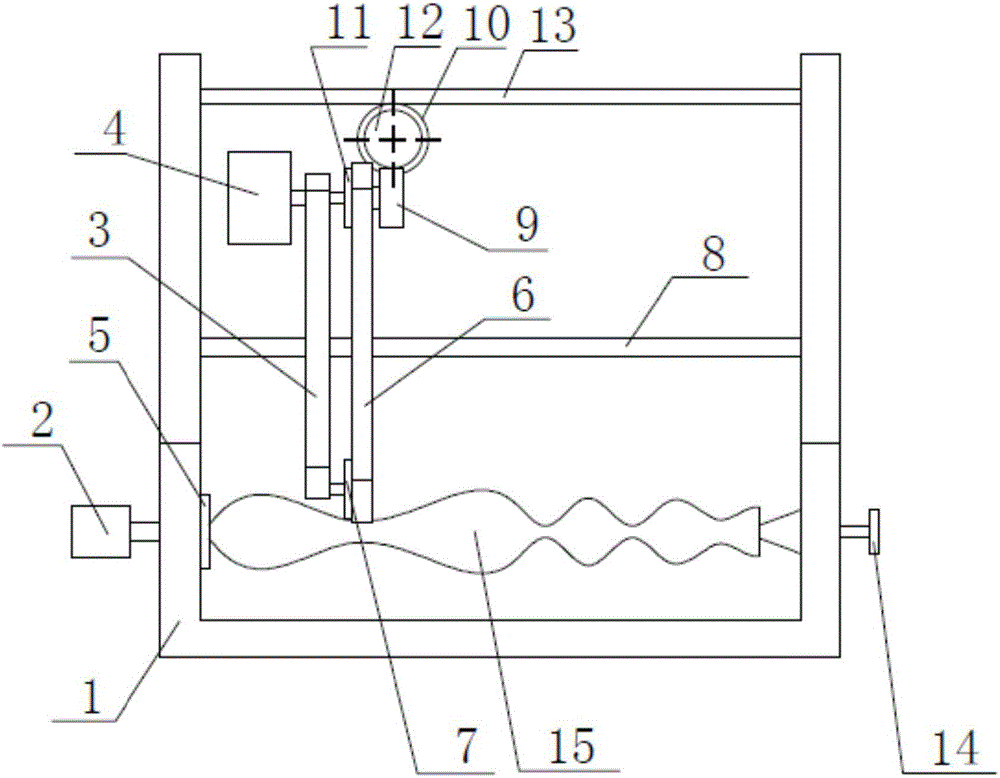

Bar polishing equipment

InactiveCN106737027ATo achieve the desired effectImprove grinding effectGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention provides bar polishing equipment. The bar polishing equipment comprises a rack, a bar clamping and rotating device, a polishing device and a sliding device, wherein the bar clamping and rotating device is used for clamping bars and making the bars rotate around the central axes; the polishing device is used for polishing the bars which are clamped on the bar clamping and rotating device and arranged above the bar clamping and rotating device; and the sliding device can make the polishing device slide in the axis direction of the bars. According to the bar polishing equipment, the bars are made to rotate at a high speed and polished through a polishing belt, the polishing belt moves in the direction opposite to the rotating direction of the bars under the effect of a belt wheel, and thus a better polishing effect is achieved; and the polishing belt moves in the axis direction of the bars along with a sliding frame so that key portions of the bars can be polished repeatedly, and an ideal effect is achieved.

