Polypropylene long-carbon-chain nylon blend and preparation method thereof

A long carbon chain, polypropylene technology, applied in the field of polymer material processing, can solve the problems that have not yet been seen, and achieve the effects of low production cost, good toughness and softness, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

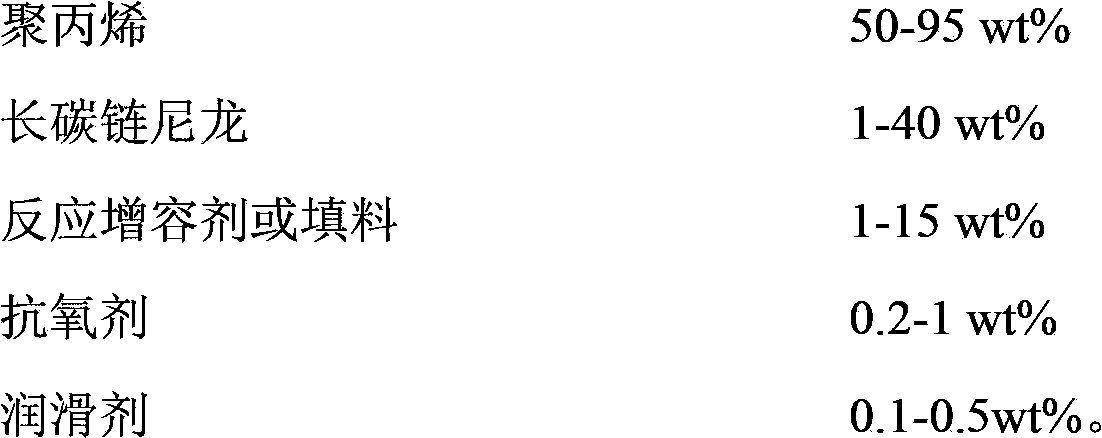

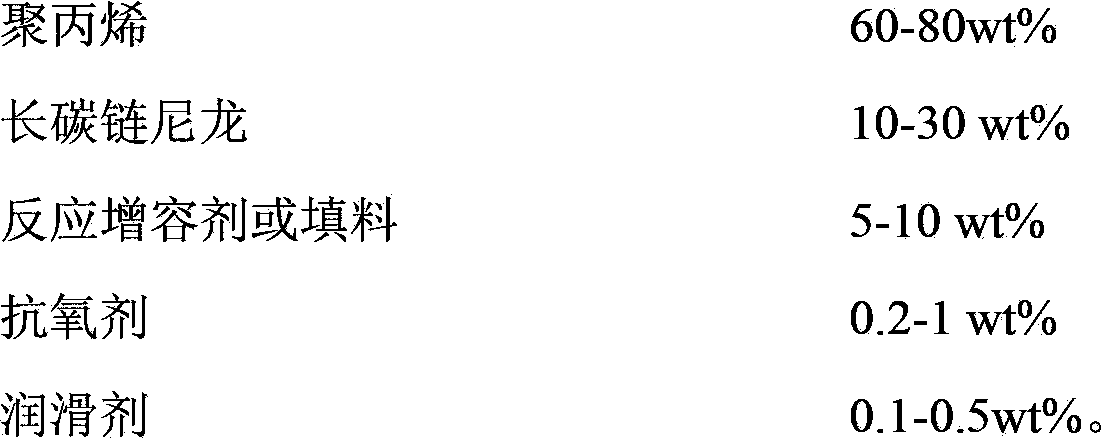

Method used

Image

Examples

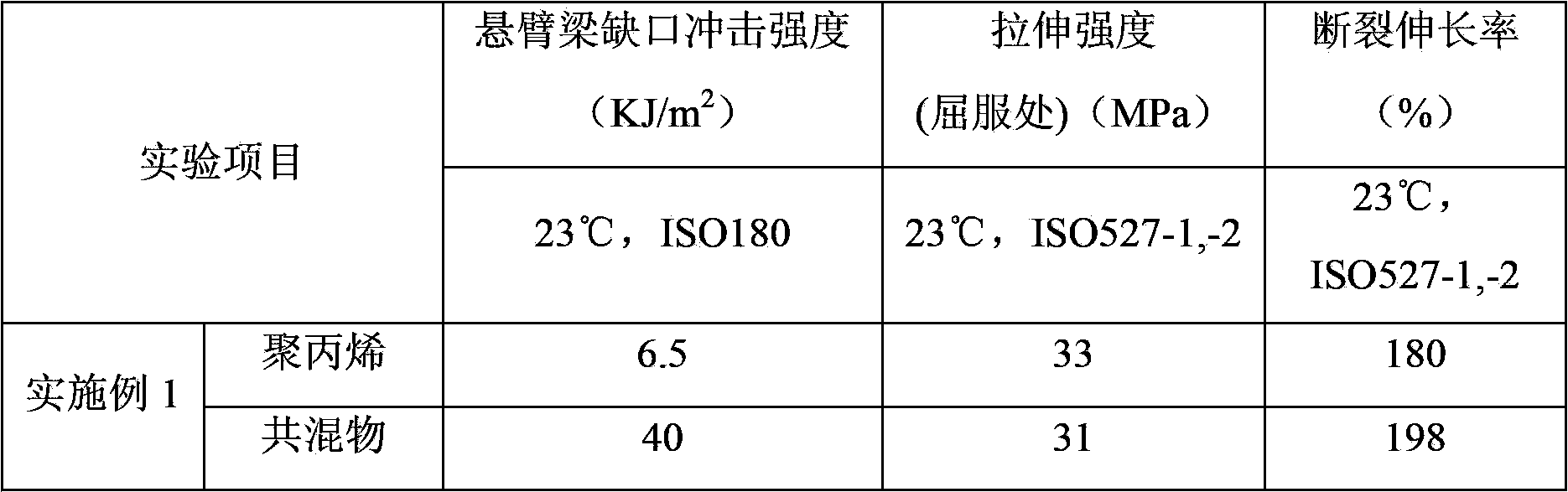

Embodiment 1

[0041] The iPP is Moplen HP555E with a melt flow index of 0.8g / 10min (230°C, 2.16Kg), and the melt flow rate of the PA1212 is 4.5g / 10min (235°C, 2.16Kg).

[0042] In terms of weight percentage, 70wt% iPP, 19.6wt% long carbon chain nylon PA1212, 10wt% reaction compatibilizer PP-g-GMA, 0.2wt% antioxidant tetrakis [β-(3,5-di Tertiary butyl-4-hydroxyl phenyl) propionic acid] pentaerythritol ester, the lubricant hexenyl bis stearamide of 0.2wt%, utilize high-speed stirrer to mix and obtain mixture, then the mixture is used twin-screw extruder at a temperature of Melt blending is carried out at 170-260°C to obtain a blend of iPP and PA1212.

Embodiment 2

