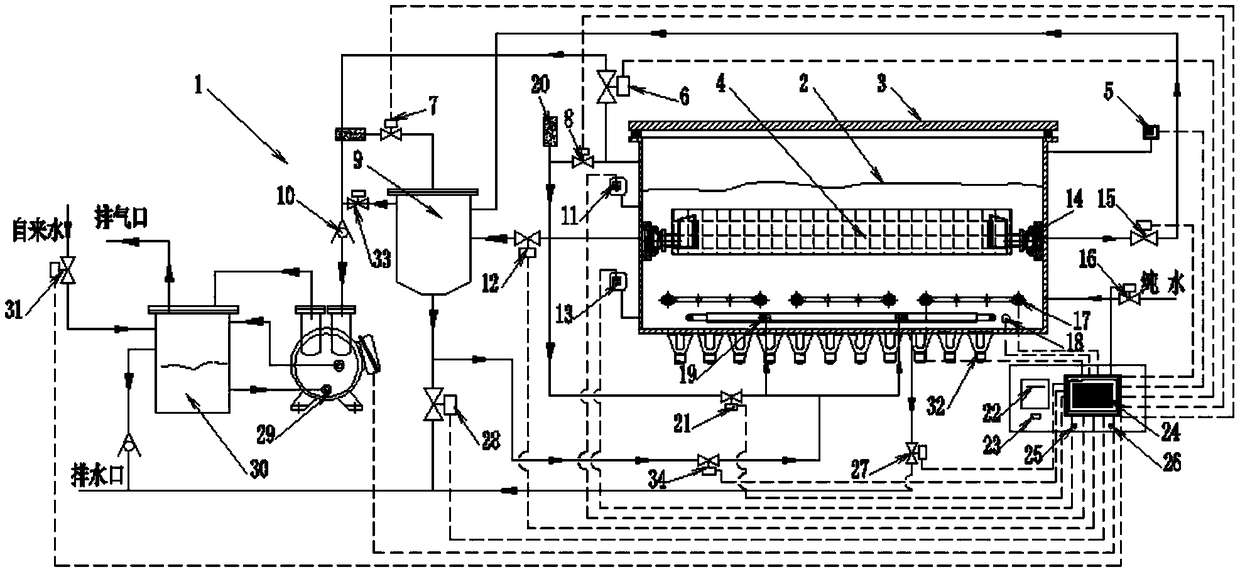

Cleaning method of multistage variable-voltage pulse cleaning system

A technology of pulse cleaning and cleaning liquid, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., which can solve the problems of difficult cleaning quality, troubles for cleaning personnel, and high risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

