Compound lining process for western-style clothes manufacturing

A technology of craftsmanship and suits, which is applied in the field of relining technology for suit making, can solve the problems of lack of curve, too flatness, low balance, etc., and achieve the effect of improving the degree of conformity, increasing the sense of curve, and improving coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

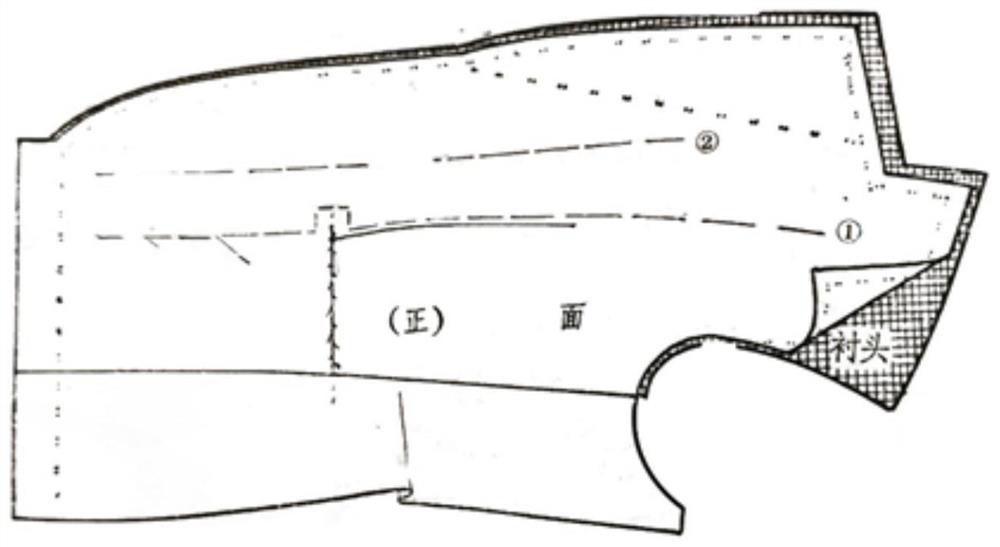

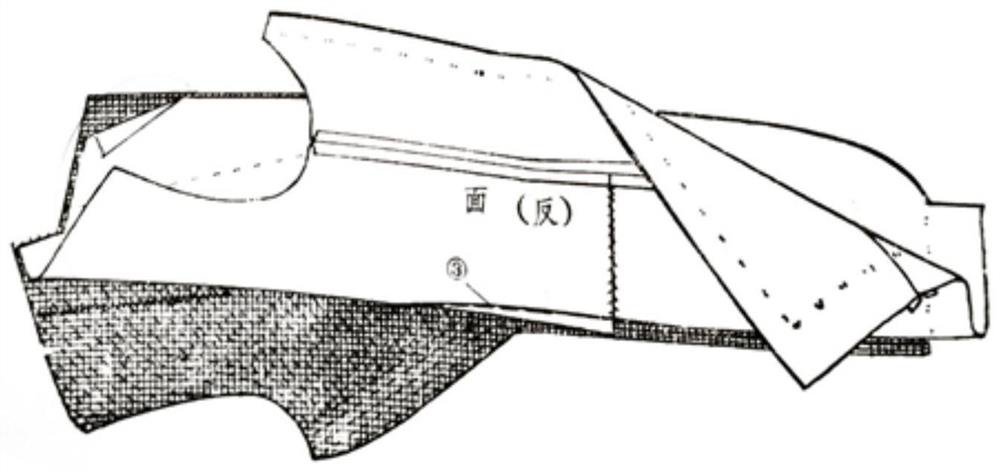

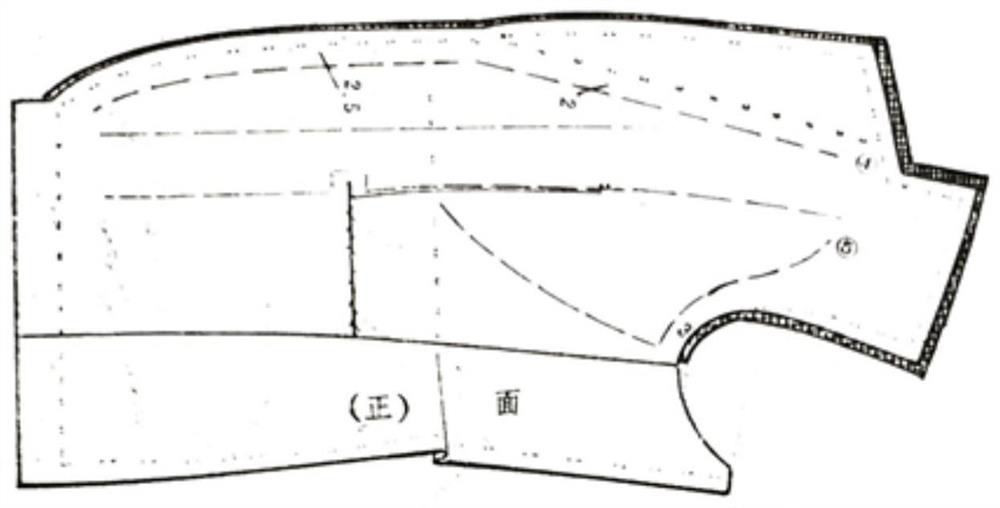

[0026] Such as figure 1 Shown, a kind of Western-style clothes is made and is used back lining process, and back lining process comprises the steps:

[0027] Step 1. Set the chest lining of the lining head down, place the front garment piece on the upper surface of the lining head, press the front garment piece and the lining head from the middle of the chest 7-11 cm away from the shoulder seam, and start with the tie thread Sew the first line with a stitch distance of 3-5 cm, tie it along the breast dart to the mouth of the big bag, and tie it into a concave shape at 1.3 cm near the line of the bag mouth, and then tie it straight to 2.5 cm above the bottom edge of the bag mouth So far, so far, the first line is over;

[0028] Step 2: Tie the second line from 10-14 cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com