Two-component polyurethane waterproof coating and preparation method thereof

A two-component polyurethane and waterproof coating technology, used in the field of architectural waterproof coatings, can solve the problems of low temperature flexibility, large influence of toluene diisocyanate volatility, poor heat resistance, etc., and achieves good construction performance, compact structure, The effect of less volatile gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A composite modified two-component polyurethane waterproof coating, which is made by mixing component A and component B according to the mass ratio of 1:1.5; wherein component A and component B are respectively made of the following raw materials:

[0028] Component A: polyether diol 40kg, polyether triol 45kg, diphenylmethane diisocyanate 30kg, organic montmorillonite 1.725kg, water glass 1.725kg;

[0029] Component B: water 15kg; dispersant (BASF-4585) 0.5kg, antioxidant (TDS-115) 0.5kg, CO 2 Absorbent (calcium hydroxide) 0.3kg, plasticizer (S-5408) 3kg, leveling agent (AMS-2020) 0.2kg, filler 30kg (including talcum powder 20kg, heavy calcium carbonate 10kg), pigment 0.2kg ( Among them, carbon black 0.06kg, phthalocyanine blue 0.02kg, medium yellow 0.12kg), defoamer (A10) 0.3kg;

[0030] The preparation method of described two-component polyurethane waterproof coating comprises the following steps:

[0031] Step 1, prepare component A and component B respectively: ...

Embodiment 2

[0037] A composite modified two-component polyurethane waterproof coating, which is made by mixing component A and component B according to the mass ratio of 1:1.2, wherein component A and component B are respectively made of the following raw materials:

[0038] Component A: polyether diol 45kg, polyether triol 40kg, diphenylmethane diisocyanate 50kg, organic montmorillonite 2.025kg, water glass 2.025kg;

[0039] Component B: water 19kg; dispersant (SN-5040) 0.8kg, antioxidant (JY-1076) 1.5kg, CO 2Absorbent (calcium hydroxide) 0.8kg, plasticizer (S-5408) 9kg, leveling agent (BYK-345) 0.5kg, filler 50kg (including talcum powder 35kg, light calcium carbonate 15kg), pigment 0.6kg ( Among them, carbon black 0.20kg, iron oxide red 0.08kg, medium yellow 0.32kg), defoamer (A10) 1.0kg;

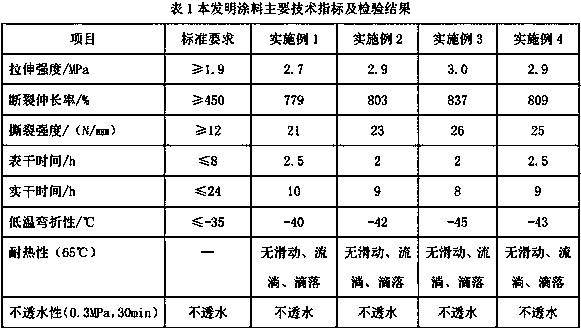

[0040] The preparation method is the same as in Example 1; the prepared coating is gray, and the main technical indicators of the coating are shown in Table 1.

Embodiment 3

[0042] A composite modified two-component polyurethane waterproof coating, which is made by mixing component A and component B according to the mass ratio of 1:1.2, wherein component A and component B are respectively made of the following raw materials:

[0043] Component A: polyether diol 50kg, polyether triol 50kg, diphenylmethane diisocyanate 60kg, organic montmorillonite 2.4kg, water glass 2.4kg;

[0044] Component B: water 17kg; dispersant (BASF-4585) 0.6kg, antioxidant (JY-1135) 1.0kg, CO 2 Absorbent (calcium hydroxide) 0.7kg, plasticizer (S-5408) 8kg, leveling agent (BYK-345) 0.4kg, filler 45kg (including talcum powder 30kg, light calcium carbonate 15kg), pigment 0.7kg ( Among them, carbon black 0.20kg, phthalocyanine blue 0.10kg, medium yellow 0.40kg), defoamer (A10) 0.8kg;

[0045] The preparation method is the same as in Example 1; the prepared coating is gray, and the main technical indicators of the coating are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com