Method for improving fluidness of magnesium alloy melt and special agitating apparatus

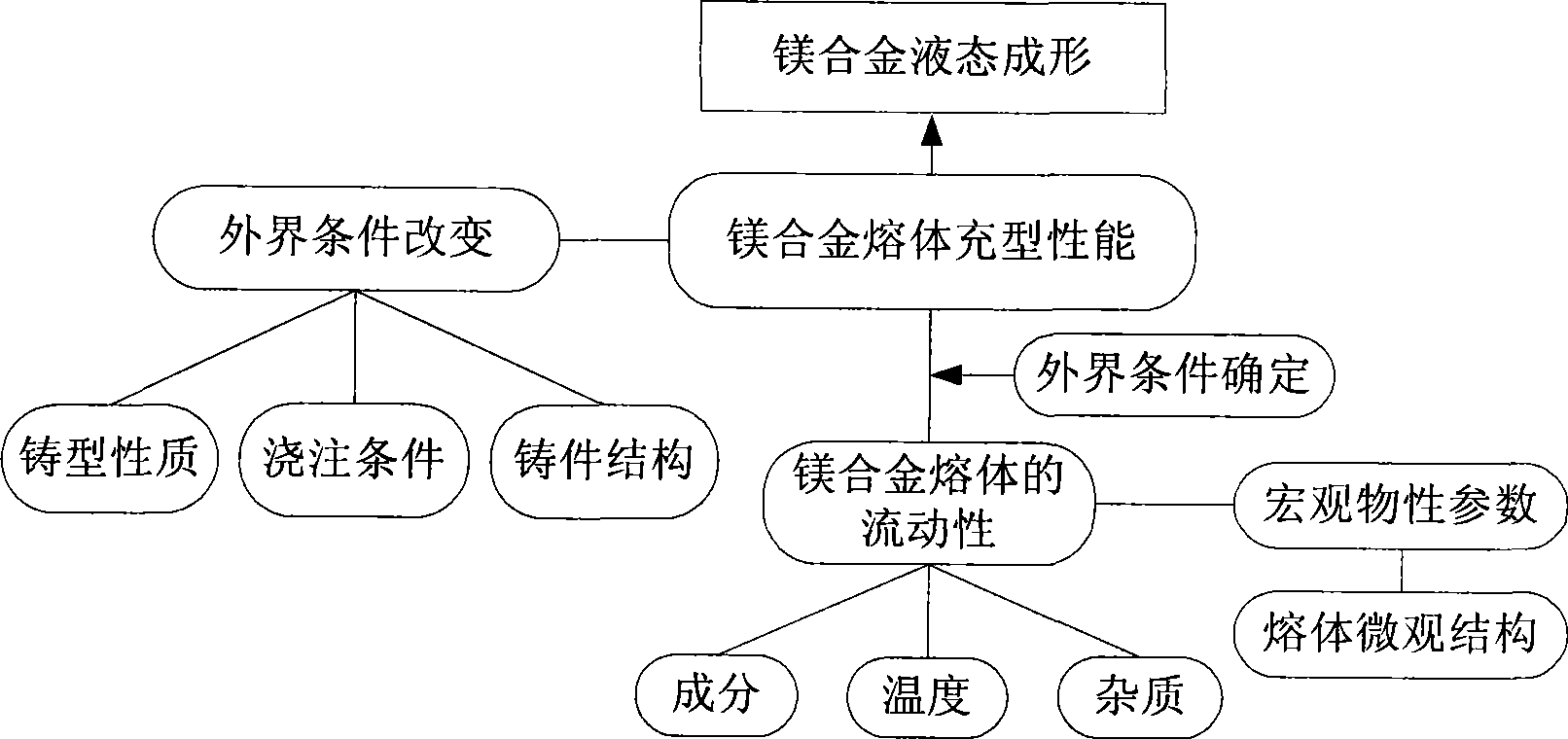

A magnesium alloy fluidity technology, applied in the field of a method to improve the fluidity of magnesium alloy melts and a special stirring device, can solve the problems of reducing the plasticity of magnesium alloys, the toxicity of Be elements, and the inability to add alloy elements. , to achieve the effects of low energy consumption and cost, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

