Crystallizer cooling device and cooling method thereof

A technology of cooling device and crystallizer, applied in the field of metal casting equipment, can solve the problems of complex structure of cooling device, uneven cooling water flow rate, uncontrollable cooling process, etc., to achieve cooling effect, simple processing method and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

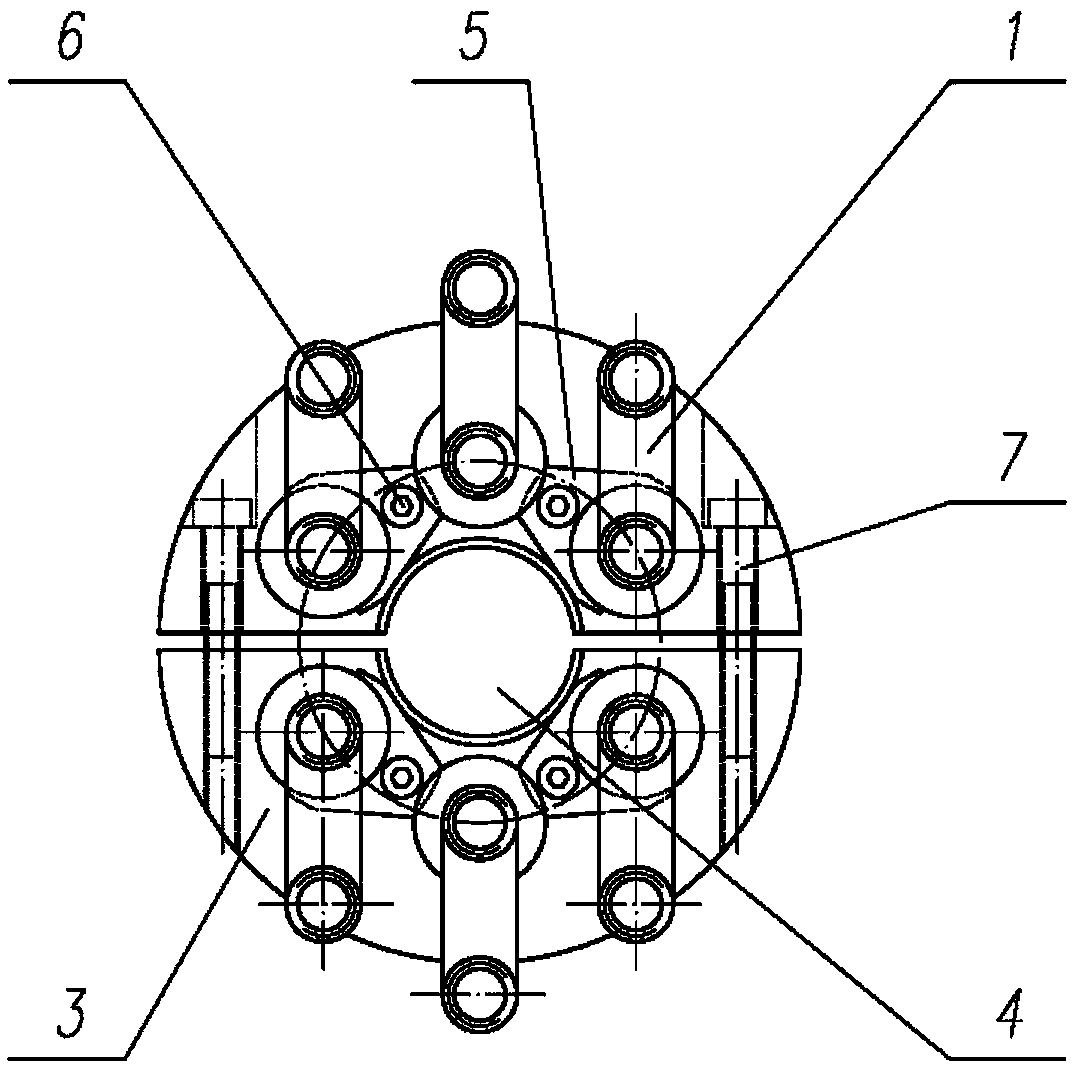

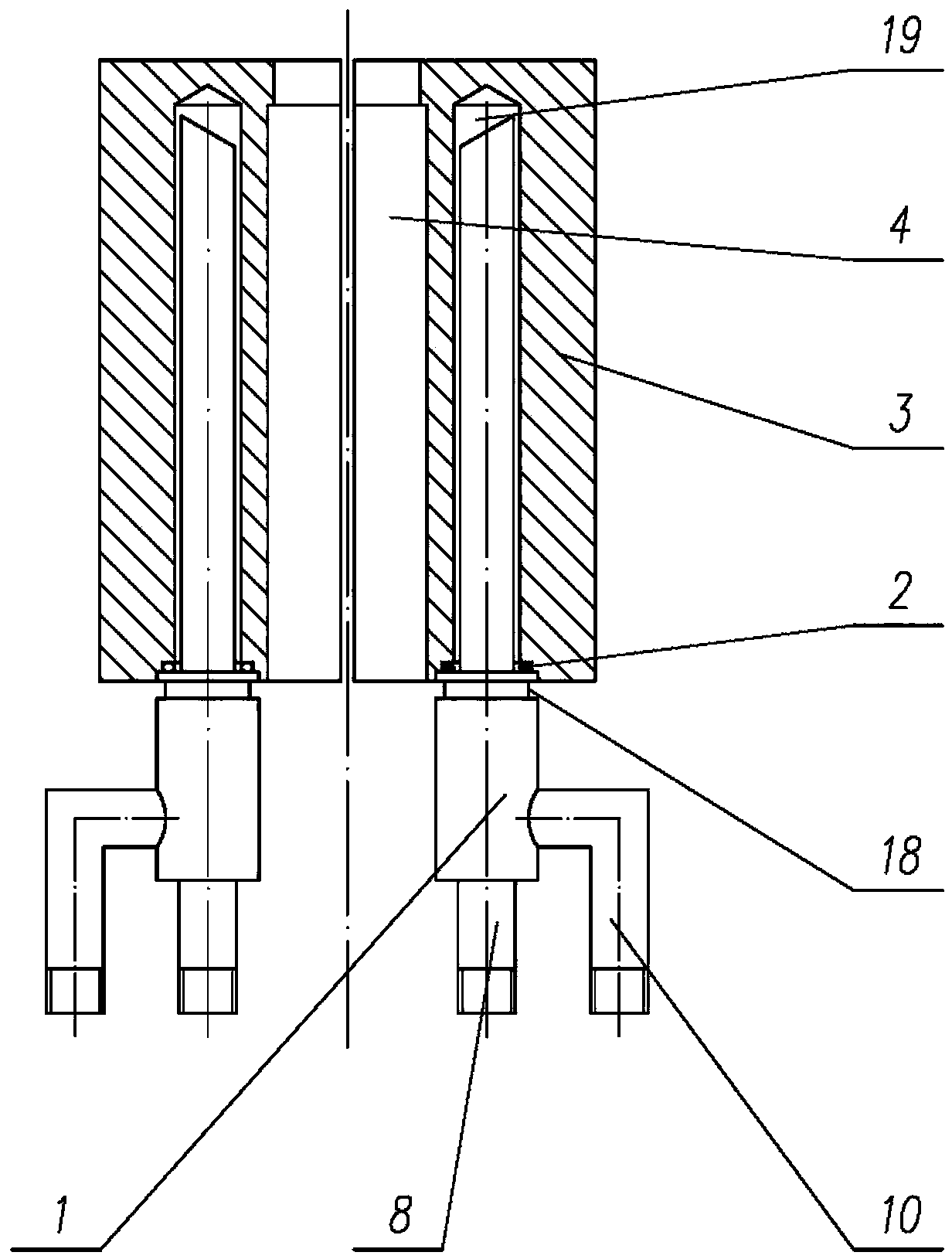

[0035] reference figure 1 , figure 2 with Figure 5 , Including a cooling jacket 3 sleeved on the crystallizer, the cooling jacket 3 is provided with a plurality of blind cooling holes 19, the cooling pipe 1 is assembled on the blind cooling hole 19 through a sealing fixing sleeve 9; the cooling pipe 1 includes a water inlet pipe 8. The sealing fixing sleeve 9 and the water return pipe 10 are sleeved on one end of the water inlet pipe 8 and connected to it by welding. The other end of the water inlet pipe 8 extends into the blind cooling hole 19 and enters There is a backwater gap between the water pipe 8 and the blind cooling hole 19; the backwater pipe 10 is fixedly connected to the side wall of the sealing fixing sleeve 9 by welding and is connected to the backwater gap through the sealing fixing sleeve 9; in order to ensure the cooling effect of the mold, The backwater gap in this embodiment is 1.5-3mm; the cooling device of this embodiment includes a plurality of cooling t...

