Pipe blank injection molding method and pipe blank mold for high-capacity plastic bottles

A technology for injection molding and plastic bottles, which is applied in the field of tube blank injection molding and tube blank mold for large-capacity plastic bottles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

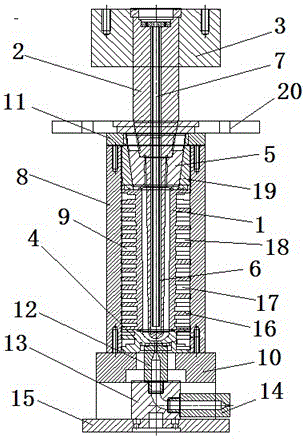

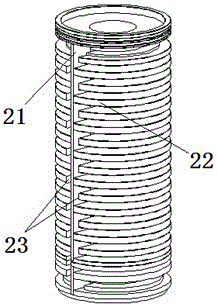

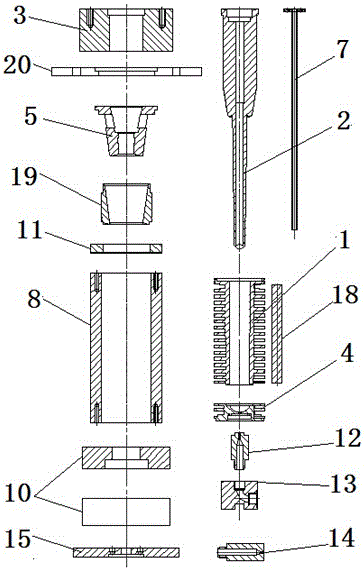

[0037] The cooling flow channel 9 formed between the core sleeve 8 and the outer surface of the tube embryo cavity 1 and the cavity bottom 4 is a labyrinth-like flow channel similar to a labyrinth, so that the cooling oil flows in the tube blank cavity and the bottom of the cavity. The outer periphery forms a labyrinth circulation cooling channel.

[0038] The labyrinth flow channel is an annular labyrinth flow channel formed by the combination of the circular groove 16, the notch 17 and the block 18, and there are more than two circular grooves 16 on the outer surface of the tube embryo cavity and the bottom of the cavity. There is a gap 17 between every two adjacent circular grooves, and a stopper 18 is arranged in each circular groove, and the stopper 18 is arranged next to the gap 17, so that the cooling medium flows from the mold core sleeve After the entrance of 8 flows in, it must go around the circular groove, and then enter the previous circular groove from the gap cl...

Embodiment 2

[0044] The part where the top of the first hot runner is in contact with the bottom mold of the cavity is provided with a heat insulation pad so that the high temperature of the first hot runner will not be transmitted to the bottom mold of the cavity. The heat insulation pad is a paper pad with a thickness of 0.5-2 mm.

[0045] Embodiment Three

Embodiment 3

[0047] The tube embryo mold core is also cooled by oil or water, and the cooling medium comes out of the oil temperature machine and is transported to the deep hole blind hole of the tube embryo core through the cooling pipe, and then passes through the cooling pipe and the periphery of the deep hole blind hole. Some gaps return to realize temperature-controlled cooling of the tube blank mold core.

[0048] Apparently, the above-mentioned embodiments are only to illustrate several examples of the present invention, any simple modification, replacement and adoption of vertical or other mold opening methods by any ordinary skilled in the art are within the protection scope of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com