Gas nitriding treatment method of 11Cr17 stainless steel slip sheet

A technology of gas nitriding and treatment method, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., which can solve the problems of environmental pollution caused by salt bath treatment liquid, unfavorable industrial production of enterprises, and large production cost. Achieve the effects of low production cost, improved service life and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

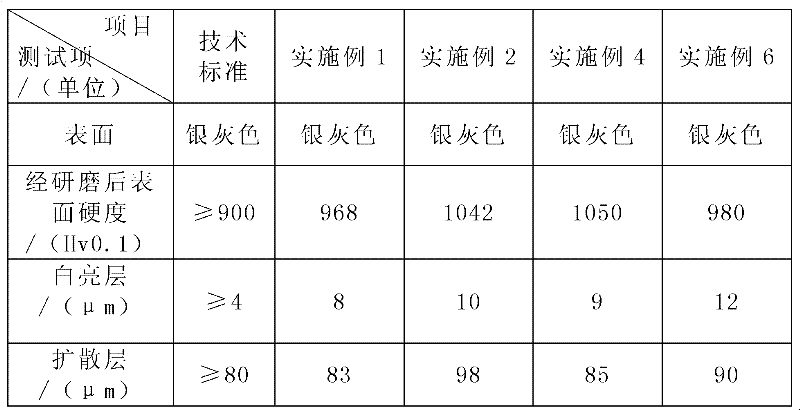

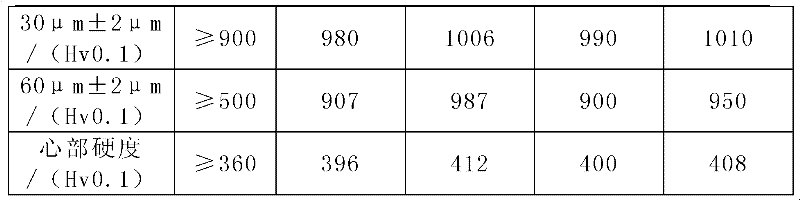

Examples

Embodiment 1

[0024] a) Degreasing and cleaning: Use degreasing agent, aviation kerosene or alcohol to degrease and clean the 11Cr17 stainless steel slide to remove surface oil;

[0025] b) Depassivation film treatment: Put the above-mentioned degreased and cleaned 11Cr17 stainless steel slide into the nitriding furnace, vacuumize, then pass in nitrogen to break the air to normal pressure, stop nitrogen, and use nitrogen to exhaust the nitriding furnace After the air inside is more conducive to removing the passivation film, replace the air in the furnace with nitriding, then raise the temperature of the furnace to 300°C, and control the temperature at 300°C to 350°C, and start adding the film remover dropwise Carry out depassivation film treatment 120min to above-mentioned sliding sheet, wherein the speed of dripping film removal agent is 90~140 drop / min, and described film removal agent is the citric acid methanol solution that mass concentration is 5%, removes Passivation film on the sur...

Embodiment 2

[0028] a) degreasing, cleaning: adopt 5% degreasing agent aqueous solution to carry out degreasing cleaning to 11Cr17 stainless steel sliding piece, remove surface greasy dirt, above-mentioned degreasing agent aqueous solution is alkaline degreasing agent aqueous solution;

[0029] b) Depassivation film treatment: Put the above-mentioned degreased and cleaned 11Cr17 stainless steel slide into the nitriding furnace, vacuumize, then pass in nitrogen to break the air to normal pressure, stop nitrogen, and use nitrogen to exhaust the nitriding furnace After the air in the furnace is removed, it is more conducive to the removal of the passivation film. After the air in the furnace is replaced by nitriding, the temperature of the furnace is raised to 350°C, and the temperature is controlled at 350°C to 400°C, and the film remover is added dropwise. Carry out depassivation film treatment 100min to above-mentioned sliding sheet, wherein the speed of dripping film removing agent is 60~1...

Embodiment 3

[0032] a) Degreasing and cleaning: Use alcohol to degrease and clean the 11Cr17 stainless steel slide to remove surface oil;

[0033] b) Depassivation film treatment: Put the above-mentioned degreased and cleaned 11Cr17 stainless steel slide into the nitriding furnace, vacuumize, then pass in nitrogen to break the air to normal pressure, stop nitrogen, and use nitrogen to exhaust the nitriding furnace After the air in the furnace, it is more beneficial to remove the passivation film. After replacing the air in the furnace with nitriding, the temperature of the furnace is raised to 400°C, and the temperature is controlled at 400°C to 450°C, and the film removal is started. depassivation film treatment on the slide for 30 minutes, wherein the speed of dropping the film remover is 50-80 drops / min, and the film remover is a citric acid methanol solution with a mass concentration of 30%. , to remove the passivation film on the surface of the slide;

[0034] c) Nitriding treatment:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com