Method for refining grain capable of dissolving aluminum alloy material

A technology for aluminum alloy materials and strengthening alloys, which is applied in the field of refining the grains of dissolvable aluminum alloy materials to achieve uniform dissolution, increase yield strength, and reduce cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

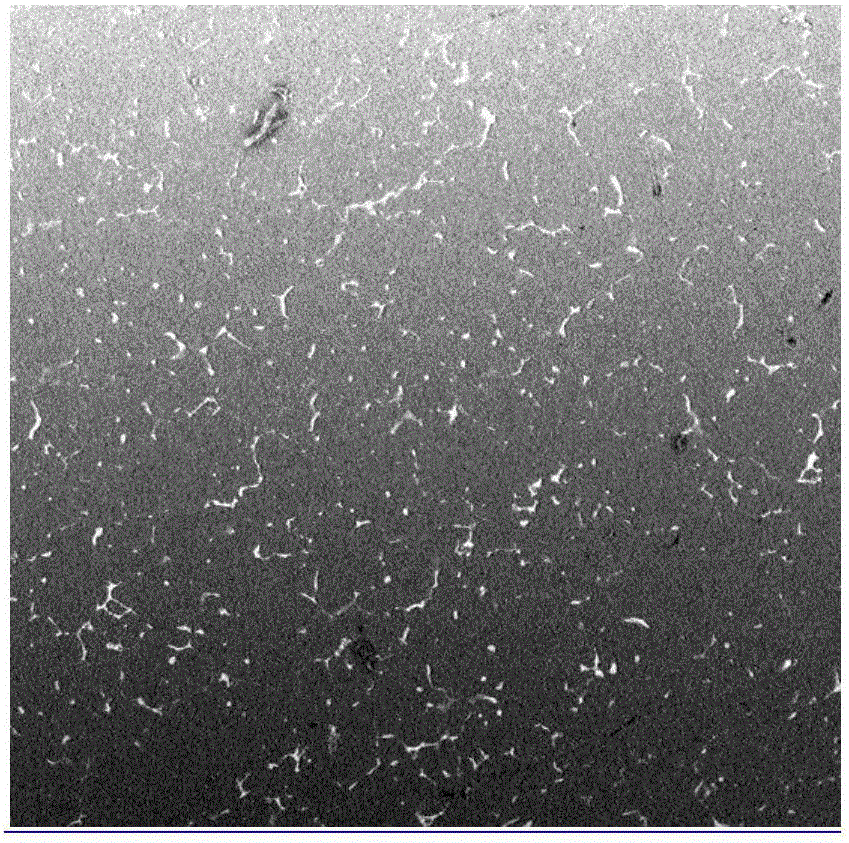

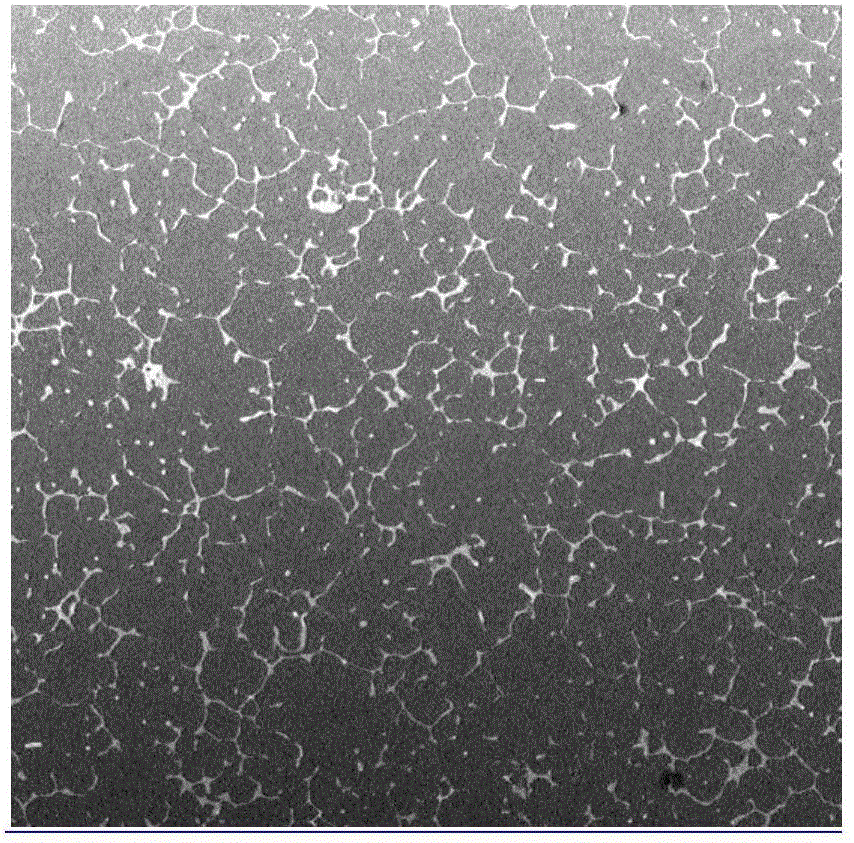

Image

Examples

Embodiment 1

[0019] Step 1. Put the aluminum ingot into the melting furnace and raise the temperature to 710°C to melt it into molten aluminum;

[0020] Step 2: Add 87.7wt% of the aluminum liquid obtained in step 1 to the prefabricated functional alloy (Al-Ga) 2wt%, strengthening alloy (Mg-Si-Mn) 5wt%, low-temperature alloy (Al-In) 0.3wt% according to the formula 87.7wt% wt% and activated alloy (Al-Mg-Sn-Zn) 5wt%, fully stirred, and kept at 710°C for 10min to make it a melt with macroscopically uniform properties;

[0021] Step 3. Add 0.6wt% defoamer to the melt obtained in step 2 and perform a slag removal process. Place the preheated mold in an oscillating magnetic field and cast it. The mechanical vibration frequency is 600 Hz, and the magnetic induction of the external magnetic field is It is 10T, and the casting is obtained;

[0022] Step 4. After cooling the casting obtained in Step 3 to room temperature, solid solution at 450°C for 6 hours, then cool in the furnace, then age at 250...

Embodiment 2

[0024] Step 1. Put the aluminum ingot into the melting furnace and raise the temperature to 710°C to melt it into molten aluminum;

