Rolling technology method for ultra-thin ultra-wide steel plate

A process method, steel plate technology, applied in the direction of metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of low rolling hit rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] This example uses a 2800mm rolling mill to produce 8mm×2600mm Q235B steel plates. The actual size of the billet is 220mm*1810mm*1117mm, the rolling thickness is 7.6mm (negative tolerance rolling), and the steel row method adopts the cutting surface row steel. Rough rolling and finishing rolling are rolled 18 times in total, of which rough rolling is 10 times, and the pass reductions are 20, 24, 22, 20, 17

[0094] , 22, 8 (the final pass of widening), 14, 15, 16, and the reduction rate is above 12% (except the first pass and the final pass of widening). There are 8 passes of finishing rolling, the pass reductions are 8.84, 7.73, 6.8, 3.34, 2.89, 2.23, 1.68, 0.99, and the reduction ratios are all above 10%. The specific process is as follows:

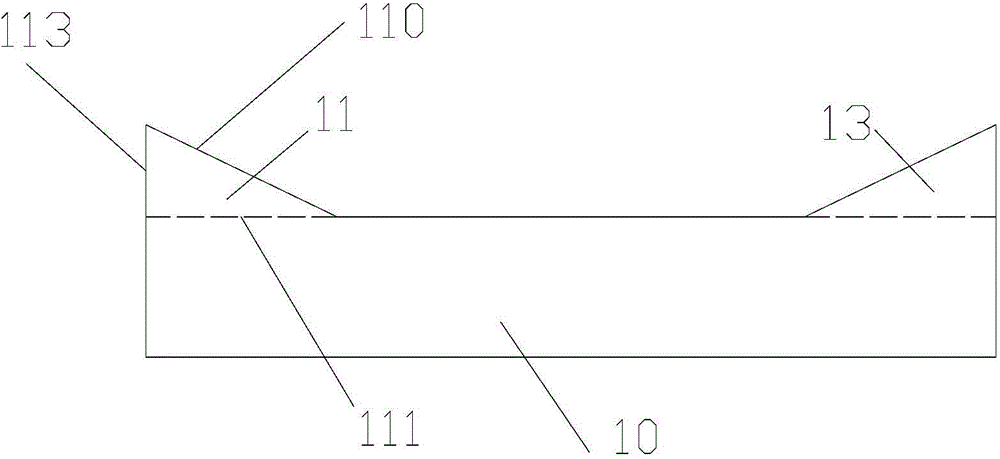

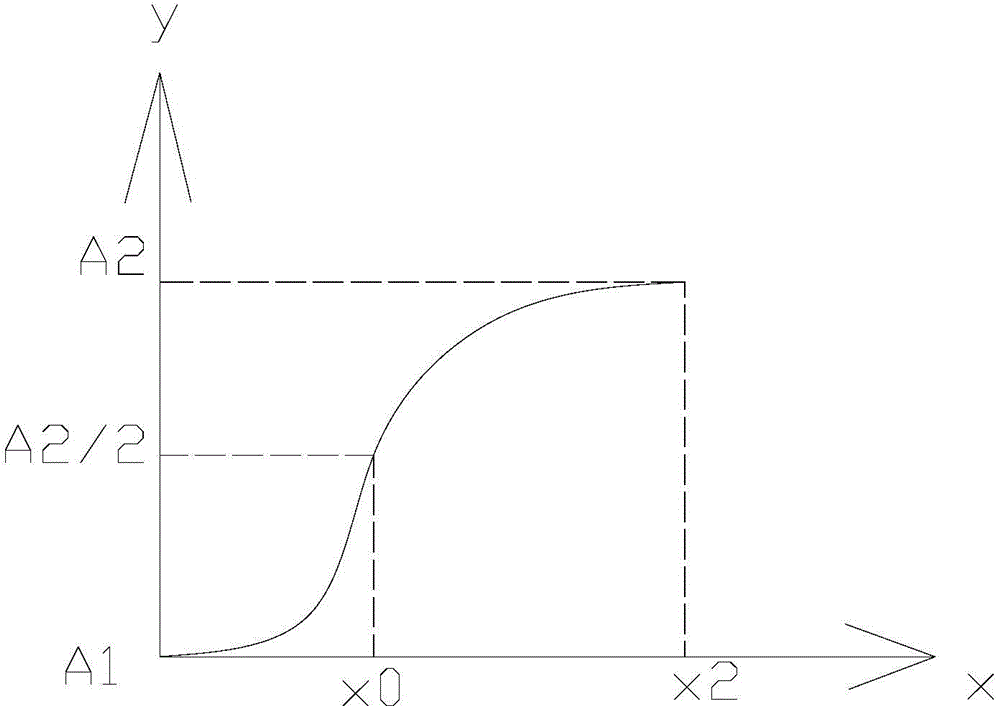

[0095] 1) Select a suitable back-up roll for the finishing mill, a flat roll with a chamfered edge, and a chamfered edge ratio of 3.5:200. Due to less rolling plans, select the work roll with a roll profile of ﹢0.06mm. The rolls...

Embodiment 2

[0101] This example uses a 2800mm rolling mill to produce a 6mm×2600mm Q345R steel plate. The actual size of the billet is 220mm*1580mm*1093mm, the rolling thickness is 7.6mm (negative tolerance rolling), and the steel row method adopts the cutting surface row steel. There are 18 passes of rough rolling and finish rolling, including 10 passes of rough rolling, and the pass reductions are 20, 28, 23.83, 22.99, 18.41, 17.5, 20.68, 18.2, 20.43, 13.7, 10.61. The reduction rate is above 10% (except the first pass), and there are 8 passes for finishing rolling. Above 13%, the specific process is as follows:

[0102] 1) Select a suitable back-up roll for the finishing mill, a flat roll with a chamfered edge, and a chamfered edge ratio of 3.5:200. Due to less rolling plans, select the work roll with a roll profile of ﹢0.06mm. The rolls were rolled after 3 hours of use. The effective cooling length of the roll is 2000mm. Before rolling, take advantage of the shift time to measure t...

Embodiment 3

[0107] Embodiment 3: In this example, a 2800mm rolling mill is used to produce a 10mm×2700mm Q235B steel plate. The actual size of the billet is 220mm*1500mm*1928mm, the rolling thickness is 9.8mm (negative tolerance rolling), and the steel row method adopts normal steel row. A total of 18 passes for rough rolling and finish rolling, including 10 passes for rough rolling, and the pass reductions are 19.86, 28.45, 25.66, 20.47, 17.89, 17.2, 11.13, 14.24, 14.38, 12.71. Rates are above 12% (except for the first pass). There are 8 passes of finishing rolling, the reductions of the passes are 4.27, 7.13, 4.08, 3.67, 3.5, 2.56, 2.05, 1.27, and the reductions of the passes are all above 10%. The specific process is as follows:

[0108] 1) Select a suitable back-up roll for the finishing mill, a flat roll with a chamfered edge, and a chamfered edge ratio of 3.5:200. Due to less rolling plans, select the work roll with a roll profile of ﹢0.06mm. The rolls are rolled after 8 hours of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com