Owner:TIANJIN YAXING FURNITURE

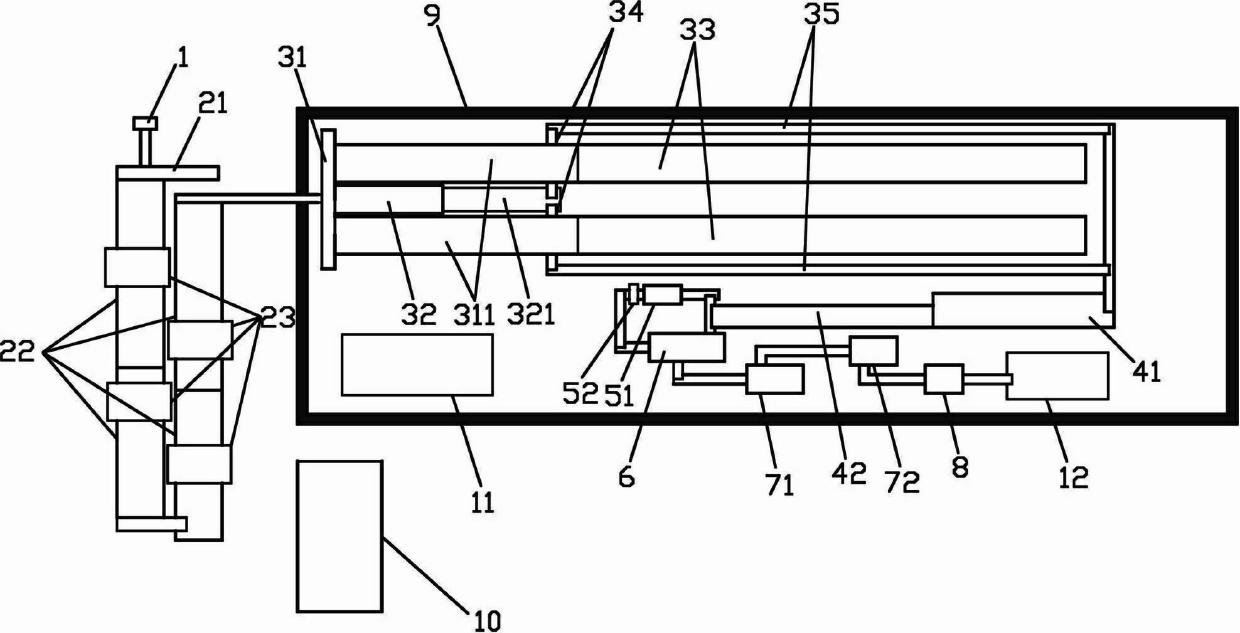

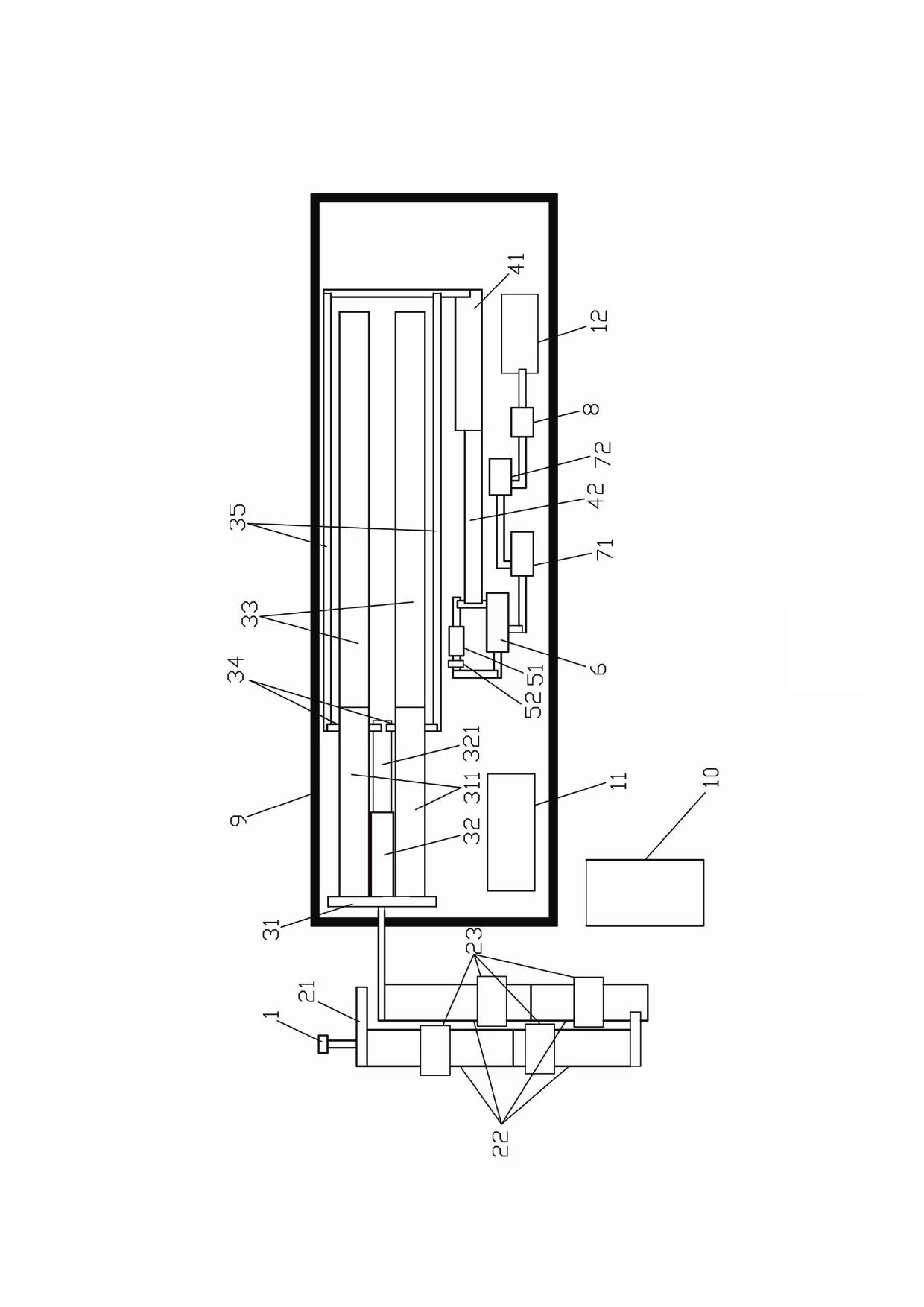

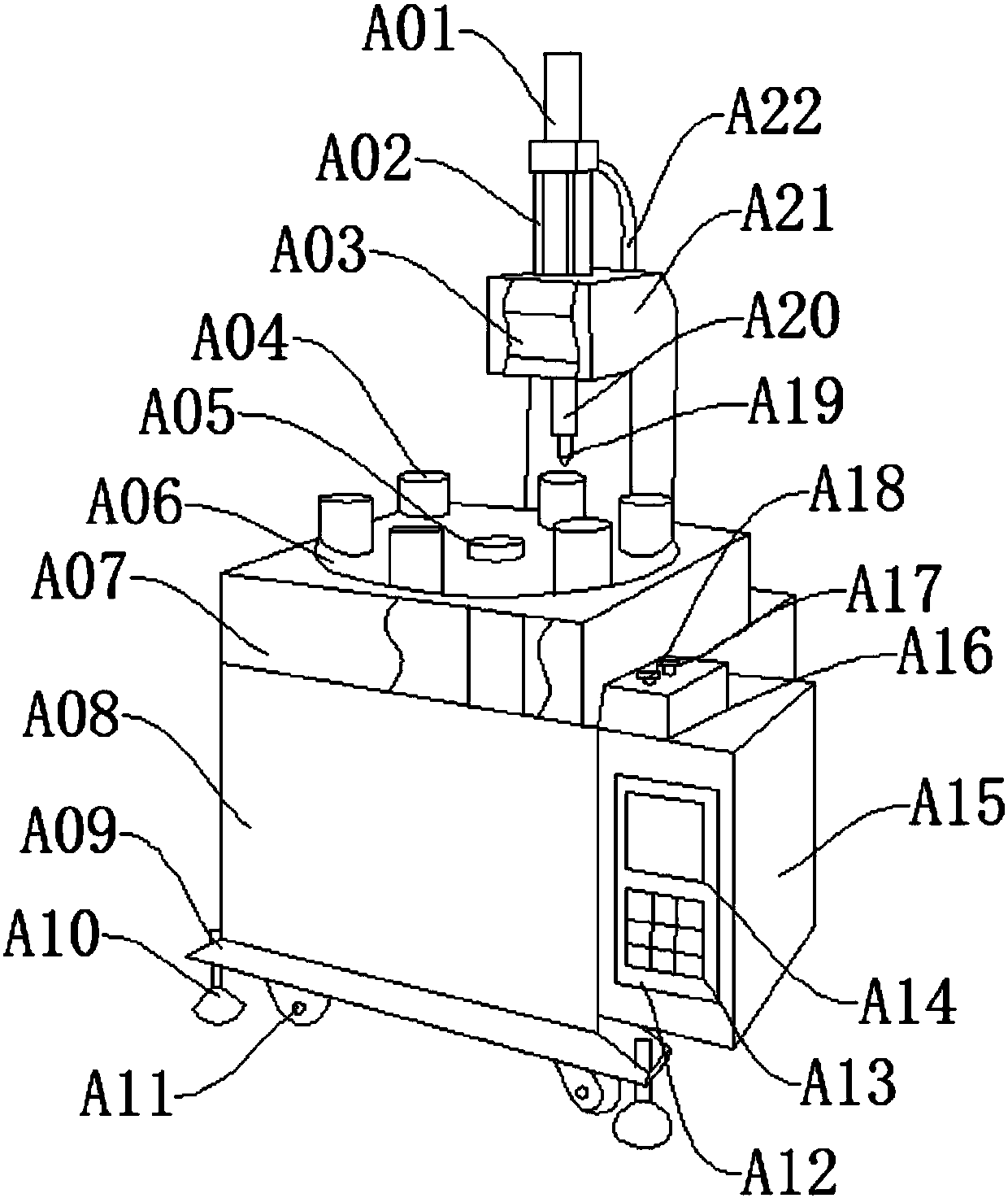

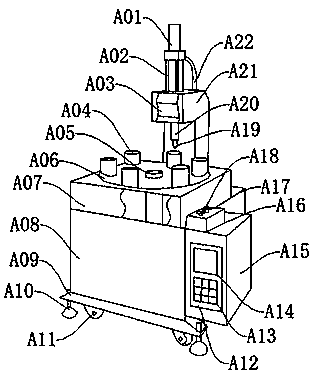

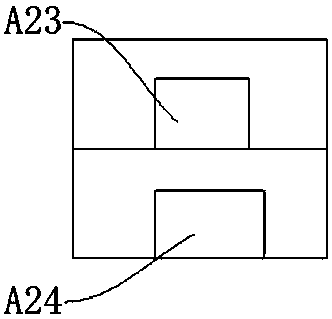

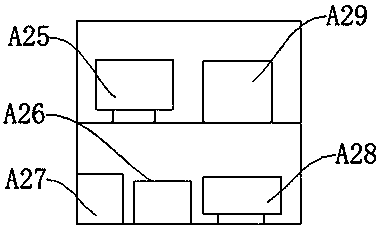

Metal marking machine capable of automatic locating and application method thereof

InactiveCN108015429AFully mechanized operationAccurate locationLaser beam welding apparatusElectric machineEngineering

The invention provides a metal marking machine capable of automatic locating and an application method thereof. The metal marking machine comprises a base, a case, a control cabinet and a scanner. Four corners of the lower end of the base are equipped with wheels. Support pads are arranged at positions, close to the wheels, of the lower end of the base. The middle part at the upper end of the baseis provided with the case. The case is internally equipped with a first motor, a speed changer, a second motor, an oil pump and an oil tank. The middle part at the upper end of the case is equipped with an operation table. The middle part in the operation table is equipped with rotary disk. The middle part in the rotary disk is provided with a rotary shaft. The design of a rotary shaft and locating blocks is adopted. Due to the design, the rotary shaft performs motion relative to the locating blocks. Even if a metal workpiece is not placed right, the metal workpiece can be driven to perform motion according to the set route. Without regulating the position, marking operation is finished. The overall process is performed in a mechanized manner. Therefore, the position is more precise and workers feel more at ease.

Owner:湖州利明五金机电设备有限公司

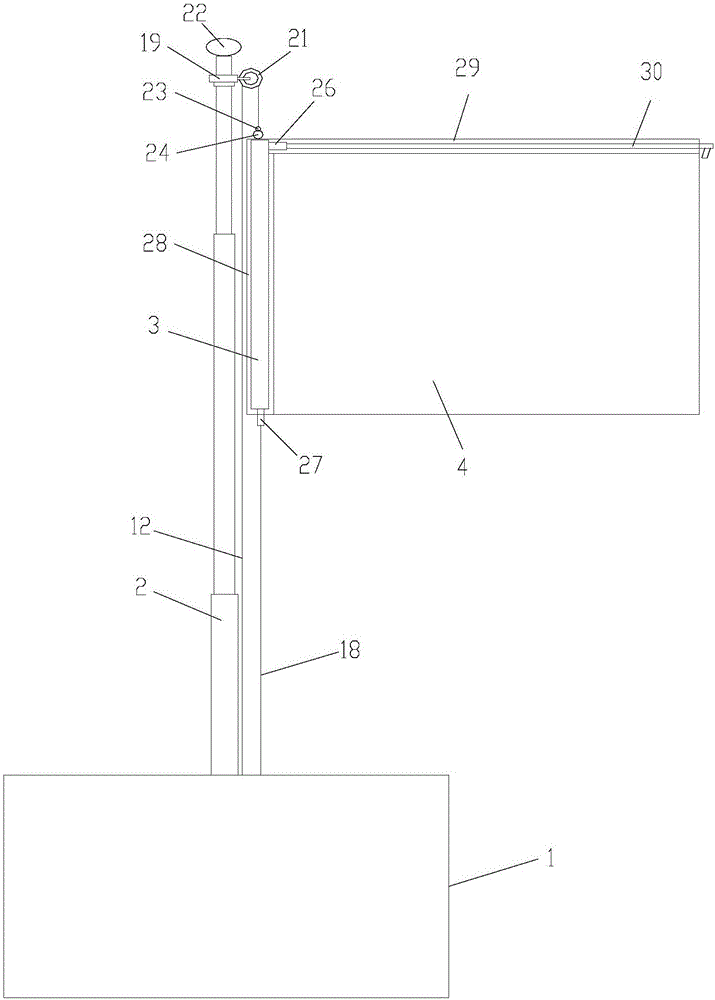

Unfolding and waving device for flag

ActiveCN106297598ACover up traces of artificial coercionPlay the role of "Gang Ju Mu Zhang"Flags/bannersEngineeringWinch

The invention provides an unfolding and waving device for a flag. The unfolding and waving device consists of a flag pole base, a main flag pole, an auxiliary flag pole and a flag, wherein a fixed pulley is arranged at the top of the main flag pole; a flag hoisting winch mechanism, a flag falling winch mechanism and an air supply system are arranged in the flag pole base; the flag hoisting winch mechanism is connected with the top end of the auxiliary flag pole through a flag hoisting rope with one end bypassing the fixed pulley; the flag falling winch mechanism is connected with the lower end of the auxiliary flag pole through a flag falling rope; a flag rope tube is arranged at the upper edge of the flag; the air supply system communicates with one end of the flag falling rope through a winding drum spindle in the flag falling winch mechanism and conveys air into the flag falling rope; the other end of the flag falling rope is connected with the lower end of the auxiliary flag pole; the upper end of the auxiliary flag pole is perpendicularly connected with one end of the flag rope tube; the air in the flag falling rope enters the flag rope tube through the auxiliary flag pole; the air in the flag rope tube is uniformly and downwards sprayed out to hoist the flag under the counter-acting force of the air to realize unfolding and waving. The unfolding and waving device for the flag simulates a dynamic effect that the flag is blown by natural wind to wave, so that the flag can achieve a naturally unfolding and waving effect in a flag hoisting process under an environment without wind and the like.

