Normalized steel plate for wind power, and production method thereof

A production method and steel plate technology, applied in the field of steel materials, can solve the problems of poor low-temperature performance, high cost, and low yield strength, and achieve the effects of enhanced low-temperature performance, reduced alloy cost, and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

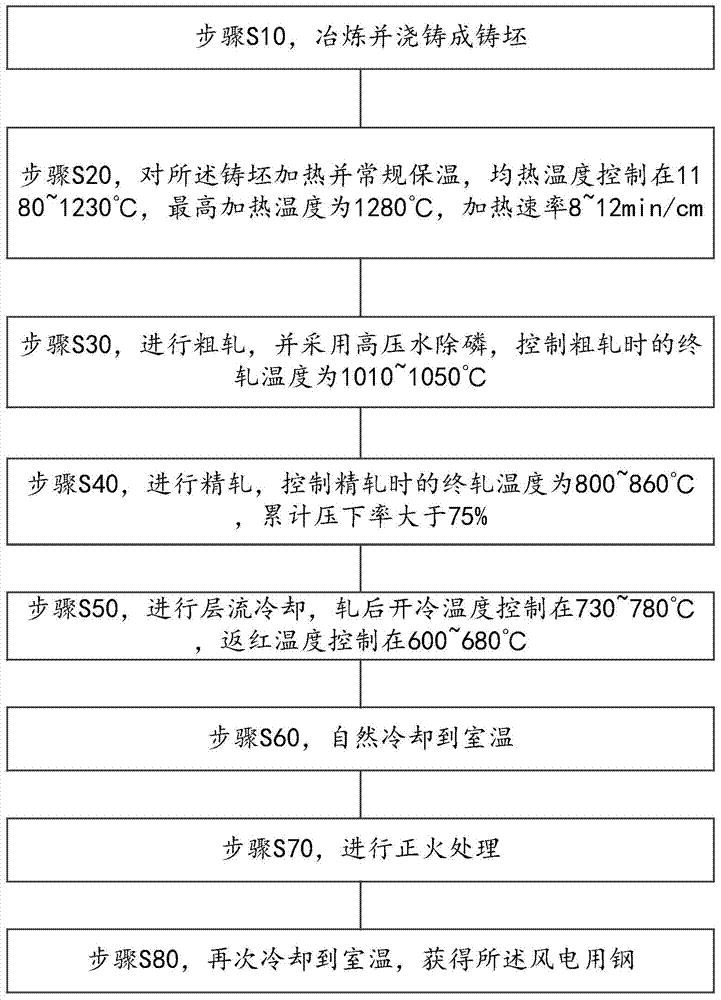

[0039] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

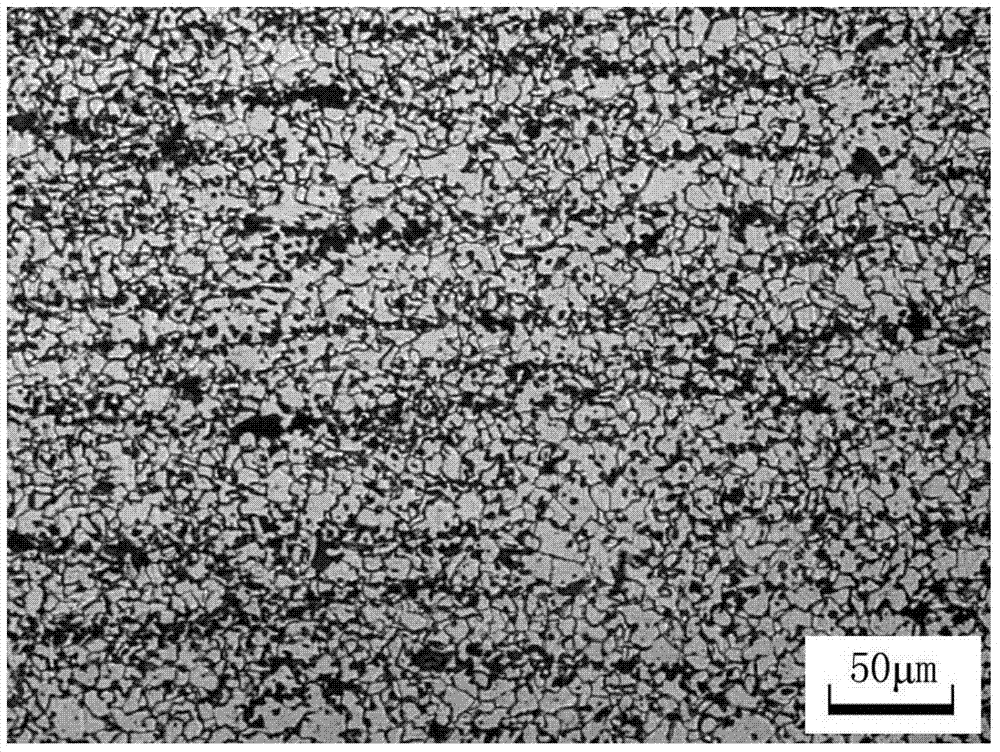

[0040] The present application provides a normalized steel plate for wind power, which can be widely used in wind power equipment. The yield strength of the