Novel platinum-based high-temperature resistance strain alloy and preparation method thereof

A resistance strain, high temperature technology, applied in the field of metal materials, can solve the problems of reduced resistivity and mechanical properties, inability to meet the requirements of strained materials, deterioration of alloy stability, etc., to reduce oxidation and volatilization, and improve organizational uniformity and stability. The effect of resistance and moderate tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Each component of the alloy is formulated according to the ingredients of 15%Rh, 5%Mo, 4%Re, 0.5%Cr, 0.3%Ni, 0.1%Y, and the balance of Pt. It is melted in a high-purity zirconia crucible and a high-frequency induction furnace. When smelting, vacuumize the smelting chamber to 0.5×10 -3 Pa, filled with high-purity argon (99.999%, volume fraction) to positive pressure, the alloy should be fully degassed in the molten state to increase the density of the ingot, and the melt is overheated at 180°C and cast into a crystallization mold. The ingot is forged at 1200°C, drawn at 800°C, drawn at room temperature, intermediate annealed, drawn into filaments, and processed into ultra-fine wires with a diameter of Φ0.03mm. Stabilization treatment: heat preservation at 1200°C for 2 minutes, water quenching, 900 ℃ stabilization treatment for 30 hours, the performance is shown in Table 1.

Embodiment 2

[0020] Each component of the alloy is formulated according to the ingredients of 20%Rh, 7%Mo, 6%Re, 1.0%Cr, 0.5%Ni, 0.2%Zr, 0.2%Y, and the balance of Pt. High-purity zirconia crucible, high-frequency induction Furnace smelting, vacuumize the smelting chamber to 0.3×10 - 2 Pa, filled with high-purity argon (99.999%, volume fraction) to positive pressure, the alloy should be fully degassed in the molten state to increase the density of the ingot, and the melt is overheated at 200 ° C and cast into a crystallization mold. The ingot is forged at 1300°C, drawn at 900°C, drawn at room temperature, intermediate annealed, drawn into filaments, and processed into ultra-fine wires with a diameter of Φ0.03mm. Stabilization treatment: heat preservation at 1200°C for 2 minutes, water quenching, 1000 ℃ stabilization treatment for 30 hours, the performance is shown in Table 1.

Embodiment 3

[0022] Each component of the alloy is formulated according to the ingredients of 30% Rh, 9% Mo, 8% Re, 1.5% Cr, and the rest of Pt. It is melted in a high-purity zirconia crucible and a high-frequency induction furnace. When melting, the melting chamber is first evacuated. to 0.3×10 -2 Pa, filled with high-purity argon (99.999%, volume fraction) to positive pressure, the alloy should be fully degassed in the molten state to increase the density of the ingot, and the melt is overheated at 230 ° C and cast into a crystallization mold. The ingot is forged at 1350°C, drawn at 950°C, drawn at room temperature, intermediate annealed, drawn into filaments, and processed into ultra-fine wires with a diameter of Φ0.03mm. Stabilization treatment: 1200°C for 2 minutes, water quenching, 1000°C Stabilized for 30 hours, the properties are shown in Table 1.

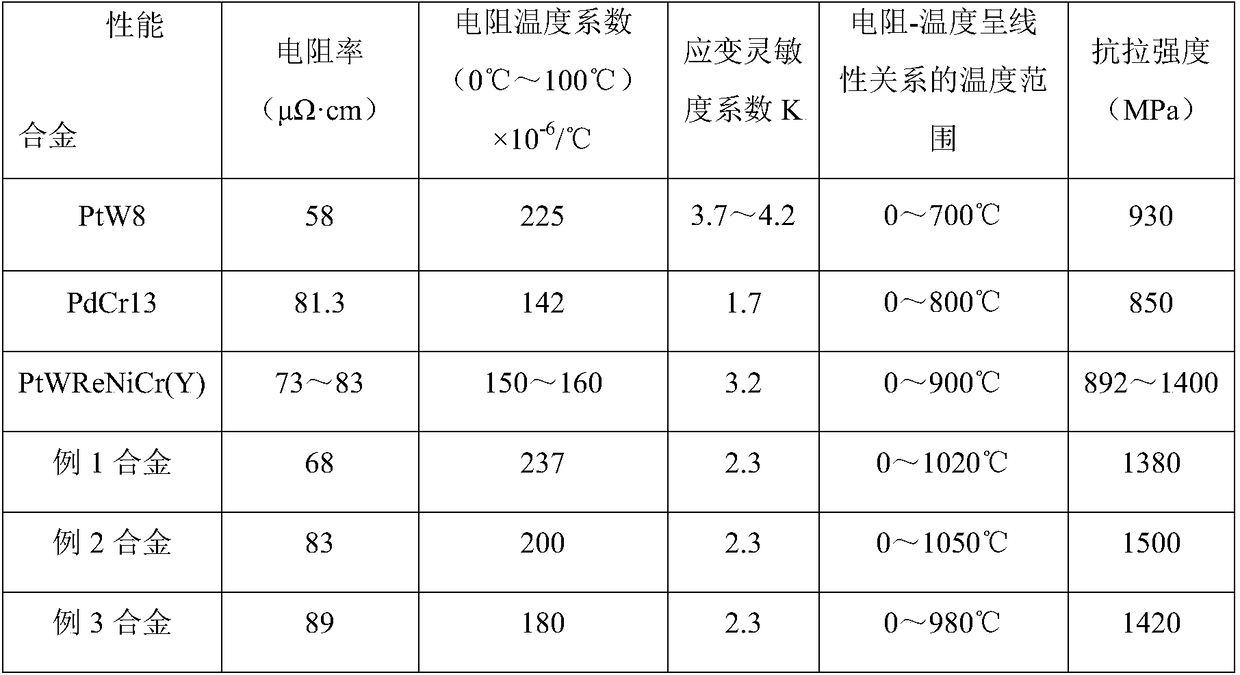

[0023] Table 1 is the comparison of mechanical properties and electrical properties of PtRhMoReCr and PdCr13, PtW8, PtWReNiCr (Y) res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com