Owner:许旸

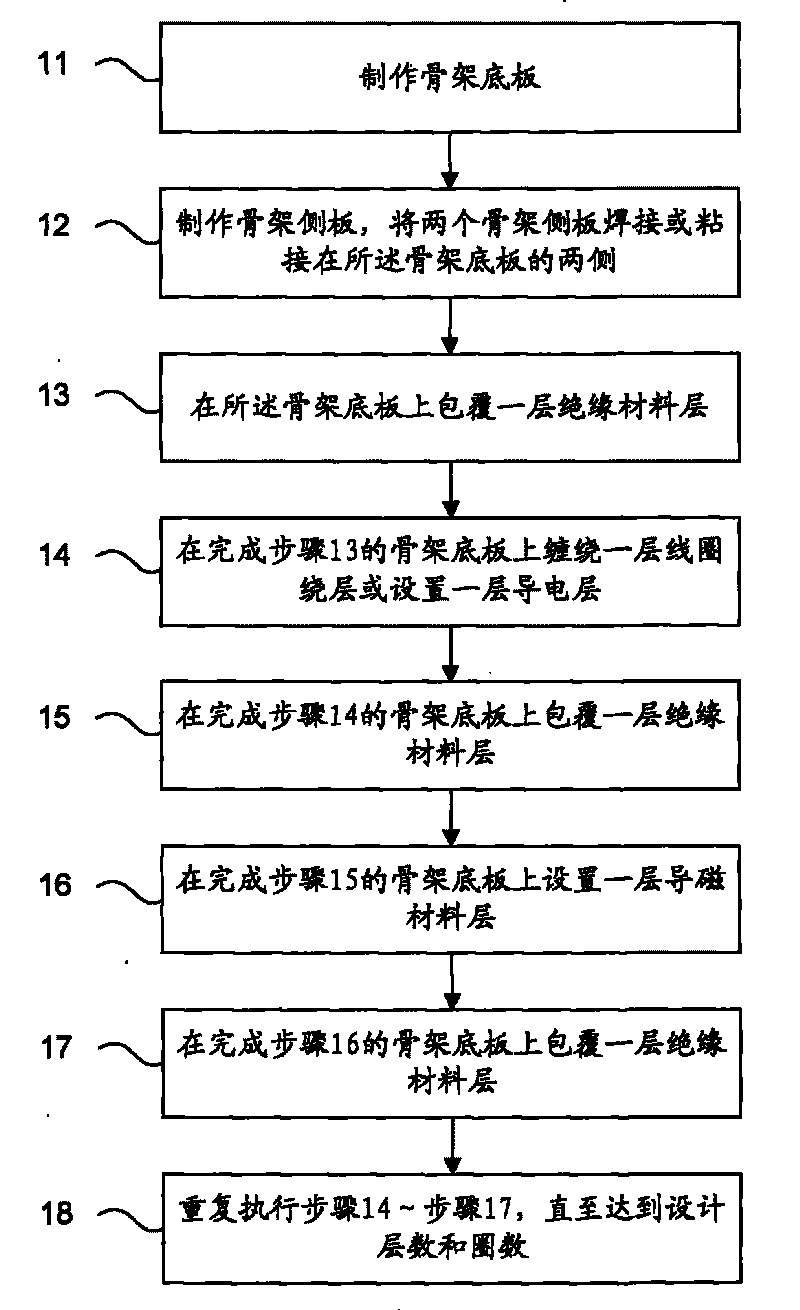

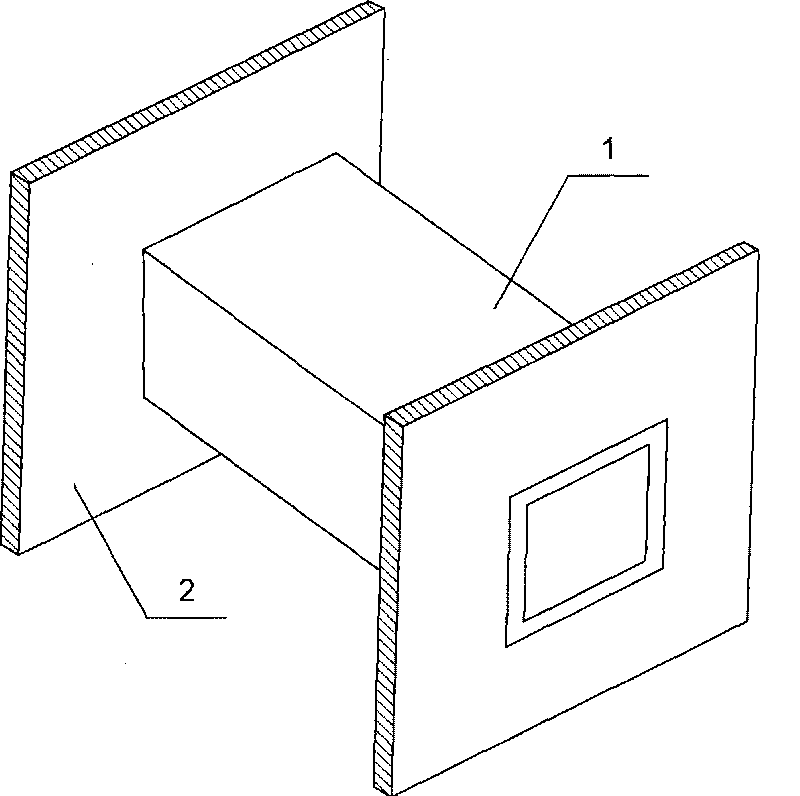

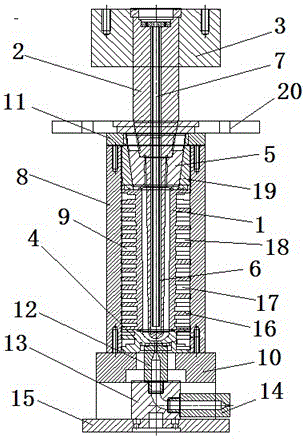

Method for manufacturing coil winding of magnetic conducting and electric conducting body

InactiveCN101699726ALow powerAchieve the desired effectManufacturing stator/rotor bodiesApplying solid insulationState of artTransformer

The invention discloses a method for manufacturing a coil winding of a magnetic conducting and electric conducting body, which comprises the following steps: manufacturing a framework bottom plate; manufacturing framework side plates, and welding or bonding the two framework side plates to the two sides of the framework bottom plate; wrapping an insulating material layer on the framework bottom plate; and arranging a magnetic conducting and electric conducting layer and the insulating material layer on the framework bottom plate completing the above steps in turn till reaching the designed layer number and number of turns. By arranging the magnetic conducting material layer between the coil winding layers, the method effectively solves the problems that the overlarge radial size of the coil winding in the prior art causes low current produced in the coil and the like, implements high current and high power of a generator, and achieves the ideal effect of the generator. The process of the method is simple; and the manufactured coil winding of the magnetic conducting and electric conducting body has a simple structure, is convenient for manufacturing and maintaining, can be used for electric equipment such as a magnetic closed generator, an electrical energy coupler, a transformer and the like, and has broad application prospect.

