A kind of preparation method of graphene oxide composite filter element material and water purification filter element

A graphene composite and composite material technology, which is applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of RO membrane being easily scratched, RO membrane of water purification filter element being easily scaled, and affecting water output, etc. Achieve superior adsorption effect, excellent adsorption effect, and the effect of increasing wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

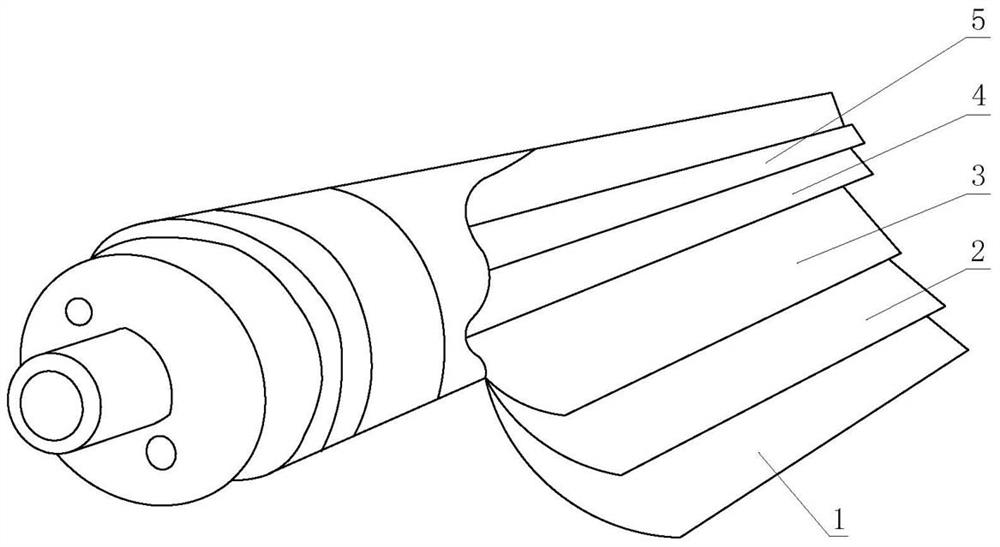

Image

Examples

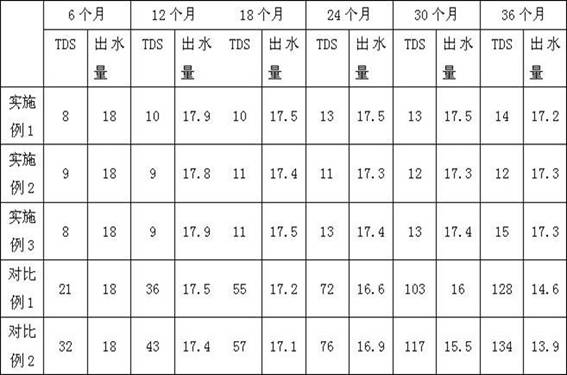

Embodiment 1

[0030] The preparation method of a kind of graphene oxide composite filter element material of the present embodiment comprises the following steps:

[0031] a) Preparation of zeolite-Ag particles: Pass zeolite powder through a 100-mesh sieve to remove large particles. After sieving, the powder is added to a silver nitrate solution with a concentration of 0.1mol / L, stirred for 2 hours, and the mixture is filtered to obtain a solid. After drying, sinter at 500°C for 0.5h to obtain Ag-loaded zeolite particles;

[0032] b) Preparation of graphene oxide-coated zeolite-Ag particles: add the zeolite-Ag particles prepared in step a) to 0.1 mg / ml graphene oxide dispersion, stir while ultrasonic, and spray-dry the mixture , to obtain graphene oxide-coated zeolite-Ag particles;

[0033] The mass ratio of the zeolite-Ag particles to graphene oxide is 10:1;

[0034] c) Paste preparation: fully mix the polypropylene powder with the graphene oxide-coated zeolite-Ag particle powder obtaine...

Embodiment 2

[0038] The preparation method of a kind of graphene oxide composite filter element material of the present embodiment comprises the following steps:

[0039] a) Preparation of zeolite-Ag particles: Pass zeolite powder through a 100-mesh sieve to remove large particles. After sieving, the powder is added to a silver nitrate solution with a concentration of 2.5mol / L, stirred for 12 hours, and the mixture is filtered to obtain a solid. After drying, sinter at 300°C for 2 hours to obtain Ag-loaded zeolite particles;

[0040]b) Preparation of graphene oxide-coated zeolite-Ag particles: add the zeolite-Ag particles prepared in step a) to a 5 mg / ml graphene oxide dispersion, stir while ultrasonicating, and spray-dry the mixture. Obtaining graphene oxide-coated zeolite-Ag particles;

[0041] The mass ratio of the zeolite-Ag particles to graphene oxide is 1:1;

[0042] c) Paste preparation: fully mix the polypropylene powder with the graphene oxide-coated zeolite-Ag particle powder o...

Embodiment 3

[0046] The preparation method of a kind of graphene oxide composite filter element material of the present embodiment comprises the following steps:

[0047] a) Preparation of zeolite-Ag particles: Pass the zeolite powder through a 100-mesh sieve to remove large particles, add the zeolite powder into a silver nitrate solution with a concentration of 5mol / L, stir for 24 hours, filter the mixed solution to obtain a solid, and dry the solid After drying, sinter at 150°C for 3 hours to obtain Ag-loaded zeolite particles;

[0048] b) Preparation of graphene oxide-coated zeolite-Ag particles: add the zeolite-Ag particles prepared in step a) to a 10 mg / ml graphene oxide dispersion, stir while ultrasonicating, and spray-dry the mixture. Obtaining graphene oxide-coated zeolite-Ag particles;

[0049] The mass ratio of the zeolite-Ag particles to graphene oxide is 1:10;

[0050] c) Paste preparation: fully mix the polypropylene powder with the graphene oxide-coated zeolite-Ag particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com