Alloy powder for high-strength bainite steel laser repairing and preparing method of alloy powder

A technology of bainitic steel and alloy powder, which is applied in the coating process and coating of metal materials, can solve the problems of poor plasticity and toughness, low strength of the repair layer, and poor interface matching, so as to achieve good bonding and avoid heat-affected zones , Improve the hardness and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

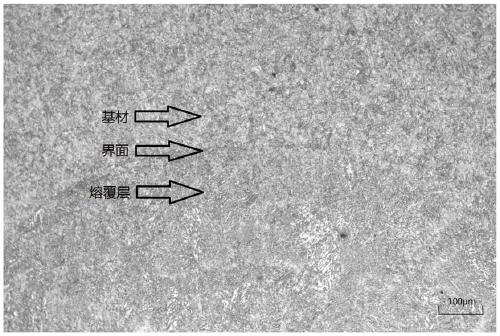

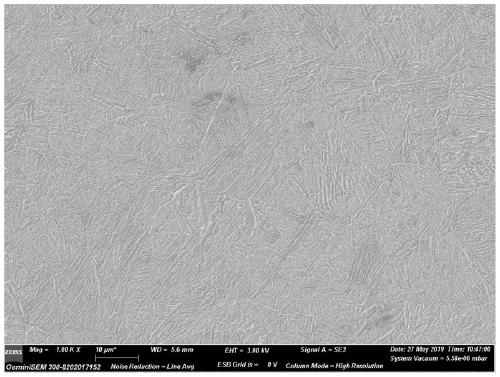

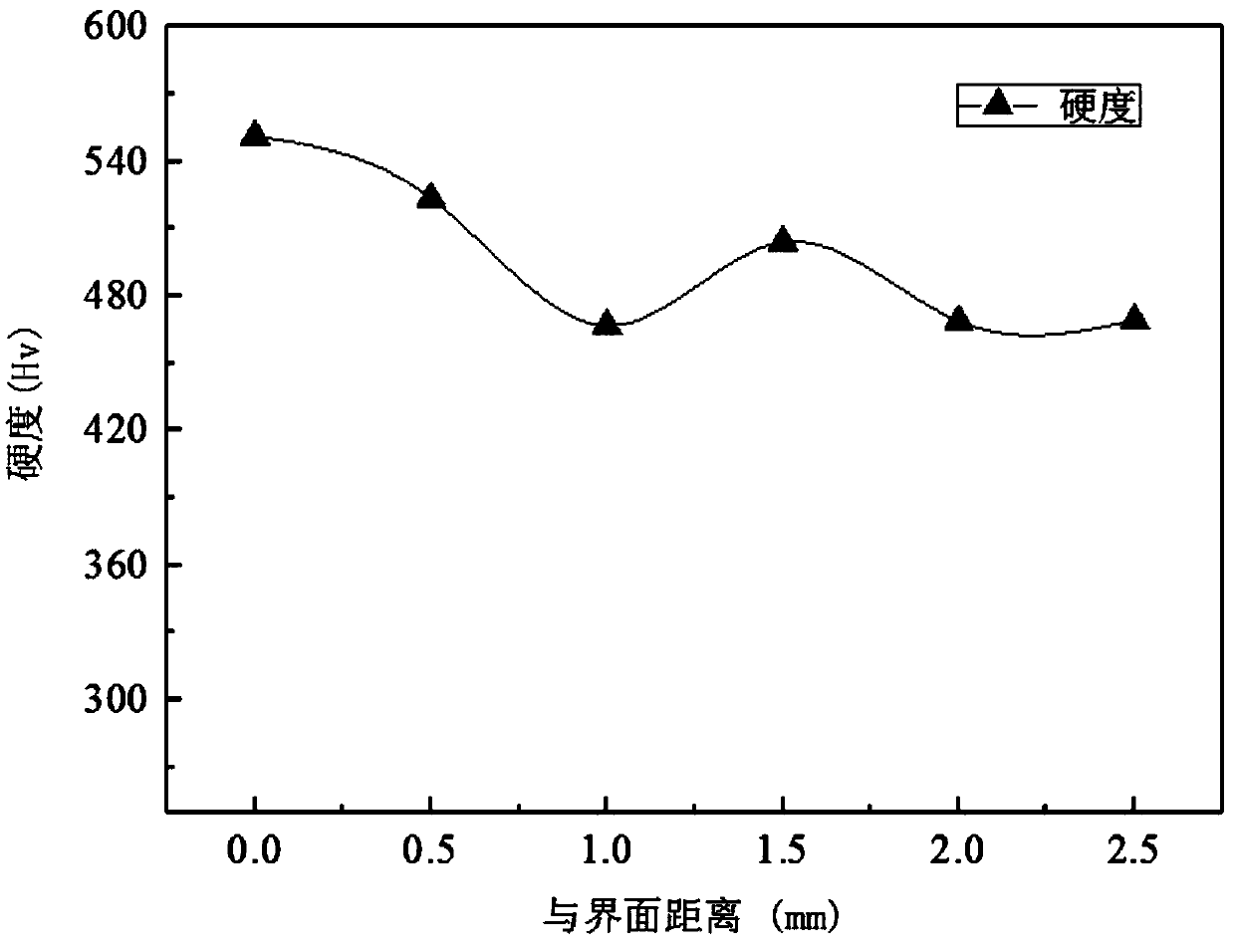

Examples

Embodiment 1

[0030] Example 1: An alloy powder for laser repair of high-strength bainite steel, with a total mass of 100g, including the following alloy components and their mass percentages: C: 0.29g; Si: 1.5g; Mn: 1.5g; Cr: 0.96g ; Ni: 1.2g; Al: 1.0g; Mo: 0.5g;

[0031] Step 1: Weigh the raw materials according to the mass percentage of the above-mentioned components, put them into a vacuum melting furnace and melt them completely, the vacuum degree of the vacuum melting furnace is 50Pa, and the melting temperature is 1620°C;

[0032] Step 2: Pour the above molten alloy solution into the atomization tower, and use inert gas for gas atomization. The atomization pressure is 8.5 MPa, and the gas atomization time is 6 minutes. The solution is crushed by the inert gas and cooled to obtain alloy powder;

[0033] Step 3: Use a powder sieving machine to select the alloy powder with a particle size of 100-214 mesh to obtain an alloy powder for laser repair of high-strength bainite steel with a pa...

Embodiment 2

[0035] Example 2: An alloy powder for laser repair of high-strength bainite steel, with a total mass of 100g, including the following alloy components and their mass percentages: C: 0.35g, Si: 2.5g, Mn: 1.5g, Cr: 2.0g , Ni: 2.0g, Al: 1.2g, Mo: 1.5g, Fe: balance, the preparation method of alloy powder for laser repair of high-strength bainitic steel comprises the following steps:

[0036] Step 1: Weigh the raw materials according to the mass percentage of the above components, put them into a vacuum melting furnace and melt them completely, the vacuum degree of the vacuum melting furnace is 35Pa, and the melting temperature is 1600°C;

[0037] Step 2: Pour the above molten alloy solution into the atomization tower, and use inert gas for gas atomization. The atomization pressure is 7.5 MPa, and the gas atomization time is 8 minutes. The solution is crushed by the inert gas and cooled to obtain alloy powder;

[0038] Step 3: Use a powder sieving machine to select the alloy powder w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com