Manufacturing method of heat-resistant high-silicon-molybdenum nodular cast iron

A technology of nodular cast iron and high silicon molybdenum, which is applied in the direction of improving process efficiency, can solve the problems of not being overcome, increasing production costs, increasing production processes, etc., and achieves the effects of improving durability, strength, and creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: a kind of preparation method of high-silicon-molybdenum heat-resistant ductile iron, the method comprises the following steps:

[0028] a. Determine chemical parameters: carbon 3.2-3.4%, silicon 3.7-4.3%, manganese ≤ 0.3%, phosphorus ≤ 0.05%, sulfur 0.007-0.12%, magnesium 0.04-0.55%, molybdenum 0.8-1.2%;

[0029] b. Raw materials and weight percentages are: pig iron: 30-40%, scrap steel: 20-30%, recycle materials: 30-40%, ferrosilicon: 1.5-2.0%, ferromolybdenum: 1-1.2%;

[0030] c. Melting:

[0031] 1) Use an intermediate frequency electric furnace for smelting, use an electronic scale to weigh main raw materials such as pig iron, scrap steel, machine iron, etc., and add the materials in the order of scrap steel-return material-pig iron to ensure stable material quality; after melting, heat up and take samples for testing, and the sampling temperature is controlled at 1420- Between 1440°C; the overheating temperature is guaranteed to be between 1480-150...

example example 2 6

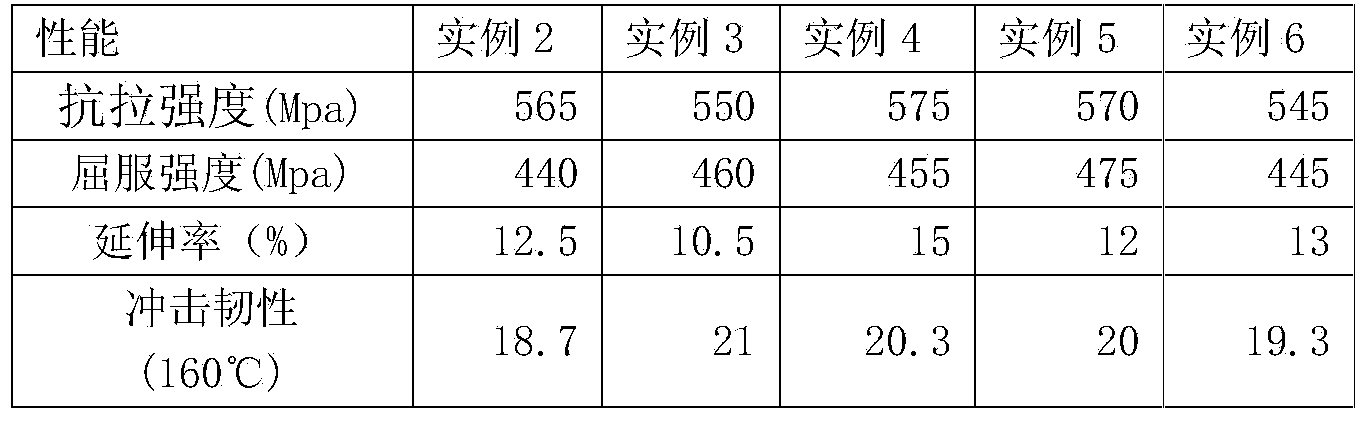

[0046] (1) Each example is basically the same as Example 1, the difference is that there are some changes in the parameters and mechanical properties in the actual control, the chemical composition and content are shown in the table below

[0047] chemical composition

Example 2

Example 3

Example 4

Example 5

Example 6

C

3.25

3.28

3.35

3.3

3.2

Si

4.01

3.9

3.95

4.05

4

mn

0.1

0.11

0.098

0.092

0.11

P

0.035

0.032

0.034

0.031

0.033

S

0.01

0.011

0.095

0.01

0.088

Mg

0.045

0.05

0.051

0.049

0.052

Mo

0.98

0.95

1.02

1.08

0.93

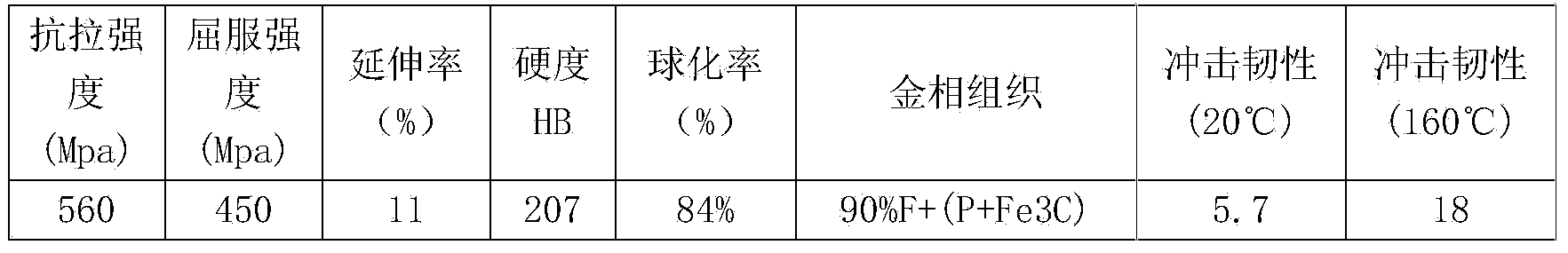

[0048] (2) The normal temperature performance of the material is shown in the table below

[0049]

[0050] (3) The high temperature performance of the material is shown in the following table:

[0051] temperature(°C)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com