Environment friendly AC-DC alkaline low-hydrogen welding rod

An AC-DC dual-purpose, low-hydrogen electrode technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as environmental pollution, and achieve reduced spatter, reduced surface tension, and good process performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0174] Environment-friendly AC and DC dual-purpose alkaline low-hydrogen electrode, its composition includes: coating, welding core. The composition of the drug skin includes: marble, fluorite, iron powder, barium carbonate, artificial rutile, feldspar, medium-carbon ferromanganese, ferrotitanium, atomized ferrosilicon, synthetic mica, titanium dioxide, soda ash, and its parts by weight The numbers are: 24 parts of marble, 21 parts of fluorite, 4 parts of iron powder, 3 parts of barium carbonate, 2 parts of artificial rutile, 1 part of feldspar, 5 parts of medium-carbon ferromanganese, 5 parts of ferro-titanium, and No. 45 atomized ferrosilicon 4 parts, 1 part of synthetic mica, 1 part of titanium dioxide, 0.5 parts of soda ash, using welding core H08A to make an environmentally friendly AC and DC dual-purpose alkaline low-hydrogen electrode.

Embodiment 2

[0176] Environment-friendly AC and DC dual-purpose alkaline low-hydrogen electrode, its composition includes: coating, welding core. The composition of the drug skin includes: marble, fluorite, iron powder, barium carbonate, artificial rutile, feldspar, medium-carbon ferromanganese, ferrotitanium, atomized ferrosilicon, synthetic mica, titanium dioxide, soda ash, and its parts by weight The numbers are: 34 parts of marble, 32 parts of fluorite, 16 parts of iron powder, 10 parts of barium carbonate, 7 parts of artificial rutile, 4 parts of feldspar, 9 parts of medium carbon ferromanganese, 12 parts of ferro-titanium, No. 45 atomized ferrosilicon 7 parts, 2 parts of synthetic mica, 3 parts of titanium dioxide, 1.5 parts of soda ash, and use welding core H08A to make an environmentally friendly AC and DC dual-purpose alkaline low-hydrogen electrode.