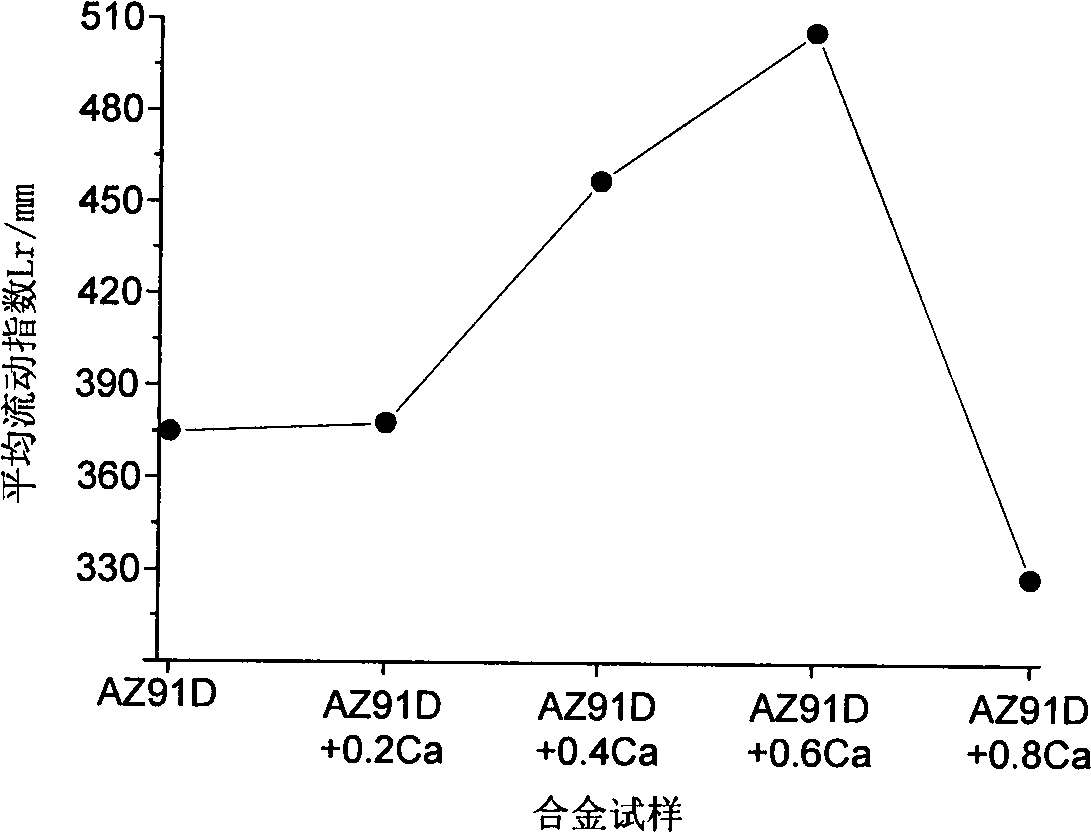

Embodiment 1

[0028] The alloy used in the test is AZ91D magnesium alloy, and its chemical composition is shown in Table 1; calcium element is added to the alloy in the form of master alloy Mg-30%Ca. The consumption of magnesium alloy in this test is 12Kg, and the molar ratio of the magnesium element in the magnesium alloy and the calcium element in the Mg-Ca master alloy is (0.15~1.5)×10 3 , the preferred molar ratio is (2.1~3.7)×10 2 .

