Rare earth-contained heat-resistant magnesium alloy and preparation method thereof

A magnesium alloy and heat-resistant technology, which is applied in the field of low-cost heat-resistant magnesium alloy containing rare earth and zinc and its preparation, can solve the problems of limiting the wide application of WE43 alloy, reducing the mechanical properties of the alloy, and the mechanical properties at low room temperature, and achieving good Effect of solid solution strengthening and aging strengthening, improving high temperature properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

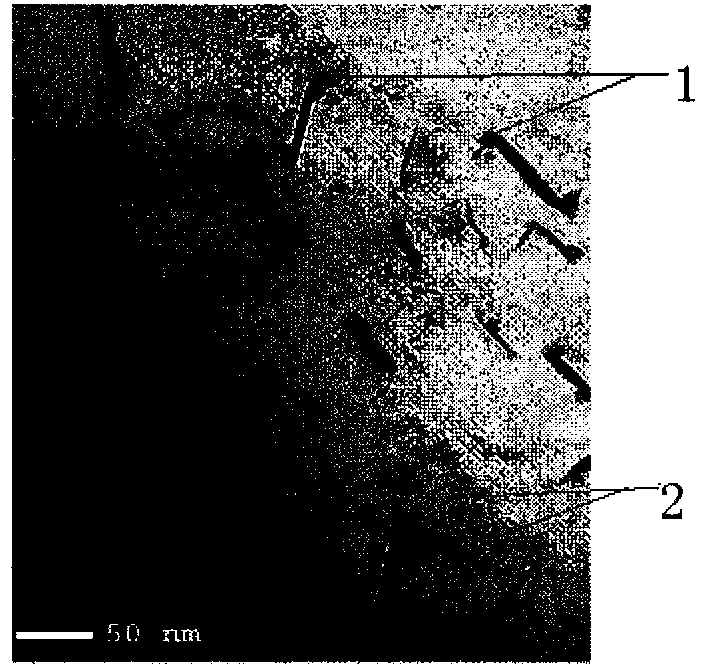

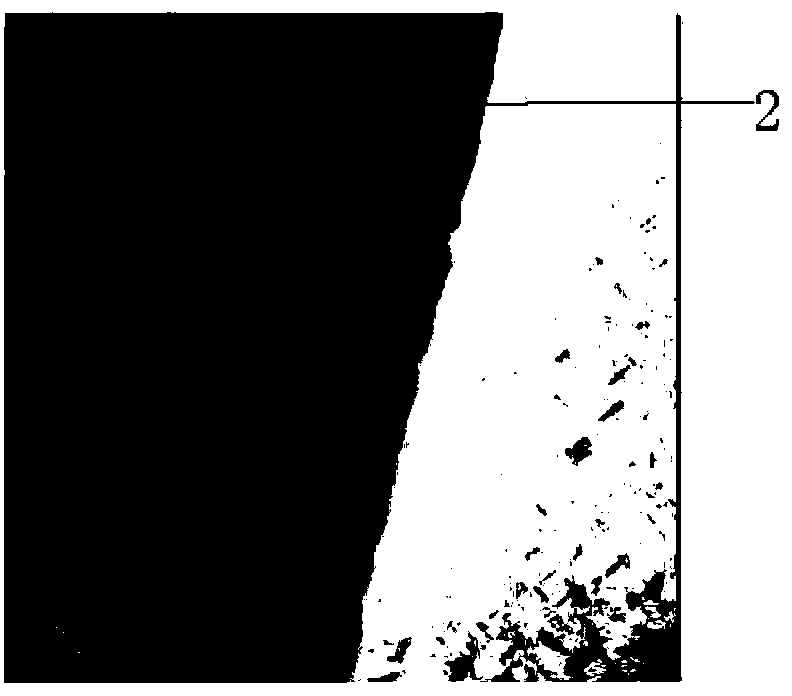

Image

Examples

Embodiment 1

[0039] Alloy composition (percentage by weight): 3%Sm, 2%Gd, 0.5%Zn, 0.5%Zr, impurity elements are less than 0.02%, and the rest is Mg.

[0040] The melting process of the alloy is as follows: prepare the alloy according to the above ingredients, fully dry the raw materials in an oven at 180°C, add pure magnesium into the resistance crucible furnace, and use SF 6 and CO 2 Mixed gas (1:95) for protection, after the magnesium ingot is completely melted, add industrial pure zinc at 680 ° C, stir and melt; when the temperature of the magnesium liquid reaches 720 ° C, add Mg-Sm intermediate alloy to the magnesium liquid, After Mg-Sm is melted, when the temperature of the molten magnesium rises to 720°C, add the Mg-Gd master alloy; after raising the temperature of the magnesium liquid to 780°C, add the Mg-Zr master alloy, stir for 2 minutes to fully melt; raise the temperature to 790°C and After heat preservation for 15 minutes, cool down to 760°C, refine for 5 minutes, and stand s...

Embodiment 2

[0045] Alloy composition (percentage by weight): 4%Sm, 4%Gd, 0.5%Zn, 0.5%Zr, impurity elements are less than 0.02%, and the rest is Mg.

[0046] The melting process of the alloy is as follows: prepare the alloy according to the above ingredients, fully dry the raw materials in an oven at 200°C, add pure magnesium into the resistance crucible furnace, and use SF 6 and CO 2 Mixed gas (1:100) for protection, after the magnesium ingot is completely melted, add industrial pure zinc at 700 ° C, stir and melt; when the temperature of the magnesium liquid reaches 720 ° C, add Mg-Sm intermediate alloy to the magnesium liquid, After Mg-Sm is melted, when the temperature of the magnesium liquid rises to 720°C, add the Mg-Gd master alloy; after the temperature of the magnesium liquid rises to 760°C, add the Mg-Zr master alloy, stir for 2 minutes to fully melt; heat up to 800°C and After heat preservation for 20 minutes, cool down to 740°C, refine for 10 minutes, and stand still after ref...

example 3

[0051] Alloy composition (percentage by weight): 5%Sm, 5%Gd, 1%Zn, 0.5%Zr, impurity elements are less than 0.02%, and the rest is Mg.

[0052] The melting process of the alloy is as follows: prepare the alloy according to the above ingredients, fully dry the raw materials in an oven at 220°C, add pure magnesium into the resistance crucible furnace, and use SF 6 and CO 2 Mixed gas (1:105) for protection. After the magnesium ingot is completely melted, industrial pure zinc is added at 720°C; when the temperature of the magnesium liquid reaches 740°C, Mg-Sm intermediate alloy is added to the magnesium liquid, and the Mg-Sm After melting, when the temperature of the molten magnesium rises to 740°C, add the Mg-Gd master alloy; after raising the temperature of the magnesium liquid to 780°C, add the Mg-Zr master alloy, stir for 2 minutes to fully melt; keep the temperature at 780°C for 30 minutes, then cool down to 750 ℃, refining for 5 minutes, standing after refining, and the stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com