Owner:刘刚

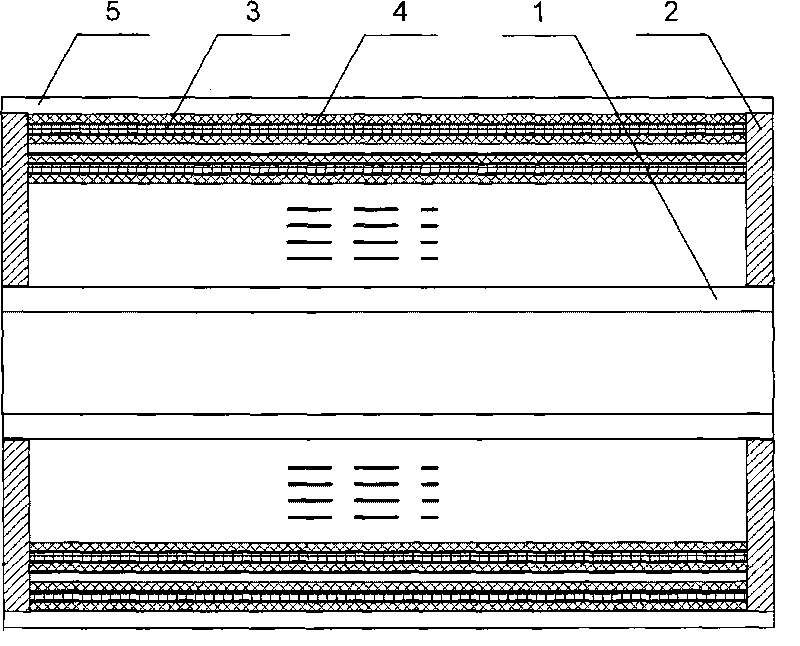

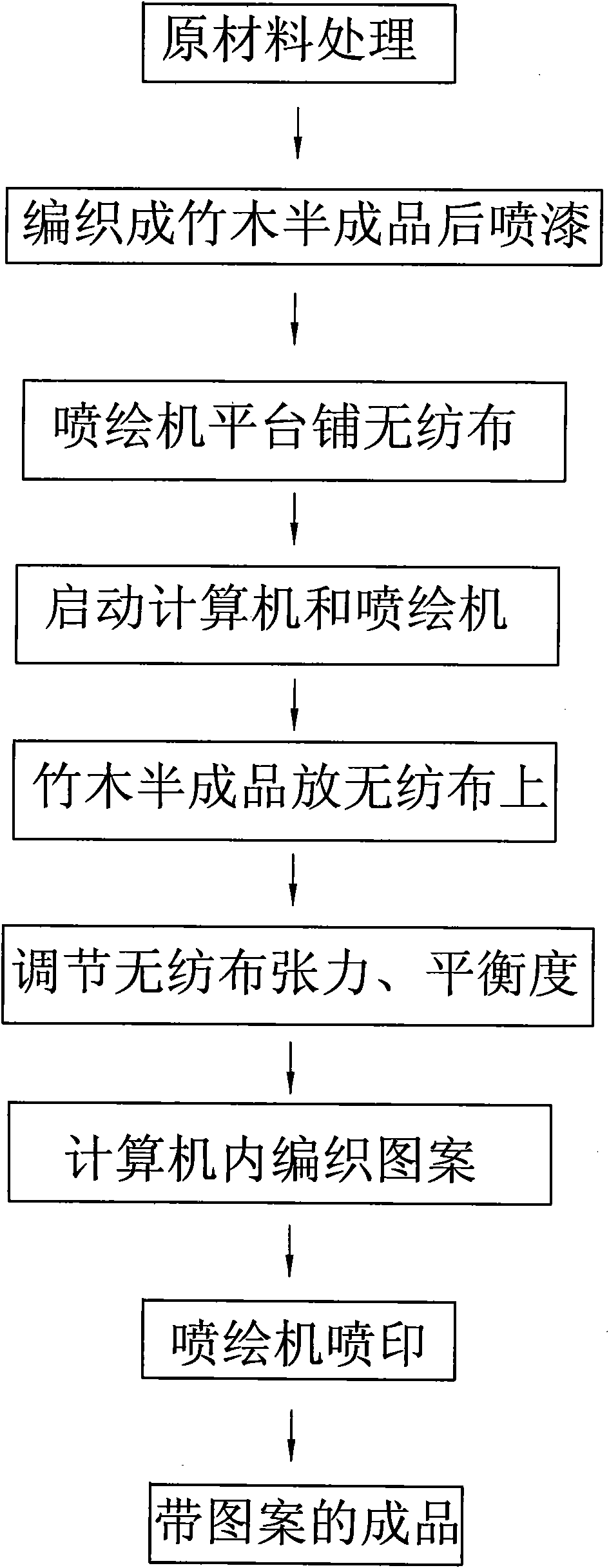

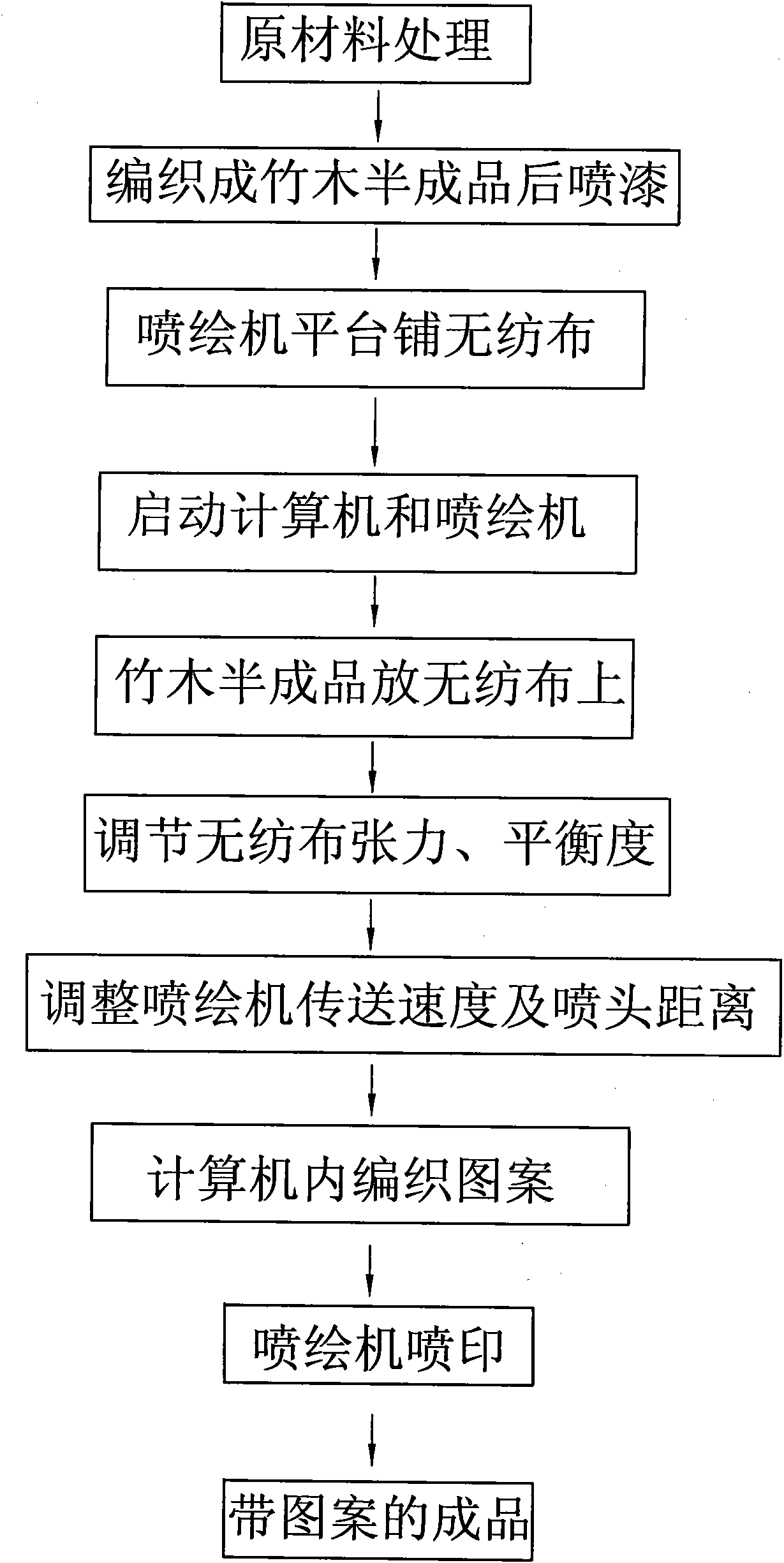

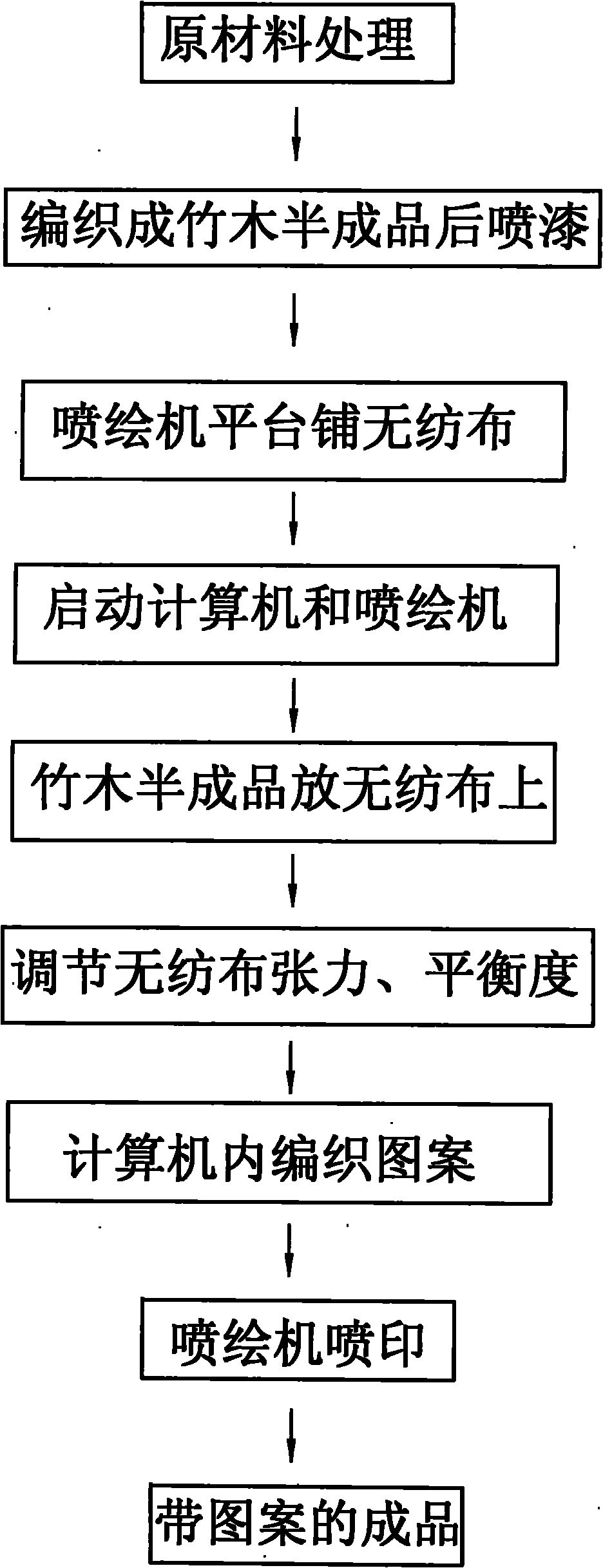

Process for spraying patterns on bamboo or wood semi-finished product

InactiveCN102029634ABright colorsReduce gapDecorative surface effectsWood working apparatusWoven fabricWork in process

The invention discloses a practical environmental-friendly process for spraying patterns on a bamboo or wood semi-finished product, belonging to the field of process for pattern spraying. The process for spraying patterns on a bamboo or wood semi-finished product comprises the following steps: stretching raw material bamboo or wood into a round or flat shape by using a grinding tool, carrying out mould and moth resisting treatment and drying treatment on the raw material bamboo or wood; weaving the raw material bamboo or wood into a sheeted bamboo or wood semi-finished product, and spraying paint on the sheeted bamboo or wood semi-finished product; spreading transmission medium on the platform of a color inkjet printer, connecting the data line of the color inkjet printer with a computer to start the color inkjet printer and the computer, and putting the sheeted bamboo or wood semi-finished product with sprayed paint on the transmission medium; adjusting the tension force and the balance degree of the transmission medium, and printing the woven patterns on the surfaces of the sheeted bamboo or wood semi-finished product on the transmission medium by using the color inkjet printer to obtain the bamboo or wood finished product. According to the technical scheme of the invention, the length of the patterns on the bamboo or wood finished product can be consistent with that of the woven patterns in the computer, the surfaces of the bamboo or wood finished product are not tainted with ink, the patterns on the bamboo or wood finished product are vivid, and the adoption of the transmission medium which is non-woven fabric is good for achieving the ideal effect.

Owner:陈义琴

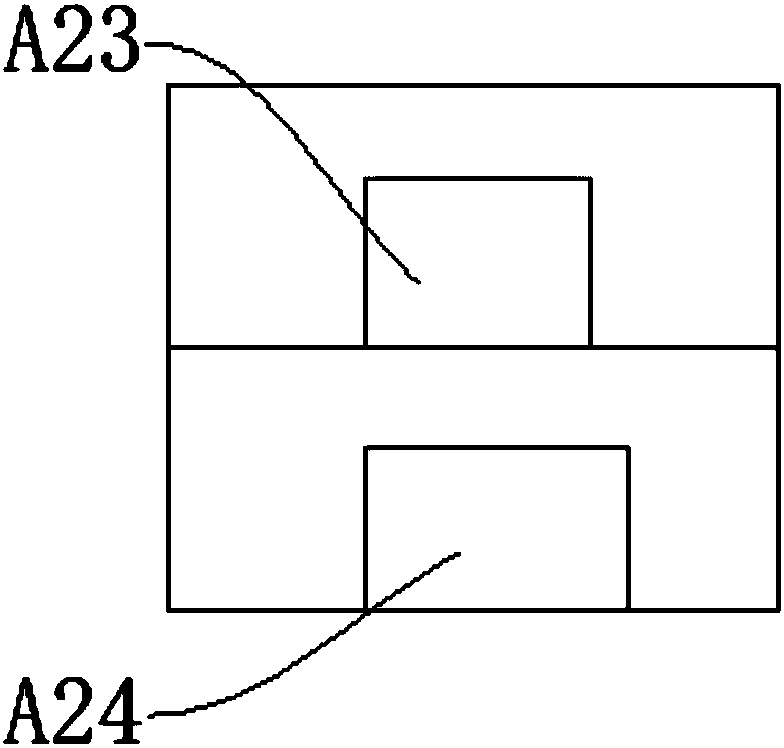

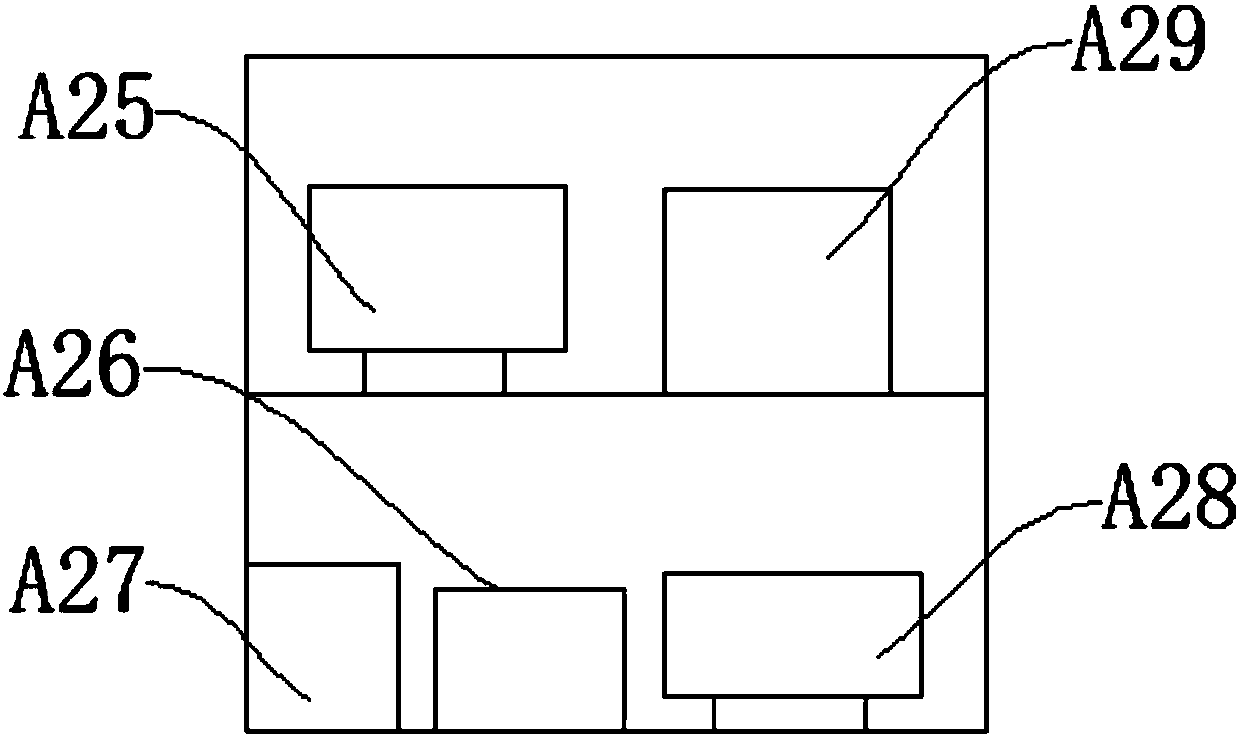

Metal marking machine capable of automatically performing positioning and using method thereof

ActiveCN108115286AFully mechanized operationAccurate locationWelding/cutting auxillary devicesAuxillary welding devicesElectric machineEngineering

The invention provides a metal marking machine capable of automatically performing positioning and a using method thereof. The metal marking machine comprises a base, a machine box, a control cabinetand a scanner, wherein wheels are disposed at four corners of the lower end of the base, and supporting pads are disposed at the positions of the lower end of the base close to the wheels, the middleportion of the upper end of the base is provided with the machine box, and a first motor, a transmission, a second motor, an oil pump and an oil tank are disposed in the machine box. An operating table is disposed at the middle of the upper end of the machine box, a turntable is disposed at the inner middle of the operating table, and a rotating shaft is disposed at the inner middle of the turntable. In the marking machine, the design of the rotating shaft and a positioning block is adopted; and through the setting, the rotating shaft and the positioning block move relative to each other. Evenif a metal workpiece is not square, the metal workpiece can also be driven to move according to a set route, marking work is completed with no position adjustment, mechanized operation is performed in the whole process, the position is more precise, and workers are also more relaxed.

