Manufacture method of irregular pipe

A manufacturing method and technology for pipe fittings, which are applied in the field of pipe manufacturing, can solve the problems of large heating times, large grain size, long production cycle of the main pipe, poor process repeatability, etc., so as to achieve less cutting allowance and improve material utilization rate. , repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] according to Figure 10 As shown, a manufacturing method of a nuclear power main pipe forging with a nozzle is as follows:

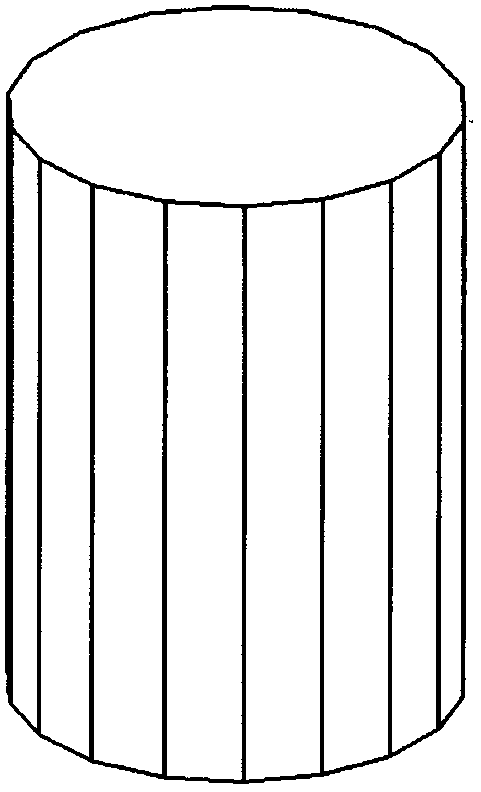

[0110] 1) Prepare steel ingot: Prepare a prismatic TP316LN material steel ingot with a nominal weight of 20000kg and a height of H1, such as figure 1 shown;

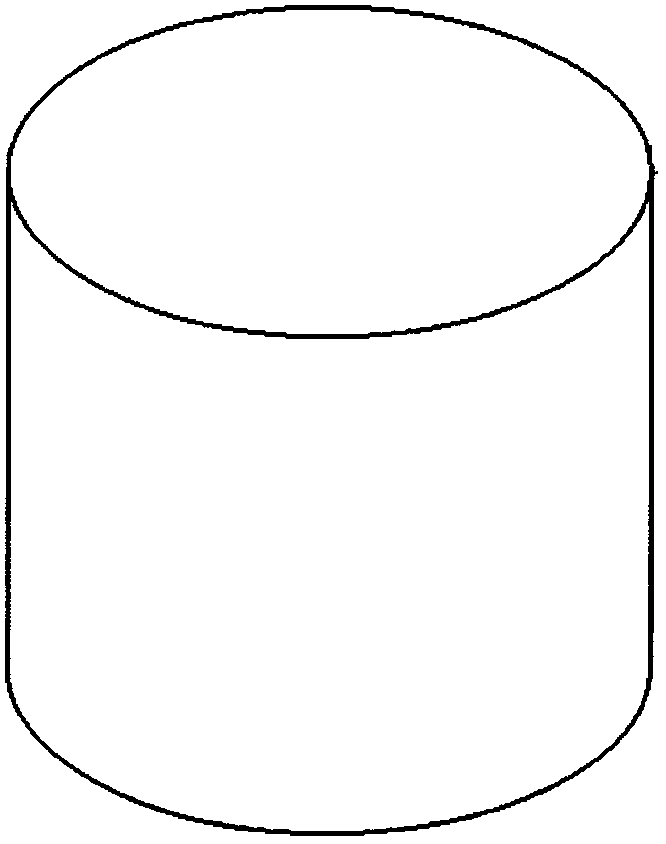

[0111] 2) Closed upsetting: put the above-mentioned steel ingot into the mold for closed upsetting, and the heating temperature is 1150°C to 1250°C. The shape of the forging after upsetting is as follows: figure 2 As shown, the specification is Φ1 in diameter and H2 in height;

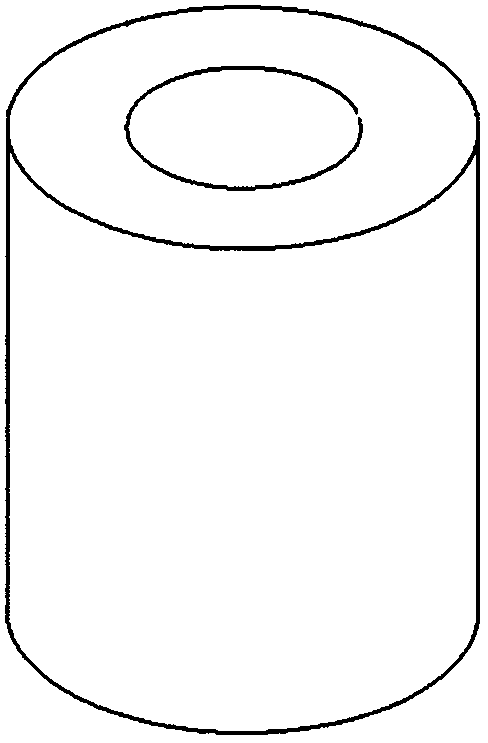

[0112] 3) Reverse extrusion piercing: use the extrusion shaft to extrude the above steel ingot to form the inner hole of the steel ingot, and then cut off the bottom, the obtained forging shape is as follows image 3 As shown, the specification is that the diameter of the inner hole is Φ3, the outer diameter is Φ2, and the height is H3;

[0113] 4) Extruded pipe fittings: Extrude the above perforated forgings a...

Embodiment 2

[0122] The steps are basically the same as those in Embodiment 1, except that the forming sequence of the first nozzle and the second nozzle in the above 6) and 7) is changed, that is, the first nozzle in step 6) is carried out in the manner shown in Figure 7, Then in step 7) the other nozzle in the remaining position in Fig. 6 is formed.

Embodiment 3

[0124] according to Figure 9 As shown, a manufacturing method of a nuclear power main pipe forging with a nozzle is as follows:

[0125] 1) will be as Figure 4 The material shown is a TP316LN seamless steel tube billet machined, sharpened and ready for forming nozzles.

[0126] 2) Upsetting and extrusion forming the first nozzle: the above-mentioned pipe fittings are formed into the first nozzle by upsetting extrusion process, that is, the two ends of the pipe fittings move towards each other at a certain speed, and the material in the heating zone on the pipe wall is under the constraint of the mold Flow out from the opening on the nozzle to form a nozzle. The heating temperature is 950 ° C ~ 1200 ° C. The shape of the obtained forging is shown in Figure 5. The specification is that the total length is H5, and the distance from the center line of the nozzle to one side is H6. The inner radius and outer radius are R4 and R5 respectively, R4=(Φ4) / 2, R5=(Φ5) / 2;

[0127] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com