An electromagnetic switching valve

An electromagnetic switching valve and valve body technology, which is applied to the valve details, valve device, valve housing structure, etc., can solve the problems of weak coordination stability of the control valve body 2, complex riveting process, and low riveting efficiency, so as to avoid positioning Unstable offset, reduced production cost, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

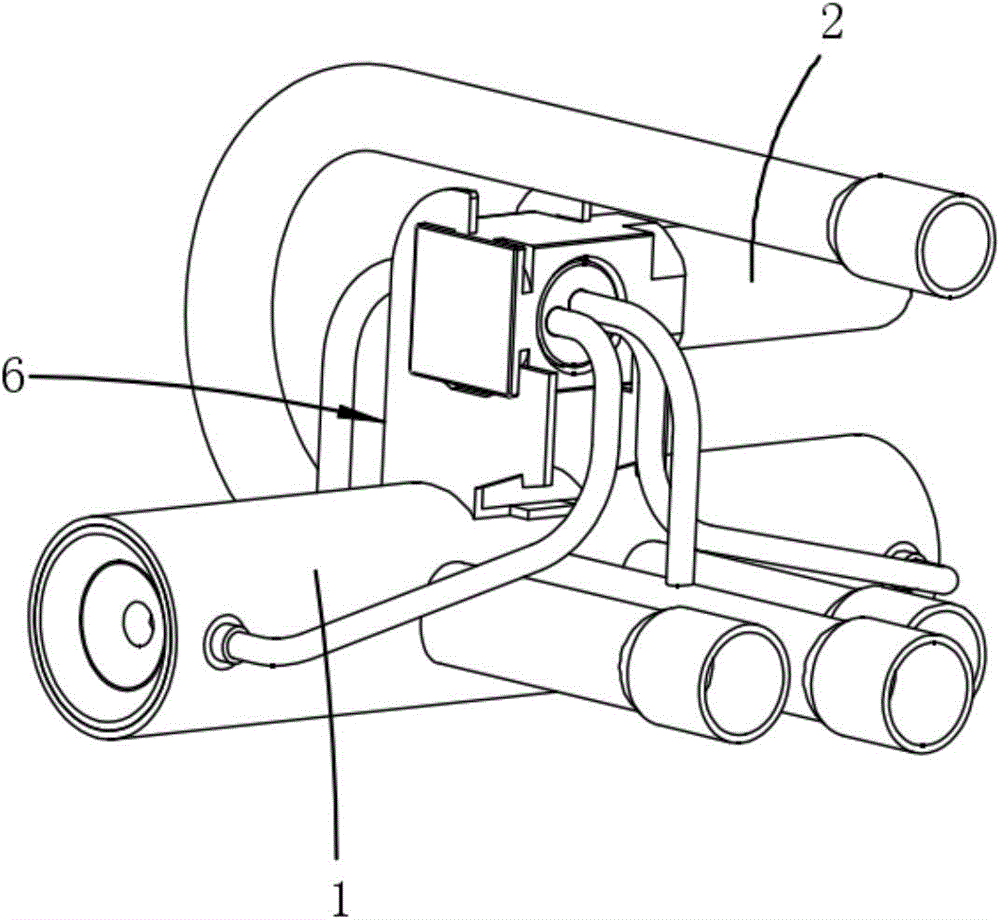

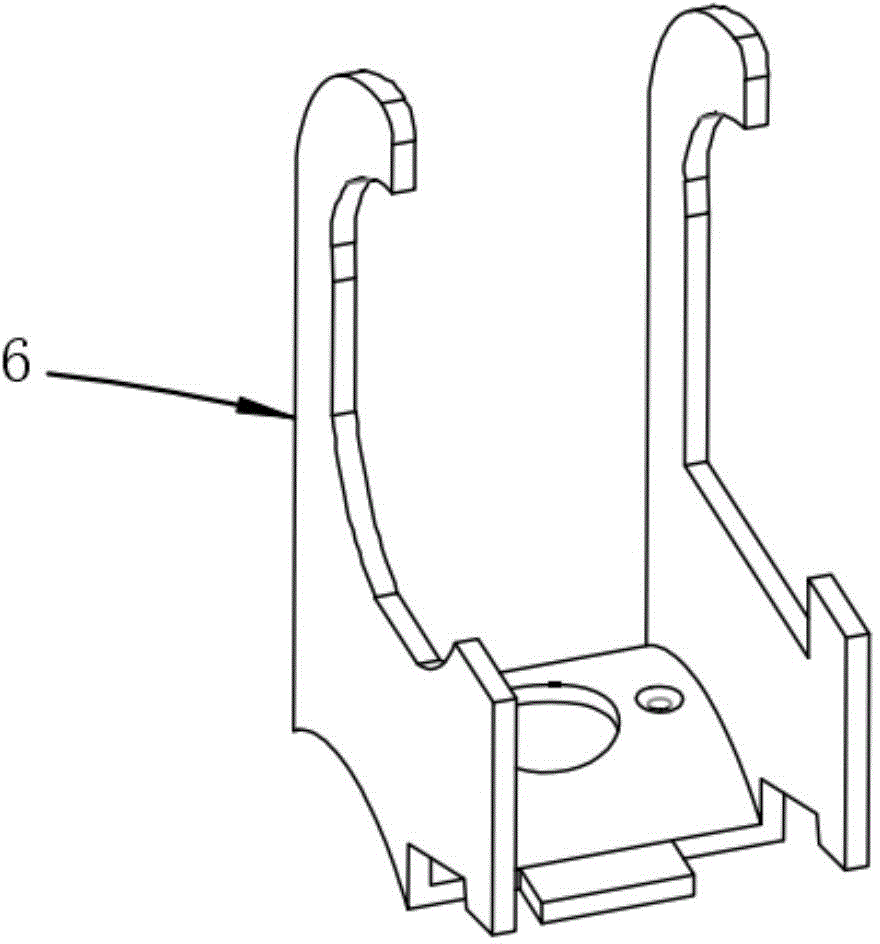

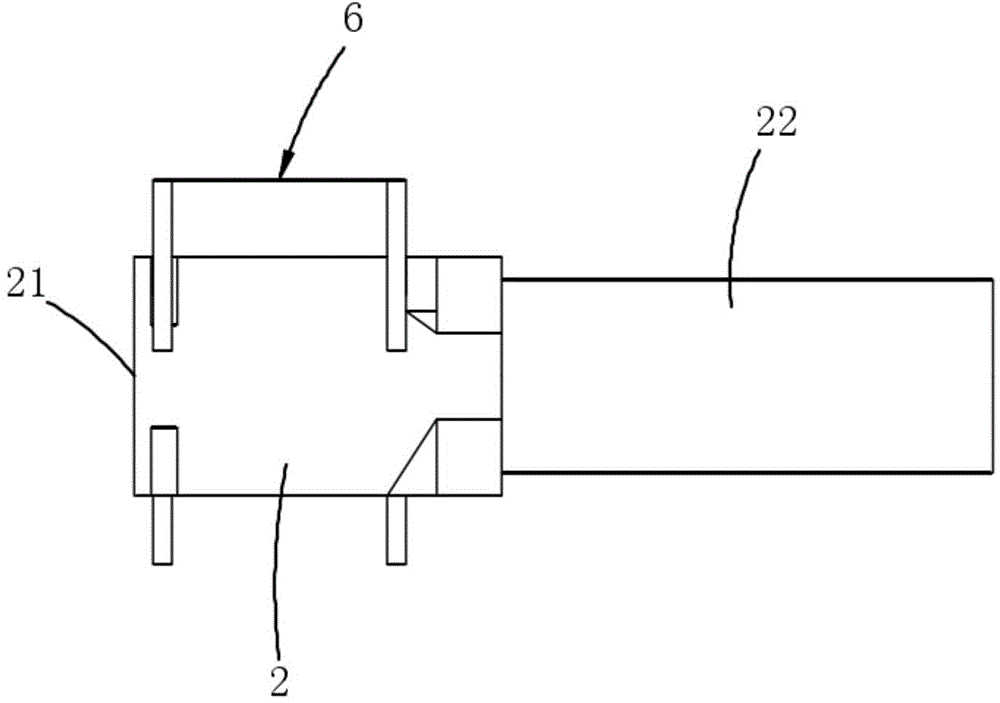

[0023] Example 1, see Figure 4 to Figure 6 Shown: an electromagnetic switching valve, including a main valve body 1, a control valve body 2 and a fixed frame 6 punched and formed by an integral die. The connecting bracket 4, the second side are provided with a round hole fixing frame 5, the buckle type fixing frame 3 and the round hole fixing frame 5 stand upright on both sides of the connecting bracket 4 respectively, the buckle type fixing frame 3, the connecting bracket 4 and the round hole The fixing frame 5 is connected into one body, the connecting bracket 4 is fixed on the main valve body 1, the side of the control valve valve body 2 close to the valve body end 21 is pierced through the round hole fixing frame 5, and the other side of the connecting conduit 22 is fixed on the Buckle mount 3.

[0024] The buckle-type fixing frame 3 includes a first sheet, the lower end of which is connected to the connecting bracket 4, and a buckle with one side opening is punched out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com