Edge shielding device for sheet and strip steel cooling control system

A technology for controlling cooling and shielding devices, used in workpiece cooling devices, temperature control, metal rolling, etc., can solve problems such as low reliability and easy failure, and achieve less maintenance workload, less space, and high flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0025] The invention provides an edge shielding device for a strip steel control cooling system.

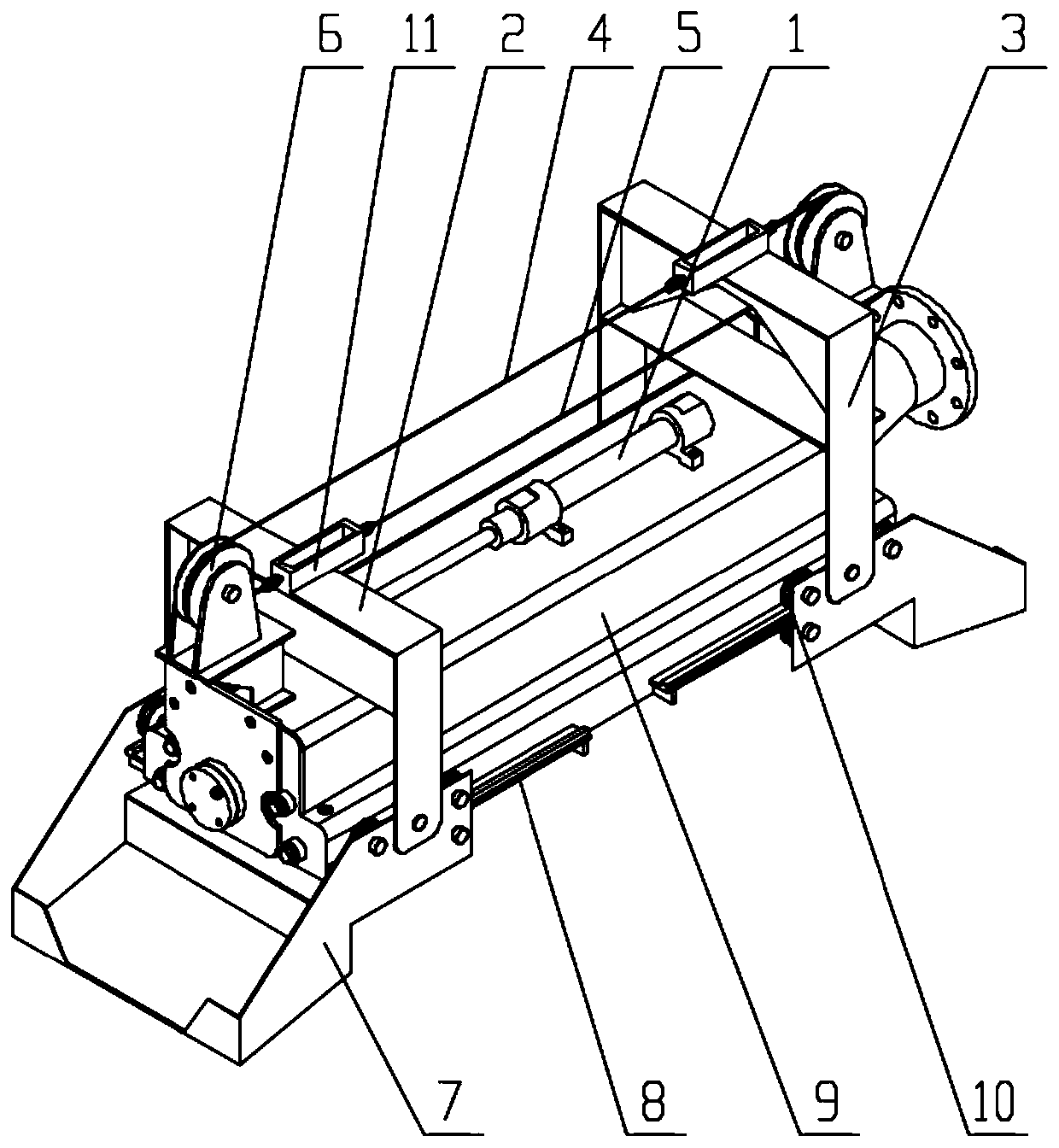

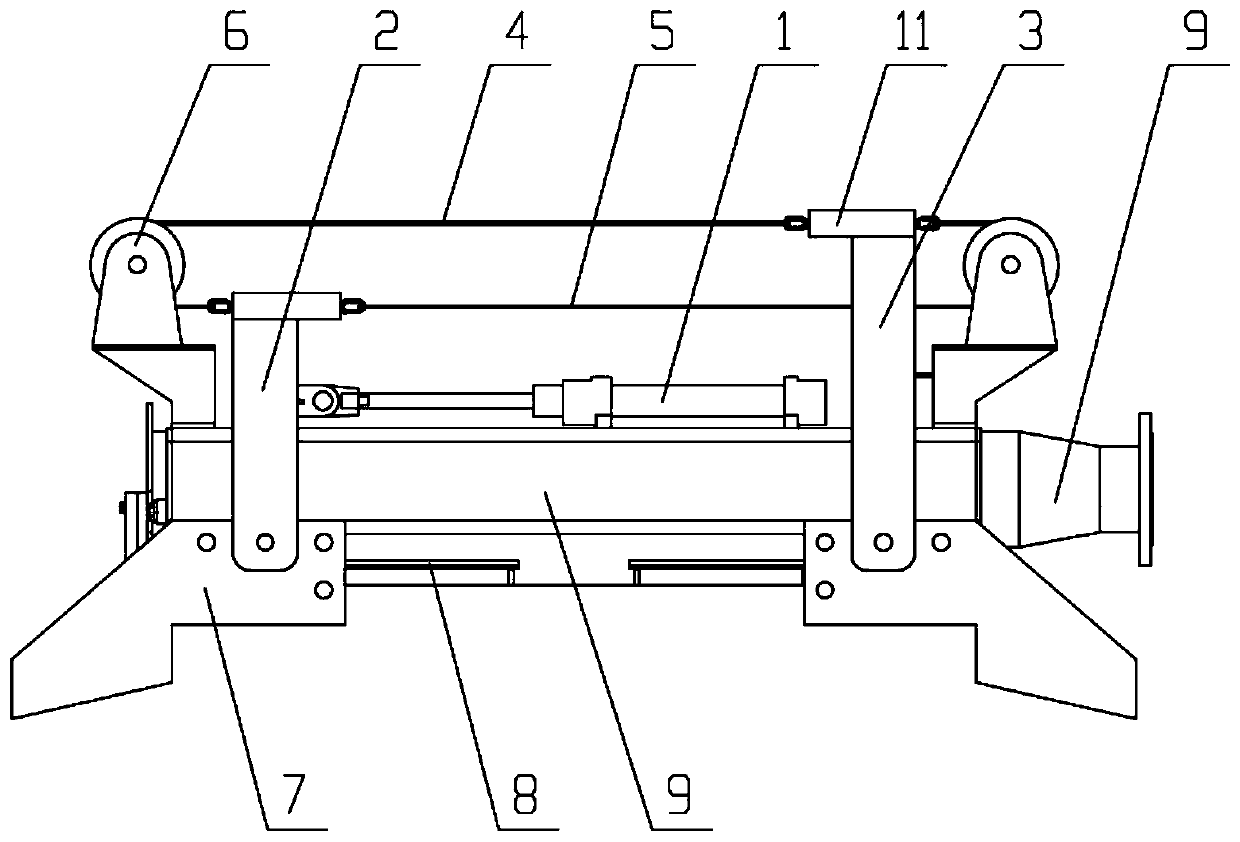

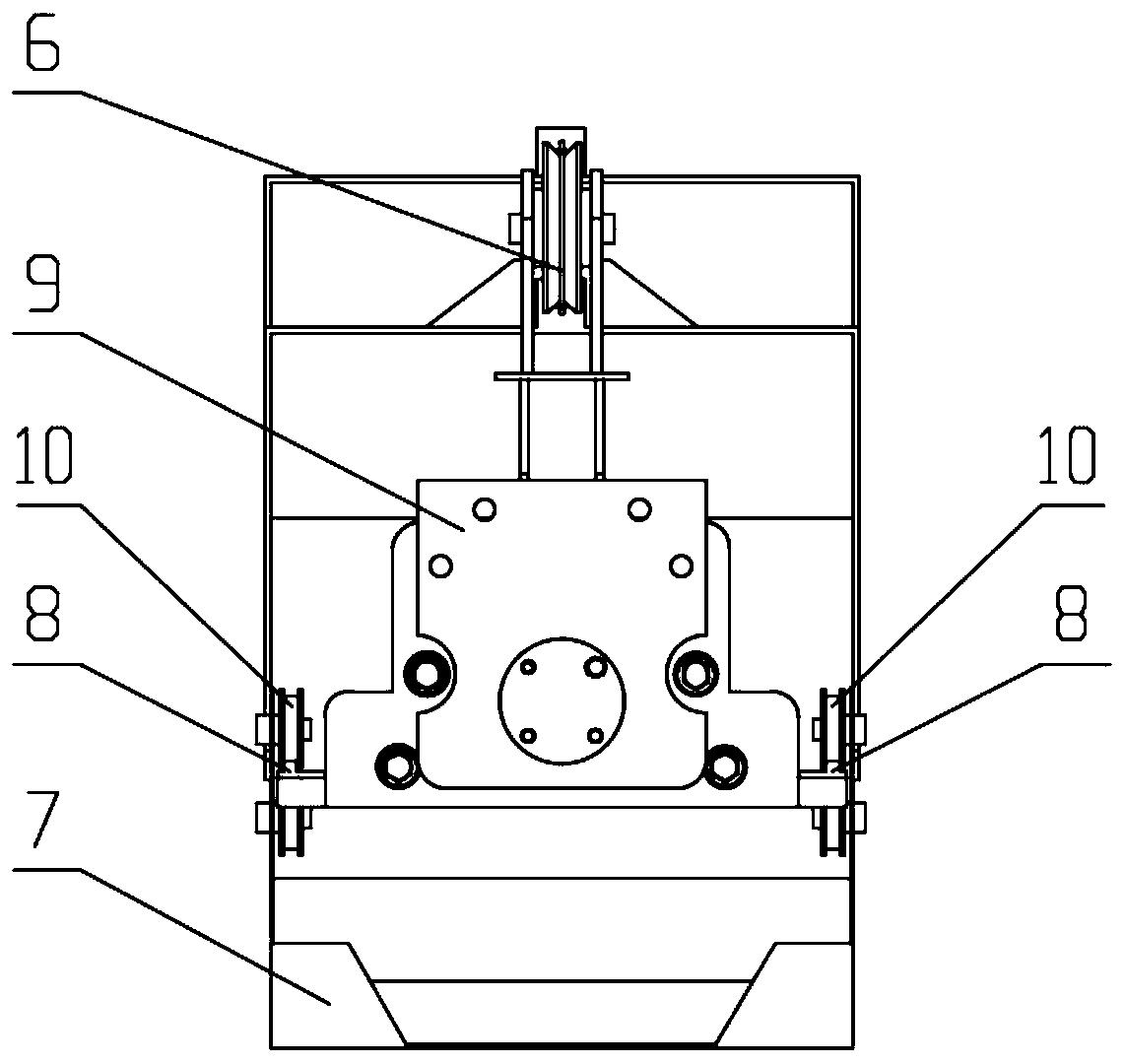

[0026] Such as figure 1 As shown, the device includes a driving device 1, a driving end frame 2, a driven end frame 3, a steel wire rope I 4, a steel wire rope II 5, a fixed pulley assembly 6, a water tray assembly 7, and a slide rail 8, wherein the driving device 1 is fixed On the top of the upper cooler 9 above the steel plate, the telescopic end of the driving device 1 is connected with the driving end frame 2 through a pin shaft; the driving end frame 2 and the driven end frame 3 are connected through a steel wire rope I4 and a steel wire rope II5, The water tray assembly 7 is connected to the driving end frame 2, and the water receiving tray assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com