High-resilience silicone rubber and preparation method thereof

A silicone rubber, high resilience technology, applied in the field of silicone rubber, can solve the problems of low resilience, low mechanical strength, limitations, etc., and achieve the effect of reducing vulcanization temperature, high mechanical strength, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

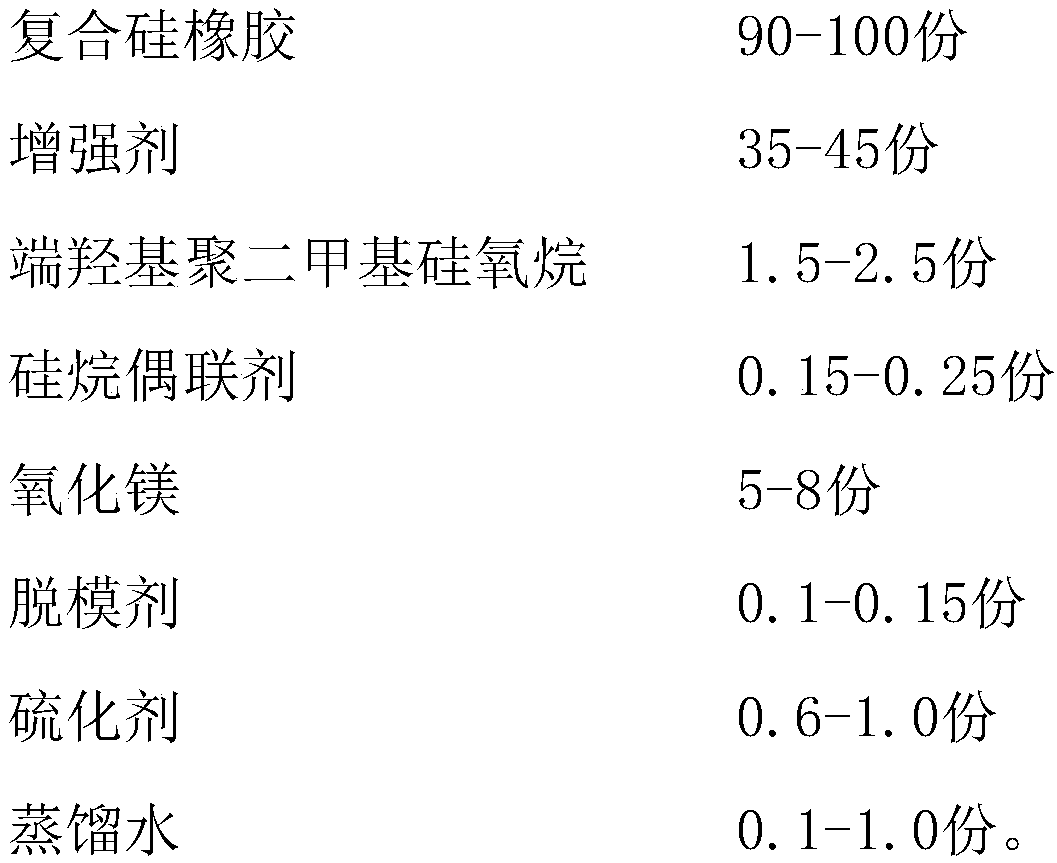

[0042] A kind of high resilience silicon rubber, comprises the raw material of following weight part:

[0043]

[0044] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 30:70; wherein, the vinyl content of the methyl vinyl silicone rubber A is 0.20 %, the methyl content is 99.80%, and the molecular weight is 650,000; the vinyl content of the methyl vinyl silicone rubber B is 0.14%, the methyl content is 99.86%, and the molecular weight is 800,000.

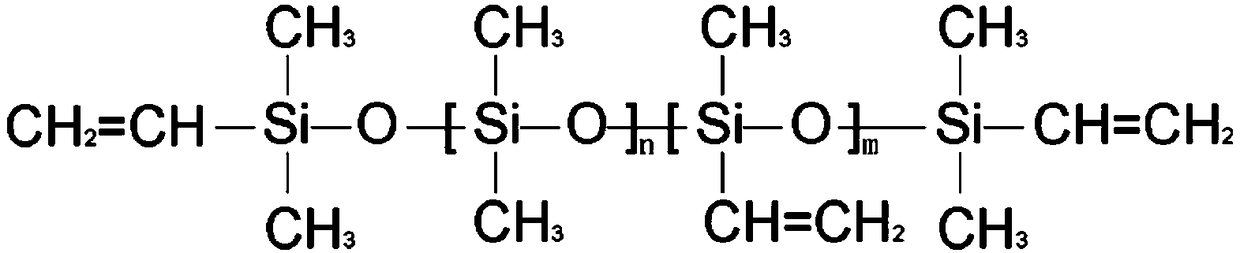

[0045] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A and methyl vinyl silicone rubber B are as follows:

[0046]

[0047] Wherein, n=8850, m=20 of the methyl vinyl silicone rubber A; n=11500, m=15 of the methyl vinyl silicone rubber B.

