Die cushion special for aluminum alloy profile extrusion

A technology for aluminum alloy profiles and die pads, which is applied in the field of aluminum alloy material manufacturing, can solve the problem of gradient distribution of mold heating without considering the rationality of cooling channels, the surface quality and mechanical properties of profiles cannot meet the requirements, and the surface quality and structure of profiles are affected. performance and other issues, to achieve the effect of improving the surface quality and organizational properties of the profiles, improving the quality and organizational properties, and increasing the extrusion speed of the profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

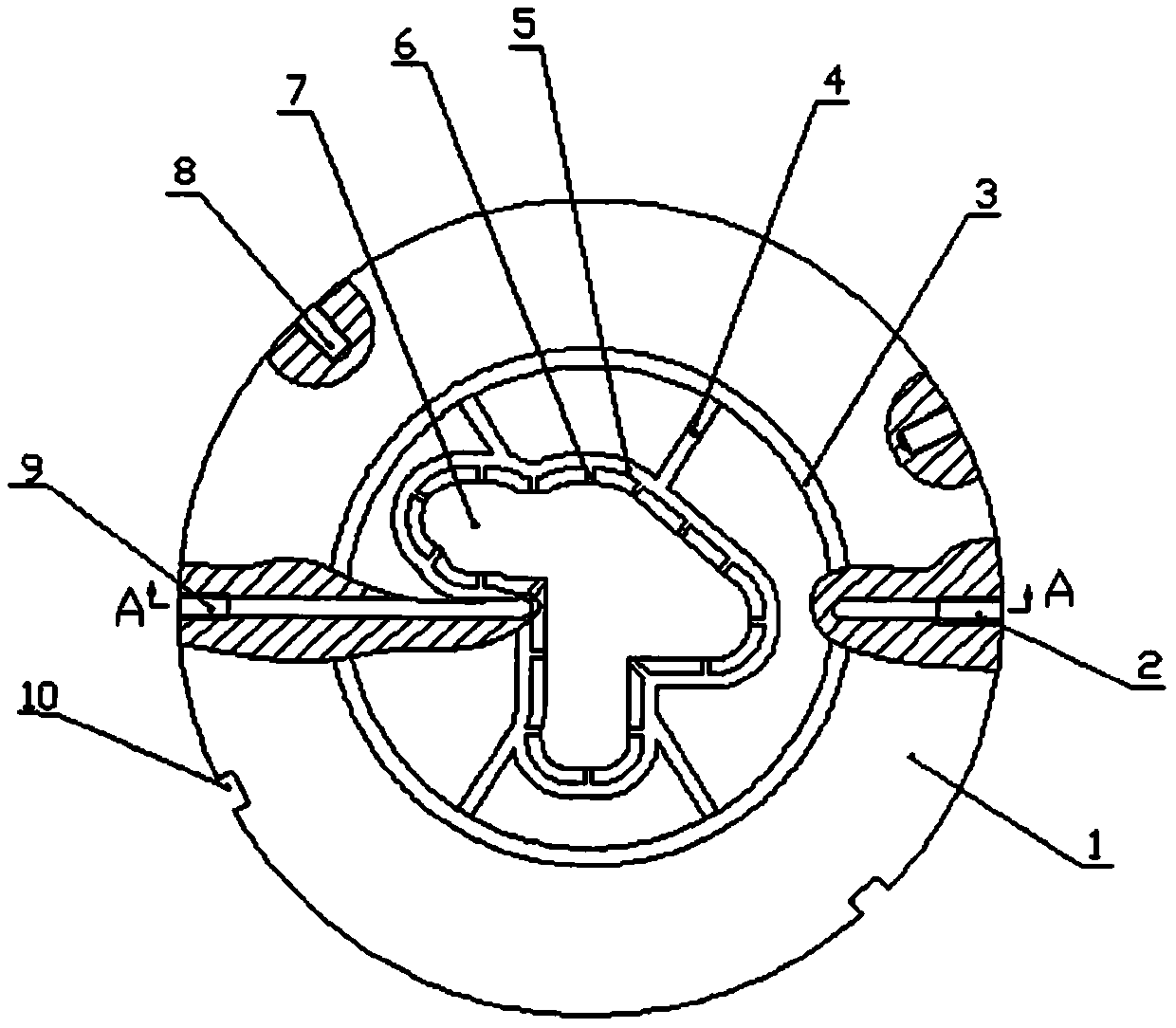

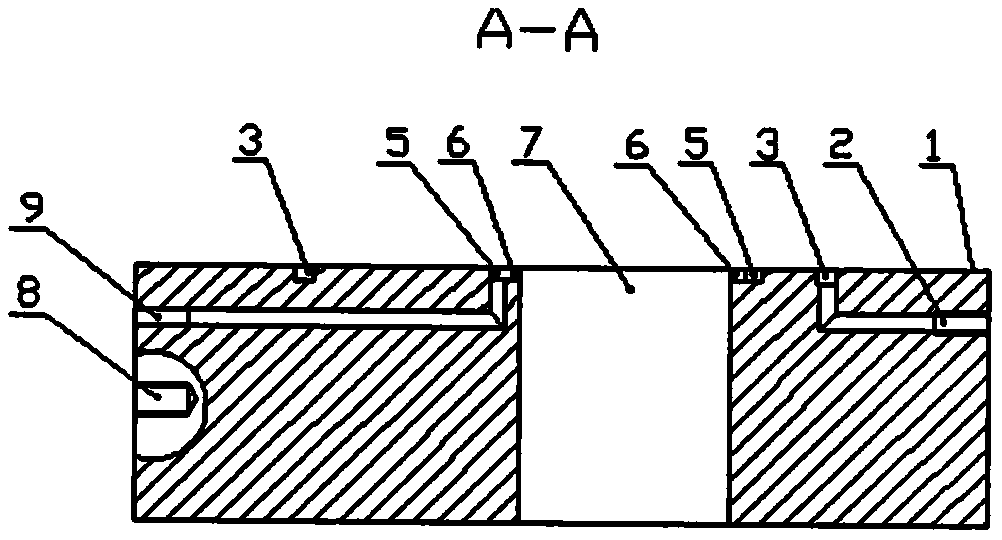

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] A special die pad for extrusion of aluminum alloy profiles includes two cooling channels, namely an outer cooling channel 3 and an inner cooling channel 5 .

[0027] The inner cooling channel 5 is located outside the extruded profile channel 7 and has the same cross-sectional shape as the extruded profile channel 7. The inner cooling channel 5 mainly cools the heat generated at the extruded part of the profile.

[0028] The outer cooling passage 3 is located outside the inner cooling passage 5, and the cross section of the outer cooling passage 3 is circular, which mainly cools the profile extrusion die.

[0029] The outer cooling passage 3 and the inner cooling passage 5 are connected through four first passages 4 , and the function of the first passages 4 is to make the liquid nitrogen in the outer cooling passage 3 enter the inner coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com