Geogrid steep slope embankment structure with wrapped faces and construction method thereof

A technology of geogrids and embankments, which is applied to the structure and construction of steep slope embankments of return-wrapped geogrids, to achieve the effects of improving stability, reducing construction costs, and solving difficulties in compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

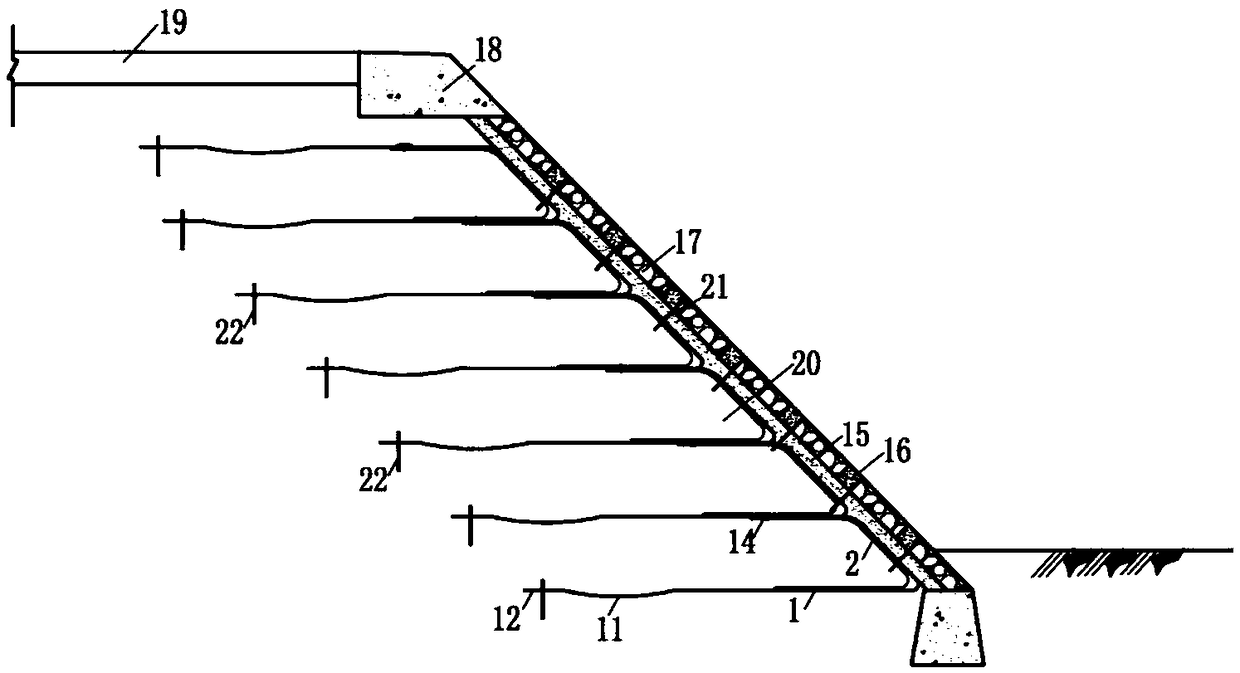

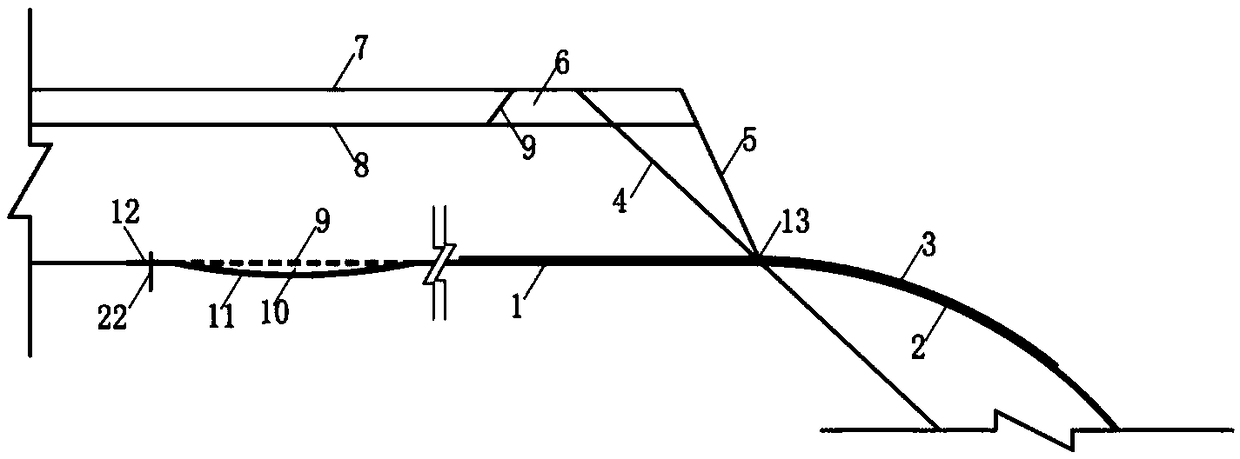

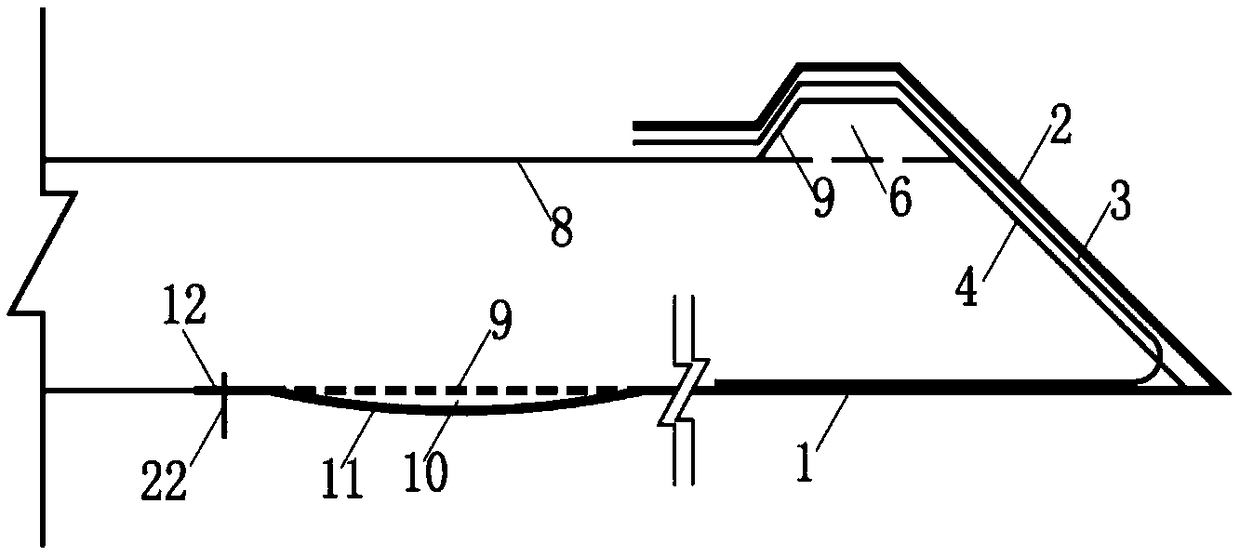

[0030] Such as figure 1 As shown, the present invention provides a return-wrapped geogrid steep slope embankment structure, the embankment slope is any slope slower than 1:0.5, and a plurality of back-wrapped geogrid layers are stacked up and down at the empty surface of the slope , laying a thick gravel cushion adjustment layer 15 and a grid prefabricated block 16 in sequence on the outside of the back-wrapped geogrid layer, and filling pebbles 17 in the grid prefabricated block 16;

[0031] The back-wrapping geogrid layer of each layer includes geogrid 1. The section of geogrid 1 in working state is a trapezoidal groove structure with one side open. The closed end of geogrid 1 is located on the empty surface of the slope. The inner wall of grid 1 is laid with geotextile, and the geote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com