Owner:MINGGUANG SANYOU ELECTRONICS

Collagen facial mask and preparation method thereof

ActiveCN102138870BEasy to degradePromote environmental protectionCosmetic preparationsToilet preparationsPOLYMER SUBSTANCECutin

The invention provides a collagen facial mask and a preparation method thereof. The method comprises the following steps of: stirring 1 to 20 mass percent of aqueous solution of collagen and 0.1 to 2 mass percent of aqueous solution of a modifier at the temperature of between 20 and 60 DEG C for reacting for 15 to 45 minutes to obtain stock solution; adding a plasticizer, a functional additive and an antimicrobial growth promoter into the stock solution, and continuing to stir at the temperature of between 20 and 60 DEG C for 30 to 60 minutes to obtain mixed solution; and pouring the mixed solution into a die for forming, and drying at the temperature of between 30 and 60 DEG C for 3 to 10 hours to obtain the collagen facial mask. The prepared collagen facial mask is mainly formed by macromolecular substances extracted from natural animals and plants, safe and effective and does not have toxic or side effect, has the high heat stability, toughness, ductility and adhesion, and can be in fit with skin well and achieve the effects of preserving moisture doubly, softening cutin skin, resisting winkle, whitening the skin, restoring the skin and the like under the assistance of the functional additive; rejected materials of the facial mask are degradable, and do not cause environmental pollution; and the collagen facial mask can be widely applied in the field of daily cosmetics and has the excellent market application prospect.

Owner:无锡贝迪生物工程股份有限公司

Eyepiece magnification viewfinder frame

The invention discloses an eyepiece magnification viewfinder frame. The viewfinder frame comprises two clamp seats. A magnifying glass is fixed between two clamp seats. Each clamp seat comprises a vertical part and clamp heads located on both ends of the vertical part. Each clamp head comprises a horizontal part and a clamp tip curved inward. The joint of each clamp tip and each horizontal part is a soft connecting band. The eyepiece magnification viewfinder frame provided by the invention has the advantage of simple structure, is portable, can be arranged on different types of digital single lens reflex cameras and film single lens reflex cameras, and is convenient for a user to accurately adjust the parallax of a camera to realize a desired effect.

