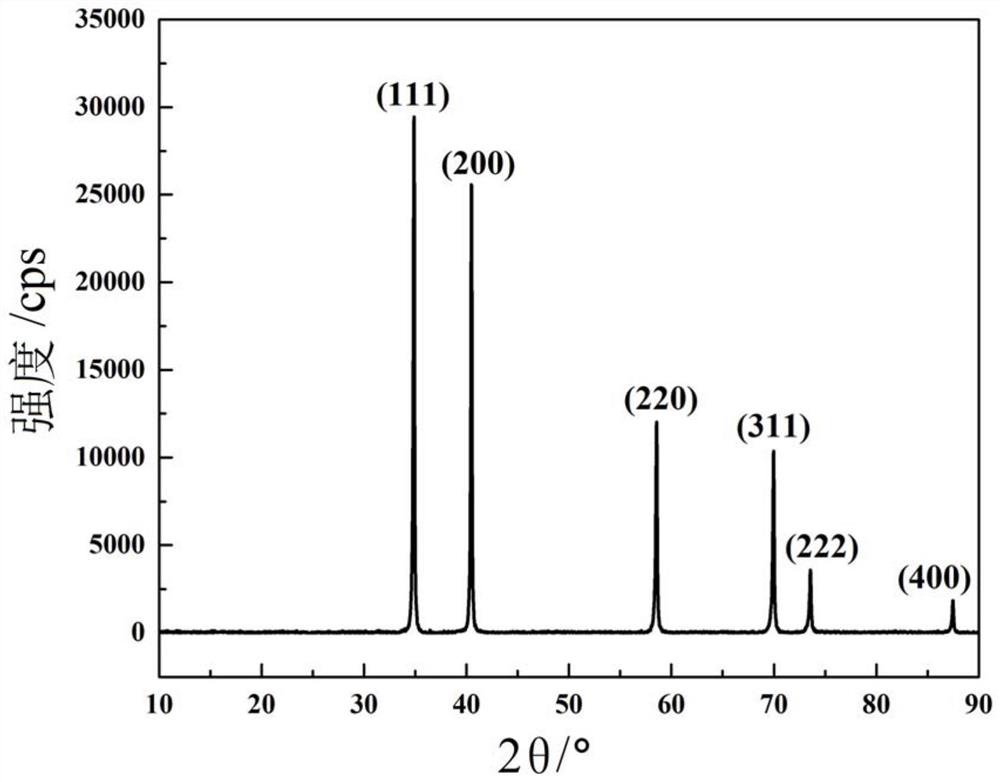

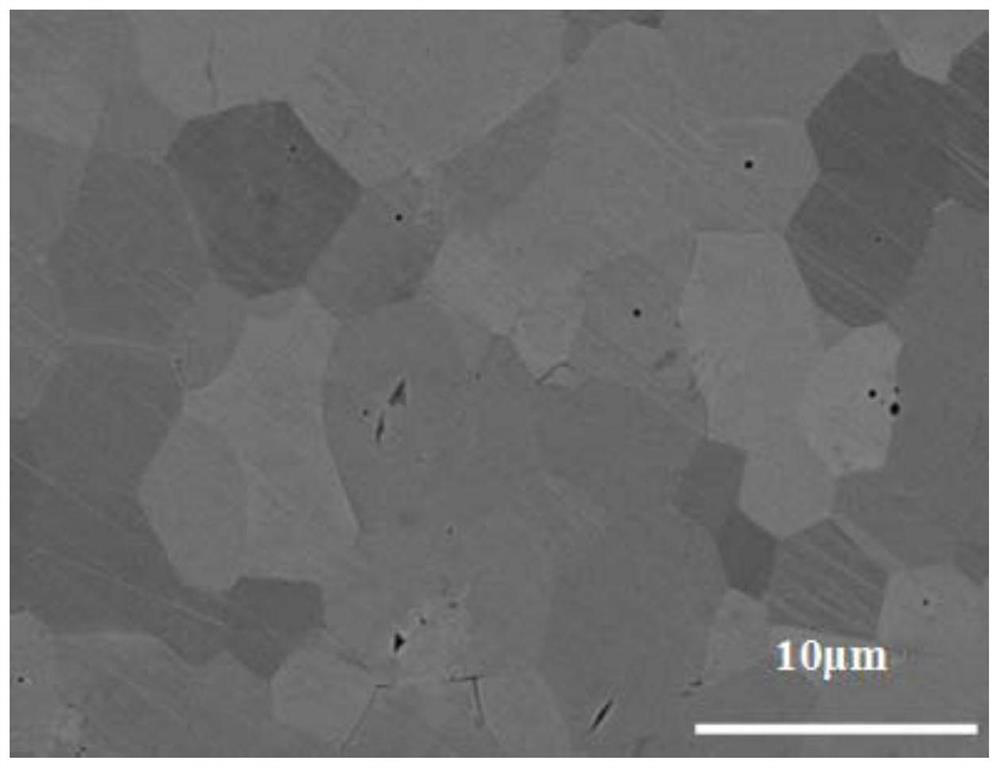

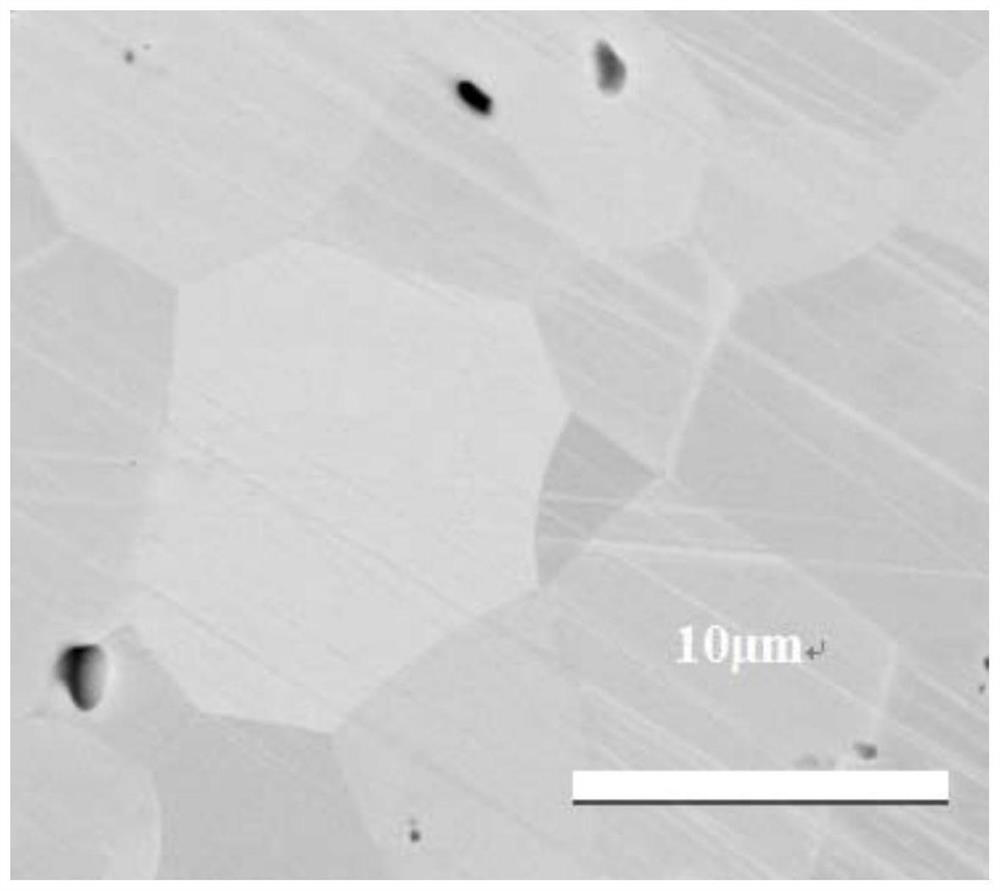

A kind of superhard five-component transition metal carbide single-phase high-entropy ceramic material and preparation method thereof

A technology for transition metals and ceramic materials, applied in the field of superhard ceramic materials, can solve the problems of multi-component carbide oxygen pollution and difficulty in increasing the density, and achieve mutual solid solution, strength and hardness improvement, and density and density. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific embodiment one: the present embodiment is a superhard five-element transition metal carbide single-phase high-entropy ceramic material whose chemical formula is (Ti x1 Zr x2 Nb x3 Ta x4 m x5 ) C; said M is V, Cr, Mo or W; said x1+x2+x3+x4+x5=1.

specific Embodiment approach 2

[0034] Specific embodiment two: This embodiment is a preparation method of a superhard five-component transition metal carbide single-phase high-entropy ceramic material, which is completed according to the following steps:

[0035] 1. Weighing:

[0036] ①. Weigh the metal oxide:

[0037] According to the molar ratio of titanium oxide, zirconium oxide, niobium oxide, tantalum oxide and M oxide is (1~4):(1~4):(1~4):(1~4):(1 ~4) Weighing titanium oxide, zirconium oxide, niobium oxide, tantalum oxide and M oxide respectively to obtain metal oxide;

[0038] ②. Calculate the total amount of reducing carbon powder:

[0039] According to the reaction equation is A x o y +(bx / a+y)C=x / aA a C b+ yCO respectively calculate the amount of reducing carbon powder required for the carbonization reaction of titanium oxide, zirconium oxide, niobium oxide, tantalum oxide and M oxide weighed in step ①, and then add up to obtain The total amount of reducing carbon powder;

[0040] A in the...

specific Embodiment approach 3

[0053] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the titanium oxide described in step one is TiO 2 or Ti 2 o 3 . Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com