[0025] Step 2: Add 1.5wt% of the prefabricated functional alloy (Al-Ga), 3wt% of the strengthening alloy (Mg-Si-Mn), and 0.5wt% of the low-temperature alloy (Al-In) to the aluminum liquid obtained in the step 1 according to the formula 90wt%. wt% and activated alloy (Al-Mg-Sn-Zn) 5wt%, fully stirred, and kept at 760 ° C for 20 minutes to make it a melt with macroscopically uniform properties;

[0026] Step 3. Add 0.6wt% defoamer to the melt obtained in step 2 and perform a slag removal process. Place the preheated mold in an oscillating magnetic field and cast it. The mechanical vibration frequency is 600 Hz, and the magnetic induction of the external magnetic field is For 15T, get the casting;

[0027] Step 4. After cooling the casting obtained in Step 3 to room temperature, solid solution at 430°C for 12 hours, then cool in the furnace, then a...

Embodiment 3

[0029] Step 1. Put the aluminum ingot into the melting furnace and raise the temperature to 760°C to melt it into molten aluminum;

[0030] Step 2. Add 65wt% of the aluminum liquid obtained in step 1 to the prefabricated functional alloy (Al-Ga) 6wt%, strengthening alloy (Mg-Si-Mn) 10wt%, and low-temperature alloy (Al-In) 8.5wt% in sequence according to the formula 65wt% % and activated alloy (Al-Mg-Sn-Zn) 10.5wt%, fully stirred, and kept at 760 ° C for 10 minutes to make it a melt with macroscopically uniform properties;

[0031] Step 3. Add 0.6wt% defoamer to the melt obtained in step 2 and perform a slag removal process. Place the preheated mold in an oscillating magnetic field and cast it. The mechanical vibration frequency is 600 Hz, and the magnetic induction of the external magnetic field is For 6T, get the casting;

[0032] Step 4. After cooling the casting obtained in Step 3 to room temperature, solid solution at 460°C for 6 hours, then cool in the furnace, then age ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com