Owner:郑林昆

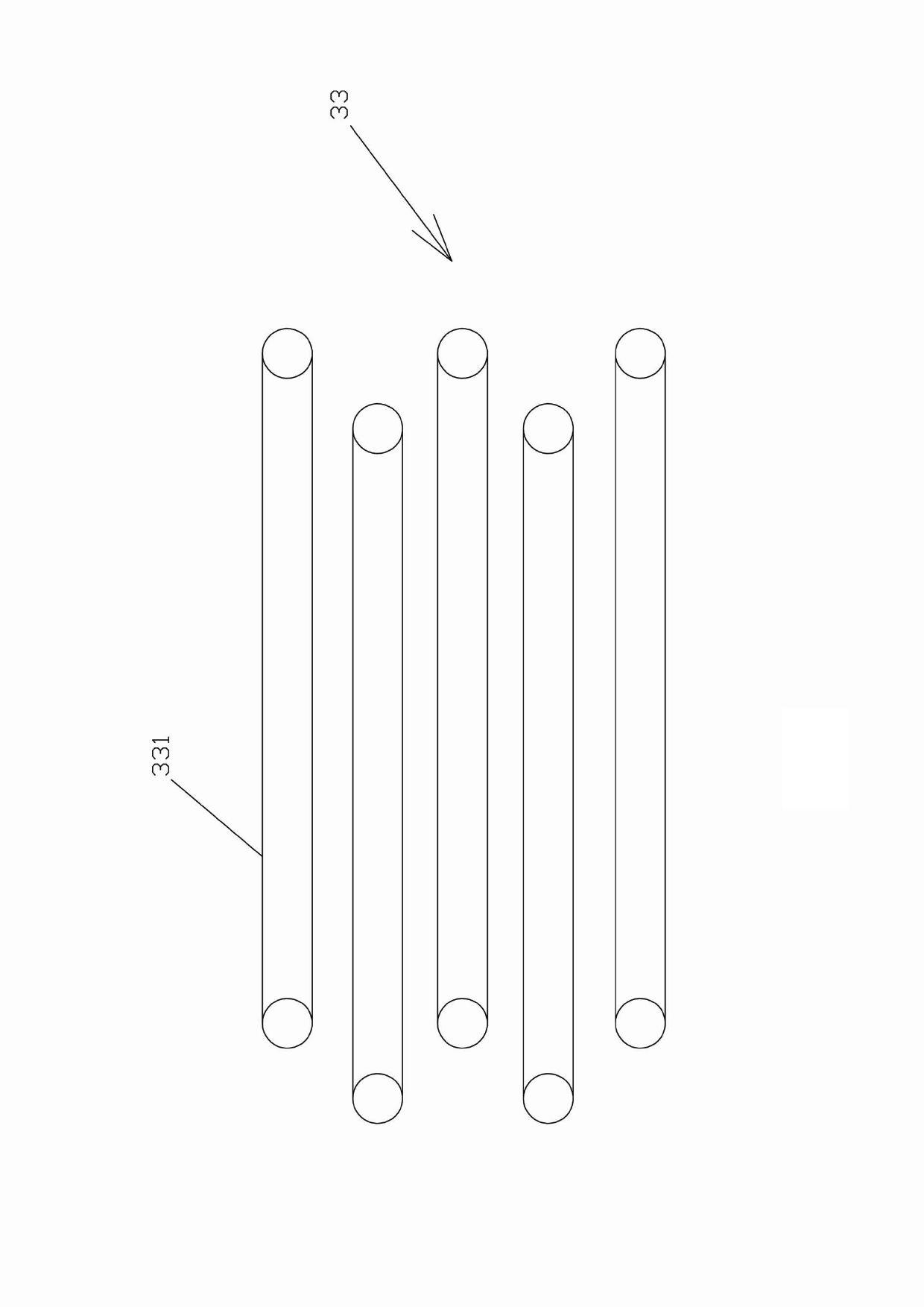

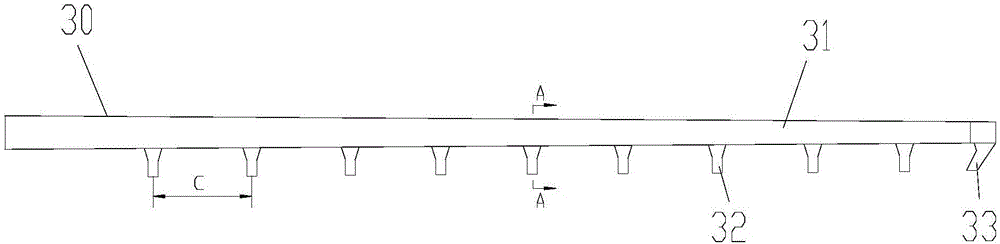

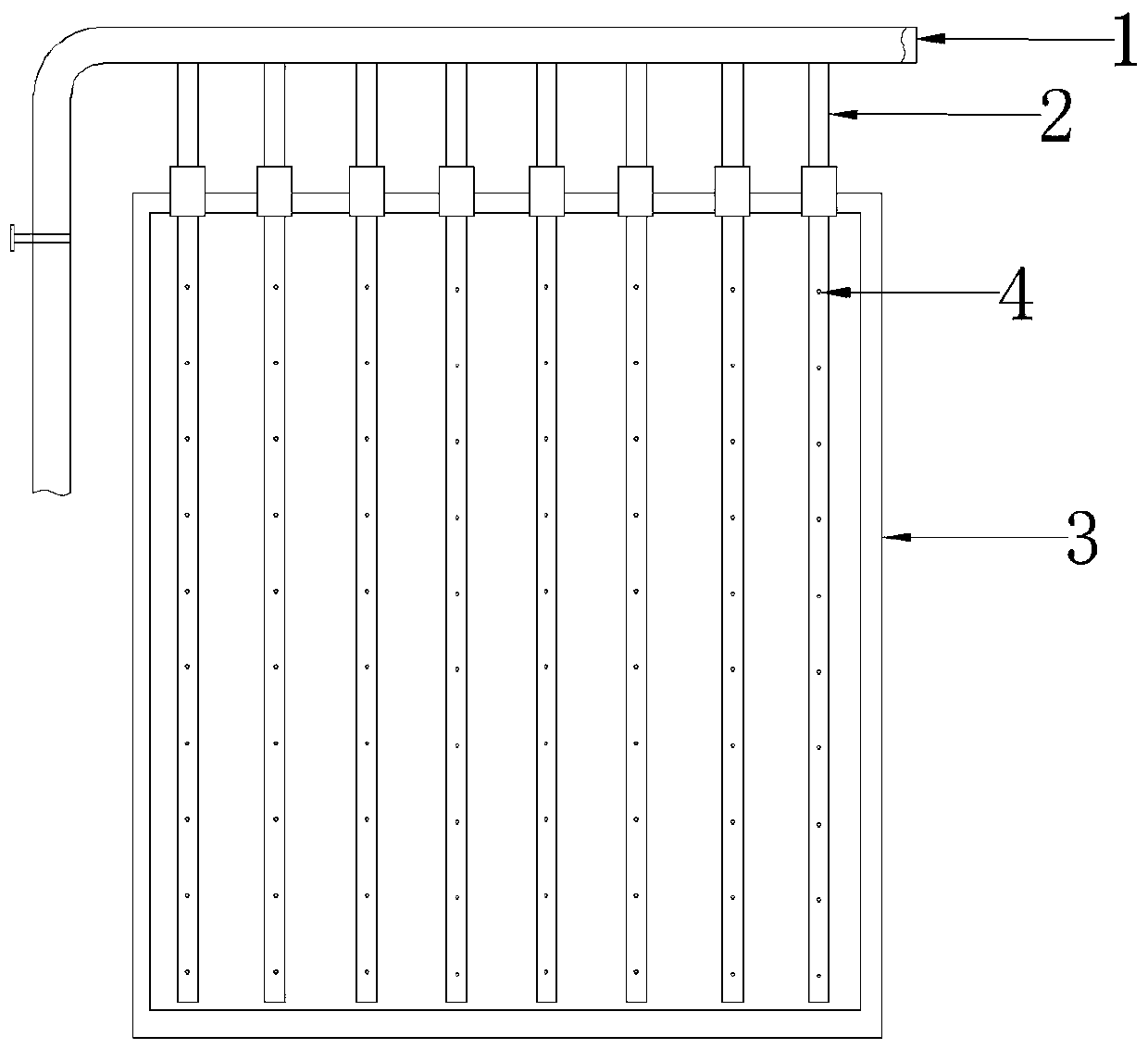

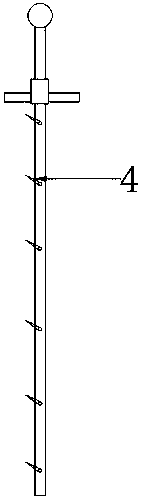

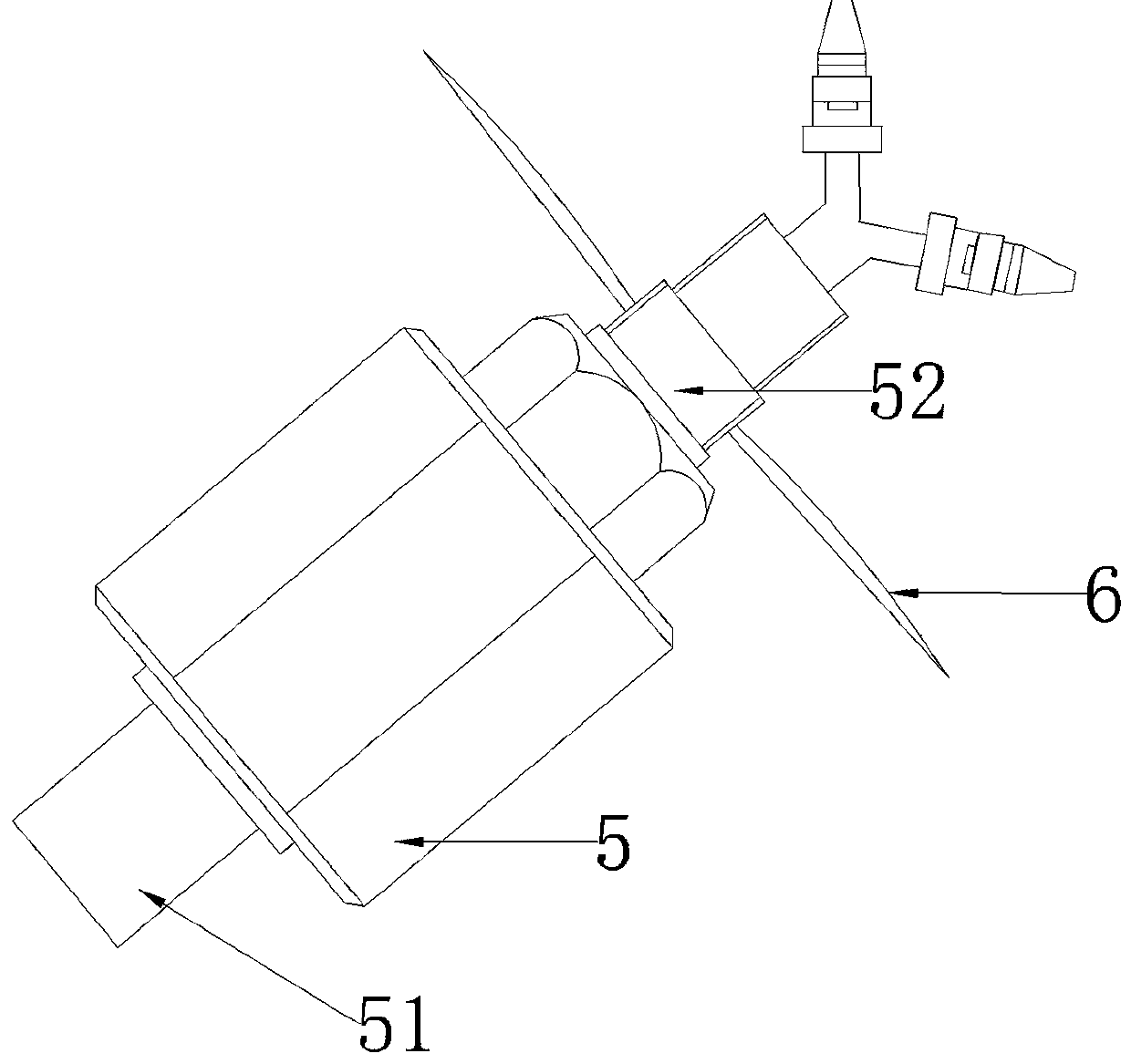

Ozone flow-field active-molecule distributor

InactiveCN107715672ASpray evenlyReach outGas treatmentDispersed particle separationFlue gasDistributor

The invention provides an ozone flow-field active-molecule distributor, comprising a main pipe, a plurality of parallel and equally spaced branch pipes communicated with the main pipe, and a pluralityof nozzles arranged on the branch pipes, wherein the branch pipes extend into a flue section and are arranged to be perpendicular to the flue section; the nozzles are connected with the branch pipesthrough single-path swivel joints; each of the single-path swivel joints comprises a fixed end and a swivel end; the fixed ends are fixed onto the branch pipes, and the swivel ends are provided with external threads and internal threads; the nozzles are fixed on the swivel ends via the internal threads on the swivel ends; the outer surface of each swivel end is provided with a flow disturbing mechanism; the nozzles are arranged at an equal interval along the direction of the branch pipes; the nozzles on adjacent branch pipes are staggerly arranged; and the nozzles are located on the sides, facing incoming flue gas flow, of the branch pipes. After flue gas is treated by the active-molecule distributor, the efficiency of ozone oxidation of oxynitrides is greatly improved.

