HRB400E high-strength aseismic coiled reinforced bar and production method thereof

A technology of anti-seismic steel bars and production methods, which is applied in the field of metal material processing and forming, can solve the problems of unfavorable cost reduction and efficiency increase, high cost of steel alloys, etc., and achieve the effect of reduced alloy costs and good organizational properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

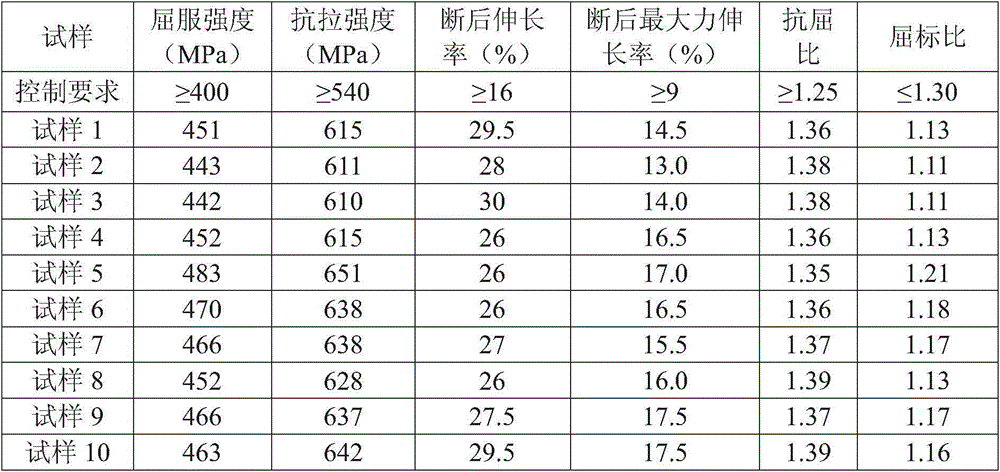

Embodiment 1

[0050] To prepare Φ6mmHRB400E high-strength anti-seismic steel coils, follow the steps below:

[0051] Step 1, according to weight percentage, weigh the following components: C: 0.20%, Si: 0.30%, Mn: 0.90%, V: 0.015%, S: 0.045%, P: 0.020%, the rest is Fe, each component The sum of the weight percentages is 100%; where V is added through the VN16 alloy, and the VN16 alloy weighs the following components according to the weight percentage: N: 14%, C: 6%, the rest is V, and the impurity content is controlled: P: 0.06 %, S: 0.1%, the sum of the weight percentages of each component is 100%;

[0052] Step 2, melting the C, Si, Mn, V, S, P and Fe weighed in step 1 as molten steel to cast a billet;

[0053] Step 3, sending the cast billet into the soaking section furnace for heating, the heating temperature is 1060°C, and the heating time is 80 minutes;

[0054] Step 4: Dephosphorize and cool the heated billet with high-pressure water, and then carry out rough rolling, intermediate ...

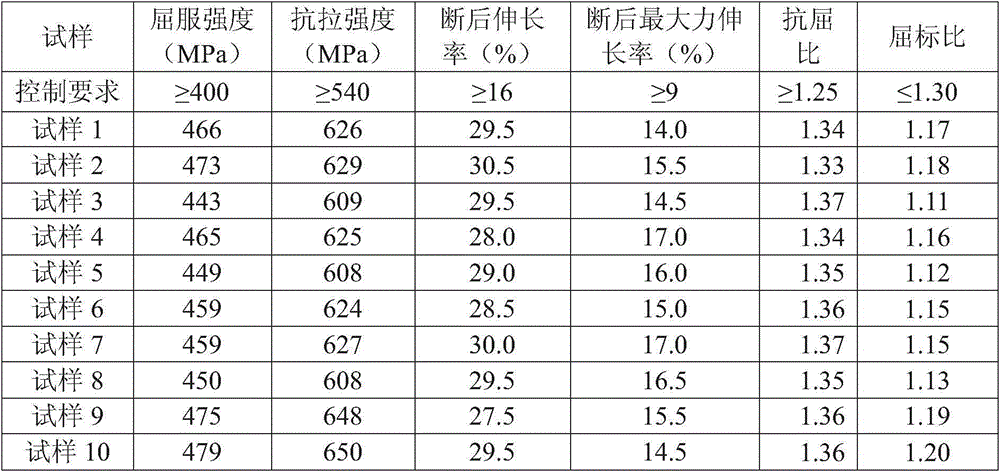

Embodiment 2

[0064] To prepare Φ8mmHRB400E high-strength anti-seismic steel coils, follow the steps below:

[0065] Step 1, according to weight percentage, weigh the following components: C: 0.25%, Si: 0.40%, Mn: 1.1%, V: 0.013%, S: 0.042%, P: 0.038%, the rest is Fe, each component The sum of the weight percentages is 100%; where V is added through the VN16 alloy, and the VN16 alloy weighs the following components according to the weight percentage: N: 16%, C: 5%, the rest is V, and the impurity content is controlled: P: 0.03 %, S: 0.1%, the sum of the weight percentages of each component is 100%;

[0066] Step 2, melting the C, Si, Mn, V, S, P and Fe weighed in step 1 as molten steel to cast a billet;

[0067] Step 3, sending the cast billet into the soaking section furnace for heating, the heating temperature is 1053°C, and the heating time is 60 minutes;

[0068] Step 4: Dephosphorize and lower the temperature of the heated steel billet with high-pressure water, and then carry out rou...

Embodiment 3

[0078] To prepare Φ10mmHRB400E high-strength anti-seismic reinforcement coils, follow the steps below:

[0079] Step 1, according to weight percentage, weigh the following components: C: 0.24%, Si: 0.32%, Mn: 0.95%, V: 0.010%, S: 0.024%, P: 0.028%, the rest is Fe, each component The sum of the weight percentages is 100%; where V is added through the VN16 alloy, and the VN16 alloy weighs the following components according to the weight percentage: N: 18%, C: 4.9%, and the rest is V, and the impurity content is controlled: P: 0.06 %, S: 0.04%, the sum of the weight percentages of each component is 100%;

[0080] Step 2, melting the C, Si, Mn, V, S, P and Fe weighed in step 1 as molten steel to cast a billet;

[0081] Step 3, sending the cast billet into the soaking section furnace for heating, the heating temperature is 1040°C, and the heating time is 70 minutes;

[0082] Step 4: Dephosphorize and lower the temperature of the heated steel billet with high-pressure water, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com