[0029] Table 1 Chemical composition of AZ91D magnesium alloy (mass percentage, %)

[0030]

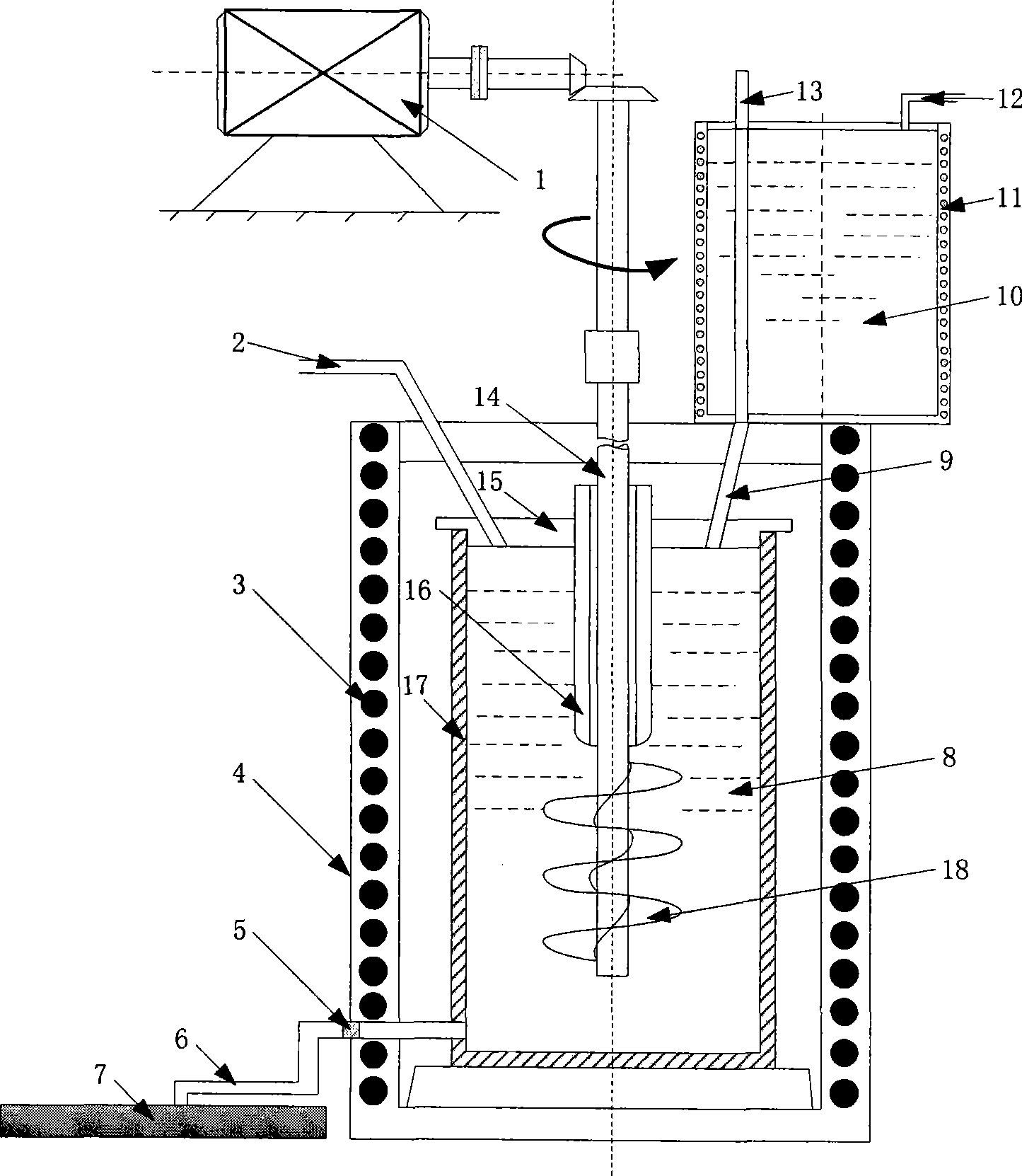

[0031] The stirring device used in this example is the sleeve screw type mechanical stirring device provided by the present invention. The device comprises a holding furnace 4 with a sealing cover whose outer wall is composed of heating elements 3; wherein, a crucible 17 with a sealing cover is provided in the holding furnace cavity; the agitator passes through the sealing cover of the holding furnace 4 and the sealing cover of the crucible 17 , placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com