Phosphoric acid based etching liquid and method for preparing same

A technology of phosphoric acid-based etching and etching solution, which is applied in the field of electronic chemicals to achieve the effects of shortening time, reducing etching rate and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

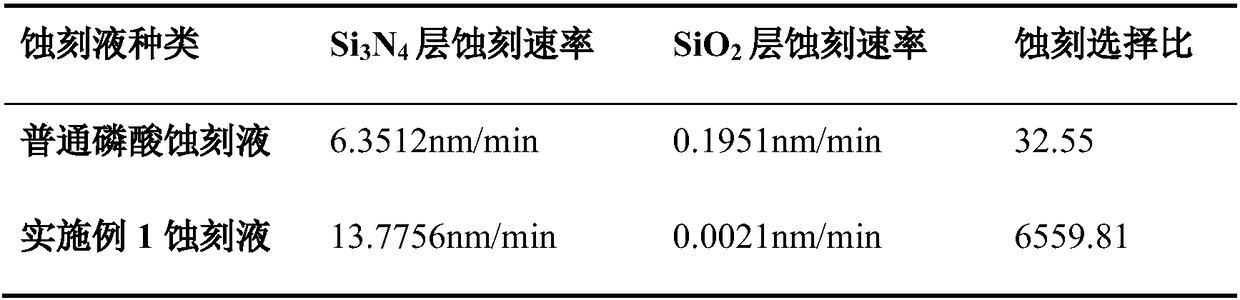

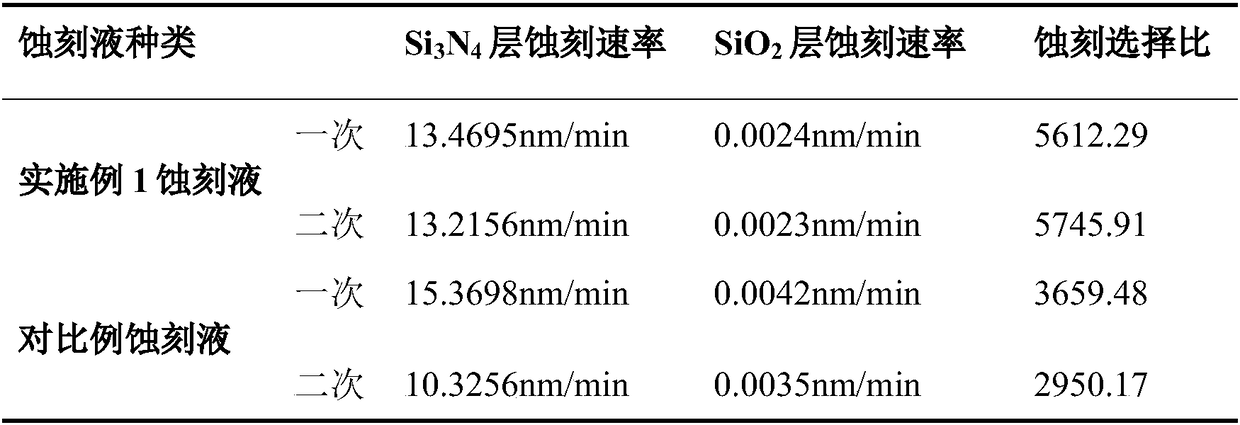

Examples

Embodiment 1

[0024] A kind of phosphoric acid-based etchant with high etching selectivity is obtained by configuring as follows:

[0025] (1) According to the mass percentage of each raw material: phosphoric acid 85%, siloxane 0.02%, ammonium fluoride 0.01%, heterocyclic fluorine stabilizer 0.01%, cationic surfactant 0.5%, select each reagent, and the remaining part is super pure water.

[0026] (2) Mix ammonium fluoride, heterocyclic fluorine stabilizer and a certain amount of ultrapure water evenly, and set aside;

[0027] (3) Add siloxane, remaining ultrapure water and cationic surfactant to electronic-grade phosphoric acid, mix evenly, and disperse by ultrasonic;

[0028] (4) Add the mixed solution in step (2) to the mixed solution in step (3), stir and sonicate, and then stand still for more than 24 hours.

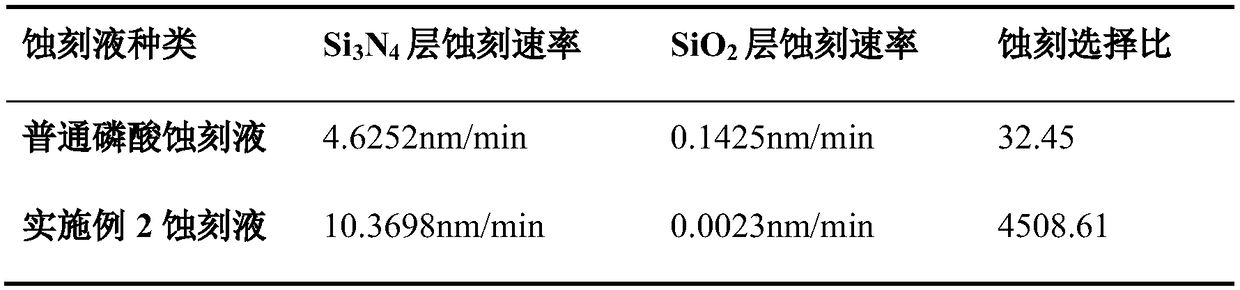

Embodiment 2

[0034] A kind of phosphoric acid-based etchant with high etching selectivity is obtained by configuring as follows:

[0035] (1) According to the mass percentage of each raw material: phosphoric acid 82%, siloxane 0.03%, ammonium fluoride 0.02%, heterocyclic fluorine stabilizer 0.02%, cationic surfactant 1%, select each reagent, and the remaining part is super pure water.

[0036] (2) Mix ammonium fluoride, heterocyclic fluorine stabilizer and a certain amount of ultrapure water evenly, and set aside;

[0037] (3) Add siloxane, remaining ultrapure water and cationic surfactant to electronic-grade phosphoric acid, mix evenly, and disperse by ultrasonic;

[0038] (4) Add the mixed solution in step (2) to the mixed solution in step (3), stir and sonicate, and then stand still for more than 24 hours.

Embodiment 3

[0040] A kind of phosphoric acid-based etchant with high etching selectivity is obtained by configuring as follows:

[0041] (1) According to the mass percentage of each raw material: phosphoric acid 82%, silanol 0.01%, fluosilicic acid 0.02%, ammonium salt fluorine stabilizer 0.02%, nonionic surfactant 1%, select each reagent, and the remaining part is super pure water.

[0042] (2) Mix fluosilicic acid, ammonium salt fluorine stabilizer and a certain amount of ultrapure water evenly, and set aside;

[0043] (3) Add silanol, remaining ultrapure water and nonionic surfactant to electronic-grade phosphoric acid, mix evenly, and disperse by ultrasonic;

[0044] (4) Add the mixed solution in step (2) to the mixed solution in step (3), stir and sonicate, and then stand still for more than 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com