Ozone flow-field active-molecule distributor

A technology of active molecules and distributors, applied in the field of air pollution control, can solve problems such as inability to achieve deep denitrification, and achieve the effect of uniform injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

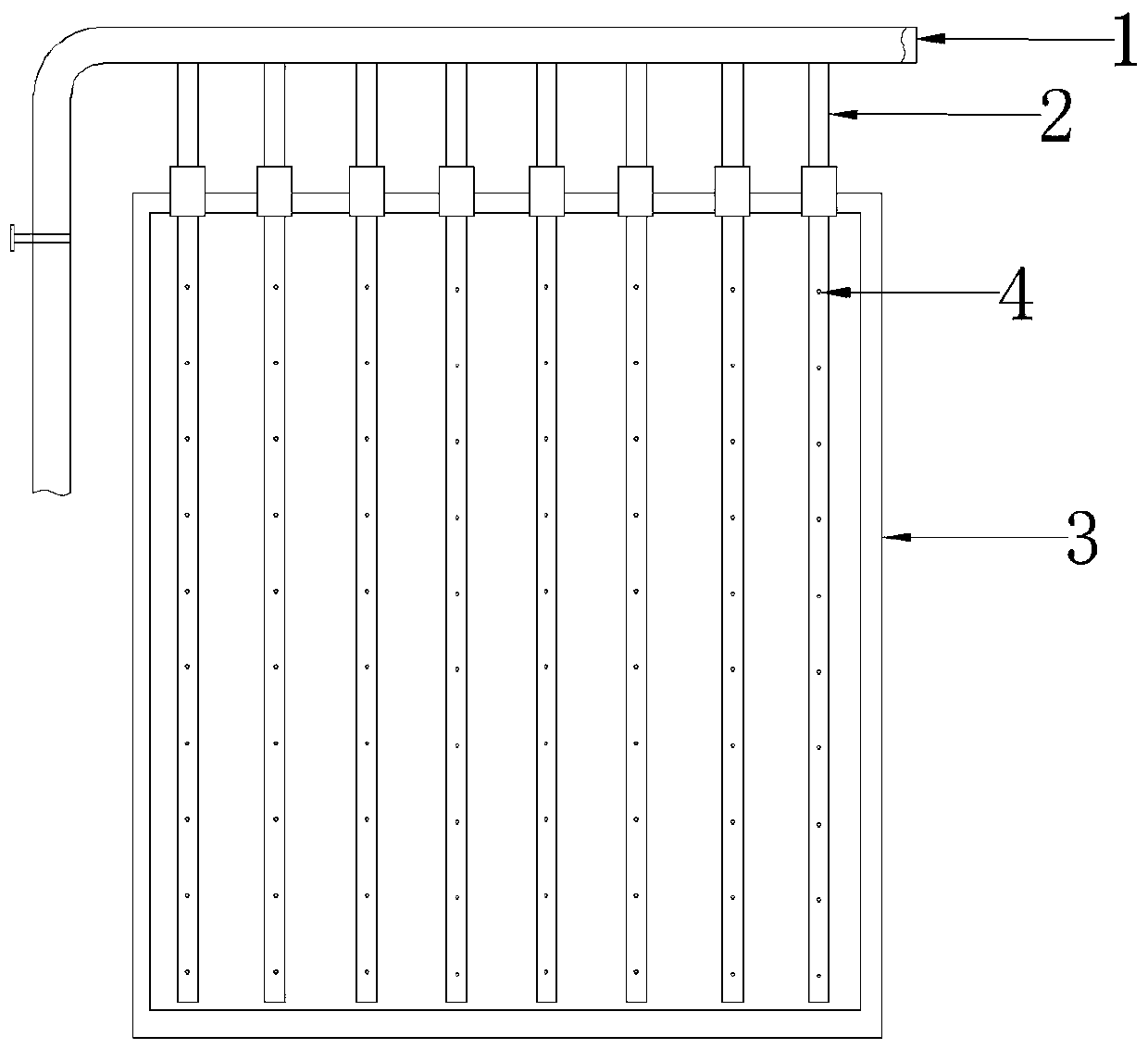

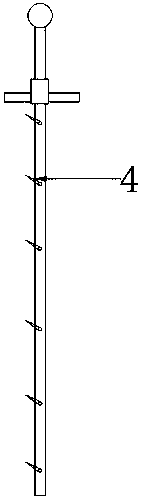

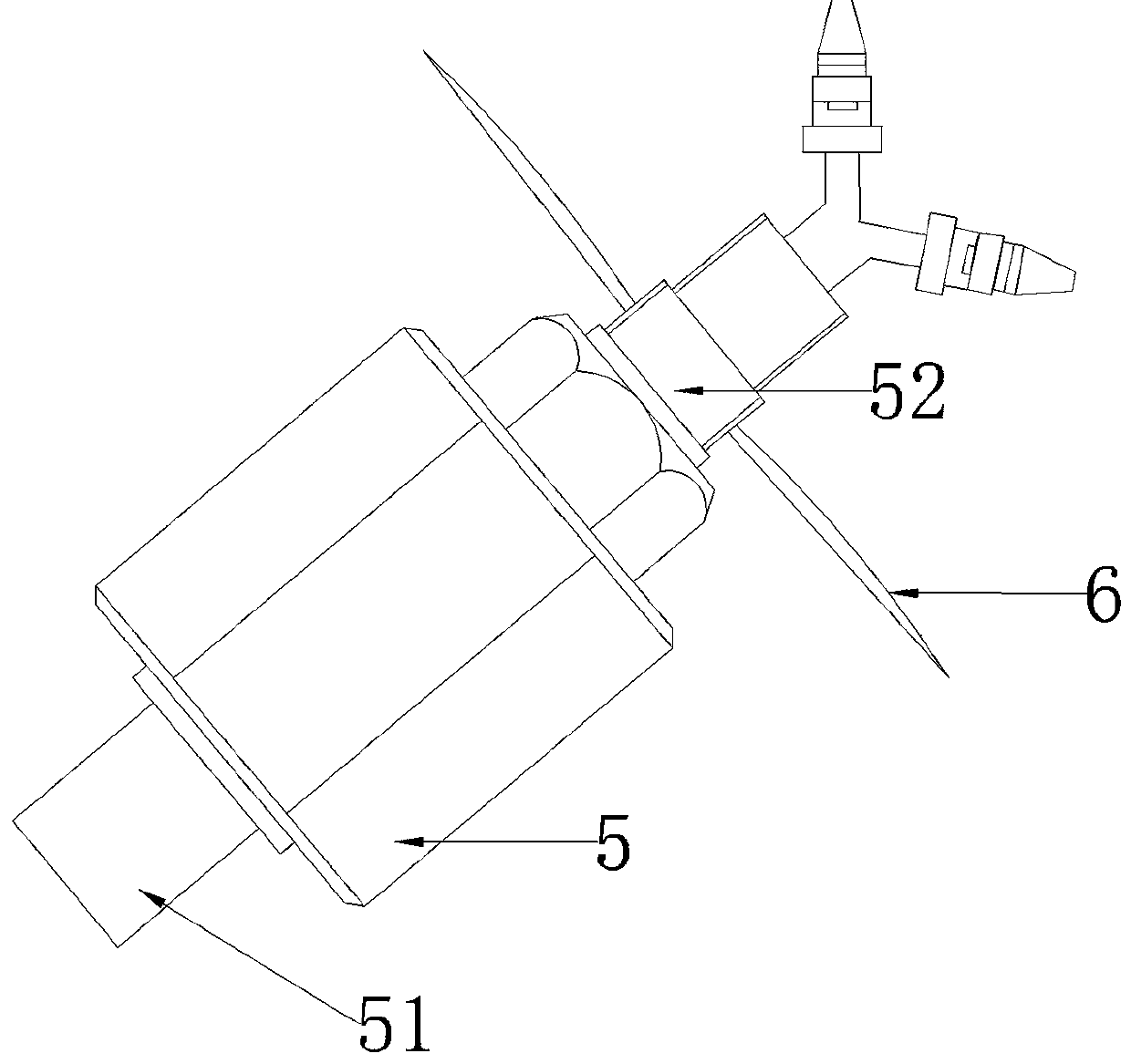

[0021] As shown in the figure, an ozone flow field active molecule distributor includes a main pipe 1, a number of branch pipes 2 connected to the main pipe parallel to each other and arranged at equal intervals, and a number of nozzles 4 arranged on the branch pipes. The branch pipes extend into the smoke Arranged in the channel section 3 and perpendicular to the flue section 3 with a temperature of 50-100°C, the nozzle 4 is connected to the branch pipe 2 through a single-channel rotary joint 5, and the single-channel rotary joint 5 in this embodiment includes a fixed end 51 and a The rotating end 52, wherein, the fixed end 51 is fixedly communicated with the branch pipe 2, and the rotating end 52 is provided with an external thread and an internal thread, and the nozzle 4 is fixed together with the rotating end 52 through the internal thread on the rotating end 52, and the rotating end The outer surface of 52 is screwed with a spoiler mechanism. The spoiler in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com