Selective laser sintering SLS laid powder preheating device

A technology of laser sintering and preheating device, which is applied in the directions of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of inability to sinter and form, and the performance and accuracy of the formed parts are reduced, so as to increase the preheating efficiency and improve the accuracy. and organizational performance, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

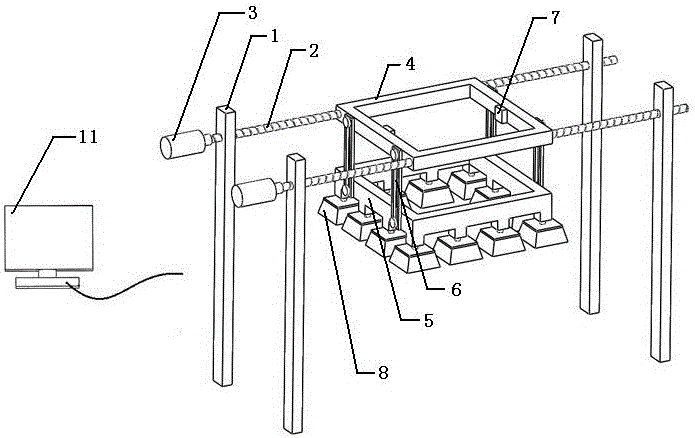

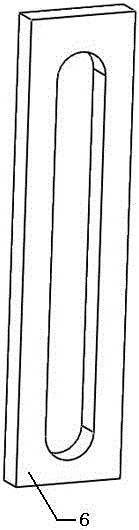

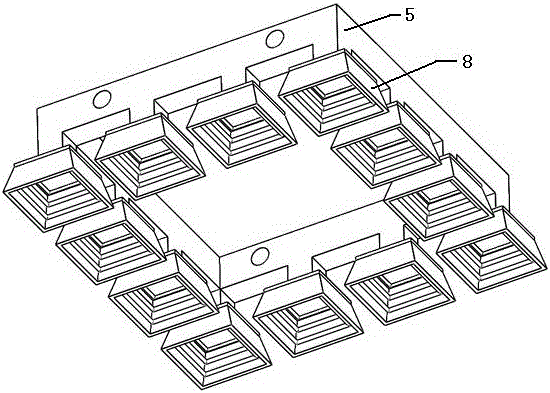

[0022] A selective laser sintering SLS powder spreading preheating device, shown in [l1], includes a column 1, a screw rod 2, a drive motor 3, an upper bracket 4, a lower bracket 5, a height adjustment plate 6, an infrared temperature measuring device 7, Square pyramid hollow shell 8, heating rod 9, reflective plate 10 and control system 11; Wherein, upper support 4, lower support 5 and height adjusting plate 6 all adopt aluminum alloy material, to reduce the weight of whole device; Upper support 4 Both sides are socketed on two horizontally fixed screw rods 2, the two ends of the screw rods 2 are respectively supported by the columns 1, and one end of the screw rods 2 is provided with a drive motor 3, when the drive motor 3 rotates, the drive screw rod 2 rotates, thereby driving The upper bracket 4 moves horizontally on the screw rod 2, the upper bracket 4 and the lower br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com