Milling machine capable of adjusting milling depth and using method thereof

A milling machine, adjustable technology, applied in the direction of roads, road repairs, roads, etc., can solve the problem of not being able to accurately adjust the milling depth, and achieve the effect of improving service life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

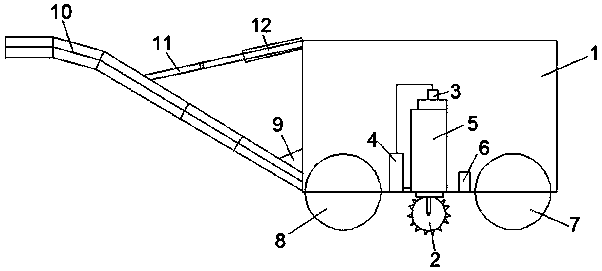

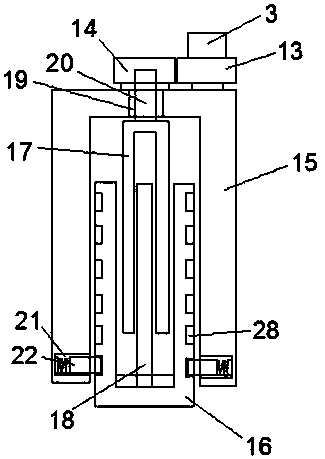

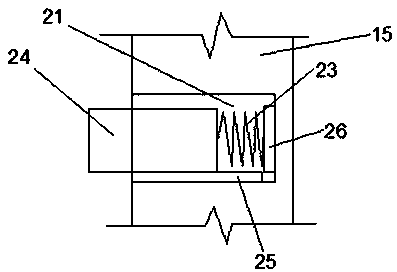

[0012] like Figure 1-Figure 4 As shown, a milling machine with adjustable milling depth is characterized in that it comprises a milling frame 1, a milling rotor 2, a motor 3, a milling depth control device 4, a milling depth adjustment device 5, a travel motor 6. Front rolling wheel 7, rear rolling wheel 8, tailgate 9, recovery belt device 10, connecting rod 11 and oil cylinder 12, the milling depth control device 4 is connected to the input port of the engine 3, and the output port of the engine 3 is connected to the The milling depth adjustment device 5, the front rolling wheel 7 and the rear rolling wheel 8 are arranged under the milling frame 1, the traveling motor 6 is connected with the front and rear rolling wheels, and the tailgate is arranged behind the milling frame 1 9 and the recovery belt device 10, the recovery belt device 10 is connected together by the connecting rod 11 and the oil cylinder 12, wherein the milling depth adjustment device 5 includes a driving w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com