Preparation method for Fe-Mn-Al alloy

A fe-mn-al alloy technology, applied in the field of light-weight high-strength alloy preparation, can solve the problems of high cost, complex process, heating rate and sintering temperature structure and composition, etc., to achieve good oxidation resistance and corrosion resistance , wide application prospects, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

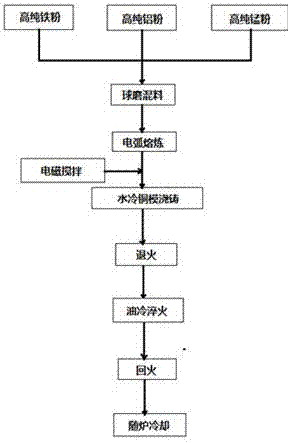

[0020] A preparation method of Fe-Mn-Al series high-strength light alloy, specifically comprising the following steps:

[0021] (1) Firstly, the manganese powder, aluminum powder and iron powder with a purity of 99.99% and a mesh size of 300 mesh are weighed and batched according to a certain mass percentage, and the mass fraction is: 30% Mn, 14.0% Al, and the rest is Fe; Put the powder into a ball mill jar and mix with a planetary ball mill, the ball-to-material ratio is 12:1, and the ball milling time is 4 hours.

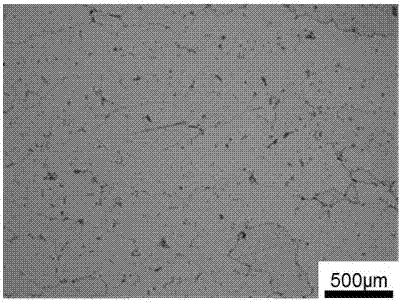

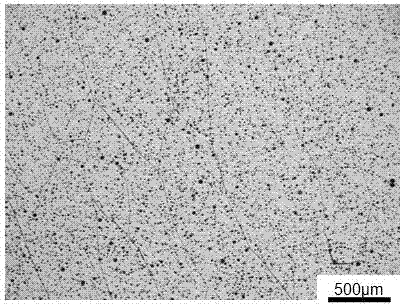

[0022] (2) Take out the mixed powder obtained in step (1), and press it under a tablet press, where the pressure is 10MPa, to obtain a metal sheet of φ15×3, and put it in a copper crucible of a vacuum arc melting furnace. Melting is carried out under a protective atmosphere, and the melt is continuously processed by electromagnetic stirring to make the melt completely homogenized, and at the same time refine the precipitated phase and matrix structure. When the te...

Embodiment 2

[0026] A preparation method of Fe-Mn-Al series high-strength light alloy, specifically comprising the following steps:

[0027] (1) First, the manganese powder, aluminum powder and high-purity iron powder with a purity of 99.99% and a mesh size of 300 mesh are weighed and batched according to a certain mass percentage, and the mass fraction is: 24.0% Mn, 13.0% Al, and the rest is Fe; Put the powder into a ball mill tank and mix with a planetary ball mill, the ball-to-material ratio is 10:1, and the ball milling time is 4 hours.

[0028] (2) Take out the mixed powder obtained in step (1), and press it under a tablet press, where the pressure is 10MPa, to obtain a metal sheet of φ15×3, and put it in a copper crucible of a vacuum arc melting furnace. Melting is carried out under a protective atmosphere, and the melt is continuously processed by electromagnetic stirring to completely homogenize the melt and refine the precipitated phase and matrix structure at the same time. When ...

Embodiment 3

[0031] A preparation method of Fe-Mn-Al series high-strength light alloy, specifically comprising the following steps:

[0032] (1) Firstly, the manganese powder, aluminum powder and high-purity iron powder with a purity of 99.99% and a mesh number of 300 mesh are weighed and batched according to a certain mass percentage, and the mass fraction is: 18% Mn, 12% Al, and the rest is Fe; Put the powder into a ball mill tank and mix with a planetary ball mill, the ball-to-material ratio is 15:1, and the ball milling time is 4 hours.

[0033] (2) Take out the mixed powder obtained in step (1), and press it under a tablet press, where the pressure is 10MPa, to obtain a metal sheet of φ15×3, and put it in a copper crucible of a vacuum arc melting furnace. Melting is carried out under a protective atmosphere, and the melt is continuously processed by electromagnetic stirring to completely homogenize the melt and refine the precipitated phase and matrix structure at the same time. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com