[0044] The PP is Moplen HP501L with a melt flow rate of 6g / 10min (230°C, 2.16Kg), and the melt flow rate of the PA1212 is 4.5g / 10min (235°C, 2.16Kg).

[0045] In weight percentage, 64.6wt% iPP, 30wt% long carbon chain nylon PA1212, 5wt% reaction compatibilizer POE-g-MAH, 0.2wt% antioxidant tris(2,4-ditertiary butyl phenyl) ester, 0.2wt% lubricant sodium stearate, and use a high-speed mixer to mix uniformly to obtain a mixture, and then melt and blend the mixture with a twin-screw extruder at a temperature of 170-260°C to obtain PP Blends with PA1212.

Embodiment 3

[0047] The PP is Moplen HP500N, the melt flow rate is 12g / 10min (230°C, 2.16Kg), and the melt flow rate of the PA1212 is 9.0g / 10min (235°C, 2.16Kg).

[0048] In terms of weight percentage, 70wt% of PP, 15wt% of long carbon chain nylon PA1212, 9.6wt% of reaction compatibilizer EAA, 5wt% of toluene diisocyanate modified silica, 0.2wt% of antioxidant pentaerythritol bis Phosphite bis (2,4-di-tert-butylphenyl) ester, 0.2wt% lubricant tristearin, use a high-speed mixer to mix uniformly to obtain a mixture, and then use a twin-screw extruder to obtain a mixture at a temperature of Melt blending at 170-260°C to obtain a blend of PP and PA1212.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com