Embodiment 2

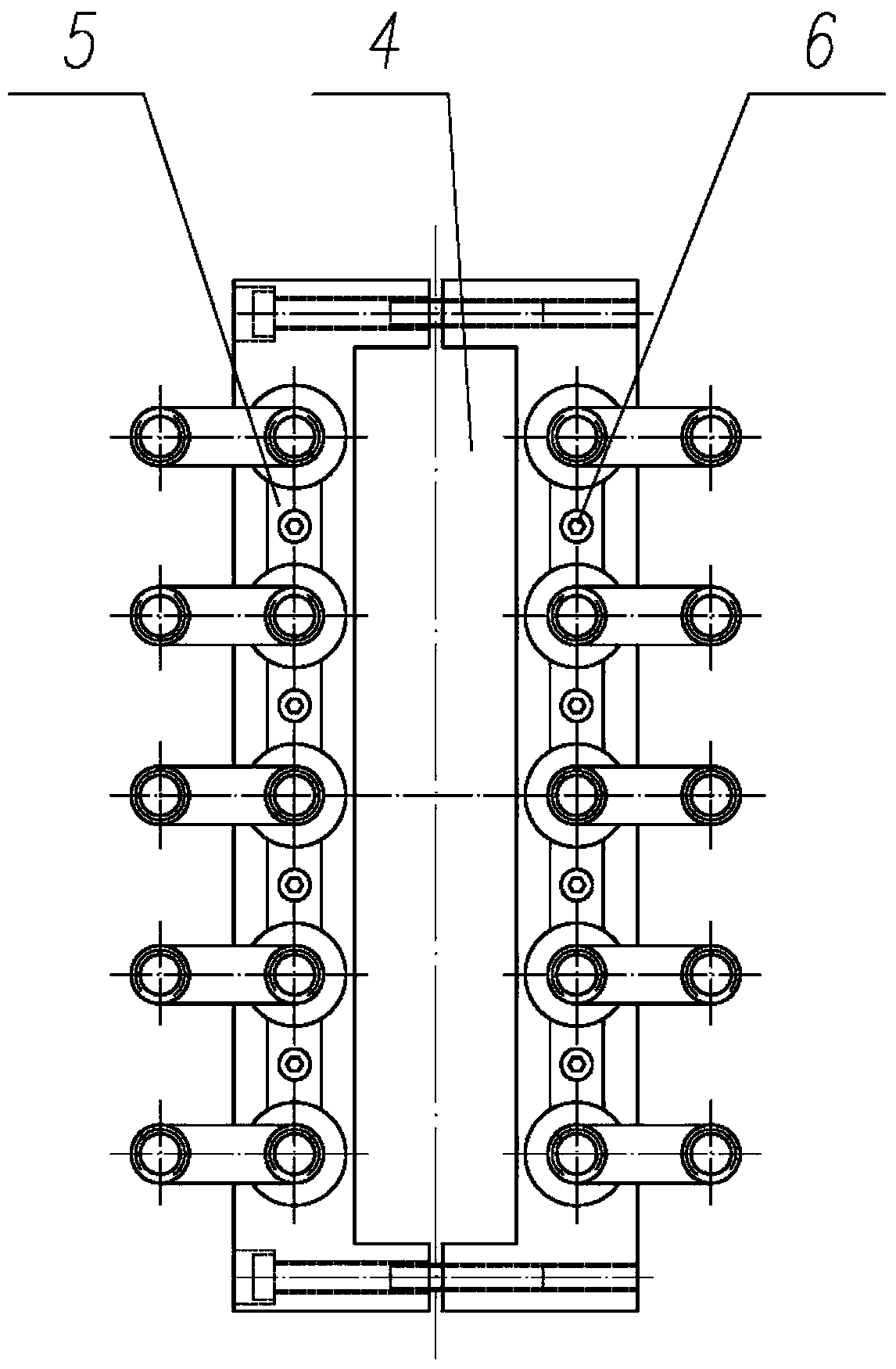

[0058] The difference between this embodiment and Embodiment 1 is that the cooling jacket 3 is a cooling jacket with a rectangular cross-sectional shape, and the mold assembly hole 4 is a mold assembly hole with a rectangular cross-sectional shape. The inside of the cooling jacket 3 is evenly distributed along its central axis on both sides of the mold assembly hole 4. The pressing member 5 is preferably a strip-shaped pressing plate, and the elongated pressing plate is provided at a position corresponding to each slot 18 A recessed structure adapted to the slot 18, the fastener 6 is preferably a bolt or a screw, and the pressure plate and the cooling pipe are further compressed and fixed by the fastener 6.

[0059] The cooling device of the present invention has a simple structure, strong applicability, and good cooling uniformity, and the cooling pipe adopts a local welding method, so that the cooling device is not easily deformed during use, and has a long service life while ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com