Preparation method of natural degradable covering yarn

A covered yarn, a natural technology, applied in the field of textiles, can solve the problems of high chemical fiber raw materials, non-degradable covered yarns, difficult to apply to the preparation of disposable fabrics, etc., and achieves the effects of good flexibility and toughness, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of natural degradable covered yarn,

[0046] The preparation method comprises the following steps:

[0047] 1) Preparation of core thread: flax fibers are blended and twisted to obtain blended fibers. The blended fibers are placed in 220g / L amylose paste and soaked at 56°C for 20min, and then taken out for 24h room temperature aging To obtain the thick fiber of the core wire, place the thick fiber of the core wire in saturated zein / 95% ethanol aqueous solution for 60 seconds, take it out and dry it in the shade at room temperature for 6 hours to obtain the core wire;

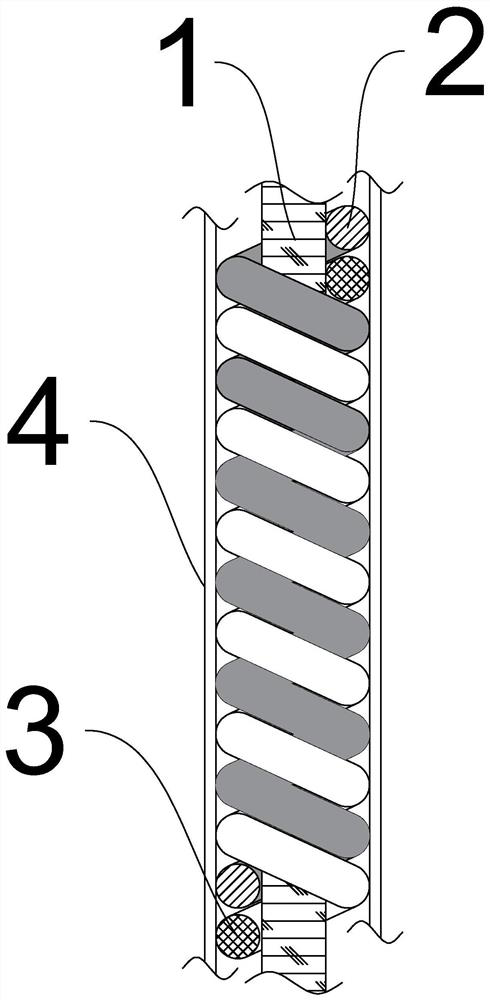

[0048] 2) Primary covering: the polylactic acid fiber and cotton fiber are wound in parallel in the same direction and spirally wrapped on the outside of the core wire to realize the primary covering and form the yarn core;

[0049] 3) Secondary coating: the bamboo fiber yarn is coated on the outside of the yarn core, and the natural degradable coated yarn is obtained after secondary...

Embodiment 2

[0052] A preparation method of natural degradable covered yarn,

[0053] The preparation method comprises the following steps:

[0054]1) Preparation of the core thread: the flax fiber is blended and twisted to obtain the blended fiber. The blended fiber is placed in 180g / L amylose paste and soaked at 59°C for 20min, and then taken out for 22h room temperature aging To obtain the core fiber, place the core fiber in a saturated zein / 95% ethanol aqueous solution for 30 seconds, take it out and dry it in the shade at room temperature for 6 hours to obtain the core fiber;

[0055] 2) Primary covering: the polylactic acid fiber and cotton fiber are wound in parallel in the same direction and spirally wrapped on the outside of the core wire to realize the primary covering and form the yarn core;

[0056] 3) Secondary coating: the bamboo fiber yarn is coated on the outside of the yarn core, and the natural degradable coated yarn is obtained after secondary coating.

Embodiment 3

[0058] A preparation method of natural degradable covered yarn,

[0059] The preparation method comprises the following steps:

[0060] 1) Preparation of the core thread: the flax fiber is blended and then plied and twisted to obtain the blended fiber. The blended fiber is placed in 260g / L amylose paste and soaked at 59°C for 15 minutes, then taken out and aged at room temperature for 24 hours To obtain the core fiber, place the core fiber in saturated zein / 95% ethanol aqueous solution for 50 seconds, take it out and dry it in the shade at room temperature for 6 hours to obtain the core fiber;

[0061] 2) Primary covering: the polylactic acid fiber and cotton fiber are wound in parallel in the same direction and spirally wrapped on the outside of the core wire to realize the primary covering and form the yarn core;

[0062] 3) Secondary coating: the bamboo fiber yarn is coated on the outside of the yarn core, and the natural degradable coated yarn is obtained after secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com