Powder metallurgy preparation method of Fe-Mn-Al series alloy

A powder metallurgy and alloy powder technology, which is applied in the field of powder metallurgy preparation of Fe-Mn-Al series alloys, can solve the influence of heating rate and sintering temperature on structure and composition, affect material strength, plasticity and comprehensive mechanical properties, and is difficult to obtain high The density and other issues can be solved to achieve the effect of good oxidation resistance and corrosion resistance, light weight and anti-oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

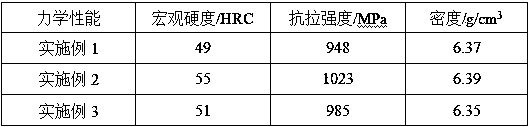

Embodiment 1

[0019] The powder metallurgy preparation method of this Fe-Mn-Al series alloy, its specific steps are as follows:

[0020] (1) First, mix nano-scale aluminum powder, manganese powder and iron powder in a mass ratio of 11:25:64 to obtain Fe-Mn-Al mixed powder;

[0021] (2) Under the protection of argon, heat the Fe-Mn-Al mixed powder obtained in step (1) to 1450°C in an induction furnace to melt for 1 hour to obtain a qualified alloy liquid, and then inject the alloy liquid into the atomizing nozzle In the tundish of the tundish, the alloy liquid flows out from the leak hole at the bottom of the tundish at a flow rate of 1.8kg / min. When passing through the HK-03 ring hole nozzle, it meets the high-speed argon gas flow with a pressure of 6MPa and is atomized into fine droplets. The liquid droplets are rapidly solidified into Fe-Mn-Al alloy powder in the closed atomizing cylinder, and pass through a 100-point injection sieve;

[0022] (3) Compress the Fe-Mn-Al alloy powder obtai...

Embodiment 2

[0024] The powder metallurgy preparation method of this Fe-Mn-Al series alloy, its specific steps are as follows:

[0025] (1) First, mix nano-manganese aluminum powder, manganese powder and iron powder in a mass ratio of 10:20:70 to obtain Fe-Mn-Al mixed powder;

[0026] (2) Under the protection of argon, heat the Fe-Mn-Al mixed powder obtained in step (1) to 1450°C in an induction furnace to melt for 1 hour to obtain a qualified alloy liquid, and then inject the alloy liquid into the atomizing nozzle In the tundish of the tundish, the alloy liquid flows out from the leak hole at the bottom of the tundish at a flow rate of 1.8kg / min. When passing through the HK-03 ring hole nozzle, it meets the high-speed argon gas flow with a pressure of 6MPa and is atomized into fine droplets. The liquid droplets are rapidly solidified into Fe-Mn-Al alloy powder in the closed atomizing cylinder, and pass through a 100-point injection sieve;

[0027] (3) Compress the Fe-Mn-Al alloy powder o...

Embodiment 3

[0029] The powder metallurgy preparation method of this Fe-Mn-Al series alloy, its specific steps are as follows:

[0030] (1) First, mix nano-scale aluminum powder, manganese powder and iron powder in a mass ratio of 12:29:59 to obtain Fe-Mn-Al mixed powder;

[0031] (2) Under the protection of argon, heat the Fe-Mn-Al mixed powder obtained in step (1) to 1450°C in an induction furnace to melt for 1 hour to obtain a qualified alloy liquid, and then inject the alloy liquid into the atomizing nozzle In the tundish of the tundish, the alloy liquid flows out from the leak hole at the bottom of the tundish at a flow rate of 1.8kg / min. When passing through the HK-03 ring hole nozzle, it meets the high-speed argon gas flow with a pressure of 6MPa and is atomized into fine droplets. The liquid droplets are rapidly solidified into Fe-Mn-Al alloy powder in the closed atomizing cylinder, and pass through a 100-point injection sieve;

[0032] (3) Compress the Fe-Mn-Al alloy powder obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com