steel plate is ≥370MPa, the tensile strength is 500-650MPa, the elongation A is ≥30%, the impact energy value at -40°C is greater than or equal to 250J, and the impact energy value at -60°C is greater than or equal to 200J.

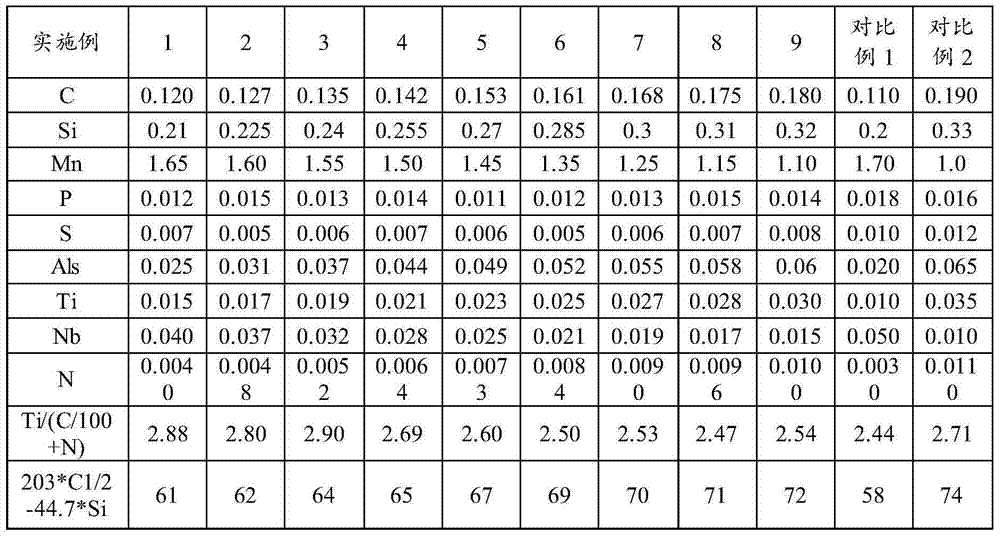

[0041] The mass percentage of the steel plate specifically includes: C (carbon): 0.12-0.18%; Si (silicon): 0.21-0.32%; Mn (manganese): 1.10-1.65%; P (phosphorus): ≤0.015%; ): ≤0.008%; Nb (niobium): 0.015-0.040%; Ti (titanium): 0.015-0.03%; Als (acid-soluble aluminum): 0.025-0.06%; N (nitrogen): 0.004-0.010%, the rest is Fe and unavoidable impurities.

[0042] And, 61≤203...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com