Preparation method of Ni-Cr-Al-Fe-series high-temperature alloy

A technology of high-temperature alloys and alloys, applied in the field of high-temperature alloys, to achieve good fatigue performance, simple process, and good high-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

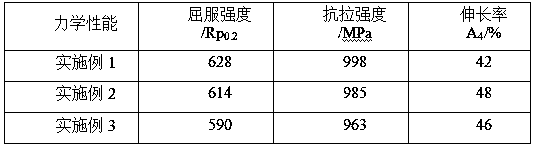

Embodiment 1

[0018] Embodiment 1: a kind of preparation method of Ni-Cr-Al-Fe series superalloy, concrete steps are as follows:

[0019] (1) Iron powder, chromium powder, aluminum powder and nickel powder were ball milled for 5 hours and mixed to obtain a mixed material; in terms of mass percentage, iron powder accounted for 4.5%, chromium powder accounted for 18.0%, and aluminum powder accounted for 5.5% in the mixed material, The rest is nickel powder; the purity of iron powder, chromium powder, aluminum powder and nickel powder is 99.99%, and the chromium powder, aluminum powder, iron powder and nickel powder are all passed through a 300-mesh sieve; the ball-to-material ratio of the ball mill is 12:1;

[0020] (2) Under the condition of a pressure of 20MPa, the mixed material obtained in step (1) is compressed into a sheet to obtain a metal sheet of φ15×3, and the metal sheet is placed in a vacuum arc melting furnace, under the protection atmosphere of argon gas and electromagnetic stirr...

Embodiment 2

[0024] Embodiment 2: a kind of preparation method of Ni-Cr-Al-Fe series superalloy, concrete steps are as follows:

[0025] (1) Mix iron powder, chromium powder, aluminum powder and nickel powder by ball milling for 6 hours to obtain a mixed material; in terms of mass percentage, the iron powder in the mixed material accounts for 3.0%, chromium powder accounts for 15.0%, and aluminum powder accounts for 5.0%. The rest is nickel powder; the purity of iron powder, chromium powder, aluminum powder and nickel powder is 99.0%, and the chromium powder, aluminum powder, iron powder and nickel powder are all passed through a 300-mesh sieve; the ball-to-material ratio of the ball mill is 10:1;

[0026] (2) Under the condition of a pressure of 50MPa, the mixed material obtained in step (1) is pressed into a sheet to obtain a metal sheet of φ15×3, and the metal sheet is placed in a vacuum arc melting furnace, under the protection atmosphere of argon gas and electromagnetic stirring. Arc ...

Embodiment 3

[0029] Embodiment 3: a kind of preparation method of Ni-Cr-Al-Fe series superalloy, concrete steps are as follows:

[0030] (1) Iron powder, chromium powder, aluminum powder and nickel powder were ball milled for 7 hours to obtain a mixed material; in terms of mass percentage, iron powder accounted for 6.0%, chromium powder accounted for 20.0%, aluminum powder accounted for 6.0% in the mixed material, The rest is nickel powder; the purity of iron powder, chromium powder, aluminum powder and nickel powder is 99.5%, and the chromium powder, aluminum powder, iron powder and nickel powder are all passed through a 300-mesh sieve; the ball-to-material ratio of the ball mill is 15:1;

[0031] (2) Under the condition of a pressure of 40MPa, the mixed material obtained in step (1) is pressed into a sheet to obtain a metal sheet of φ15×3, and the metal sheet is placed in a vacuum arc melting furnace, under the protection atmosphere of argon gas and electromagnetic stirring. Arc melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com