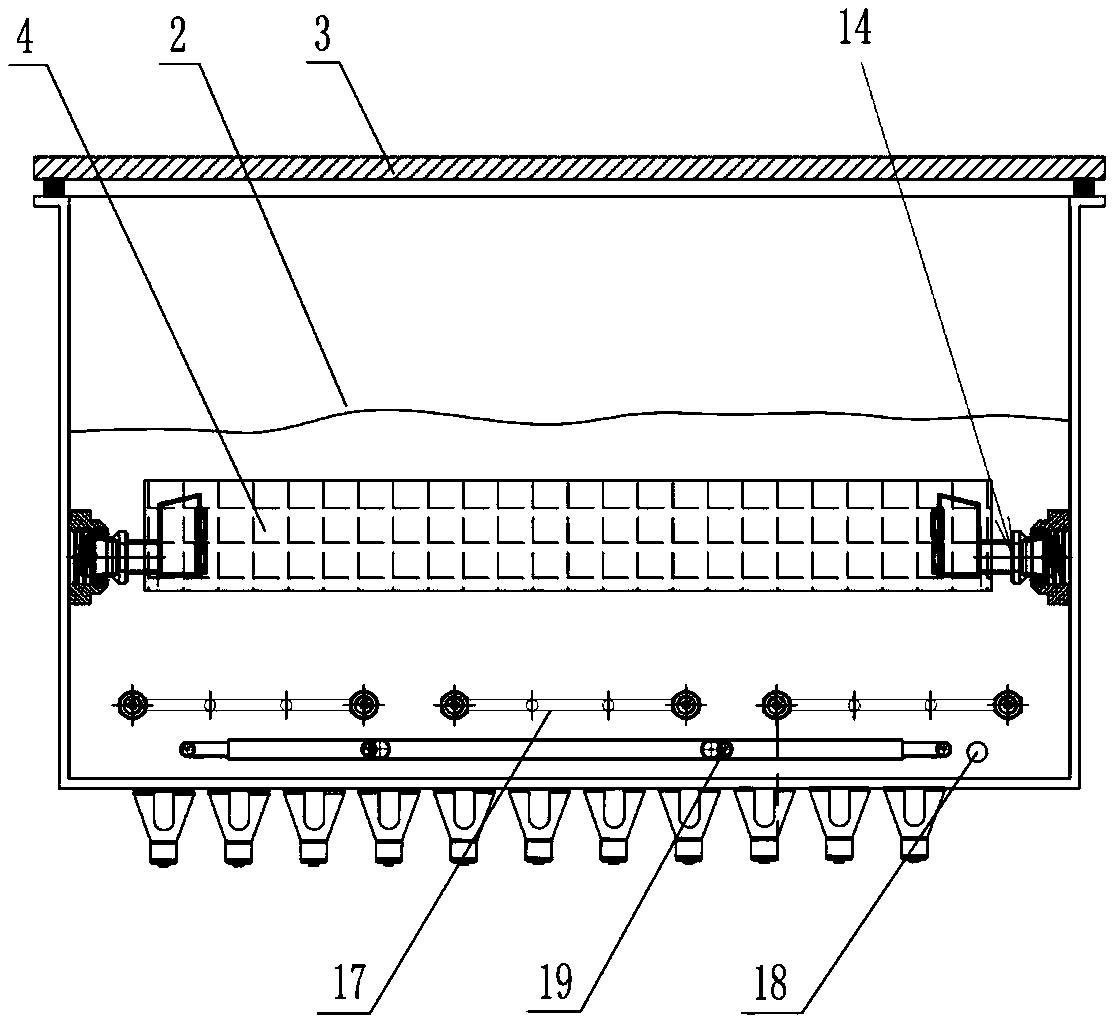

Embodiment 1

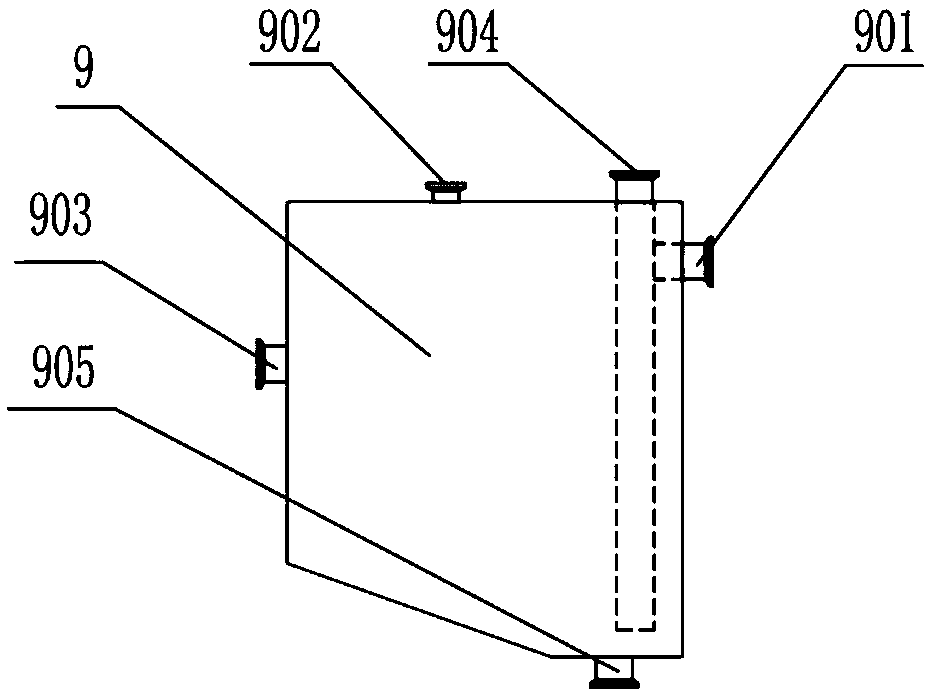

[0114]A multi-stage variable pressure pulse cleaning device: the silica gel suction device 14 is connected to the left pulse valve and the right pulse valve at the left and right ends of the cleaning cabin, the left pulse valve and the right pulse valve are respectively connected to the vacuum tank, and the vacuum tank has multiple structural parts The interfaces are respectively (the first connection port 901, the second connection port 902, the third connection port 903, the fourth connection port 904, and the fifth connection port 905). The tank pumping valve is connected to the vacuum pump through the one-way valve, the second connection port 902 of the vacuum tank 9 is installed at the inlet of the gas breaker valve pipeline, the filter is installed, the third connection port 903 of the vacuum tank is the left pulse valve pipeline, and the fourth connection port 904 of the vacuum tank is the right pulse valve Pipeline, the fifth connection port 905 drain valve pipeline of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com