Electromagnetic on-line detection method of retained austenite of rolling bearing

A technology of residual austenite and detection method, which is applied in the direction of material magnetic variable, etc., can solve the problems of large measurement error, large phase difference, slow preparation of samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

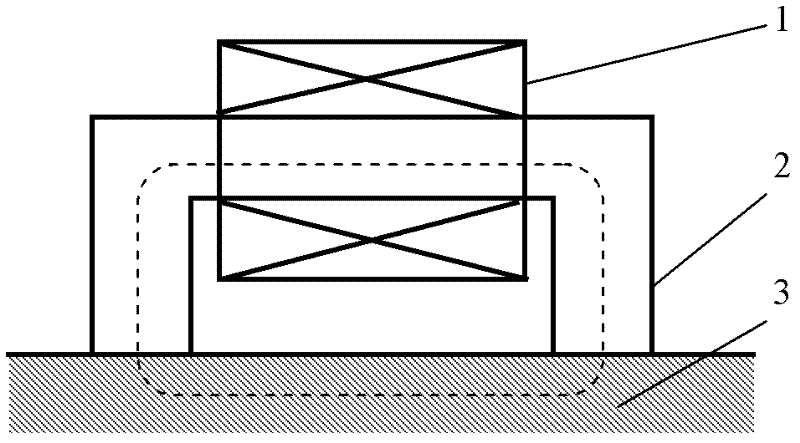

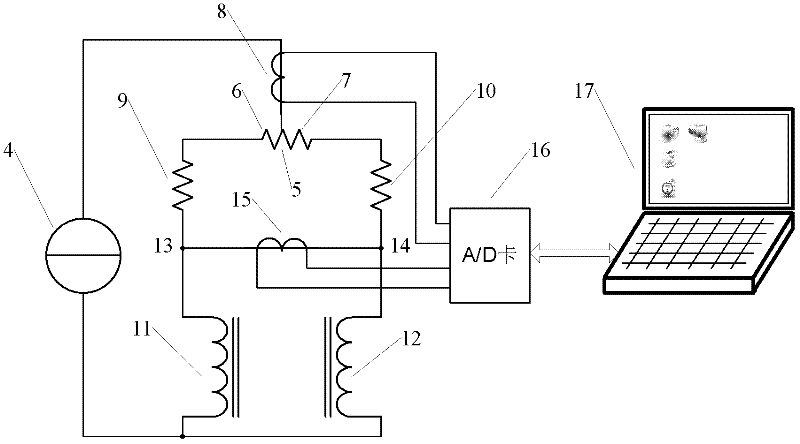

Image

Examples

Embodiment 1

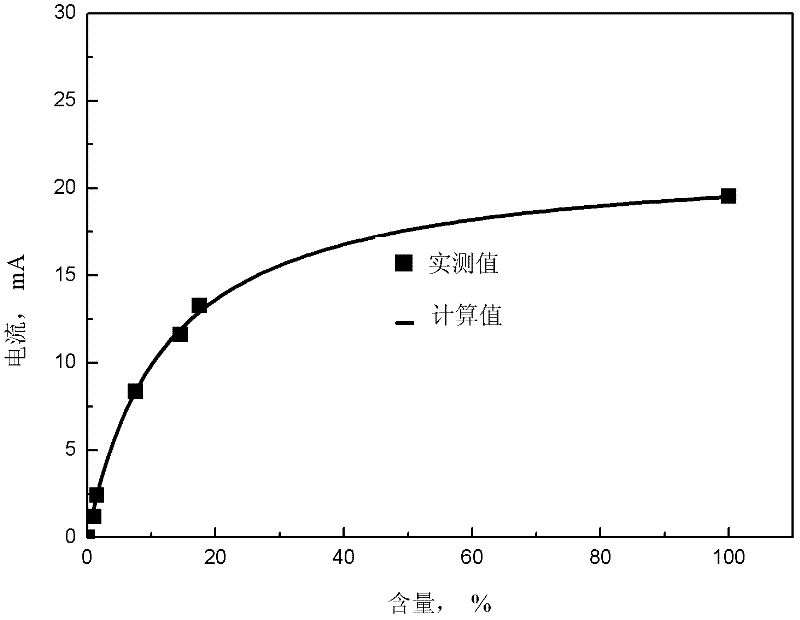

[0083] roller test

[0084] Fig. 3 is the comparison result of measuring the residual value of the roller according to this method and the X-ray method.

[0085] Take a bearing roller with a diameter of φ=20mm, and the measurement results are shown in Table 1 and Figure 4.

[0086] Table 1 Paralympic content of rollers

[0087]

[0088] Figure 3(a) is the relationship between the test unbalanced current and the paralyzed content, and Figure 3(b) is the relationship between the tested unbalanced current and the paralyzed content. From Fig. 3, the comparison result of the parasitic value of the roller measured by the method of the present invention and that of the X-ray method (■) can be obtained.

Embodiment 2

[0090] bearing ring

[0091] Table 2 Residual content of bearing rings

[0092]

[0093] Take a bearing ring with a diameter of φ=78mm, and its measurement results are shown in Table 2 and Figure 4. When the retained austenite content is less than 18.5%, the difference with the X-ray method is less than 1%.

[0094] Figure 4(a) is the relationship between the test unbalanced current and the paralyzed content, and Figure 4(b) is the relationship between the tested unbalanced current and the paralyzed content. From Fig. 4, the comparison result of the paralyzed value of the ferrule measured by the method of the present invention and the paralyzed value of the X-ray method (■) can be obtained.

Embodiment 3

[0096] Field measurements

[0097] In Luoyang Bearing Research Institute and Luoyang Bearing Roller Factory, various types of bearing rings and rollers were measured by Paralympic electromagnetic method and X-ray method, and the results are shown in Table 3-6.

[0098] It can be seen from the X-ray results that for the same type of sample, the same sample is measured multiple times, and the dispersion is relatively large. The maximum difference between the three samples of 7011 is 3.9%, and the difference between the two samples of 7215 is 2.2%. The magnetic test result 7010 has a maximum deviation of 0.15% from the mean value.

[0099] table 3

[0100]

[0101] Table 4 7010 bearing outer ring

[0102]

[0103] Table 5 7011 bearing outer ring

[0104]

[0105] Table 6 7521 bearing rollers

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com