[0048] The reinforcing agent has a specific surface area of 140m 2 / g of precipitated silica.

[0049] The silane coupling agent is propyltrimethoxysilane.

[0050] The rele...

Embodiment 2

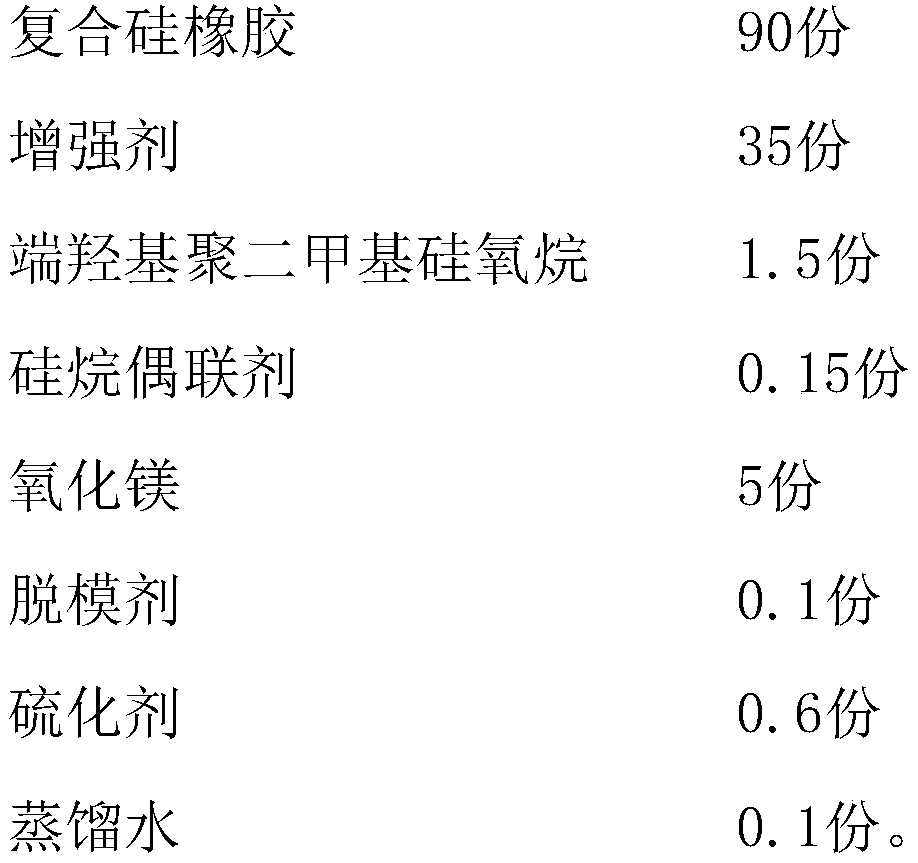

[0063] A kind of high resilience silicon rubber, comprises the raw material of following weight part:

[0064]

[0065]

[0066] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 50:50; wherein, the vinyl content of the methyl vinyl silicone rubber A is 0.23 %, the methyl content is 99.77%, and the molecular weight is 700,000; the vinyl content of the methyl vinyl silicone rubber B is 0.16%, the methyl content is 99.84%, and the molecular weight is 850,000.

[0067] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A and methyl vinyl silicone rubber B are as follows:

[0068]

[0069] Wherein, n=8800, m=22 of the methyl vinyl silicone rubber A; n=11470, m=18 of the methyl vinyl silicone rubber B.

[0070] The reinforcing agent has a specific surface area of 150m 2 / g of precipitated silica.

[0071] The silane coupling agent is vinyltrimethoxysilane.

[007...

Embodiment 3

[0085] A kind of high resilience silicon rubber, comprises the raw material of following weight part:

[0086]

[0087] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 40:60; wherein, the vinyl content of the methyl vinyl silicone rubber A is 0.25 %, the methyl content is 99.75%, and the molecular weight is 750,000; the vinyl content of the methyl vinyl silicone rubber B is 0.18%, the methyl content is 99.82%, and the molecular weight is 900,000.

[0088] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A and methyl vinyl silicone rubber B are as follows:

[0089]

[0090] Wherein, n=8750, m=25 of the methyl vinyl silicone rubber A; n=11450, m=20 of the methyl vinyl silicone rubber B.

[0091] The reinforcing agent has a specific surface area of 170m 2 / g of precipitated silica.

[0092] The silane coupling agent is vinyltriethoxysilane.

[0093] The releas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com