Embodiment 3

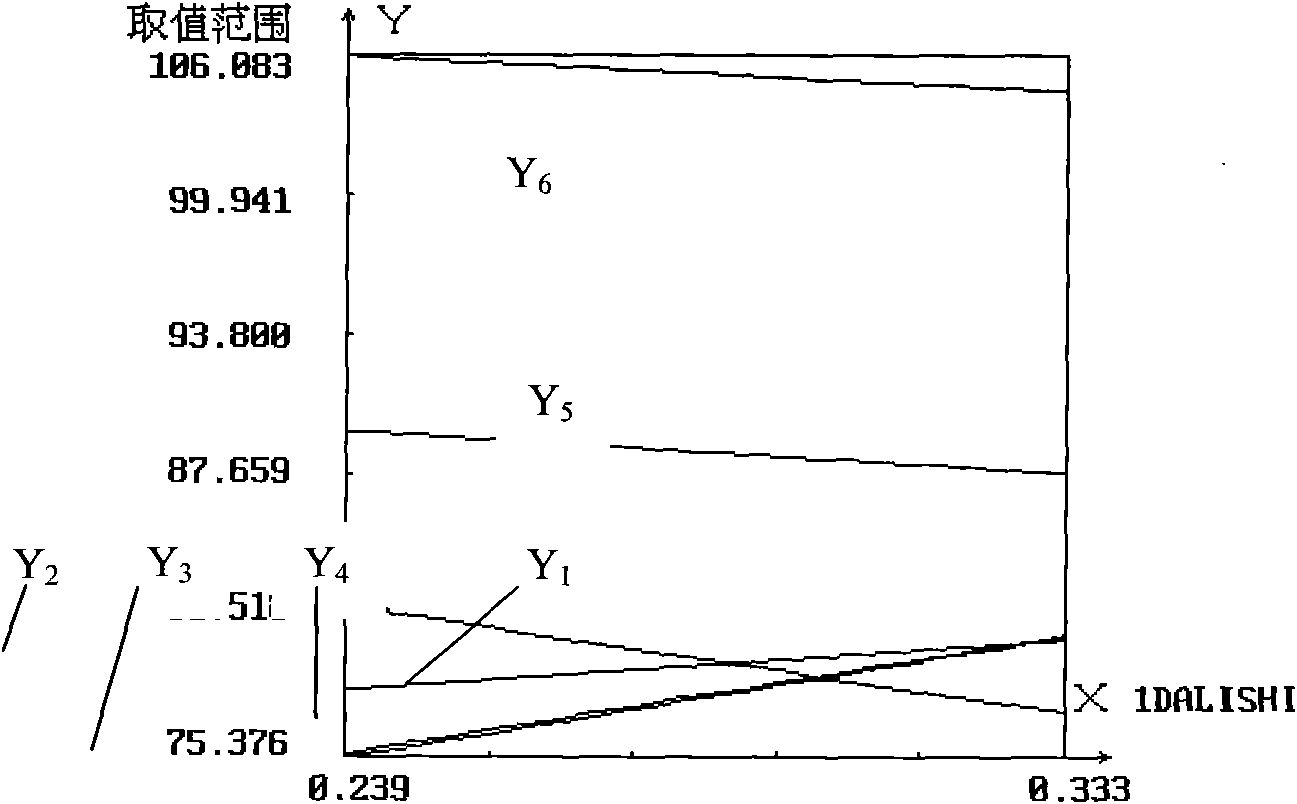

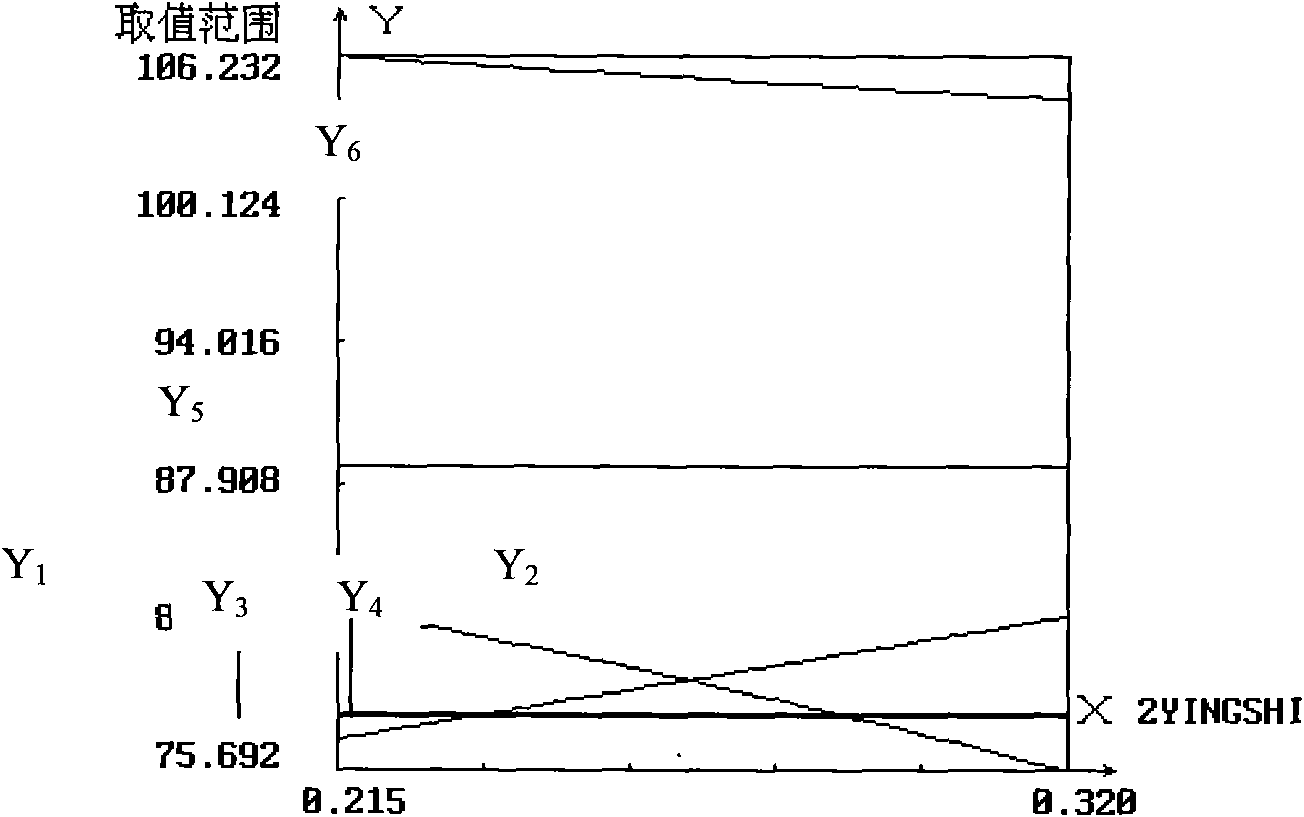

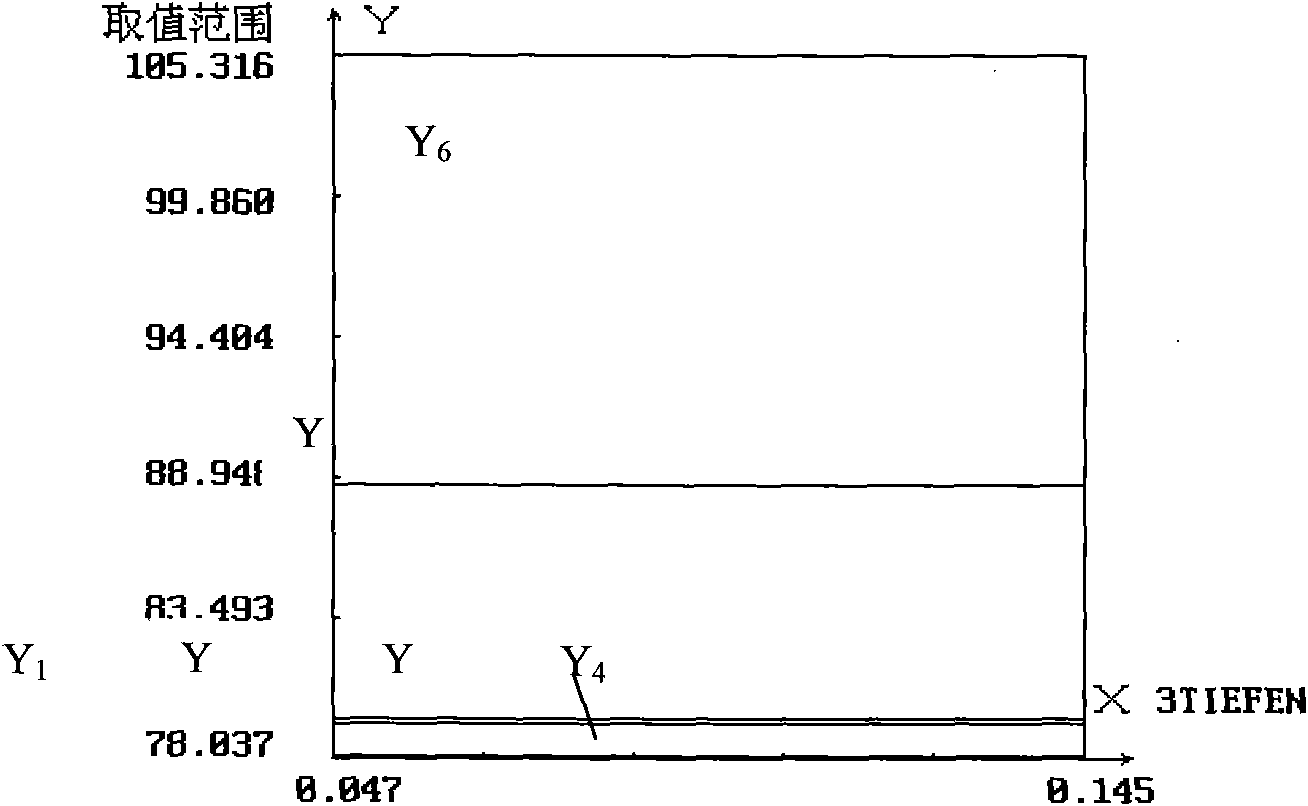

[0178] Environment-friendly AC and DC dual-purpose alkaline low-hydrogen electrode, its composition includes: coating, welding core. The composition of the drug skin includes: marble, fluorite, iron powder, barium carbonate, artificial rutile, feldspar, medium-carbon ferromanganese, ferrotitanium, atomized ferrosilicon, synthetic mica, titanium dioxide, and soda ash. Use uniformly designed computer software to set the limited range of each process performance index under the column of full arrangement, and find out the excellent drug skin formula, as shown in Table 5.

[0179] Table 5 Example of search formula results in full array of optimized process performance indexes

[0180]

[0181]

[0182] According to Table 5, the parts by weight of the electrode coating components are selected as follows: 30.2 parts of marble, 28.5 parts of fluorite, 4.7 parts of iron powder, 5.7 parts of barium carbonate, 2.6 parts of artificial rutile, 1 part of feldspar, and 5.9 parts of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com