Owner:江苏天立方环保工程有限公司

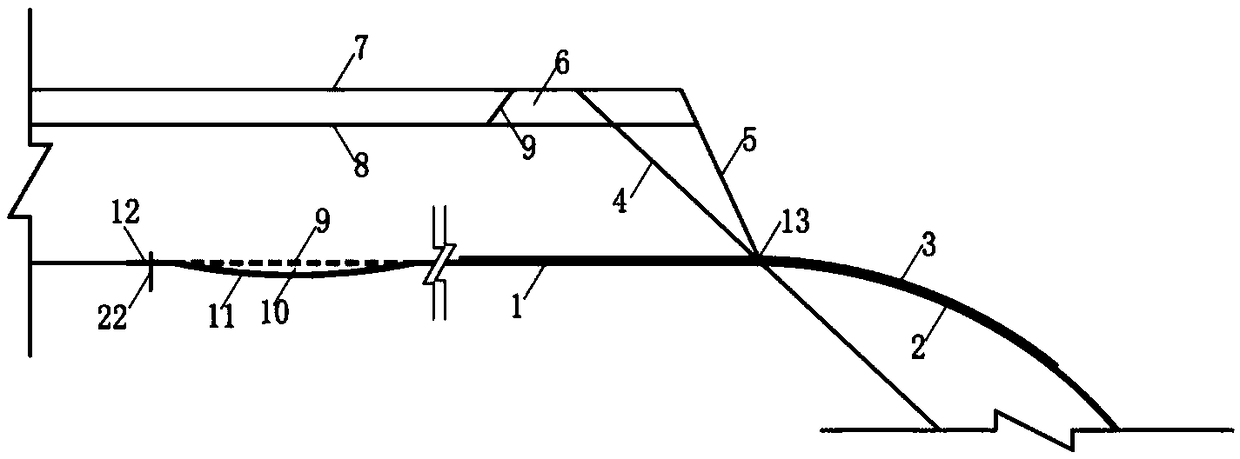

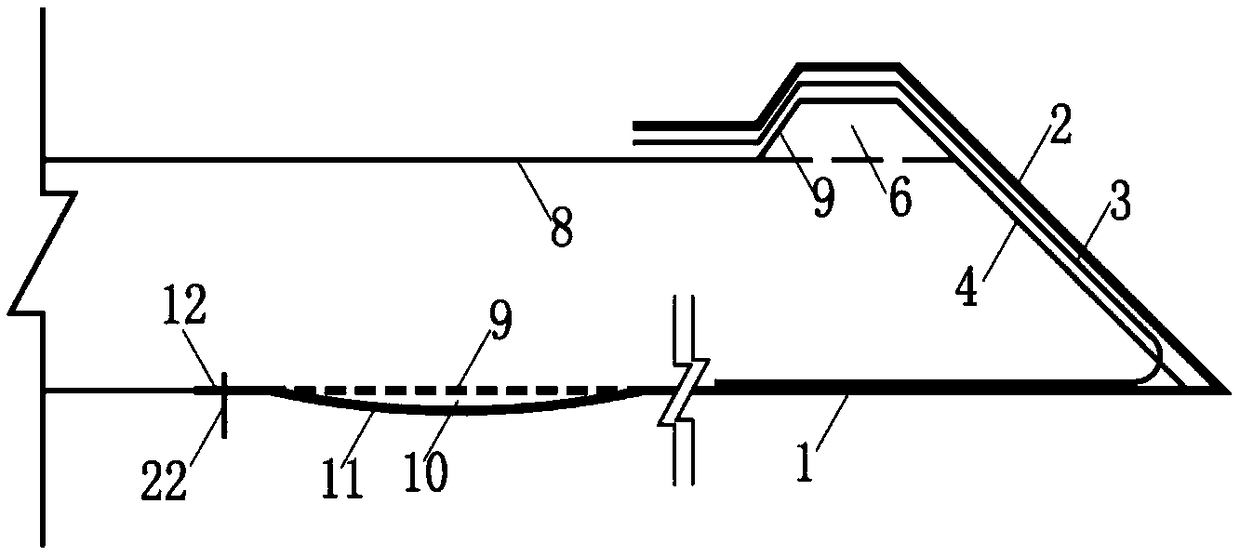

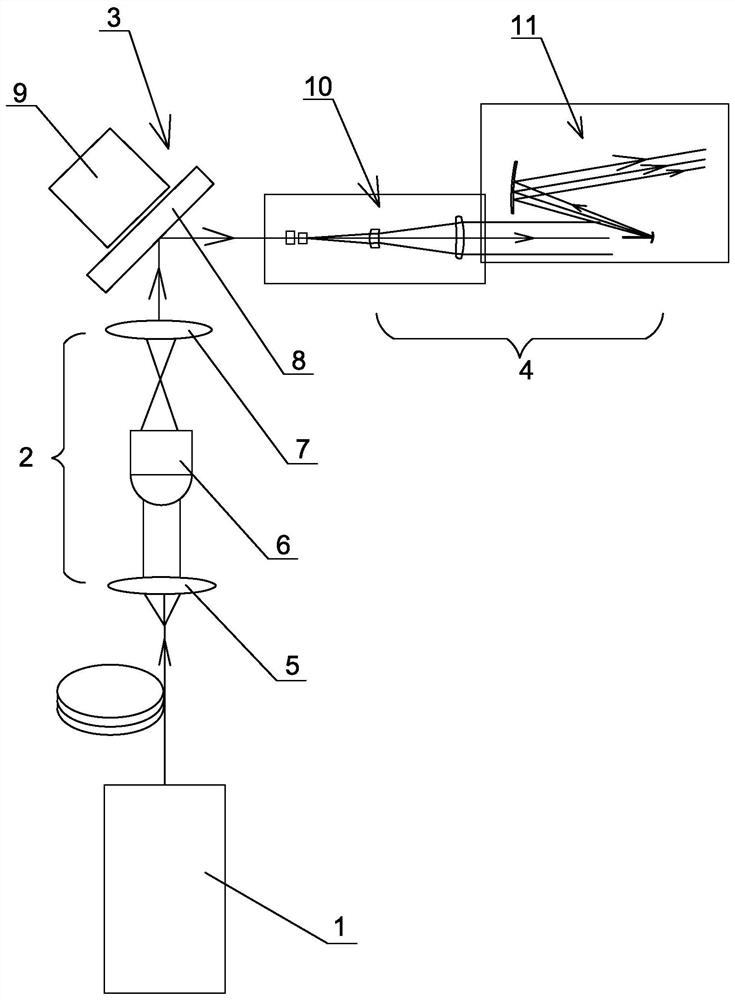

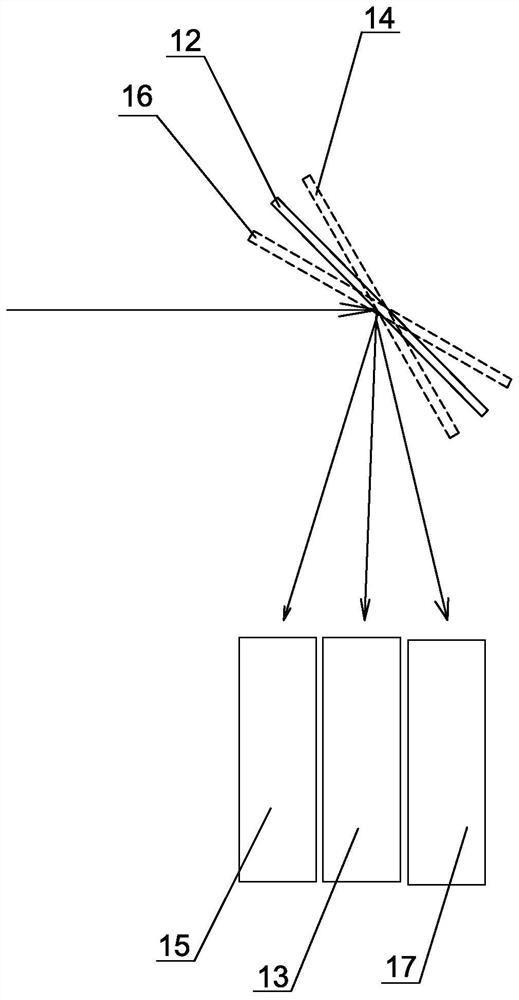

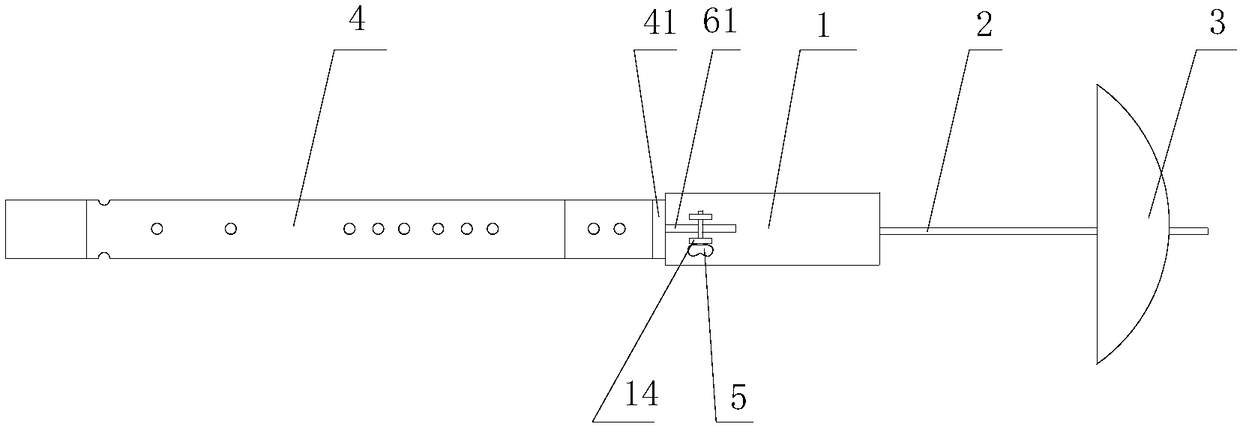

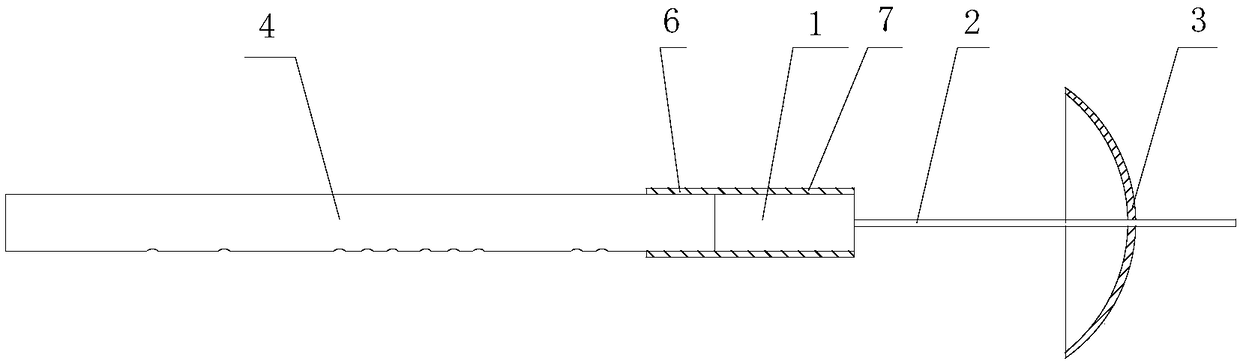

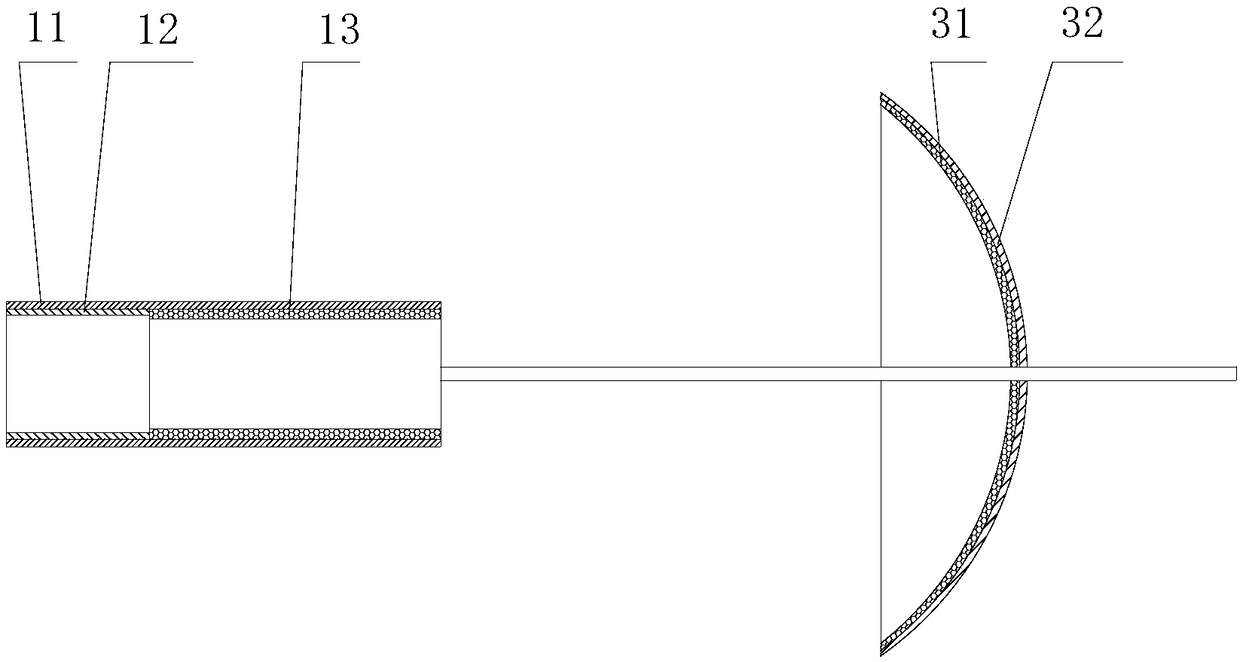

One-dimensional galvanometer scanning type laser eyepiece device

InactiveCN112797847AImprove uniformityIncrease the effective rangeWeapons typesOptical elementsEyepieceLight spot

The invention discloses a one-dimensional galvanometer scanning type laser eyepiece device. The laser eyepiece device is characterized in that the one-dimensional galvanometer scanning type laser eyepiece device comprises a laser device, an optical lens group, a galvanometer scanning system and an emission optical system which are arranged in sequence, and the laser device is a semiconductor green laser device with tail fiber output and used for emitting laser; the optical lens group is used for converting laser emitted by the laser into linear light spots; the galvanometer scanning system is used for converting the linear light spots into square light spots; and the emission optical system is used for expanding the beam diameter of the square light spots to realize adjustment of the far and near field square light spots. According to the laser eyepiece device, the operating distance is increased, the environment adaptability is improved, and the eyepiece effect is guaranteed.

Owner:江苏亮点光电研究有限公司

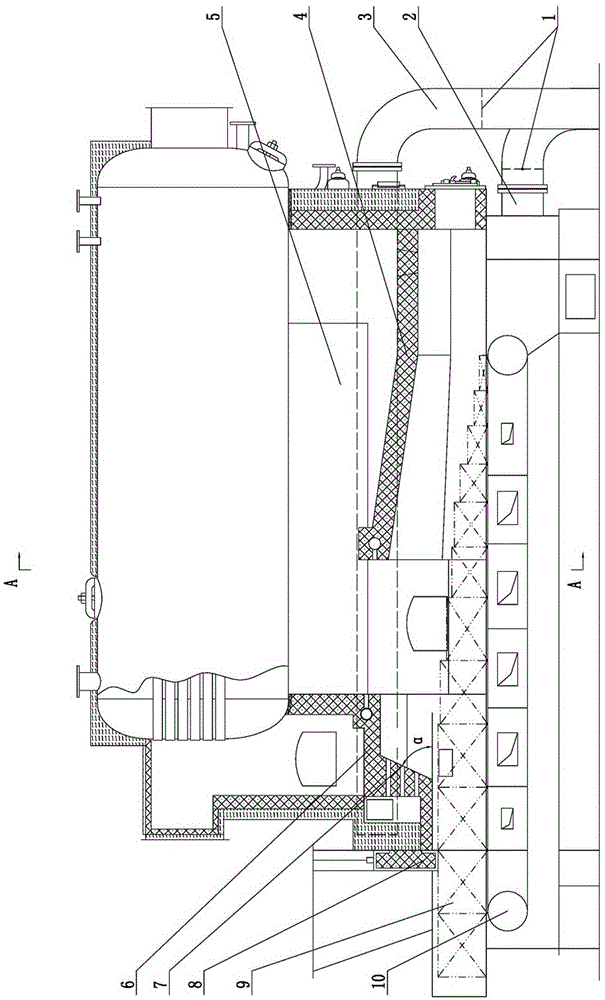

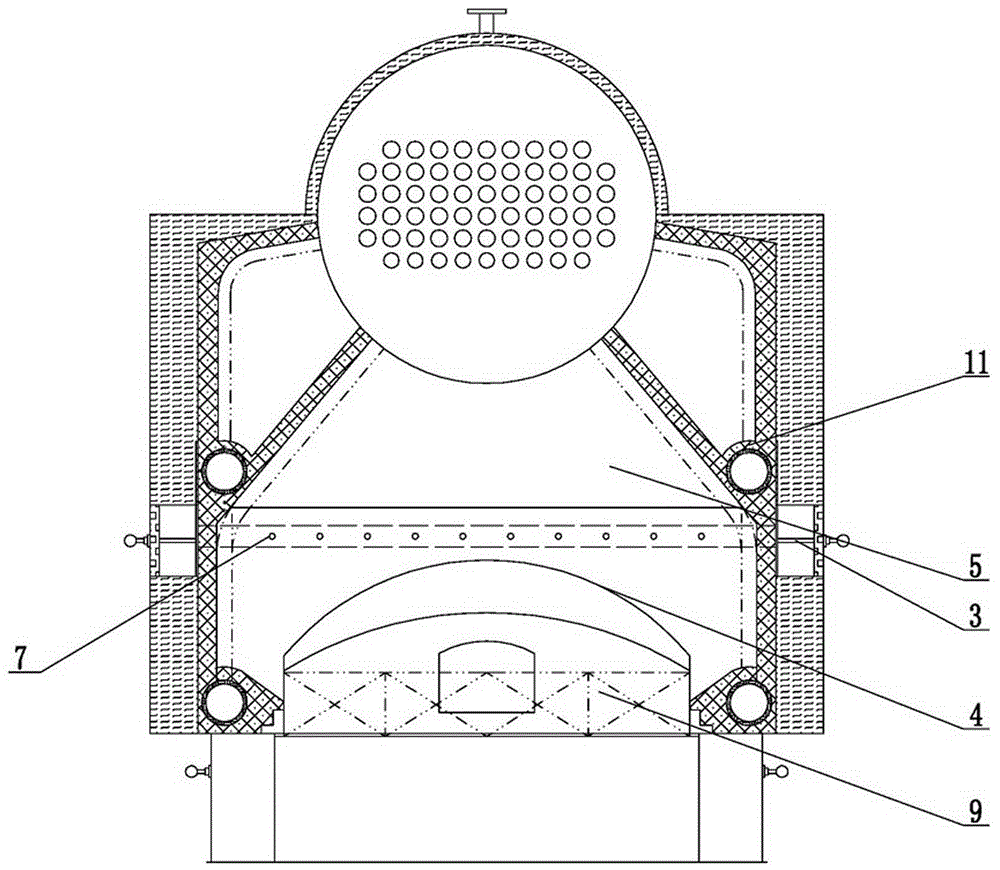

Bundling direct-burning type straw boiler

InactiveCN105276567ARun smoothlyContinuous and stable combustionSolid fuel combustionCasings/liningsEngineeringHearth

The invention discloses a bundling direct-burning type straw boiler, and relates to an improvement of a boiler structure. By means of the bundling direct-burning type straw boiler, straw is directly bundled through special equipment in the field and conveyed to a boiler room, and then the straw can be directly burnt, and the burning cost is reduced. The bundling direct-burning type straw boiler comprises a boiler body with a primary air tube and a secondary air tube, a fuel inlet is formed in the front end of the boiler body, a conveying belt type fire grate is arranged in the boiler body, and the front end of the fire grate extends out from the fuel inlet and is arranged outside the boiler body; and a front arch and a rear arch are arranged at the positions, corresponding to the fire grate, in the boiler body, and an outlet of the secondary air tube of the boiler body is arranged in the front arch and the rear arch. The bundling direct-burning type straw boiler is structurally characterized in that an inlet of the secondary air tube of the boiler body is formed in the back end of the boiler body, and the secondary air tube of the boiler body is arranged in a boiler wall passing through a hearth; and an included angle formed between the front arch and the horizontal plane is larger than or equal to 55 degrees and smaller than or equal to 70 degrees.

Owner:李征

Portable bamboo flute mute device and use method thereof

InactiveCN108091317AGood effectTo achieve the desired effectWind musical instrumentsFluteEngineering

The invention relates to the field of musical instruments, and discloses a portable bamboo flute mute device, comprising a mute tube, an adjustment rod and a mute umbrella. The mute tube is detachablyconnected to a rear inlaid opening of a bamboo flute. The other end of mute tube is fixedly connected with the adjustment rod. The mute umbrella is connected onto the adjustment rod. The mute tube includes a connecting section and a mute section. The outer side of the connecting section and the mute section are wrapped with a steel tube and fixedly connected or integrally formed. The inner surface of the connecting section is fixedly connected to a buffer layer, and the inner surface of the mute section is adhered with porous sound-absorbing cotton. The mute device is connected to the rear inlaid opening of the bamboo flute and can be applied to various bamboo flutes, and through the dual function of the mute tube and the mute umbrella, the effect of the mute device is improved. The invention also discloses a use method of the portable bamboo flute mute device, whereby the bamboo flute mute device can be conveniently and quickly installed and used and the mute device can be adjusted according to the user to achieve a desired effect.

Owner:JIAMUSI UNIVERSITY

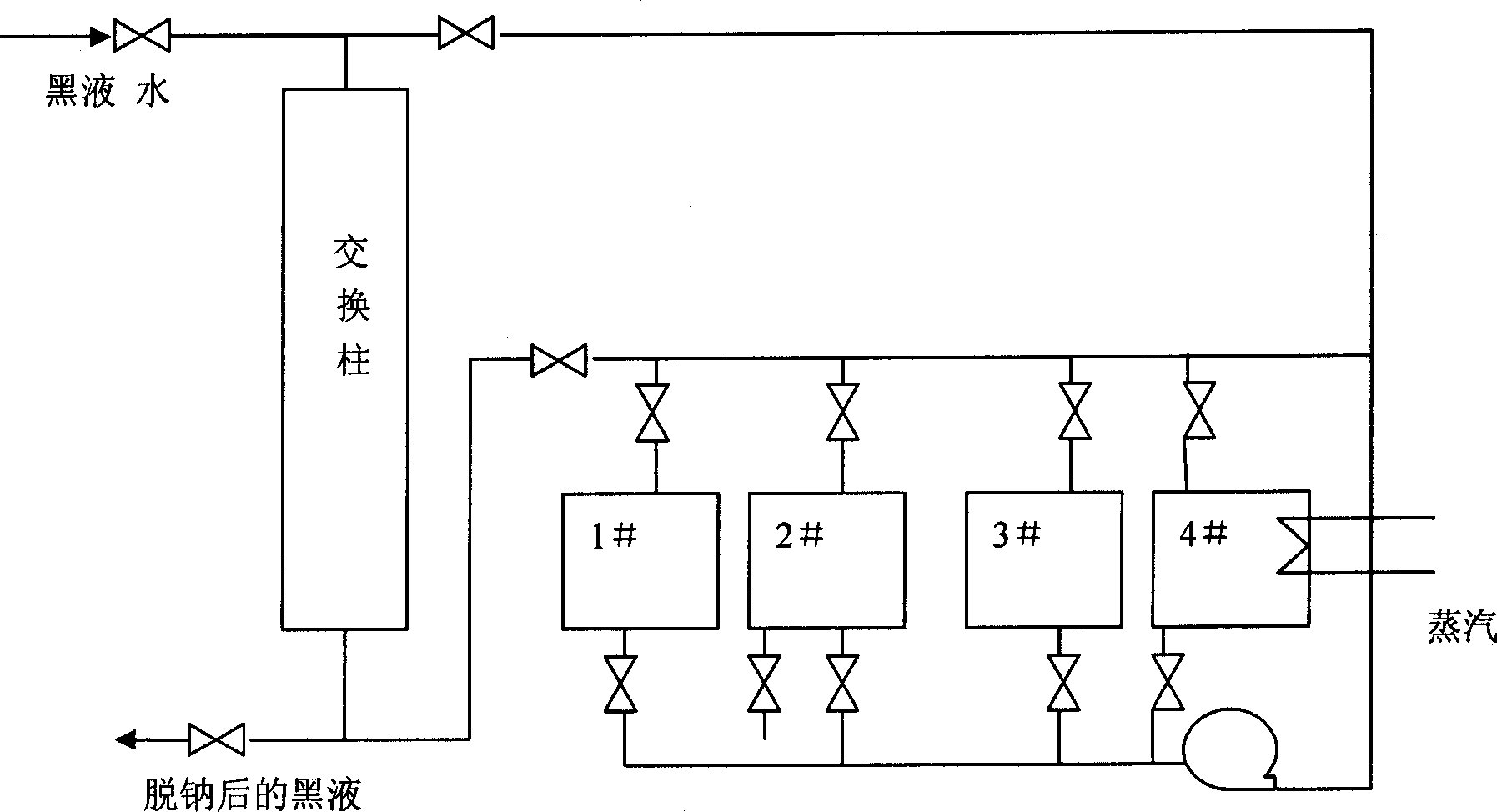

Method for recovering papermaking black liquor liquid soda

InactiveCN1888305AFast exchangeLittle impact on working swap capacityRegeneration of alkali lyeSulfite saltIon exchange

The present invention relates to a method for recovering liquid alkali from papermaking black liquor. It is characterized by that it adopts on ion exchange process to convert sodium ions into ammonium ions, so that it not only can eliminate the hazard of sodium hydroxide and sodium sulfite, but also can increase fertilizer effect, besides, it can completely control papermaking black liquor so as to attain the goal of pollution-free discharge. Besides, said invention also provides the concrete technical scheme and its concrete implementation steps.

Owner:NORTHWEST A & F UNIV

Dermatitis curative

InactiveCN101757026ATo achieve the desired effectHydrocarbon active ingredientsHydroxy compound active ingredientsDiseaseWestern medicine

The invention discloses a novel external application drug for treating skin diseases, which uses nine Chinese and western medicine as raw materials, such as realgar. The drug is mainly used for treating various skin diseases, such as pruritus and scabies. The invention has the advantages of scientific and unique prescription and good curing effect.

Owner:胡三明

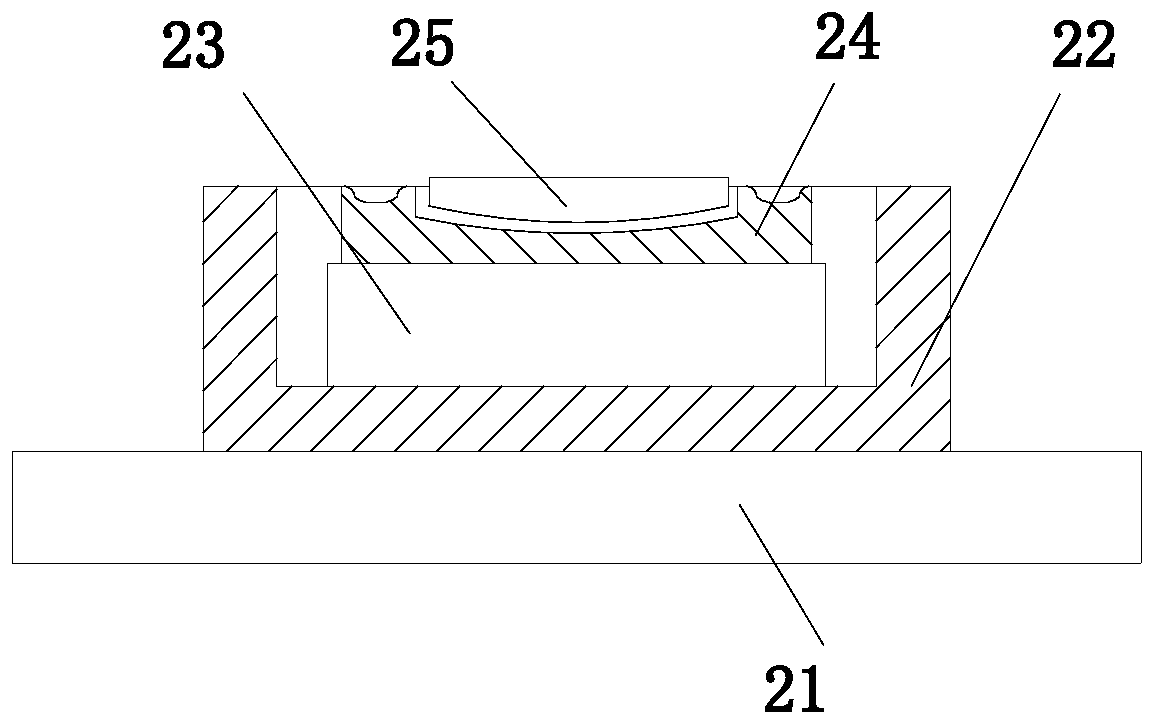

Pipe blank injection molding method and pipe blank mold for high-capacity plastic bottles

The invention discloses a pipe blank injection molding method and a pipe blank mold for high-capacity plastic bottles. The injection molding method includes filling the temperature-control pipe blank mold with injection molding materials to form pipe blanks by means of injection molding, and is characterized in that the integral pipe blank mold is of a cooling structure with multiple flow channels, a pipe blank mold core and a pipe blank mold cavity are cooled in a temperature-control mode, and the temperatures of cooling media are controlled by temperature control equipment, so that the temperature of cooling oil of the pipe blank mold core is 50-60 DEG C under the control, and the temperature of cooling oil of the pipe blank mold cavity is 45-55 DEG C under the control; the hot flow channel of a bottom feed inlet is divided into three portions, and heat of each portion can be preserved differently, so that heat of residual materials which are not fed into the pipe blank mold cavity can be preserved, and the residual materials can be prevented from flowing outwardly. The pipe blank injection molding method and the pipe blank mold have the advantages that the integral pipe blank mold is of the cooling structure with the multiple flow channels, the temperatures of the different portions can be differently controlled by temperature control devices, accordingly, the molding temperatures of products can be effectively controlled, the molding quality of the products can be guaranteed, and the residual materials can be prevented from being hardened or flowing outwardly.

Owner:湖南昊兴机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com